The choice between ASA (Acrylonitrile Styrene Acrylate) and PETG (Polyethylene Terephthalate Glycol) is critical for projects ranging from 3D printing to outdoor applications, as each thermoplastic offers unique properties tailored to specific needs.

This comprehensive comparison guide delves into the main differences between ASA and PETG.

Understanding these factors will help you select the most suitable filament brand and material for your project, considering aspects such as dimensional stability, weight, and cost-effectiveness in recent years.

What Is Acrylonitrile Styrene Acrylate (ASA)?

ASA, or Acrylonitrile Styrene Acrylate, is a durable thermoplastic made from acrylonitrile, styrene, and acrylate.

It combines the strength of styrene with excellent UV resistance from acrylate, maintaining color and mechanical properties even under harsh sunlight and outdoor conditions.

Known for its toughness, high impact resistance, and dimensional stability, ASA is ideal for outdoor parts, automotive components, and functional pieces requiring high temperature resistance.

It is commonly available as sheets, filaments for 3D printing, and molded parts.

Widely used in industries such as automotive, signage, and outdoor equipment, ASA’s lower density compared to some plastics makes it a preferred choice over ABS for lightweight yet strong applications.

What Is Polyethylene Terephthalate Glycol (PETG)?

PETG, or Polyethylene Terephthalate Glycol, is a versatile thermoplastic derived from polyethylene terephthalate modified with glycol.

It offers excellent flexibility, high clarity, and ease of fabrication, making it ideal for 3D printing, packaging, and food-safe containers.

PETG filament is known for strong layer adhesion and dimensional stability, with less warping than many materials. However, it absorbs moisture from the air, so proper storage in a dry environment is essential.

While PETG has moderate UV resistance suitable for indoor and short-term outdoor use, it is less durable under prolonged sunlight compared to ASA.

Overall, PETG balances strength, flexibility, ease of printing, and light weight, making it suitable for a wide range of functional and aesthetic projects.

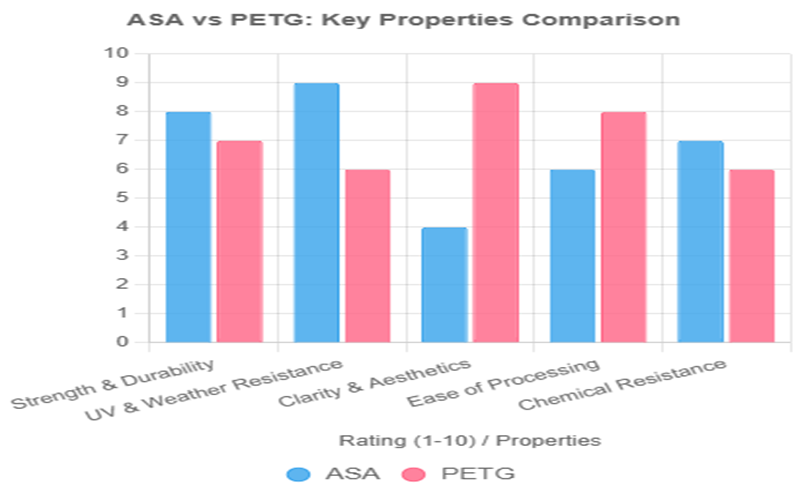

ASA vs PETG : Key Properties Comparison

The key properties of ASA and PETG highlight their distinct strengths for different applications, helping you choose the right filament brand and material for your project.

Physical Properties

ASA (Acrylonitrile Styrene Acrylate) exhibits high impact resistance and toughness, similar to ABS but with superior weather resistance, making it ideal for durable outdoor parts and automotive components.

It offers moderate flexibility, being less brittle than PLA, and is well-suited for functional parts requiring high temperature resistance and dimensional stability.

With a density of approximately 1.07 g/cm³, ASA is slightly less dense than PETG, contributing to a lighter yet robust feel.

ASA provides a smooth, glossy surface finish with excellent layer adhesion, ensuring strong connections between layers and aesthetically pleasing prints.

In contrast, PETG (Polyethylene Terephthalate Glycol) is known for its balance of strength and flexibility, offering good impact resistance while being more flexible than ASA, which enhances its versatility for various applications.

PETG has a higher density, approximately 1.27 g/cm³, giving it a sturdier feel. It produces a smooth, slightly glossy finish with excellent layer adhesion that helps printed parts stick well together, minimizing delamination and ensuring high-quality, durable functional parts.

Thermal Properties

ASA (Acrylonitrile Styrene Acrylate) offers excellent thermal resistance, with a heat deflection temperature of 95–105°C and a glass transition temperature around 100°C, making it ideal for outdoor use requiring high temperature resistance and UV stability.

Printing ASA requires higher nozzle (230–260°C) and bed temperatures (90–110°C), plus an enclosed chamber to prevent warping and maintain dimensional stability.

Its thermal stability and UV resistance help ASA parts retain mechanical properties under prolonged heat and sunlight.

In contrast, PETG (Polyethylene Terephthalate Glycol) has moderate thermal performance, with a heat deflection temperature of 70–85°C and a glass transition temperature near 80°C, less suited for extended outdoor exposure.

PETG prints at lower temperatures (nozzle 220–250°C, bed 70–85°C), with less warping and strong layer adhesion.

While flexible and thermally stable, PETG degrades faster under prolonged heat and UV exposure, limiting long-term outdoor use. Proper dry storage is important to maintain print quality.

Chemical Properties

ASA (Acrylonitrile Styrene Acrylate) and PETG (Polyethylene Terephthalate Glycol) are both insoluble in water and resistant to environmental stress cracking, but they differ significantly in their chemical resistance profiles.

ASA filament offers superior chemical resistance, effectively withstanding oils, greases, and various acids, while also exhibiting excellent UV resistance that prevents degradation and color fading over prolonged outdoor exposure.

This resilience makes ASA highly suitable for outdoor applications where maintaining mechanical properties and appearance over time is critical.

In contrast, PETG filament provides good resistance to a range of chemicals, including acids, alkalis, and some solvents, making it versatile for indoor and functional parts.

However, PETG is less robust against UV exposure and prolonged sunlight, which can lead to yellowing, brittleness, and reduced mechanical strength, limiting its suitability for extended outdoor use.

Which Is The Better Filament, ASA Or PETG?

Choosing the better filament between ASA and PETG depends on the specific requirements of your 3D printing project.

ASA Filament

ASA is a robust material ideal for outdoor 3D-printed parts due to its excellent UV and weather resistance, ensuring long-term color and strength retention.

It offers high impact resistance, a heat deflection temperature of 95–105°C, and strong chemical resistance to oils, greases, and some acids.

Printing ASA requires a nozzle temperature of 230–260°C and a bed temperature of 90–110°C, but it can be prone to warping without precise settings, making it suitable for durable, heat-resistant applications.

PETG Filament

PETG is a versatile, user-friendly material favored for its ease of printing and balanced properties. It provides good strength, flexibility, and a smooth, slightly glossy finish with excellent layer adhesion, reducing delamination.

With a lower printing temperature (nozzle: 220–250°C, bed: 70–85°C) and minimal warping, PETG is ideal for indoor applications.

While it offers decent chemical resistance to acids and alkalis, its moderate heat deflection temperature (70–85°C) and susceptibility to UV-induced yellowing make it less suitable for prolonged outdoor use.

In a word, the better filament, ASA or PETG, depends on your needs. ASA excels for outdoor, UV-resistant, and heat-tolerant prints, while PETG is ideal for easier printing and indoor applications with good strength and flexibility.

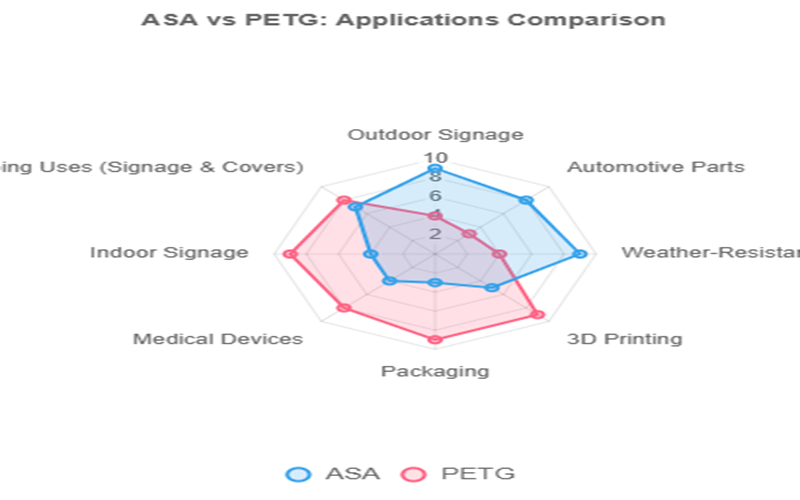

ASA vs PETG : Application Example

ASA and PETG serve distinct but sometimes overlapping applications, each leveraging unique properties to meet specific project needs.

Applications For ASA

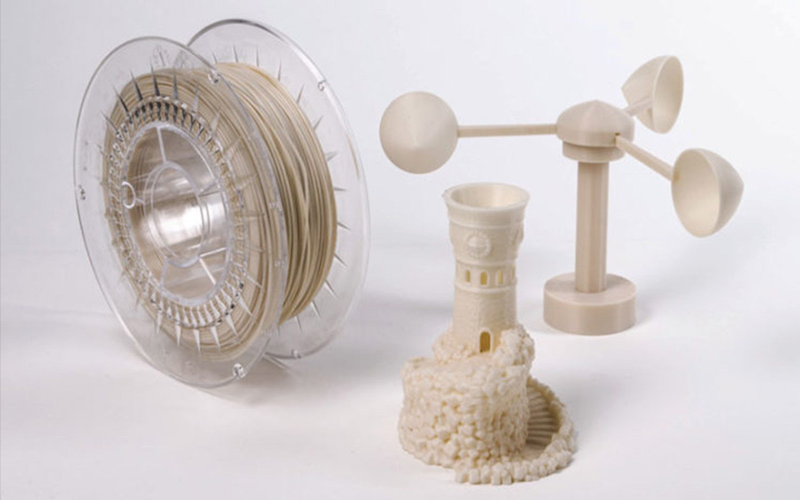

ASA is commonly used for outdoor signage, automotive parts, and weather-resistant components due to its excellent UV resistance, high temperature resistance, and mechanical strength.

Printing ASA requires a stable environment, often with an enclosed chamber to prevent warping and ensure strong layer adhesion.

These traits make ASA ideal for outdoor parts exposed to sunlight, rain, and temperature changes, providing excellent dimensional stability and durability.

Typical ASA parts include automotive exteriors, outdoor furniture, power tool housings, and door and window profiles designed for outdoor use.

Printing ASA demands careful settings to ensure bed adhesion and avoid failures, with online forums and comments being valuable for troubleshooting and advice on filament brands and parameters.

Applications For PETG

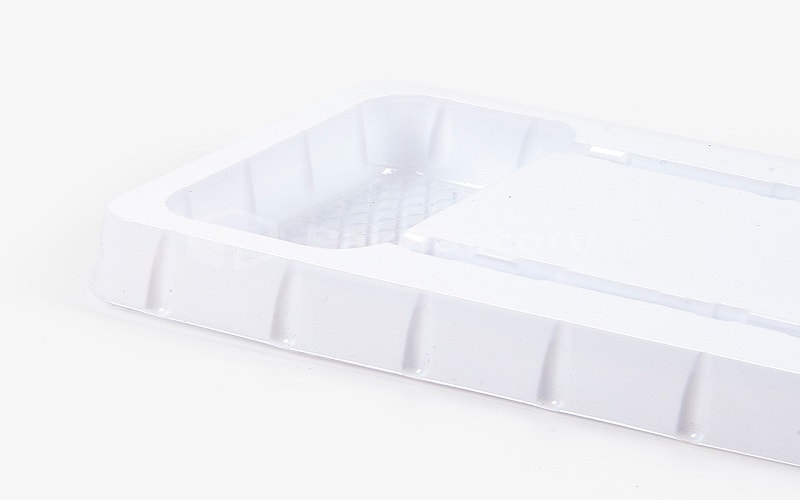

PETG excels in 3D printing, packaging (like food containers), medical devices (such as protective shields), and indoor signage, thanks to its flexibility, clarity, and food-safe properties.

PETG offers strong layer adhesion and chemical resistance, suitable for functional parts, prototypes, and transparent or complex designs.

Its lower printing temperature and reduced warping risk make it ideal for projects with less demanding environmental exposure.

Both ASA and PETG are used in signage and protective covers; however, ASA outperforms PETG outdoors due to superior UV and weather resistance, maintaining physical properties despite exposure to air, light, and stress.

PETG, while somewhat UV resistant, is better for indoor or short-term outdoor use prioritizing clarity and ease of printing.

In summary, ASA is preferred for outdoor, high-stress, and durable applications, while PETG suits functional, clear, and food-safe projects. Having quality filament, proper equipment, and good post-processing is essential to maximize performance and appearance with either material.

ASA vs PETG: Pros And Cons

When comparing ASA and PETG, it is essential to understand their respective advantages and disadvantages to choose the most suitable material for your specific project needs.

Advantages Of ASA

ASA stands out for its exceptional weatherability, offering superior UV resistance and the ability to withstand harsh outdoor environments, including prolonged exposure to sunlight, moisture, and temperature variations.

Its excellent mechanical properties, such as high impact resistance, toughness, and dimensional stability, make ASA ideal for producing durable outdoor parts, automotive components, and other applications requiring high temperature resistance.

Disadvantages Of ASA

However, ASA is generally more expensive and poses greater challenges during 3D printing, necessitating precise temperature control, an enclosed chamber, and careful cooling management to prevent warping and ensure optimal print quality.

Additionally, ASA’s typically opaque appearance limits its use in projects where transparency or aesthetic clarity is important.

Advantages Of PETG

In contrast, PETG provides excellent flexibility and toughness, allowing it to bend under stress without cracking, which is advantageous for parts requiring ductility.

PETG is easier to print and fabricate due to its lower printing temperatures, reduced warping risk, and strong layer adhesion, making it accessible for beginners and suitable for rapid prototyping. Its food-safe nature expands its application to packaging, medical devices, and consumer goods.

Disadvantages Of PETG

Nonetheless, PETG has comparatively lower UV resistance, making it less ideal for long-term outdoor exposure.

Additionally, it is more prone to surface scratching and can lose its visual appeal over time due to wear and environmental factors.

PETG also tends to absorb moisture from the air, which can negatively affect print quality if not stored properly.

How To Choose ASA And PETG For Your Project?

Selecting between ASA and PETG depends largely on the specific requirements and conditions of your project. Consider the following factors to make an informed decision.

Environmental Exposure

If your project involves prolonged outdoor use where UV resistance and high temperature resistance are critical, ASA is the better choice. Its superior ability to withstand sunlight, heat, and weathering ensures durability and long-lasting performance for outdoor parts and automotive components.

Ease Of Printing

For projects that prioritize ease of printing, especially if you lack an enclosed chamber or advanced printing setup, PETG is more forgiving. It prints at lower temperatures with less warping risk and offers excellent layer adhesion, making it suitable for beginners and rapid prototyping.

Mechanical Requirements

ASA offers higher impact resistance and dimensional stability, making it ideal for parts subjected to mechanical stress and environmental challenges. PETG, while tough and flexible, excels in applications requiring some degree of ductility and clarity.

Aesthetic Considerations

PETG’s natural transparency and glossy finish make it suitable for projects where visual clarity is important, such as packaging or decorative items. ASA typically has a matte finish and is opaque, which may limit its use in such cases.

Post-Processing Needs

Both materials can be sanded, painted, and glued, but ASA’s higher hardness allows for a smoother finish after sanding. PETG can be flame polished to enhance surface smoothness and clarity.

Cost And Availability

Consider the filament brand, cost per roll, and availability. ASA tends to be slightly more expensive and may require more precise storage to maintain quality, while PETG is widely available and generally more affordable.

By evaluating these factors alongside your project’s functional and aesthetic needs, you can choose the filament that best responds to your requirements and ensures the success of your 3D printing or manufacturing project.