Struggling with die casting design? Here are essential die casting design tips to help you create parts that are precise, cost-effective, and durable.

This guide covers everything from material selection to wall thickness management and fillet integration. Read on to optimize your die casting designs and ensure the success of your next project.

Understanding Die Casting Design Requirements

Designing die cast parts is no small feat. It requires careful consideration of several factors to ensure the end product meets all necessary requirements, including:

- Application

- Appearance

- Performance

- Precision

- Cost Each of these aspects plays a crucial role in the overall success of the die cast part die casting project.

One of the first steps in the design process is conducting a detailed cost budget analysis. This analysis is crucial as it directly influences manufacturing choices and overall feasibility. Understanding the cost implications of different design decisions allows designers to make informed choices that balance quality and budget constraints.

Choosing the appropriate casting material is crucial in die casting design. Aluminum castings are commonly chosen for their excellent strength-to-weight ratio and corrosion resistance. High pressure die casting, cold chamber die casting, and die casting involves the use of aluminum alloys, casting alloy, and aluminum casting, which affect the material characteristics.

The material characteristics not only affect the performance and durability of the final product but also influence the casting process itself. High precision in die casting results in dimensionally accurate parts with a premium finish, requiring stringent quality control throughout the manufacturing process to achieve tight tolerances.

This ensures that the parts meet the required specifications and perform as intended in their applications, contributing to high dimensional stability through hot chamber die casting.

Key Principles in Die Casting Design

When embarking on a die casting project, consulting experienced manufacturers is vital for ensuring proper die design and process controls. These experts can provide valuable insights and help optimize complex aluminum die casting projects. Their experience can be the difference between a successful project and one fraught with issues.

Applying design for manufacturability (DFM) techniques is another cornerstone of effective die casting design. DFM techniques help reduce manufacturing costs while maintaining quality. Designing parts for easier manufacturing streamlines the production process and helps avoid costly rework or adjustments.

Die casting is favored for its precision and speed, particularly for high volumes of parts, which leads to significant cost savings. Essential factors for die casting design include die casting equipment, part size, wall thickness, production volume, and material characteristics.

Ensuring the design meets the strength and durability standards requires discussing part strength requirements with the die caster. Choosing the proper materials, including die steel, is equally important to achieve the desired strength and longevity in the final parts.

Additionally, low-pressure die casting can improve the consistency and integrity of parts, contributing to overall quality. This method helps in reducing porosity and ensuring that the parts meet the required specifications.

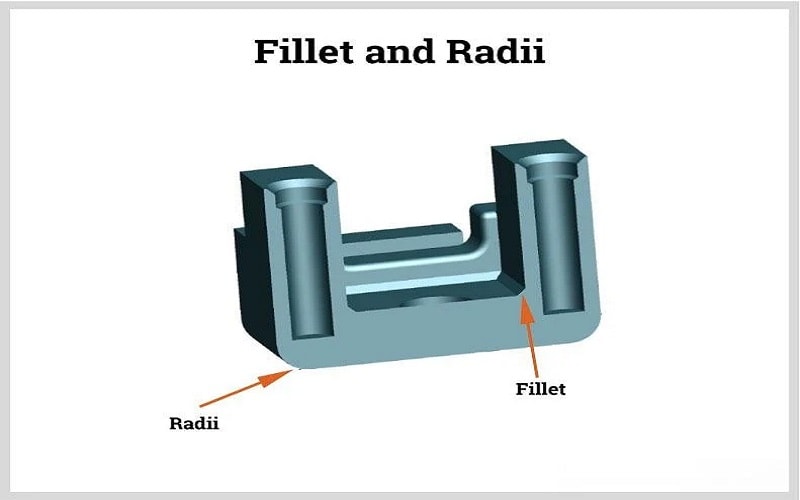

Fillets and Radii in Die Cast Parts

Fillets and radii might seem like minor details, but they play a crucial role in die casting design. Fillets are inner rounded corners, while radii refer to outer edges in die cast parts. These features are essential for reducing stress concentrations and improving metal flow, which enhances the overall structural integrity of die cast parts. Avoiding sharp corners where die halves meet helps achieve this.

Incorporating fillets and radii in your design can significantly improve metal flow and reduce the likelihood of defects. This is particularly important around holes and windows, where turbulence can impede efficient casting. Integrating fillets and radii in these areas mitigates flow turbulence effectively. This not only ensures a better-quality finish but also contributes to the durability of the parts.

Properly designed fillets and radii also help in facilitating easier ejection from the mold, reducing the risk of damage during the manufacturing process. Using the ejector die half with these features can make a significant difference in the performance and longevity of the final product.

Managing Wall Thickness

Managing wall thickness is a critical aspect of die casting design. Maintaining consistent wall thickness in die cast components is crucial for:

- Achieving strength and reducing weight

- Promoting even cooling, which reduces the risk of defects such as surface sinks and internal voids

- Contributing to the overall structural integrity and durability of the die cast parts

However, thicker walls can increase stiffness, delay cooling, and risk poor casting quality. On the other hand, thin walls can prevent adequate flow of molten metal and are susceptible to warping.

Therefore, when molten metal starts to flow in the mold cavity of a casting machine, it is essential to strike a balance between wall thicknesses and thinner walls to ensure optimal results, especially for high volume production.

Gradual transitions are preferred when variations in wall thickness are necessary. Sudden changes should be avoided. Introducing gradual transitions using fillets or radii can avoid stress concentrations and enhance the overall quality of the parts.

Optimizing wall thickness can also lead to better dimensional control, ensuring parts meet specified tolerances effectively. Maintaining uniform wall thickness in bosses often involves incorporating a central hole.

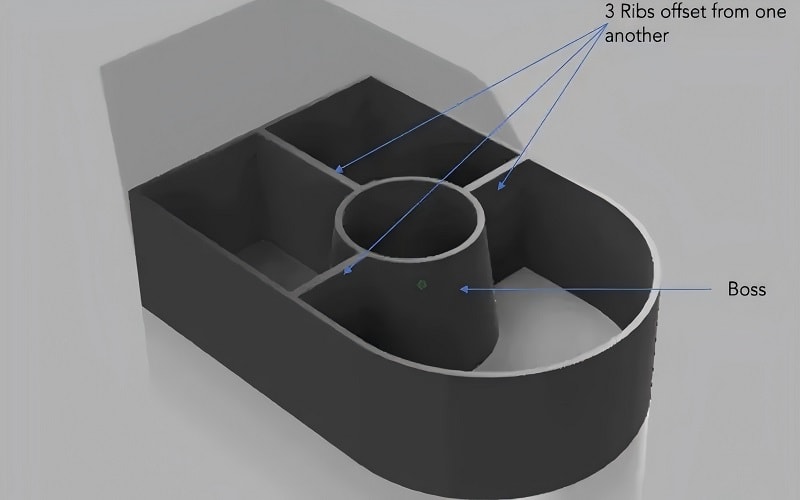

Designing Ribs for Strength

Ribs are a powerful tool in the die casting design arsenal, offering a way to increase strength and improve metal flow without adding significant weight or cost. Incorporating ribs helps ensure that molten metal flows into all areas of the die cast, maintaining quality and structural integrity. This is particularly important in thinner sections where additional support is needed.

Ribs can enhance the strength of die cast parts without increasing wall thickness, making products lighter and more cost-effective. When designing ribs, consider the following:

- Add fillets and appropriate draft angles in rib designs to enhance both strength and metal flow.

- Incorporate ribs with weaker sections like thin walls to ensure structural integrity.

- Avoid overusing ribs as this can lead to stress concentration and complicate the design.

- Consult an engineer to determine the optimal ribbing strategy.

Ribs significantly improve the stiffness of thin wall die cast parts, contributing to the overall strength of aluminum die castings. This makes them an invaluable feature in designs that require both light weight and high strength.

Incorporating Holes and Windows

Holes and window features are common features in die cast parts, but they can introduce complexities in the casting process. The presence of holes and windows can lead to complex molten metal flow, resulting in turbulence that impedes efficient casting. This turbulence can create problems for metal flow, leading to potential casting flaws.

Key considerations for holes and windows in casting design include:

- High drafting is necessary for holes and windows to facilitate easier ejection from the die due to their connection with the die surface.

- Proper design around these features is essential to prevent issues during the ejection process.

- Holes located too close to the edges can lead to excessive stress concentration and weaken the casting.

Maintaining minimum clear distances for adjacent holes is critical to ensure the structural integrity of the parts. Carefully considering the placement and design of holes and windows minimizes these issues and ensures a higher quality final product.

Avoiding and Managing Undercuts

Undercuts are a common challenge in die casting design, as they are recessed surfaces that are inaccessible with a straight tool. Avoiding undercuts in your design whenever possible can simplify manufacturing and reduce costs. Redesigning parts to align geometric features parallel to the die pull out direction can also help reduce the need for undercuts.

If an undercut is essential, consider designing the parting line around it or using more complex dies. Slides in die casting are used to manage undercuts, but they can increase the complexity and cost of die construction. Using side cores or slides can complicate the casting cycle and increase costs, so it is important to carefully evaluate whether they are necessary.

Minimizing undercuts and using effective design strategies streamlines the die casting process and reduces manufacturing costs.

Boss Features in Die Casting

Bosses are essential elements in die casting, primarily used for mounting components and providing structural integrity. They serve as stand offs or mounting points in die cast parts. However, improper boss design can create manufacturing difficulties and increased costs.

Boss design considerations include:

- Increasing material requirements and part weight, which impacts overall efficiency.

- Ensuring proper metal flow by having ample fillets at the connection points of bosses.

- Maintaining uniform wall thickness by adding a hole to the center of the boss, which helps ensure consistency in the material’s thickness.

Carefully designing bosses improves the structural integrity of the parts and ensures efficient manufacturing processes.

Draft Angles for Ejection

Draft angles play a crucial role in reducing friction during the ejection of parts from the mold. Parts with complex shapes generally require draft angles to avoid damage during ejection. Proper design around holes is essential to prevent the metal from gripping the ejector die during ejection.

Draft angles of 1-2 degrees are recommended to facilitate easier ejection from molds. These angles should be included on all cast surfaces that are parallel to the die movement. Holes and windows within the design require a draft angle to ensure smoother ejection from the die.

Incorporating draft angles into designs can alter the component’s shape, impacting assembly. However, using draft angles can help reduce shrinkage and facilitate easier removal of cast parts. Considering draft angles in your design improves the efficiency of the manufacturing process and reduces the risk of damage during ejection.

Handling Shrinkage

Shrinkage is a common phenomenon in aluminum die casting, characterized by the contraction of the metal as it cools. Thicker sections of die cast parts are more prone to shrinkage, often resulting in defects like shrinkage porosity. Local overheating during the casting process can cause localized spots of shrinkage.

To compensate for shrinkage, designers must make adjustments in product design, following specific guidelines. Maintaining a proper balance in wall thickness and addressing local overheating are key best practices for reducing shrinkage defects. Carefully considering these factors minimizes shrinkage and ensures the quality of the final product.

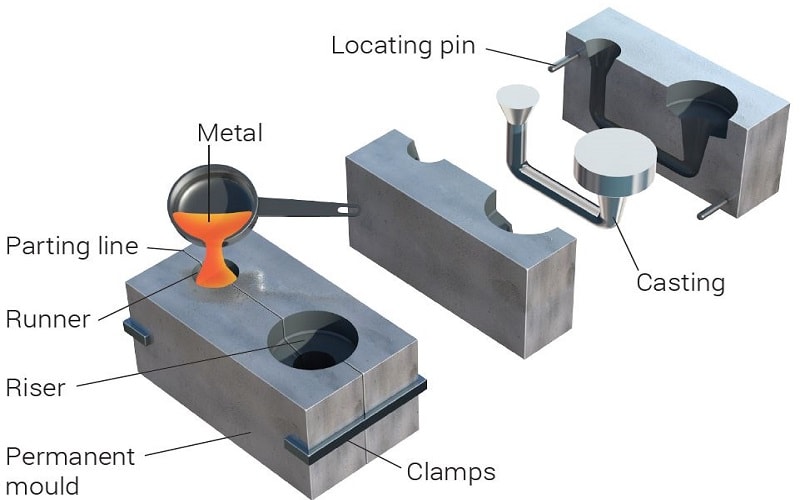

Parting Line Considerations

The parting line in die casting is important because:

- It indicates the interface of the mold halves, affecting the quality of the die cast component.

- Proper placement is vital for die functionality and can prevent the casting from adhering to the mold.

- Flash formation at the parting lines can lead to increased thickness and affect dimensional accuracy, highlighting the significance of die separation.

Key design considerations include:

- Taking measurements from only one die half to minimize tolerance issues.

- Paying attention to flash defects that require trimming during the design process.

- Considering geometry and required die components when designing parting line locations, especially when working with two die halves and die halves and cover die half.

Cosmetic surfaces are typically located on the cover side of the casting to enhance appearance. Careful consideration of the parting line placement ensures the quality and appearance of the final casting cast part product.

Pressure Tightness in Die Castings

Pressure tightness in die cast parts is primarily influenced by density and porosity. Porosity in die cast parts can lead to leaks, compromising their integrity. The integrity of aluminum die casting is measured through its ability to withstand high pressures.

Entrapped air in aluminum die casting is a significant concern as it contributes to porosity. Gas porosity occurs when gases like air or hydrogen are trapped in molten metal, leading to structural weaknesses. Minimizing porosity can be achieved through effective design for manufacturability (DFM) and quality control measures.

Filling the die cavity with oxygen before injecting molten metal helps to prevent gas bubbles by eliminating trapped gas pores. Vacuum die casting reduces porosity and enhances the surface finish, ultimately improving strength, ensuring that the die cavity is completely filled.

Optimizing design parameters and using techniques to minimize porosity enhances the pressure tightness of aluminum die cast parts.

Integrating Inserts

An insert in die casting is a solid material integrated into die cast parts. Inserts increase production costs and complexity. In die casting, molten aluminum and molten alloy are poured into the mold. It flows and surrounds the insert to finish the casting process. The complexity of die casting parts increases when incorporating inserts, necessitating more advanced design considerations.

While integrating inserts can offer benefits such as added strength or unique material properties, it is important to weigh these benefits against the increased complexity and cost. Carefully considering the use of inserts allows for informed decisions that enhance the functionality and performance of the final product.

Secondary Machining Operations

Secondary machining operations play a vital role in achieving better precision and surface finish in die cast parts. These operations are essential for refining parts to meet specific tolerances and surface quality requirements. However, challenges in secondary machining can include surface roughness and geometric deviations that may need correction.

Incorporating machining features like core slides or pulls during design can help minimize the necessity for secondary machining operations. Key considerations include:

- Designing parts that require fewer secondary operations to streamline the production process and reduce costs.

- Machining allowances, which refer to the extent of material removed post-casting, are critical to consider.

- Recommendations typically suggest a minimum machining allowance of 0.010 inches to ensure enough material is available for machining without compromising the part’s integrity.

Preparing for secondary machining operations during the initial design stage can lead to significant improvements in the final product’s quality and performance. Anticipating potential issues and designing with secondary machining in mind achieves a higher level of precision and finish in die cast parts, including post machined features and secondary operation.

Surface Finish Specifications

Specifying the surface finish classification in die casting design is crucial as it influences manufacturing costs and quality. The type of surface finishing chosen impacts the protective benefits and overall appearance of the final product. When selecting a surface finish classification, it is advisable to aim for the lowest classification that meets the application requirements to balance cost and functionality.

Casting surface roughness can be quantified using Ra or Rz values, which vary by application. For instance, automotive component surfaces typically require a roughness of Ra 3.2 to 12.5 µm. In contrast, industries such as aerospace often demand a surface finish finer than Ra 3.2 µm for precision parts. Achieving the desired surface finish may involve post-casting processes like polishing and coating.

Carefully selecting and specifying surface finish requirements ensures that the final product meets the necessary standards for quality and performance without incurring unnecessary costs.

Summary

The journey through die casting design is intricate but immensely rewarding. From understanding the fundamental requirements to incorporating features like fillets, radii, ribs, and bosses, every design decision plays a crucial role in the final product’s quality and performance. By maintaining consistent wall thickness, managing undercuts, and considering draft angles, designers can ensure the structural integrity and manufacturability of die cast parts.

In conclusion, mastering die casting design requires a blend of knowledge, experience, and attention to detail. By following these essential tips and continuously seeking to optimize the design process, you can create parts that are not only functional and durable but also cost-effective. Let your creativity and technical expertise guide you in creating die cast components that stand the test of time.

Frequently Asked Questions

Why is maintaining consistent wall thickness important in die casting?

Maintaining consistent wall thickness is vital for ensuring the strength and durability of the die-cast parts while minimizing defects such as surface sinks and internal voids. This consistency also aids in achieving optimal weight and promotes even cooling during the casting process.

How do fillets and radii improve the quality of die cast parts?

Fillets and radii significantly enhance the quality of die cast parts by reducing stress concentrations, improving metal flow, and bolstering structural integrity. This ultimately leads to more durable and reliable components.

What role do ribs play in die casting design?

Ribs play a crucial role in die casting design by enhancing strength and improving metal flow, which allows for lighter, more cost-effective components without compromising structural integrity.

How can draft angles affect the ejection process in die casting?

Draft angles are crucial in die casting as they minimize friction during the ejection process, thereby preventing damage to the parts, especially those with complex shapes. Properly designed draft angles enhance the overall efficiency and effectiveness of ejection.

What are some best practices for handling shrinkage in die casting?

To effectively manage shrinkage in die casting, ensure a balanced wall thickness, address overheating in localized areas, and adhere to established design guidelines to minimize defects such as shrinkage porosity. Implementing these practices will significantly enhance the quality of your castings.