Delrin injection molding involves using Delrin, a highly durable and low-friction engineering thermoplastic, to manufacture precise and reliable plastic parts.

This advanced molding process is especially suitable for applications that demand exceptional mechanical strength, excellent dimensional stability, and outstanding chemical resistance.

In this comprehensive article, you’ll discover what sets Delrin, the critical aspects of its injection molding process, and the diverse industrial and consumer applications that benefit from Delrin’s superior performance and durability.

What Is Delrin?

Delrin is a brand name for polyoxymethylene (POM), a high-performance engineering thermoplastic known for its strength, stiffness, and durability.

It is widely used in injection molding to produce precise, wear-resistant plastic parts that perform reliably in demanding industrial and consumer applications.

Available in both homopolymer acetal and copolymer acetal grades, Delrin can be tailored to meet specific project needs, serving industries like automotive, medical, electronics, and food processing with high-quality molded parts.

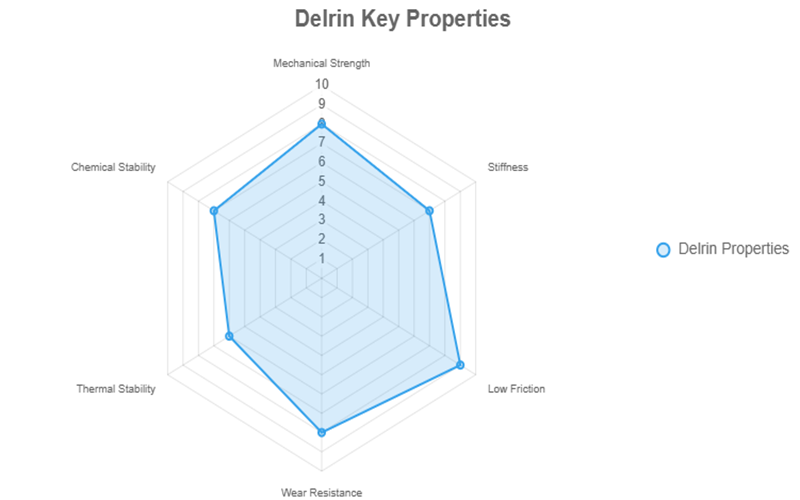

What Are The Properties Of Delrin Material?

Delrin, also known as polyoxymethylene (POM), is a high-performance thermoplastic with exceptional properties that make it a preferred material in various engineering applications.

It exhibits high strength, stiffness, and dimensional stability, allowing it to maintain its shape and performance under mechanical stress.

Delrin has a low coefficient of friction and excellent wear resistance, making it ideal for precision parts like gears, bearings, and bushings.

Its resistance to creep and fatigue ensures long-term durability, while its good chemical resistance protects against many solvents, fuels, and chemicals.

Additionally, Delrin offers low moisture absorption, maintaining consistent performance in humid environments, and its machinability allows for tight tolerances in manufacturing.

These properties make Delrin a versatile material for industries ranging from automotive to consumer electronics.

Considerations Of Delrin Injection Molding

When working with Delrin injection molding, several important considerations must be taken into account to optimize part quality and performance.

First, careful design of the mold and process parameters is essential to fully leverage Delrin’s excellent properties, including its increased strength, stiffness, and chemical resistance.

Controlling the drying process of Delrin resin is crucial, as any residual moisture can cause defects such as bubbles, voids, or surface imperfections.

Maintaining precise temperature control during melting and injection is vital to prevent thermal degradation and ensure consistent flow characteristics, which directly affect the dimensional stability and mechanical strength of the molded parts.

Mold design plays a vital role; it should promote uniform filling, efficient cooling, and easy ejection to minimize warpage, sink marks, and dimensional inaccuracies.

Designers should also focus on maintaining uniform nominal wall thickness to avoid stress concentrations and reduce the risk of internal stresses or deformation.

Additionally, proper venting is necessary to allow trapped air to escape, preventing voids and improving surface finish.

Advantages Of Delrin Injection Molding

Delrin, a high-performance acetal resin , offers numerous advantages in injection molding, making it a preferred material for producing precision components across various industries.

High Mechanical Strength

Delrin provides exceptional durability and rigidity, enabling the production of robust and reliable parts like gears and fasteners that can withstand significant mechanical stress and demanding operational conditions.

Low Friction

Delrin’s self-lubricating properties significantly reduce friction and wear, making it ideal for applications involving moving parts such as bearings, gears, and conveyor systems.

This characteristic effectively extends component lifespan and enhances overall mechanical efficiency.

Excellent Dimensional Stability

Delrin maintains tight tolerances and resists deformation, ensuring consistent part dimensions even under varying temperatures, humidity levels, and demanding mechanical stresses.

High Efficiency

Delrin, a polyoxymethylene (POM) polymer, exhibits consistent flow characteristics and minimal shrinkage, enabling high-precision injection molding with reduced cycle times and enhanced production efficiency.

Its better mechanical properties compared to other polymers contribute to superior part quality, durability, and dimensional stability, making it ideal for demanding industrial applications.

Minimal Post Processing

The smooth surface finish of Delrin parts significantly reduces the need for secondary finishing operations, thereby lowering manufacturing costs and production time while enhancing overall efficiency and product consistency.

Disadvantages Of Delrin Injection Molding

Despite its many advantages, Delrin injection molding also presents several limitations that must be considered during material selection and part design.

Limited Thermal Resistance

Delrin has a relatively low melting point (around 175°C), which restricts its use in high-temperature environments, as it may soften or deform under prolonged heat exposure, limiting its application in certain industries.

Susceptibility To UV Degradation

Prolonged exposure to ultraviolet (UV) light can degrade Delrin, causing discoloration and reduced mechanical properties, making it less suitable for outdoor applications without proper UV stabilization.

Potential For Warping

During injection molding, Delrin’s high crystallinity can lead to uneven cooling and shrinkage, increasing the risk of warping or dimensional inaccuracies, especially in complex or thin-walled parts.

Poor Bonding Characteristics

Delrin’s low surface energy makes it difficult to bond with adhesives or coatings, often requiring specialized surface treatments to achieve strong adhesion, which adds complexity and cost to manufacturing.

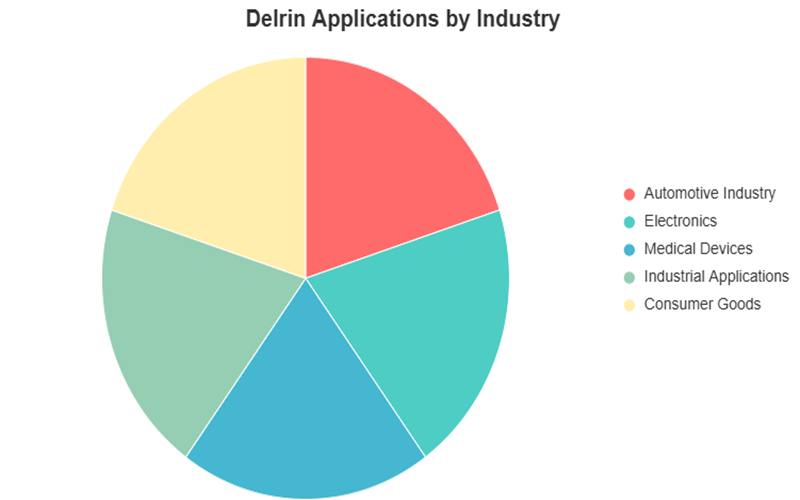

Applications Of Delrin Injection Molded Parts

Delrin plastic injection molding is widely used across various industries due to its exceptional strength, low friction, excellent dimensional stability, and outstanding chemical resistance.

These properties make it highly suitable for manufacturing durable and precise plastic parts that perform reliably in demanding applications.

Automotive Industry

Delrin is widely used in the automotive industry to produce durable components like gears, bushings, and fuel system parts.

These parts benefit from Delrin’s high wear resistance, mechanical strength, and dimensional stability, ensuring reliability under demanding conditions.

Its chemical resistance also guarantees long-term performance when exposed to automotive fluids and solvents, enhancing the durability and safety of automotive systems.

Electronics

Delrin is ideal for connectors, switches, and insulators due to its excellent electrical insulation, dimensional accuracy, and durability.

Its low friction and high wear resistance ensure reliable performance in electronic parts with frequent movement.

Delrin’s chemical resistance also protects electronics from solvents and environmental exposure, making it a preferred material in demanding industrial and consumer electronics.

Medical Device

Delrin’s excellent biocompatibility, chemical resistance, and mechanical strength make it ideal for surgical instruments, drug delivery parts, and medical device housings.

Its high wear resistance and dimensional stability ensure reliable performance through repeated sterilization and chemical exposure.

Delrin’s low friction and toughness enhance durability and smooth operation of precision medical components.

Industrial Application

Delrin’s low friction, high wear resistance, and mechanical strength make it ideal for industrial components like conveyor belt links, bearings, and fasteners.

Its excellent chemical resistance and durability ensure reliable performance under heavy loads, repetitive motion, and elevated temperatures.

These qualities make Delrin a top choice for tough plastic parts in conveyor belts, safety restraints, gears, and other critical industrial components.

Consumer Goods

Delrin is commonly used in consumer goods like zippers, appliance parts, and sporting equipment due to its toughness, durability, and smooth finish.

Its low friction and high wear resistance ensure reliable performance for frequently moving parts.

Delrin’s excellent dimensional stability and chemical resistance help maintain consistent quality and appearance under tough conditions, making it a top choice for durable plastic parts in various consumer products.

Summary

In summary, Delrin offers unparalleled advantages in injection molding, making it a preferred material across diverse industries.

Its unique combination of high tensile strength, excellent dimensional stability, low friction, and outstanding resistance to wear and chemicals makes it exceptionally suitable for demanding applications that require durability and precision.

By adhering to best practices in the injection molding process—including careful drying, precise temperature control, and optimized mold design—designers and engineers can fully maximize the performance, reliability, and longevity of Delrin parts.

Moreover, Delrin’s versatility extends beyond injection molding to other manufacturing methods such as extrusion and machining, further enhancing its appeal for producing complex plastic parts with superior mechanical properties.

As manufacturing technologies advance and industry requirements evolve, Delrin remains a steadfast and innovative material choice that consistently meets the rigorous demands of modern industrial, automotive, medical, and consumer applications.

Frequently Asked Questions

What Makes Delrin A Preferred Material For Injection Molding?

Delrin is preferred for injection molding because of its exceptional tensile strength, dimensional stability, low friction properties, and resistance to wear and chemicals, making it suitable for demanding applications.

What Are The Key Considerations In The Injection Molding Process For Delrin?

Key considerations in the injection molding process for Delrin include ensuring proper drying of the resin prior to processing, utilizing stainless steel molds, adhering to recommended injection pressure, and designing efficient cooling systems to produce high-quality parts.

Which Industry Is Delrin(Polyoxymethylene POM)Commonly Used?

Delrin is commonly used in the automotive, medical, and consumer goods industries, owing to its durability and performance in demanding conditions. Its compliance with regulatory standards further enhances its application across these sectors.

What Challenges Are Associated With Processing Delrin?

Processing Delrin presents challenges due to its sensitivity to heat, necessitating precise control of melt temperature to maintain optimal melt characteristics and ensure high-quality parts. Proper temperature management is crucial for successful processing.

What Are The Advantages Of Using Delrin Over Metal?

Delrin provides notable advantages over metal, such as reduced weight, cost efficiency, superior wear resistance, and low friction. These characteristics make Delrin an excellent choice for high-load mechanical applications.