Wondering whether to use thermoplastic rubber (TPR) or thermoplastic polyurethane (TPU) for your project? Understanding their key differences, especially in the context of TPR vs TPU, is crucial.

TPR is known for its flexibility and durability, making it great for consumer goods. TPU, on the other hand, excels in elasticity and chemical resistance, suitable for industrial uses.

This article will compare their properties, uses, recyclability, and cost to help you make an informed decision.

Understanding Thermoplastic Rubber (TPR)

Thermoplastic Rubber (TPR) is a copolymer composed of 23% polystyrene and 77% butadiene, blending the elasticity of rubber with the moldability of plastics.

This unique combination enables TPR to maintain its shape despite significant stretching or compression, offering versatility for various applications, including styrene butadiene styrene, thermoplastic elastomer, and thermoplastic rubbers. Glass transition temperature and temperature resistance are key factors in its performance.

Key characteristics of TPR include:

- Flexibility

- Abrasion resistance

- Tear resistance

- Slip resistance

- Water resistance

These properties make TPR an excellent material for products that require durability and resilience.

Moreover, TPR exhibits better ozone, weathering, and UV resistance compared to traditional rubber, enhancing its longevity in outdoor applications. Blow molding is a common process for shaping TPR, leveraging its moldability.

Besides its physical properties, TPR provides chemical stability and impact strength, making it suitable for diverse applications.

Furthermore, TPR’s capacity to endure fatigue and sustain performance under stress highlights its utility in demanding environments.

Exploring Thermoplastic Polyurethane (TPU)

Thermoplastic Polyurethane (TPU) is another versatile polymer material, composed of diisocyanates, polyols, and chain extenders.

This composition results in a block structure that alternates hard and soft regions, giving TPU its unique characteristics.

Available in both solid and expanded types, TPU can be tailored for various applications, including the automotive sector and conveyor belts.

TPU is notable for:

- High elasticity

- Exceptional abrasion resistance

- Impressive tear resistance

- Durability

- Excellent chemical resistance

- Tearing resistance

These properties make TPU ideal for applications needing both flexibility and toughness, and they broaden TPU’s usability and ability across different industries.

A notable feature of TPU is its versatility. It can be engineered for different hardness levels, suitable for both rigid and flexible applications. This adaptability makes TPU suitable for various applications, from shoe soles to industrial seals and more.

Comparing Physical Properties of TPR and TPU

When comparing TPR and TPU, several physical properties highlight their differences. TPR hardness ranges from 10 to 69 on the Shore D scale, while TPU hardness varies from 59 to 83, indicating that TPU can be made significantly harder than TPR. This difference in hardness affects their suitability for various applications.

The tensile strength of TPU is also generally higher than that of TPR. TPR’s ultimate tensile strength ranges from 0.345 to 80.0 MPa, whereas TPU’s tensile strength spans 28.0 to 96.0 MPa. This higher tensile strength makes TPU more suitable for applications where high strength impact and stress resistance are critical.

Abrasion resistance is another key difference. TPR generally shows higher Taber abrasion resistance (30 to 800 mg per 1000 cycles), whereas TPU has much lower abrasion resistance (5 to 25 mg).

This makes TPU more suitable for applications needing high wear resistance, such as sports equipment and industrial components.

Applications in Various Industries

TPR and TPU find their uses in a variety of industries, each material bringing its unique strengths to the table. TPR is often utilized in industries that demand durability and flexibility, such as automotive and consumer goods.

For instance, it is used in construction for seals in doors and windows due to its excellent weathering properties.

In the medical field, TPR is frequently used for components like air tubes and syringe seals, thanks to its chemical stability and flexibility. Consumer products like mobile phone covers also benefit from TPR’s cushioning and shock absorption properties.

TPU is extensively used in various industries due to its unique properties:

- In the automotive parts industry, for interior components because of its durability and superior surface finish.

- In agriculture, as ID tags for animals, benefiting from its flexibility and weather resistance.

- For sports equipment and other high-impact applications, due to its superior abrasion resistance.

Choosing between TPR and TPU depends on the specific application requirements. For products requiring flexibility in low temperatures, TPU is preferable as it retains its properties without becoming brittle.

Conversely, TPR may be better for applications needing higher abrasion resistance and lower costs.

Recyclability and Environmental Impact

Thermoplastic Polyurethane (TPU) stands out for its biodegradability. Under suitable conditions, TPU can break down in landfill or compost within 3 to 5 years, leaving no toxic residues.

This aligns with the EN13432 standard, which classifies materials as ‘bio’ if they biodegrade over 90% within six months.

While both TPU and TPR are highly recyclable, they differ in their environmental impact:

- TPU’s recyclability can be enhanced through specific processing techniques that allow for reprocessing into high-quality raw material.

- After thermal decomposition, the material tends to degrade.

- It typically becomes second-grade quality.

TPR is also highly recyclable, but like TPU, the recycled material becomes second-grade and degrades slowly in the environment.

Emerging bio-based TPR materials derived from algal monomer sources show promise for improved sustainability. These innovations are leading to more environmentally friendly thermoplastics, contributing to long-term sustainability by returning nutrients to the soil through biodegradation.

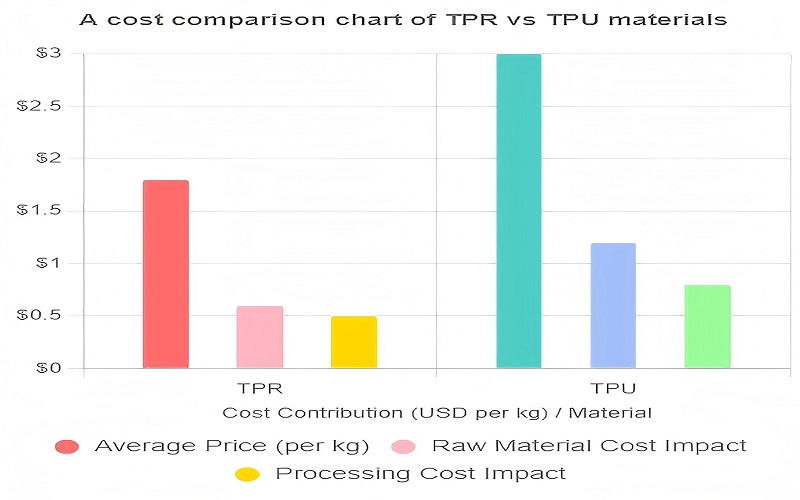

Cost Comparison: TPR vs. TPU

Regarding cost, TPR is generally more budget-friendly than TPU. TPR is priced between $1.60 and $2.00 per kilogram, making it a viable option for less demanding applications.

In contrast, TPU costs approximately $2.00 to $4.00 per kilogram, reflecting its higher performance characteristics.

Several factors influence the cost of TPR and TPU, including raw material prices, processing techniques, and production volumes. Cost considerations significantly influence material selection, especially for large-scale manufacturing projects.

Design and Manufacturing Considerations

A well-designed molded mold is crucial for TPU injection molding to avoid defects and optimize production efficiency.

Using wear-resistant materials in mold construction is important to withstand the abrasive nature of TPU. Incorporating draft angles of 3–5° helps with part ejection, countering TPU’s tendency to adhere to molds.

Key design guidelines include:

- Maintaining uniform wall thickness of 0.8–3 mm to avoid sink marks and ensure proper cooling of extruded parts.

- Designing mold gates at the thickest part of the part to facilitate uniform filling and reduce pressure loss.

- Controlling mold temperatures between 15–50°C to maintain consistent cooling and prevent warpage.

Reducing sticking in TPU molding can be achieved by using mold release agents, cooler molds, generous draft angles, and polishing mold surfaces.

Proper mold temperature adjustment during TPU injection ensures correct filling and flow, minimizing defects.

Alternative Materials to TPR and TPU

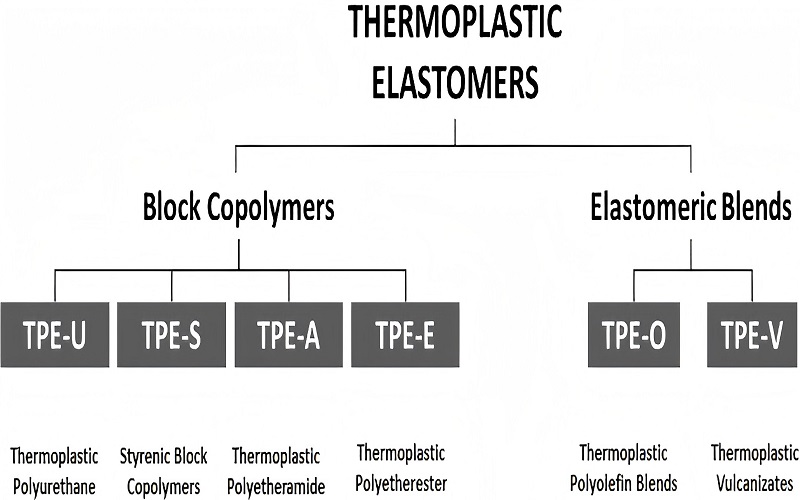

Several alternatives to TPR and TPU offer unique properties suitable for specific applications.

Styrenic Block Copolymers (TPE-S) provide high impact resistance, making them a viable option for applications where tpe tpr or TPU may be used.

Melt-Processable Rubber (MPR) can be an effective substitute due to its unique properties.

Different types of thermoplastic elastomers and their properties include:

- Thermoplastic Vulcanisates (TPE-V): offer a balance of properties comparable to TPR and TPU.

- Thermoplastic Polyolefins (TPE-O): offer flexibility and chemical resistance, making them suitable substitutes.

- Thermoplastic Copolyesters (TPE-E): present a good balance of properties, making them advantageous alternatives.

- Thermoplastic Polyamides (TPE-A): provide excellent mechanical strength and heat resistance, ideal for high-performance applications.

Vulcanized natural rubber (NR), Fluoropolymer Elastomers (FPE), and Nitrile rubber (NBR) are also noteworthy alternatives, each offering specific advantages in terms of elasticity, chemical resistance, and oil resistance respectively.

These alternatives offer a range of options for various applications, depending on specific requirements.

Choosing the Right Material for Your Project

Selecting the right material for your project involves considering various factors, including cost and environmental impact.

Two materials, TPR and TPU, differ in affordability, with TPR being generally more affordable than TPU, making it a viable option for less demanding applications.

However, TPU typically has a higher recyclability rate than TPR, which might be crucial for environmentally conscious projects.

Specific application requirements also play a significant role in material selection. Evaluating necessary characteristics like flexibility, durability, and chemical resistance helps determine whether TPR, TPU, or an alternative material is most suitable.

For example, TPU is preferable for items requiring high elasticity and resilience, while TPR might be better for applications demanding higher abrasion resistance and maintaining original shape.

Ultimately, the right material choice depends on a balance of cost, performance, and environmental considerations, including cost effectiveness. Thoroughly evaluating these factors ensures the success and sustainability of your project.

Summary

In summary, both TPR and TPU offer unique advantages and are highly valuable in various industries.

TPR is characterized by its flexibility, abrasion resistance, and cost-effectiveness, making it suitable for automotive, construction, and consumer goods.

TPU, on the other hand, excels in elasticity, chemical resistance, and durability, making it ideal for automotive interiors, sports equipment, and medical devices.

Choosing the right material involves evaluating the specific requirements of your project, including cost, performance, and environmental impact.

By understanding the key differences between TPR and TPU, you can make informed decisions that enhance the efficiency and sustainability of your applications.