Polyethylene Terephthalate (PET) injection molding is a cornerstone of modern manufacturing, enabling the efficient production of high-quality, durable, and versatile products.

Renowned for its exceptional clarity, strength, recyclability, and good chemical resistance, PET is a preferred material across diverse applications in numerous industries, including consumer goods, automotive components, and industrial packaging.

This article explores the fundamentals of PET injection molding, covering the material’s unique properties, critical processing parameters, key advantages and limitations.

What Is Polyethylene Terephthalate (PET)?

Polyethylene Terephthalate, commonly known as PET, is a versatile thermoplastic polymer widely used in injection molding due to its excellent strength, clarity, and chemical resistance.

It is a member of the polyester family and is prized for its durability and lightweight properties.

PET is commonly found in products such as plastic bottles, food containers, and packaging materials, making it a popular choice across various industries including food and beverage, automotive, and consumer goods.

Its ability to be recycled also contributes to its sustainability, further enhancing its appeal in modern manufacturing processes.

Material Properties Of PET Plastic

Polyethylene Terephthalate (PET) is a widely used thermoplastic polymer in injection molding, valued for its unique material properties that make it ideal for various applications.

PET exhibits excellent clarity and transparency, resembling glass, which is perfect for producing visually appealing bottles and containers.

Its high tensile strength and impact resistance ensure durability, while its lightweight nature enhances cost-efficiency in packaging.

A key advantage of PET is its low moisture absorption, which helps maintain dimensional stability and prevents degradation during the injection molding process, ensuring consistent quality.

PET is also chemically stable, offering resistance to moisture, acids, and bases, which makes it suitable for food and beverage applications.

Additionally, PET is fully recyclable, supporting sustainable manufacturing with the use of recycled PET, though it requires careful processing due to its sensitivity to moisture and high melting point.

Its capability for high precision molding allows manufacturers to produce components with tight tolerances and excellent surface finish, essential for applications demanding accuracy and reliability.

Key Parameters In PET Injection Molding Process

The success of PET injection molding largely depends on precise control of key process parameters. Critical factors include drying temperature and time, melt temperature, injection pressure, mold temperature, and injection speed.

Proper drying of PET pellets at temperatures between 100–120°C for 3–4 hours is essential to reduce moisture content, preventing defects like hydrolysis and ensuring optimal material properties.

Melt temperatures typically range from 260–295°C to achieve the right viscosity for smooth flow during injection, allowing the material to withstand high temperatures without degradation.

Injection pressure and speed must be carefully balanced to fill molds completely without causing material degradation or warping.

Mold temperature, usually maintained between 100–140°C, influences cooling rate and dimensional stability of the final parts.

Additionally, controlling cycle time and screw rotation speed enhances production efficiency while maintaining high precision and quality.

These optimized parameters enable manufacturers to produce large quantities of consistent, durable, and high-quality PET components suitable for diverse applications.

| Parameter | Typical Range | Parameter | Typical Range |

|---|---|---|---|

| Drying Temperature (°C) | 100–120 | Melt Temperature (°C) | 260–295 |

| Drying Time (h) | 3–4 | Injection Pressure (MPa) | 80–140 |

| Mold Temperature (°C) | 100–140 | Locking Force (ton/in²) | 3–4 |

| Residual Material Amount (mm) | 3–8 | Injection Speed | High Speed |

| Screw Rotation Speed (rpm) | 60–90 | Reuse of Scrap Material (%) | 10–20 |

Benefits Of PET Injection Molding

Polyethylene Terephthalate (PET) injection molding offers numerous advantages that make it a preferred manufacturing process for producing high-quality plastic components.

Cost Effective

PET’s lightweight nature reduces material and transportation costs, making it an economical and cost-effective choice for high-volume production such as packaging applications.

Additionally, its excellent wear resistance and low moisture absorption contribute to durable, high-quality parts that minimize waste and rework.

The use of PET resin pellets optimized for injection molding ensures efficient processing in the molding machine’s cylinder, further enhancing production efficiency and reducing cycle times.

Versatility In Applications

The ability to mold PET into precise and complex shapes allows its use across diverse industries, from packaging and food industry applications to automotive components, meeting varied design and performance requirements.

PET injection molding is well suited for producing high-precision parts with excellent dimensional stability and durability, making it a reliable choice for manufacturers.

Its versatility extends to creating pet preforms, beverage bottles, and other consumer goods, highlighting its importance in packaging applications.

This adaptability, combined with PET’s good chemical resistance and low moisture absorption, enables it to perform effectively in demanding environments across multiple sectors.

Efficient Production

PET injection molding supports high-speed production with short cycle times, enabling manufacturers to achieve high output while maintaining consistent quality.

This efficiency is driven by the material’s low moisture absorption and excellent flow characteristics during the injection molding process, which reduce defects and minimize downtime.

Additionally, the use of advanced injection molding machines ensures precise control over temperature, pressure, and injection speed, further optimizing production performance.

Limitations Of PET Injection Molding

While PET injection molding offers numerous advantages, it also presents certain limitations that manufacturers must address to ensure optimal performance and quality.

Complex Mold Design Requirements

Producing high-quality PET parts often requires advanced mold designs, including features such as hot runners and precise cooling channels.

These sophisticated designs enhance the efficiency and quality of the injection molding process but also increase initial setup costs and complexity.

Careful mold engineering is essential to optimize cycle times, minimize defects, and ensure consistent dimensional stability in the final products.

Restricted Use Of Recycled PET Material

While PET is recyclable, the incorporation of recycled PET is typically limited to 10–20% in many injection molding applications.

This limitation arises due to potential inconsistencies in the material properties of recycled PET, such as variations in molecular weight and contamination levels, which can adversely affect the mechanical performance, dimensional stability, and overall quality of the final molded parts.

Equipment Wear

The abrasive nature of PET, especially when processed with additives, can accelerate wear on screws and barrels of the injection molding machine.

This necessitates more frequent maintenance or the use of specialized equipment such as direct-feed nozzles and wear-resistant components.

Proper equipment selection and regular upkeep are essential to maintain consistent production quality and extend the lifespan of the molding machine.

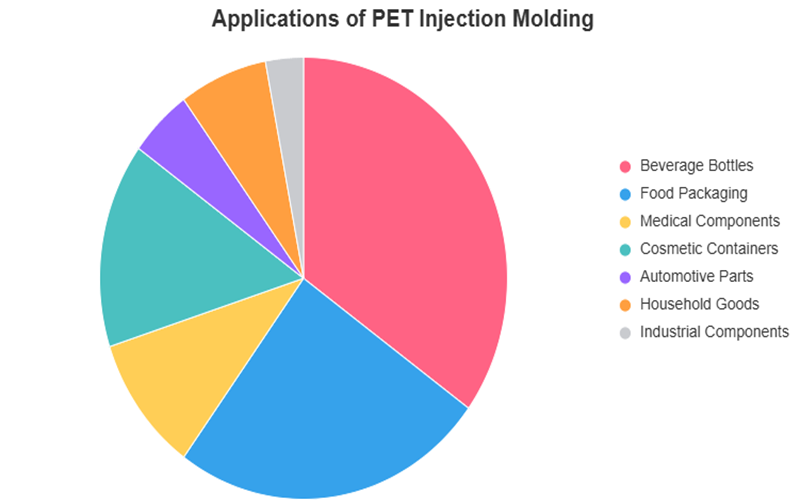

Applications Of PET Injection Molded Parts

PET injection molding is widely utilized across various industries due to its versatility, strength, and clarity, enabling the production of precise and durable components.

Food Industry

PET is widely used to manufacture containers, trays, and jars for food products due to its excellent chemical resistance and ability to meet strict hygiene and safety standards.

Notably, PET is the preferred material for packaging carbonated beverages, as it withstands the pressure of carbonation while maintaining product integrity and safety.

PET bottles are a common example of this application, offering lightweight, durable, and recyclable packaging solutions for beverages and other food products.

Medical Components

PET’s excellent strength, chemical resistance, and ability to be sterilized make it ideal for medical device parts, including syringe bodies, diagnostic equipment housings, and other precision medical components that require durability and hygiene.

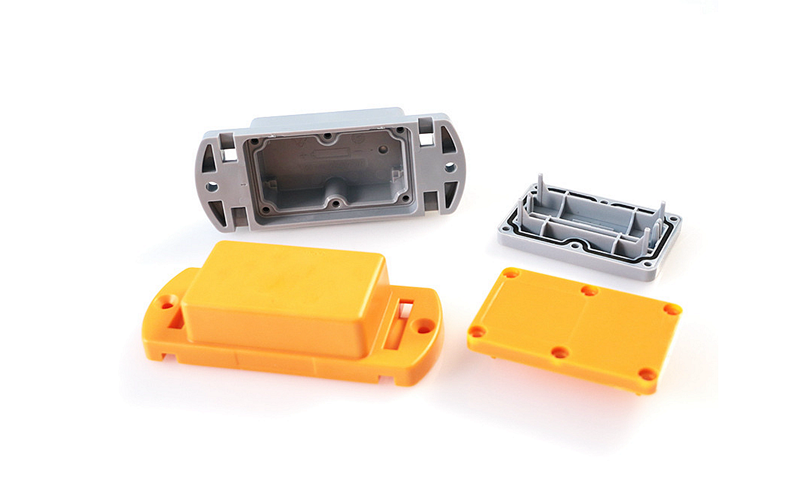

Automotive Parts

PET’s lightweight yet robust properties make it an excellent choice for manufacturing automotive components such as sensor housings, interior trim parts, and other precision components that demand durability and dimensional stability.

Its excellent wear resistance and good chemical resistance ensure long-lasting performance even in harsh automotive environments, making PET injection molding a reliable and cost-effective solution for the automotive industry.

Household Goods

PET injection molding is widely used for producing durable household items, such as storage containers, kitchenware, and other everyday products, thanks to its excellent impact resistance, dimensional stability, and chemical resistance.

These properties ensure that household goods made from PET are long-lasting, safe, and suitable for various consumer applications, making PET a reliable and cost-effective material choice in this sector.

Industrial Components

PET’s outstanding mechanical strength and excellent wear resistance make it well suited for producing a wide range of industrial components such as gears, fittings, and bearings, where high precision, durability, and reliability are critical.

Its good chemical resistance and dimensional stability ensure consistent performance even under demanding industrial applications, making PET injection molding a preferred choice for manufacturers seeking quality and efficiency.

Summary

To summarize, PET injection molding offers numerous benefits, including high efficiency, cost-effectiveness, and sustainability.

The process is well-suited for producing a wide range of consumer products, catering to diverse customers with varying needs.

Different grades of PET material provide manufacturers with options to tailor properties such as durability, clarity, and chemical resistance for specific applications.

For example, PET grades used in food packaging differ from those employed in automotive components, ensuring optimal performance in each sector.

However, PET injection molding also comes with limitations such as pearlescence, shrinkage, and limited toughness, which require careful management.

The future potential of PET injection molding is vast, with ongoing advancements in technology promising even greater efficiencies and applications.

By understanding and mastering this process, manufacturers can continue to produce high-quality components that meet the evolving demands of various industries and customers.