Deciding whether injection molding vs casting is better for your project?

This article breaks down their key differences, including cost, material compatibility, and production speed, to help you make an informed choice.

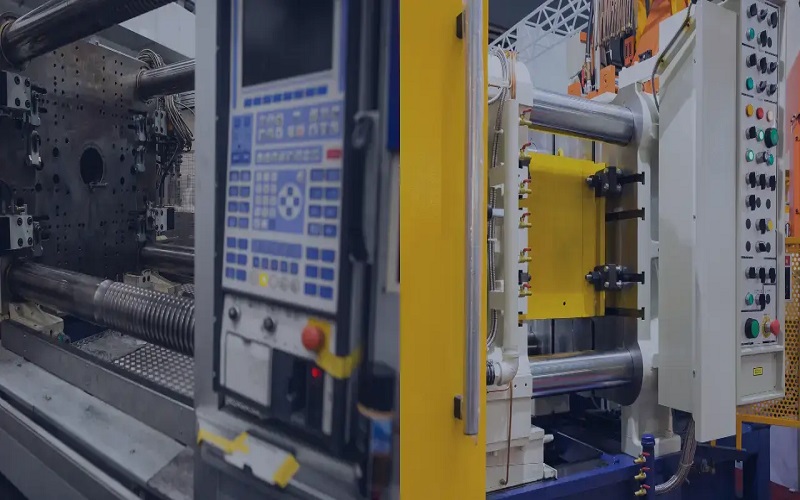

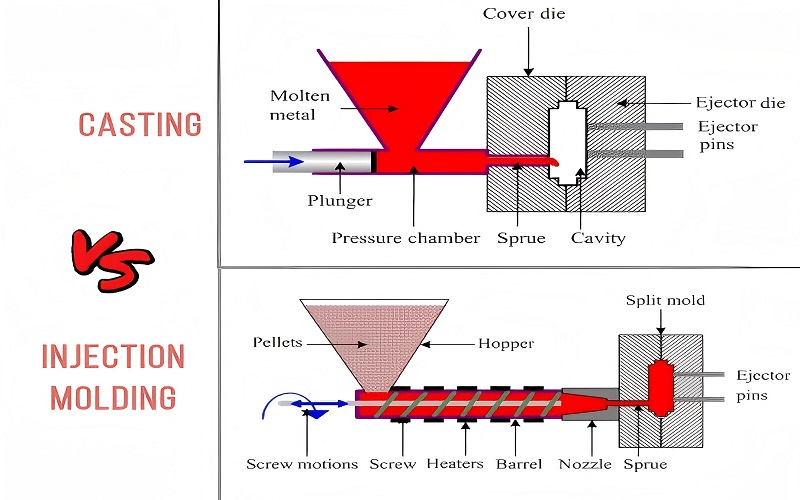

Understanding Injection Molding

Injection moulding is a versatile manufacturing process that creates injection molded plastic parts by injecting molten metal or molten plastic into injection molds under high pressure, ensuring complete mold filling for the desired shape.

This process, often referred to as plastic injection molding, involves controlling temperature and material flow to optimize results.

Compared to die casting vs other methods, it benefits from simpler mold tooling and lower manufacturing costs, enhancing its efficiency and precision across various industries.

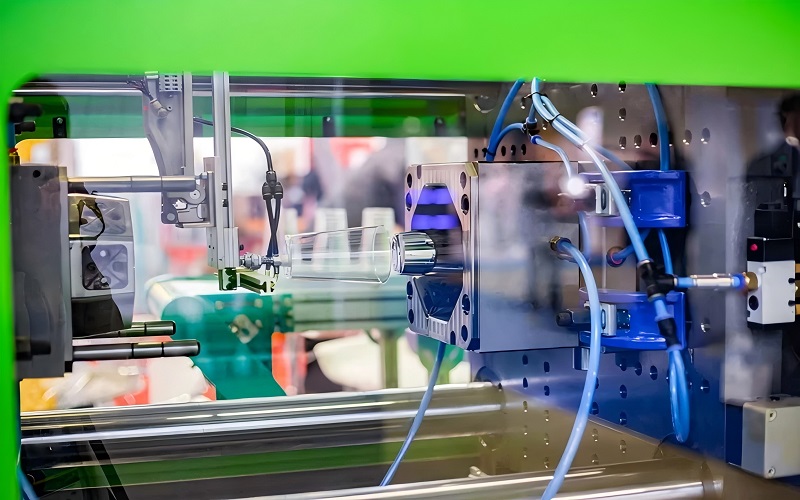

Injection Molding Process Steps

The injection molding process involves the following steps:

- Mold preparation, including lubrication to prevent molten plastic from sticking and to ensure easy ejection.

- Heating the plastic resin to a molten state, usually between 300 to 800°F.

- Injecting the molten plastic into the mold through a nozzle, filling the cavity completely.

After filling the mold cavity, the plastic cools and solidifies, forming the final product. The cooled product is then ejected from the mold, ready for any post-processing or assembly.

Advantages of Injection Molding

A major advantage of injection molding is its ability to produce intricate designs with high accuracy and repeatability, making it ideal for complex plastic parts with precise dimensions and tight tolerances.

It also achieves highly efficient production rates, suitable for large-scale manufacturing and mass production. Unlike cast molding offers simpler processes, injection molding excels in precision, often using compression molds and soft molds to enhance flexibility.

Injection molding offers consistent quality and precision, producing parts with tight tolerances that meet required specifications and quality standards.

Disadvantages of Injection Molding

Despite its advantages, injection molding comes with drawbacks, particularly high tooling costs. Creating precise molds requires expertise, which increases expenses and extends lead times.

The use of liquid metal and thin walls in complex systems further complicates the process, raising costs compared to vs injection molding simpler alternatives.

Using injection molding for prototyping can be cost-prohibitive due to the need for hard tooling, resulting in higher expenses and longer lead times, making it less ideal for projects requiring rapid prototyping and frequent design changes.

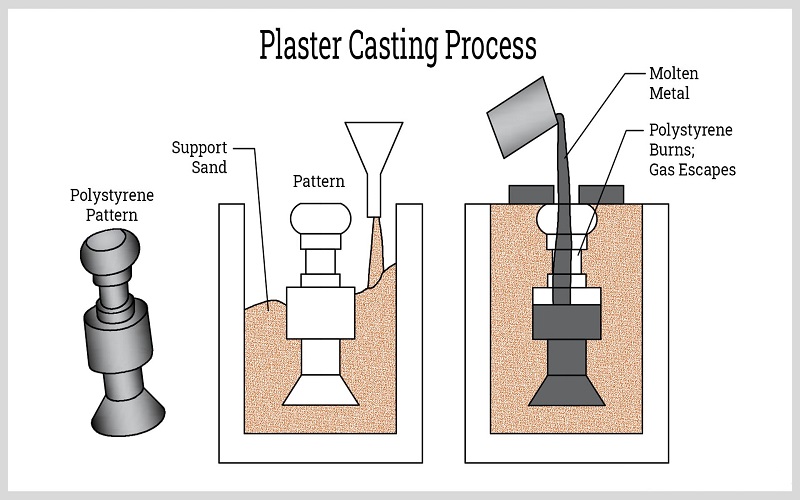

Understanding Casting

Casting is a traditional manufacturing method where molten form material is poured into closed metal molds to create parts created, using various materials such as metals, thermoset polyurethanes, and silicone rubber during the die cast casting process.

Techniques like die casting and vacuum casting are particularly useful for producing components with complex geometries and specific material properties.

Types of Casting Processes

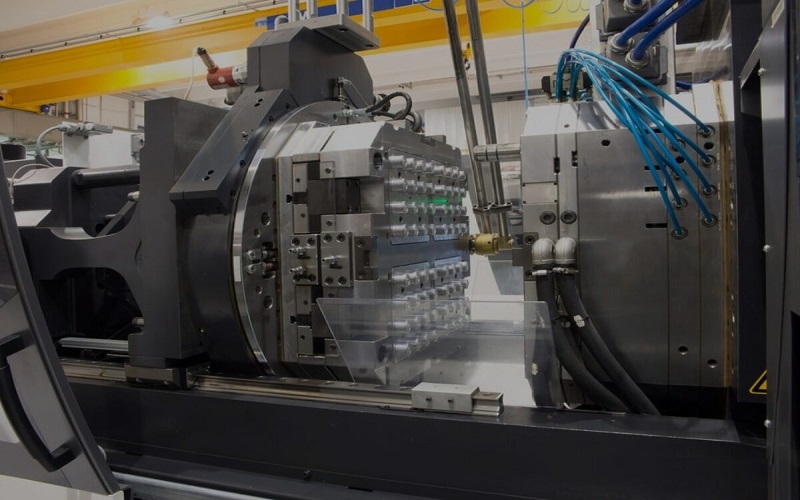

Die casting, a widely used process, involves the die casting process of casting metal under extreme force. Key aspects include:

- Materials typically used: aluminum, zinc, and copper

- Methods: gravity die casting, cold die casting, and hot die casting

- Surface finishes achievable: anodizing and powder coating

The typical finish quality is medium.

Sand casting, another ancient metal processing method, uses packed sand around a core to form molds. The process involves:

- Pouring metal into the sand mold

- Allowing the metal to cool

- Breaking open the mold to retrieve the part

- Grinding off excess material

While sand casting generally offers lower tooling costs due to simpler mold designs, it does not achieve the same precision and surface finish quality as die casting.

Advantages of Casting

Casting processes are capable of creating complex geometries that might be challenging to manufacture through other methods.

Thermoset materials used in casting provide better abrasion and chemical resistance compared to thermoplastics, making them suitable for high-melting-point applications.

Compared to the sintering process, two processes like casting offer distinct advantages.

Casting generally requires lower initial tooling costs, making it a low-cost choice for many applications.

Disadvantages of Casting

Casting has disadvantages, such as mold deterioration when using die casting for ferrous metals due to high melting points, which can introduce porosity problems.

In vacuum casting, the type of plastic and part geometry, including broader range of wire spools, can impact output quality, potentially causing porosity issues.

Additionally, casting generally exhibits less surface finish quality compared to methods like injection molding.

Injection Molding vs. Casting: Key Differences

Understanding the key differences between injection molding and casting helps in making informed manufacturing decisions.

Factors such as material compatibility, process complexity, and production volume and speed play crucial roles in determining the most suitable method for your project.

Material Compatibility

Injection molding primarily uses plastics and polymers like polyethylene, ABS, nylon, and polypropylene, while casting and injection molding often employs thermoset materials like thermoset polyurethanes and non-ferrous metals such as aluminum and zinc in a liquid state.

Metal injection molding can include advanced materials, specifically ferrous metals and alloys like stainless steel and titanium, as well as other materials, including metal parts.

The choice of material significantly impacts the properties and applications of the final plastic products, with a detailed comparison revealing distinct advantages for each process.

Process Complexity

Injection molding tools is generally more complex due to the need for precise temperature and flow control. It is considered faster than casting because of rapid cooling and pressurized filling, although metal injection molding has post-molding processes that increase the overall cycle time.

In contrast, die casting molds tend to have a longer lifespan and require less temperature regulation compared to injection molding.

Production Volume and Speed

Injection molding can produce hundreds to thousands of parts per day, significantly higher than casting capabilities, thanks to multiple cavities and shorter cycle times. Metal injection molding is typically faster than traditional die casting during the actual molding phase.

Injection molding also has shorter production lead times compared to casting, making it more suitable for high-volume production.

Cost Considerations in Injection Molding and Casting

Cost is a significant factor in choosing between injection molding and casting, with primary considerations including tooling costs and per-part costs, both varying significantly depending on design complexity and production volume.

Tooling Costs

The initial setup and design of molds can lead to significant upfront costs in injection molding, with tools being significantly more expensive than those used in casting methods due to complex designs and expensive machining.

Cast molding, however, can use various mold designs, resulting in lower tooling costs compared to injection molding. Tooling costs are a crucial factor in evaluating production methods.

Per-Part Costs

Higher production volumes in injection molding lead to lower per-part costs, as fixed mold costs are distributed over more units. Understanding how production volume influences per-part costs is crucial in evaluating manufacturing processes and determining the most cost-effective method for your project.

Surface Finish and Tolerances

Surface finish and dimensional tolerances are critical in determining the quality and functionality of the final product. Injection molding typically achieves higher surface finish quality and maintains tighter dimensional tolerances compared to casting, making it more suitable for precision parts.

Surface Finish Quality

Injection molding often requires additional surface finishing to enhance aesthetics and functionality. Techniques like bead blasting and polishing achieve different finishes, categorized into secondary operations:

- Degating

- Deflashing

- Cleaning

- Decorating

Casting methods can exhibit defects such as gas porosity, impacting overall surface finish quality.

Dimensional Tolerances

Dimensional tolerances affect the fit, function, and aesthetics of final parts. Injection molding can achieve tolerances as tight as 0.025 mm under optimal conditions, typically around 0.1 mm, which can lead to a significant difference in the overall quality of the final product.

The precision of parts produced by metal injection molding surpasses that of standard die casting, which struggles with wall thickness control. Maintaining tight tolerances allows for complex designs and integration in precision-dependent applications.

Applications and Use Cases

Both injection molding and casting have unique applications across various industries. Understanding where each method excels helps in choosing the right process for specific needs.

Injection Molding Applications

Injection molding is widely used in industries like automotive, aerospace, medical, and consumer electronics for producing complex parts efficiently.

For instance, automotive parts like dashboard components and storage compartments are often produced via injection molding to streamline production and reduce weight.

Consumer electronics heavily rely on injection molding to create components like housings for smartphones, laptops, and other electronic devices, ensuring durability and impact resistance.

Casting Applications

Heavy machinery production often uses casting and cnc machining to fabricate large components like engine blocks and frames, which require durability and strength.

Casting’s ability to produce large, robust components capable of withstanding significant stress is crucial in the heavy machinery industry.

Casting is also employed in the aerospace sector to create intricate shapes and specific part requirements that might be challenging to achieve through other methods.

Choosing the Right Manufacturing Process

Choosing the right manufacturing process is crucial and should reflect the specific design, desired raw materials, and intended use of the component.

Key factors include project requirements, common manufacturing processes, manufacturing methods, material considerations, budget constraints, and production processes.

For example, if the project requires high production volumes and tight tolerances, injection molding might be the better choice. Conversely, if the project involves creating complex geometries with lower initial tooling costs, casting might be more suitable.

Summary

In summary, both injection molding and casting have their unique advantages and disadvantages.

Injection molding excels in producing high volumes of precise plastic parts, while casting is ideal for creating complex geometries with a variety of materials.

By understanding the key differences, benefits, and considerations of each process, you can make an informed decision that best suits your project’s needs.

Frequently Asked Questions

What are the main differences between injection molding and casting?

The main differences between injection molding and casting lie in their materials and processes; injection molding typically utilizes high-pressure techniques to mold plastics, whereas casting involves pouring molten materials, often metals, into molds.

This distinction fundamentally affects the types of products and applications suitable for each method.

Which process is more cost-effective for high-volume production?

Injection molding is more cost-effective for high-volume production, as it significantly reduces per-part costs and can produce hundreds to thousands of parts daily.

What are the tooling costs associated with injection molding?

Tooling costs for injection molding can vary significantly, starting from around $100 for simple designs and exceeding $100,000 for complex, high-volume molds. Due to the intricacy involved, these costs are generally higher than those associated with casting.

Can casting be used for high-precision parts?

Casting can produce complex geometries but typically offers lower surface finish quality and precision compared to methods like injection molding. Therefore, for high-precision parts, other manufacturing techniques may be more suitable.

What industries commonly use injection molding?

Injection molding is primarily utilized in the automotive, aerospace, medical, consumer electronics, construction, and consumer goods industries to efficiently produce complex parts. This versatile manufacturing process is crucial for creating high-quality components across these sectors.