PU foam, or polyurethane foam, is a multipurpose material widely used for insulation, cushioning, and more.

In this article, we’ll explain what PU foam is, explore its types, and highlight its key uses and benefits.

Whether you’re looking to understand its application in construction, automotive, or consumer products, this guide will provide the insights you need.

What is PU Foam?

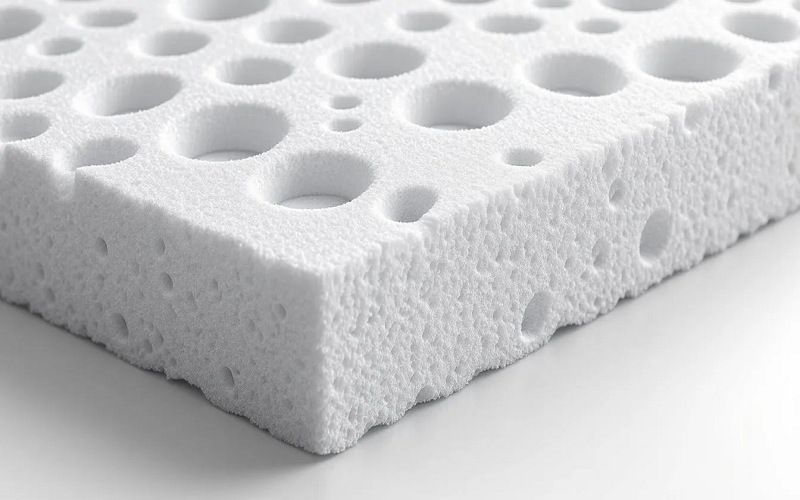

Polyurethane foam is an engineered material created from a chemical reaction between a polyol component, including high molecular weight polyols, and diisocyanates, resulting in a porous and cellular structure.

This composition comprises a solid phase formed by polyurethane elastomers and a gaseous phase introduced using blowing agents, such as carbon dioxide.

The introduction of the gaseous phase during the reaction enhances the foam’s thermal and sound insulation properties, as well as its flexibility and low density.

Blowing agents play a key role in PU foam formation by introducing gas during the chemical reaction, which creates the foam’s characteristic cellular structure. This cellular structure is what gives cured foam its unique properties, making it suitable for a wide range of applications.

Types of PU Foams

Polyurethane foam is broadly categorized into two main types: flexible and rigid, each serving distinct purposes and showcasing unique properties.

Flexible polyurethane foams typically feature lower densities and are commonly used in applications such as cushions and mattresses, utilizing ethylene glycol and propylene oxide in their chemical composition for enhanced flexibility.

On the other hand, rigid polyurethane foams are denser and are ideal for insulation purposes, providing superior thermal conductivity combined with thermal efficiency.

Flexible foams are generally white, while rigid foams tend to be yellow. This simple color distinction helps identify the type of foam at a glance.

Next, we will explore the specifics of each foam type, their applications, foam properties, and the industries they serve.

Flexible Polyurethane Foams

Flexible polyurethane foams are incredibly versatile, finding their way into a multitude of applications, including:

- Furniture and bedding

- Automotive seating

- Athletic equipment

- Packaging

- Footwear

- Carpets

Their physical properties, including compression, load-bearing capacity, and resilience, make them highly suitable for diverse applications.

The manufacturing of flexible polyurethane foams involves continuous (slabstock) and molding techniques, enabling the production of various shapes and sizes.

This adaptability is essential for industries like aerospace, defense, and automotive, where open-faced polyurethane foams meet specific needs. The durability of flexible polyurethane foam aligns with the lifespan of its applications, enhanced by urethane groups, aromatic isocyanate, and primary hydroxyl groups.

Flexible polyurethane foams play a vital role across multiple sectors, providing cushioning and insulation that boost comfort and functionality. Their ability to adapt to different forms and requirements makes them a top choice, including in cast elastomers.

Rigid Polyurethane Foams

Rigid polyurethane foams are known for:

- Low thermal conductivity

- Low density

- Good dimensional stability

- Excellent strength-to-weight ratios

These characteristics make them perfect for applications demanding robust and durable insulation. The closed-cell structure of rigid polyurethane foams, characterized by non-interconnected pores and cell size, contributes to their strength and durability.

This closed-cell structure not only makes rigid foams strong and durable but also prevents them from absorbing water, enhancing their suitability for various applications. Typical uses of closed-cell rigid polyurethane foams include:

- Tooling

- Mold making

- Composite core production

- Prototyping

- Protection of sensitive materials.

Rigid polyurethane foams play a crucial role in industries that demand high-performance insulation and structural integrity. Their distinct properties enable them to withstand harsh conditions, making them indispensable in various sectors.

Manufacturing Processes for PU Foams

The production of polyurethane foam involves a multi-step process that begins with the preparation of a polymer system, followed by the foaming process.

Polyurethane foams, classified as cellular plastics, are typically produced using continuous-reaction processes or batch processes with aqueous solutions and diethylene glycol, ensuring the foam meets specific requirements for different applications.

Common processing technologies for producing polyurethane foams include the molding process and slabstock foaming. These methods allow for the production of large foam blocks or precisely shaped foam items, catering to a wide range of industrial needs.

These manufacturing processes offer insights into tailoring PU foams to meet various application requirements.

Slabstock Process

The slabstock process allows for continuous production, where foam expands into large blocks that can be cut into various shapes as needed on a conveyor belt. This method is efficient and cost-effective, making it suitable for industrial scale production.

Producing large foam blocks through the slabstock process allows manufacturers to meet high demand while maintaining consistent quality, with each cubic foot of foam being particularly useful for applications that require large quantities of foam, such as furniture and bedding.

Molding Process

In the molding process, raw materials are poured into molds to create foam items in specific shapes. This method allows for precise shaping of the materials used in PU foams, ensuring that the final product meets exact specifications.

The molding process is highly efficient, reducing waste and allowing for the production of complex shapes. Molded foam flexible polyurethane foams can be tailored to fit specific needs, making them ideal for automotive seating and other specialized applications.

Spray Foam Application

Spray foam is a type of polyurethane foam commonly used for insulation purposes in construction materials. As a semi-flexible foam, it has properties that allow it to conform to various shapes and surfaces, providing effective insulation.

Spray foam applications are particularly effective for creating a seamless barrier that enhances thermal efficiency in buildings.

Recommended coatings for painting spray foam include automotive or woodworking grades, as well as acrylic-latex or enamel for outdoor use. This versatility makes spray foam a popular choice for both residential and commercial construction projects.

Key Properties of PU Foams

The key properties of polyurethane foams make them indispensable in numerous applications.

From thermal insulation and cushioning materials to sound absorption, PU foams offer a range of benefits that enhance their functionality. Common applications include mattresses, upholstered furniture, and vehicle seating.

Recognizing these properties allows us to appreciate the versatility and performance of PU foams. As we explore the thermal properties, thermal insulation, mechanical properties, and sound absorption capabilities of PU foams, we gain a deeper insight into why they are so widely used.

Thermal Insulation

Polyurethane foams exhibit low thermal conductivity, making them highly efficient for maintaining temperature control in buildings and appliances.

Rigid polyurethane foams, in particular, are known for their energy efficiency and are frequently used in insulation for buildings and appliances, often incorporating fatty acids and carbon monoxide in advanced formulations by Dow Chemical.

These foams provide excellent thermal insulation, making them ideal for roofing, wall systems, and energy-efficient building designs. Spray foam insulation can be applied directly onto surfaces, creating a seamless barrier that enhances thermal efficiency in buildings. This method greatly improves energy efficiency in residential and commercial settings.

New PU foam formulations are being engineered to provide improved fire resistance and better thermal regulation, addressing growing safety and energy efficiency demands. These advancements ensure that PU foams continue to meet the evolving needs of various industries.

Mechanical Properties

The mechanical properties of polyurethane foams are crucial for their performance across diverse industries. The compressive strength of PU foams can vary significantly, influenced by the foam’s density and production techniques.

These properties ensure that PU foams are suitable for various applications, from construction materials to automotive components. The ability to tailor the mechanical properties of PU foams makes them a versatile choice for many industries.

Sound Absorption

Flexible polyurethane foams are effective sound absorbers, specifically designed to reduce noise in various environments by modulating their acoustic properties.

The open-cell structure of these foams allows them to efficiently absorb sound and provide comfort in various applications.

These foams are extensively utilized in various settings, including automotive interiors, to enhance sound insulation and comfort materials. Their ability to reduce noise makes them an essential component in creating quiet and comfortable environments.

Environmental Impact and Sustainability

The flexible polyurethane foam industry is focused on improving environmental impact through reduced toxicity and emissions. Raw materials extraction and production account for about 90% of total greenhouse gas emissions in flexible PU foam.

The introduction of eco-friendly blowing agents like water and hydrocarbons has shifted away from older harmful agents like CFCs, while also considering the role of isocyanate groups in the production process.

Polyurethane production results in significantly less waste compared to traditional plastic manufacturing processes. Recent developments in PU foam technology focus on enhancing sustainability and performance by integrating renewable materials and improving energy efficiency in manufacturing processes. These advancements ensure that PU foam production continues to evolve towards a more sustainable future.

Renewable Raw Materials

The use of bio-based new raw materials in polyurethane foam helps reduce reliance on fossil fuels and lowers the overall carbon footprint. General Plastics incorporates rapidly renewable bio polyols as part of their strategy to enhance the sustainability of their foam products.

Integrating renewable raw materials such as vegetable oils and algae oil into the production process ensures that PU foams are more environmentally friendly. These efforts contribute to the overall sustainability of PU foam products by utilizing renewable sources.

Recycling Methods

At the end of its life cycle, polyurethane foam cannot be melted for reuse. The most common waste management methods currently used for PU foam include landfilling and energy recovery.

Despite the challenges in recycling PU foam, efforts are being made to develop more efficient recycling methods.

These include chemical recycling processes that can deconstruct polyurethane foam back into its raw materials, allowing for new foam production. These advancements help mitigate waste and promote a circular economy.

Common Applications of PU Foams

Polyurethane foams are utilized across various sectors, including automotive, construction, and consumer goods, for their versatility and performance. Flexible polyurethane foam represents around 30% of the North American polyurethane market, primarily used in bedding and automotive applications.

Polyurethane foams are also extensively used in the medical field for applications such as cushions, supports, and protective padding. Recognizing the common applications of PU foams underscores their significance in our daily lives.

Automotive Industry

Flexible polyurethane foams are commonly used in automotive seat cushions, providing essential comfort and support for passengers, creating a cushioning effect. PU foams are also effective sound insulators in automotive applications, helping to minimize noise and enhance the driving experience.

Polyurethane foams play a vital role in the automotive industry, particularly in enhancing comfort and performance in vehicles. Their versatility and performance make them essential components in modern automobiles.

Construction Materials

Rigid polyurethane foams are widely used in construction, particularly for building insulation and structural components. These foams contribute to energy efficiency by providing excellent insulation, which helps to maintain building temperatures.

Closed cell polyurethane foams are commonly used across various industries, including marine, aerospace, and construction, showcasing their versatility. Using rigid foams in construction enhances energy efficiency, reduces heating and cooling costs, and improves overall sustainability.

Consumer Products

Flexible polyurethane foams play a significant role in everyday consumer products due to their comfort and durability. They are commonly found in everyday items such as shoe soles, furniture cushioning, and mattress padding.

These foams enhance the quality and comfort of consumer products, making them a preferred choice for manufacturers and consumers alike. Their widespread use highlights the importance of PU foams in improving our daily lives.

Innovations in PU Foam Technology

Recent innovations in PU foam technology are focused on improving performance characteristics, making them suitable for a wider array of applications.

New formulations are being developed that enhance the fire resistance and thermal regulation properties of PU foams, contributing to greater safety and efficiency.

Emerging techniques in additive manufacturing allow for the creation of complex foam structures with tailored properties, pushing the boundaries of traditional manufacturing.

These advancements not only bolster the performance of PU foams but also support sustainability efforts by optimizing material usage and decreasing waste.

Advanced Formulations

Advanced formulations in PU foam technology aim to enhance various properties, including fire resistance and thermal regulation, to meet the evolving needs of industries.

Fire-resistant PU foams are developed using flame retardants that slow down the spread of fire, making them essential for safety in applications such as construction and automotive.

Recent developments have resulted in PU foams with enhanced thermal regulation, minimizing heat transfer and maximizing insulation efficiency.

Innovative blending of conventional materials with new compounds enhances the functionality of PU foams, leading to better fire resistance, insulation performance, and resistance to thermal stability and thermal degradation.

Additive Manufacturing

Additive manufacturing, often referred to as 3D printing, plays a crucial role in the production of complex foam structures, enabling more intricate designs than traditional manufacturing methods.

Emerging techniques such as gradient density printing allow for varying foam density throughout a single object, providing enhanced functionality and performance tailored to specific applications.

Additive manufacturing can create foams with tailored properties such as variation in stiffness and elasticity, making them suitable for specialized usage scenarios.

Additive manufacturing in PU foam production reduces waste and enables rapid prototyping, accelerating innovation in foam applications.

Summary

Throughout this journey into the world of polyurethane foams, we have explored their versatile nature, from their basic composition to their wide-ranging applications.

PU foams, whether flexible or rigid, have proven to be indispensable in industries such as automotive, construction, and consumer goods.

Their unique properties, including thermal insulation, mechanical strength, and sound absorption, make them a preferred choice for various applications.

As advancements in PU foam technology continue, with innovations in formulations and manufacturing processes, the future of this material looks promising.

Frequently Asked Questions

What is polyurethane foam made of?

Polyurethane foam is produced through a chemical reaction between polyols and diisocyanates, creating its characteristic porous and cellular structure. This composition ensures its versatility for various applications.

What are the main types of polyurethane foams?

The main types of polyurethane foams are flexible foams, commonly used in upholstery and bedding, and rigid foams, which are primarily utilized for insulation and structural applications.

How is polyurethane foam used in construction?

Polyurethane foam is primarily utilized in construction for its insulation properties and as structural components, enhancing energy efficiency and sustainability in buildings.

What are the environmental impacts of polyurethane foam production?

Polyurethane foam production can significantly impact the environment due to its associated toxicity and emissions; however, the industry is actively working to mitigate these effects by implementing renewable materials and improving manufacturing sustainability.

What are some recent innovations in polyurethane foam technology?

Recent innovations in polyurethane foam technology focus on advanced formulations that improve fire resistance and thermal regulation, alongside additive manufacturing techniques enabling the production of complex foam structures with customized properties.

These advancements significantly enhance the material’s performance and application potential.