Polycarbonate glass is a tough, lightweight material frequently used as a substitute for traditional glass. Known for its high impact resistance and UV protection, it outperforms regular glass in many ways.

This article will explain what polycarbonate glass is, its key benefits, and its various applications across industries.

We’ll also compare it to traditional glass to help you understand why it might be the better choice.

Polycarbonate Glass: An Overview

Polycarbonate glass is a transparent thermoplastic known for its incredible durability and versatility.

Commonly found in applications ranging from windows to lenses, this material stands out due to its chemical composition, which includes carbonates.

Its extensive use across multiple industries underscores its reliability and performance.

Composition and Fabrication

The creation of polycarbonate involves intricate chemical processes, primarily the reaction of bisphenol A with phosgene, known as the phosgene route.

Alternatively, the transesterification process employing bisphenol A and diphenyl carbonate is also used. These methods result in a material that can be custom-fabricated with precision, allowing for quick modifications without requiring heating.

Polycarbonate can be shaped and molded through various techniques such as thermoforming, injection molding, and CNC machining.

This adaptability makes it an ideal choice for a wide range of applications, from construction panels like glass sheets to intricate design elements exposed to direct sunlight.

Its ease of molding and shaping distinguishes polycarbonate from traditional glass and other materials.

Properties and Characteristics

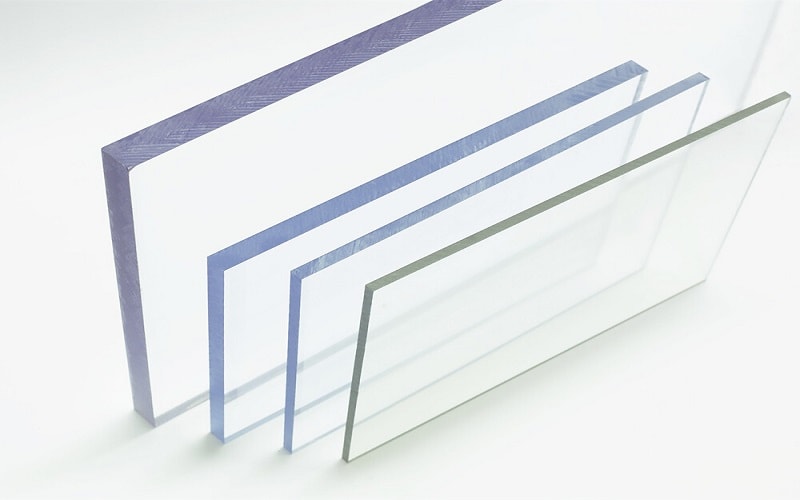

One of the standout properties of polycarbonate sheeting is its lightweight nature—six times lighter than standard glass panels.

Despite its lightness, it boasts exceptional light transmissibility and better insulation quality compared to traditional glass. These characteristics make it not only energy-efficient but also ideal for various applications where clarity and light are essential.

Renowned for its exceptional impact resistance, polycarbonate offers unbreakable durability that traditional glass simply cannot match.

Additionally, it provides superior UV protection, preventing harmful rays from penetrating the perfect material and thus extending its lifespan and maintaining its clarity.

Comparing Polycarbonate Sheets to Traditional Glass

The difference between polycarbonate sheets and traditional glass is striking. As a durable and lightweight plastic, a polycarbonate sheet offers shatter-resistant properties that make it an excellent alternative to traditional glass.

Key aspects of this comparison include impact resistance, heat resistance, heat and UV resistance, and weight and installation.

Impact Resistance

Polycarbonate stands out for its high impact resistance, significantly outperforming traditional glass. Key advantages of polycarbonate include:

- It deforms without breaking upon impact, unlike glass which shatters into sharp pieces.

- It is a safer option for high-risk environments like schools and hospitals.

- It is 250 times stronger than regular glass.

This exceptional impact resistance makes polycarbonate ideal for impact resistant windows and other exterior applications, especially in areas exposed to harsh weather.

The material’s ability to withstand significant force without damage ensures longevity and safety, reducing the need for frequent replacements.

Heat and UV Protection

Polycarbonate’s ability to endure extreme temperatures without distortion or breakage sets it apart from traditional glass:

- It can handle sudden temperature spikes up to 1166 degrees without suffering damage.

- Traditional glass cannot achieve this level of temperature resistance.

- This makes polycarbonate an excellent choice for environments with fluctuating temperatures.

Polycarbonate can discolor over time when exposed to UV rays, but special UV coatings enhance its resistance, preventing yellowing and maintaining both aesthetic and functional qualities.

These coatings are crucial for ensuring the longevity of polycarbonate in outdoor applications.

Weight and Installation

A major advantage of polycarbonate over traditional glass is its lightweight nature:

- Laminated glass typically weighs between 3 to 4 pounds per square foot, making it considerably heavier than polycarbonate.

- This lightweight characteristic allows for quicker and easier installation.

- It reduces labor costs and time.

Unlike glass, which often requires specialty saws and complex installation processes, polycarbonate can be cut on-site using standard tools.

This ease of handling, combined with its light weight, makes polycarbonate a superior choice for construction projects, enhancing efficiency and reducing costs.

Advantages of Polycarbonate Glass in Construction

| Category | Advantages |

| Durability and Longevity | Exceptional durability |

| Withstands harsh conditions | |

| Long-lasting weather resistance | |

| Cost-Effectiveness | 2-3 times cheaper than laminated glass |

| Low maintenance | |

| Versatility in Applications | Customizable thickness and shape |

| Ideal for security with high impact |

The construction industry increasingly favors polycarbonate glass for its numerous advantages over traditional materials.

With exceptional impact resistance, cost-effectiveness, and versatile material, polycarbonate sheets are making their mark in various sectors.

These benefits, explored in detail in the following subsections, highlight why polycarbonate is becoming the material of choice.

Durability and Longevity

Celebrated for its exceptional durability and ability to withstand harsh conditions, polycarbonate is a preferred choice over glass. Its advantages include:

- Exceptional durability

- Ability to withstand harsh conditions

- Strength and weather resistance that ensure longevity even in extreme conditions

- Greater longevity than traditional glass, which often requires frequent replacements Polycarbonate excels in exterior applications and endures harsh weather.

Protective coatings, such as scratch-resistant layers, further enhance the durability and lifespan of polycarbonate products.

These coatings are particularly beneficial in high-traffic areas, where maintaining the material’s integrity is crucial.

Cost-Effectiveness

Polycarbonate glass provides significant cost benefits compared to traditional glass options:

- Laminated glass is typically 2 to 3 times more expensive than polycarbonate glass.

- Polycarbonate glass offers durability.

- It requires lower maintenance.

This cost-effectiveness, coupled with its durability and lower maintenance requirements, makes polycarbonate a budget-friendly choice for construction projects.

Versatility in Applications

Polycarbonate’s versatility in various applications is a standout feature. It can be customized in terms of thickness, shape, and dimensions to suit specific project requirements.

Ideal for security applications due to their high impact resistance and durability, polycarbonate sheets suit environments requiring enhanced safety measures.

Modern public buildings often use polycarbonate for natural lighting while maintaining safety and durability. Combining functionality and aesthetic appeal, polycarbonate is an excellent choice for a wide range of construction projects.

Special Coatings and Treatments for Polycarbonate Glass

Special coatings and treatments maximize the performance and longevity of polycarbonate glass.

Addressing issues like scratches, UV exposure, and glare, these coatings ensure polycarbonate maintains its superior qualities in diverse environments.

Scratch Resistant Coatings

Though incredibly durable, polycarbonate glass is more prone to scratches compared to traditional glass.

This vulnerability can be mitigated with anti-scratch coatings, significantly enhancing the material’s scratch resistance. Varying in hardness, superior grades of these coatings provide enhanced protection against surface damage.

DURAVUE® abrasion-resistant hardcoats, designed to protect polycarbonate from scratches and enhance optical clarity, are an example of an effective anti-scratch coating. Though these coatings improve performance, they may increase the overall cost of polycarbonate glass.

UV Protective Coatings

Special UV coatings prevent the discoloration and degradation of polycarbonate glass over time. Protecting the material from harmful UV rays, these special coating maintain its aesthetic and functional qualities.

Double-sided UV protection protects is particularly vital for prevent yellowing.

Anti-Fog and Anti-Glare Treatments

Anti-fog and anti-glare treatments enhance the usability of polycarbonate glass in various environments.

These treatments ensure the material maintains clarity and performance, even in challenging conditions. Scratch-resistant coatings help maintain clarity by preventing surface damage.

UV protective coatings prevent harmful rays from reaching the surface and improve safety and usability in outdoor applications. These treatments make polycarbonate ideal for a wide range of uses, from safety glass to architectural elements.

Polycarbonate Glass for Windows and Exterior Applications

Polycarbonate glass is an excellent alternative to traditional glass and glass substitutes in polycarbonate windows and exterior applications.

Replacing glass with polycarbonate offers durability, safety, and design flexibility, making it a superior choice for environments like schools, subways, bus shelters, greenhouses, and hospitals.

A window into the future of building materials, polycarbonate is transforming how we think about safety and design.

Specific benefits and examples are detailed in the following subsections.

Enhanced Weather Resistance

Polycarbonate glass’s ability to withstand harsh climates makes it ideal for environments prone to severe weather.

This weather resistance ensures polycarbonate glass maintains its integrity and performance, even when exposed to extreme elements.

Its weather resistant durability and resistance to UV rays further enhance its suitability for exterior applications.

Aesthetically Pleasing Designs

Polycarbonate glass can be molded into various shapes, allowing designers to create unique architectural elements.

Its lightweight nature makes it easy to work with, enabling intricate designs that may not be achievable with traditional glass. Available in various colors and tints, polycarbonate glass adds a creative touch to structures, enhancing their beauty.

The transparent quality of polycarbonate glass allows natural light to penetrate spaces, highlighting interior designs. Combining functionality and aesthetic appeal, polycarbonate is an excellent choice for a wide range of construction projects.

Case Studies and Examples

Polycarbonate panels can create private spaces while allowing natural light, utilized in settings like offices and healthcare facilities.

Translucent polycarbonate skylights effectively diffuse sunlight, minimizing glare in architectural designs.

Polycarbonate’s light diffusion capabilities are ideal for backlit facades, enhancing brand visibility and community landmarks. Polycarbonate’s lightweight nature allows for creative canopy designs that require less structural support, reducing costs.

Custom Solutions with Polycarbonate Glass

Polycarbonate glass offers custom solutions that can significantly enhance the efficiency and effectiveness of various projects.

Architects and builders can leverage this material’s versatility to create innovative and appealing designs tailored to specific needs.

Tailored Fabrication Processes

Formable at room temperature and when heated, polycarbonate is easy to manipulate for various applications.

This versatility allows for creative architectural designs, including curved and custom shapes that traditional glass cannot easily accommodate.

AC. Plastics offers custom design solutions to business needs and provides a large inventory in various colors and sizes for acrylic polycarbonate sheets.

Industry-Specific Applications

Polycarbonate glass offers cost-effective and lightweight options for various commercial applications. It is effectively used in:

- Building construction

- Subways

- Bus shelters

- Schools

- Greenhouses

Consulting professionals can optimize the selection, fabrication, and application processes for polycarbonate glass.

Access to Expert Guidance

Expert guidance is crucial for custom polycarbonate glass solutions, ensuring that projects meet safety and durability standards.

Industry-specific experts provide insights on the best practices and applications of polycarbonate glass relevant to particular sectors.

Expert advice allows businesses to make informed decision, tailoring polycarbonate solutions to meet specific project requirements effectively with permission. Engaging professionals can streamline the customization process, helping achieve optimal results.

Summary

Polycarbonate glass stands out as a superior choice for durability, safety, and versatility. Its exceptional impact resistance, lightweight nature, and cost-effectiveness make it a valuable material in various industries, particularly construction.

The numerous benefits, including enhanced weather resistance, UV protection, and the potential for custom solutions, highlight its adaptability and long-term value.

As we look towards the future, the use of polycarbonate glass is set to revolutionize the way we build and design.

Its innovative qualities and practical advantages ensure that it will remain a cornerstone in modern construction, offering solutions that are as safe as they are aesthetically pleasing.