Injection molding is a cornerstone of modern manufacturing, enabling the production of precise, high-quality plastic components used in industries ranging from automotive to consumer electronics.

However, even with advanced technology and skilled operators, defects in injection-molded parts can arise, leading to costly rework, production delays, and compromised product performance.

These imperfections, such as sink marks, warping, or flash, often stem from material issues, improper machine settings, or suboptimal mold designs.

This article explores the most common injection molding defects, delves into their root causes, and provides practical, actionable solutions to mitigate them.

What Is Injection Molding?

Injection molding is a widely used manufacturing process that involves injecting molten material, typically plastic, into a precisely designed injection mold cavity.

This process enables the mass production of complex and highly detailed molded plastic parts with consistent quality and efficiency.

Proper control of injection pressure, injection speed, and mold temperature is critical to avoid common injection molding defects such as short shots, flow lines, warping, and other potential injection molding defects.

Additionally, troubleshooting injection molding defects often involves analyzing factors such as inadequate injection pressure, poor mold design, and material temperature to identify root causes.

Injection molding is essential in industries ranging from automotive to consumer electronics, where high volume production of precise components is required, making it a cornerstone of modern plastic injection molding processes.

What Are The Most Common Injection Molding Defects?

Common injection molding defects, such as sink marks, warping, flash, short shots, burn marks, and weld lines, are common challenges in the manufacturing process that can compromise part quality and production efficiency.

Flow Lines

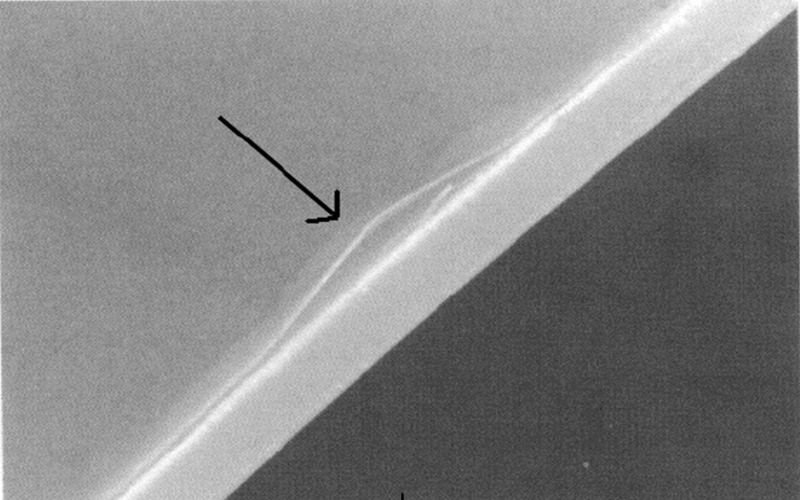

Flow lines are one of the most common defects in injection molding, appearing as visible streaks or patterns on the surface of molded plastic parts.

These lines often differ slightly in color or texture from the surrounding material and typically occur where the molten plastic flows through the mold cavity at varying speeds.

The defect occurs because the molten material cools unevenly, leading to differences in solidification rates across the part’s surface.

Several factors contribute to the formation of flow lines, including slow injection speed, low mold temperature, and variations in wall thickness.

Flow lines not only affect the aesthetic quality of the molded part but may also indicate underlying issues with material flow that could impact the part’s structural integrity.

To prevent flow lines, manufacturers should optimize injection speed and pressure to ensure a smooth and consistent flow of molten plastic.

Sink Marks

Sink marks are one of the most common plastic injection molding defects, manifesting as small depressions or dimples on the surface of molded plastic parts.

These defects typically occur in areas with varying wall thicknesses, where thicker sections cool and shrink at a different rate than thinner sections.

The insufficient injection pressure or inadequate packing during the molding process often leads to weak material bonding in these regions, causing the surface to pull inward and form sink marks.

To prevent sink marks, it is essential to maintain uniform wall thickness throughout the molded component, optimize mold design for even material flow, and carefully control processing parameters such as injection pressure, mold temperature, and cooling time.

Surface Delamination

Surface delamination is a notable injection molding defect characterized by the peeling or separation of thin layers from the surface of a molded plastic part.

This defect not only compromises the cosmetic appearance but also significantly undermines the structural integrity of the molded component.

Surface delamination often results from contamination within the molding material, such as residual mold release agents or moisture, which hinder proper bonding between layers.

To prevent surface delamination, it is essential to ensure thorough material preparation by pre-drying plastics, minimizing mold release agents, and maintaining clean mold cavities.

Weld Lines

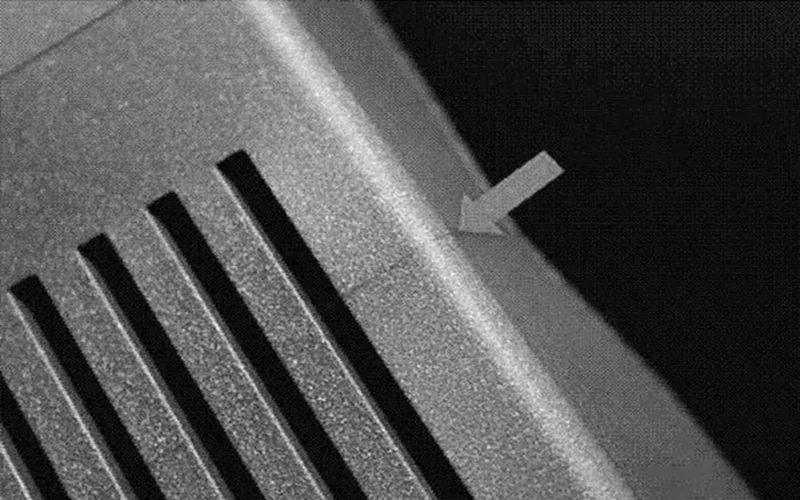

Weld lines, also known as knit lines, are common injection molding defects that occur when two or more molten plastic flow fronts meet but fail to fuse properly within the mold cavity.

This incomplete bonding results in visible lines or marks on the surface of the injection molded plastic parts and can significantly weaken the structural integrity of the molded component.

Weld lines occur around holes, ribs, or where multiple gates feed the molten material into the mold, making mold design a critical factor in their prevention.

To reduce weld lines, manufacturers should optimize processing parameters such as increasing injection speed and pressure to maintain the temperature of the molten plastic, ensuring smooth material flow and fusion.

Short Shots

Short shots are a common injection molding defect that occurs when the mold cavity is not completely filled with molten plastic, resulting in incomplete or partially formed molded parts.

This defect can significantly impact both the appearance and functionality of the injection molded components, leading to increased waste and production delays.

The primary causes of short shots include insufficient injection pressure or injection speed, improper calculation of shot size, inadequate heating of the plastic material, and complex mold designs that restrict material flow.

Additionally, trapped air pockets within the mold cavity can prevent the molten material from filling the entire space, further contributing to short shots.

To prevent short shots, manufacturers should optimize processing parameters such as increasing injection pressure and speed to ensure the mold cavity is completely filled.

Warping

Warping is a common injection molding defect caused by uneven internal stresses that develop during the cooling and solidification process of molded parts.

This defect typically occurs when there are significant variations in wall thickness, leading to differential shrinkage rates that cause bending, twisting, or distortion of the part.

Excessive injection pressure and excessive injection speeds can worsen warping by creating uneven material flow and cooling patterns within the mold cavity.

Additionally, poor mold design, such as insufficient cooling channels, inconsistent mold temperature, or improper placement of mold components, can contribute to internal stresses that cause warping.

To minimize warping, it is essential to maintain consistent wall thickness throughout the molded component and implement gradual transitions between thick and thin sections.

Optimizing the cooling process and ensuring adequate thermal stability of the injection molding materials also play crucial roles in reducing internal stresses.

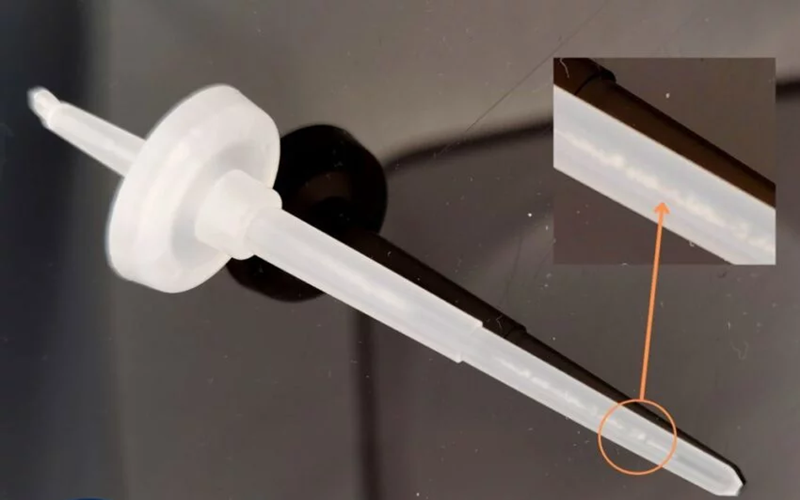

Vacuum Voids

Vacuum voids are a common injection molding defect characterized by trapped air pockets or bubbles within or just beneath the surface of molded plastic parts.

These voids occur when air becomes trapped in the mold cavity during the injection process, often due to inadequate injection pressure or poor mold venting.

Uneven cooling or solidification between the mold wall and the inner sections of the part can also cause vacuum voids, as the material shrinks and pulls away from the trapped air.

Preventing vacuum voids involves optimizing several key factors in the injection molding process. Increasing injection pressure helps to fully fill the mold cavity and forces out trapped air pockets.

Improving mold venting allows air to escape more easily during injection, reducing the likelihood of air entrapment.

Additionally, adjusting mold design elements, such as increasing gate size or modifying the placement of gates, can improve material flow and minimize void formation.

Flash

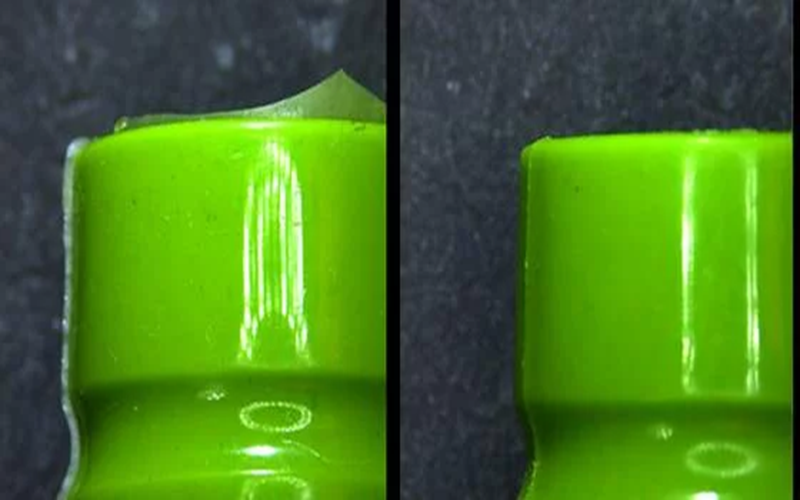

Flash is a common injection molding defect characterized by excess material that protrudes from the edges or parting lines of molded plastic parts.

This defect occurs when molten plastic escapes the intended mold cavity, often due to high injection pressure, inadequate clamping force, or mismatches in the parting line.

Other contributing factors include improper venting, low viscosity of the molten material, and worn or damaged mold components.

Flash not only affects the aesthetic appearance of injection molded parts but can also interfere with their assembly and function, leading to increased post-processing costs and potential product failures.

To reduce flash, manufacturers should focus on optimizing injection pressure and speed, ensuring proper mold alignment, and maintaining sufficient clamping force during the injection process.

Burn Marks

Burn marks are a common injection molding defect characterized by dark discolorations or streaks on the surface of molded plastic parts.

These marks typically appear as brown or black areas and can sometimes indicate overheating or degradation of the plastic material.

The defect occurs when trapped air pockets within the mold cavity compress and overheat during the injection process.

To prevent burn marks, it is essential to optimize processing parameters such as reducing injection speed and pressure, improving mold venting to allow trapped air to escape, and maintaining appropriate mold temperature.

How To Prevent Defects In Injection Molding Process?

Preventing defects in the injection molding process requires a comprehensive approach that combines careful mold tooling design, precise control of processing parameters, and diligent quality control measures.

Ensuring the mold cavity is completely filled with molten plastic is fundamental to avoiding defects such as short shots.

This can be achieved by optimizing injection pressure and injection speed, allowing the molten material to flow smoothly and uniformly throughout the mold.

Proper mold design, including uniform wall thickness and strategic gate placement, helps minimize issues like weld lines, which occur when two flow fronts fail to fuse correctly.

Additionally, reducing injection pressure when excessive can prevent defects such as flash, where excess material escapes the mold cavity.

Maintaining consistent mold temperature and melt temperature supports uniform cooling and reduces internal stresses that cause warping and sink marks.

Regular maintenance of mold components and effective venting prevent trapped air pockets and burn marks.

By integrating these practices, manufacturers can significantly reduce common injection molding defects and enhance the overall quality and reliability of injection molded parts.

Summary

In summary, understanding and addressing common molding defects is crucial for maintaining product quality and production efficiency.

By identifying the causes of defects such as sink marks, surface delamination, weld lines, short shots, warping, vacuum voids, and flash, and implementing preventive measures, manufacturers can produce high-quality, defect-free parts.

By applying the knowledge gained from this blog, you can enhance your manufacturing process, reduce waste, and ensure that your products meet the highest standards.

Let this be the start of your journey to mastering injection molding and achieving excellence in your production line.