Quality foam packaging protects products by absorbing shock and preventing damage.

This article covers the types, benefits, and applications of various foam materials.

Understanding Foam Packaging Materials

Foam packaging materials are the backbone of any effective protective packaging solution. These materials are designed to absorb shock, cushion fragile items, and prevent damage during transit.

Quality Foam Packaging offers three main types of foam materials: polyurethane foam, polyethylene foam, and expanded polystyrene (EPS).

The versatility of foam packaging lies in its ability to be tailored to fit any shape or size, ensuring a snug and secure fit for any product. Modern foam packaging utilizes advanced manufacturing methods, allowing precise control over properties like density and shock absorption.

This section explores each type of foam material, highlighting their unique properties and applications.

Polyurethane Foam

Polyurethane foam is celebrated for its flexibility and adaptability. This foam material is particularly suitable for packaging fragile items due to its excellent cushioning properties.

It can be customized with varying densities and shapes to meet diverse packaging needs, making it a popular choice in the industry.

One of the standout features of polyurethane foam is its durability. It retains its appearance for a long time, making it an economical choice for long-term use.

Additionally, it offers the largest variety of density options, providing cost-effective solutions for various packaging applications.

Polyethylene Foam

Polyethylene foam is known for its closed cell foam structure, which provides excellent water resistance.

This makes it an ideal choice for packaging moisture-sensitive products.

The closed-cell structure ensures that the foam remains waterproof, thereby protecting sensitive items from moisture.

Available in various densities and thicknesses ranging from 1/2′′ to 3′′, polyethylene foam offers versatility in application.

Its ability to provide consistent protection under different environmental conditions makes it a reliable choice for custom foam packaging solutions.

Expanded Polystyrene (EPS)

Expanded Polystyrene (EPS) is recognized for being a great insulator, light weight, and cost-effective.

Its light weight nature makes it an ideal choice for various packaging applications, as it helps minimize shipping costs.

EPS can be custom-designed using standard stock block shapes. It can also be wire cut to any pattern, offering versatile cushion packaging options. Its key features include:

- Custom design using standard stock block shapes

- Wire cutting to any pattern for versatile cushion packaging

- Cost-effectiveness

- Excellent insulation properties These qualities make it a staple in the foam packaging industry.

Custom Foam Packaging Solutions

Custom foam packaging solutions are designed to offer tailored protection against shock, vibration, and static for unique products.

These solutions enhance product protection by addressing specific needs and vulnerabilities, ensuring that items remain intact during transit.

Technological innovations have enabled the creation of custom foam solutions tailored to specific product needs.

Whether it’s through advanced fabrication capabilities or precise cutting techniques, custom foam packaging is the perfect solution for safeguarding your products.

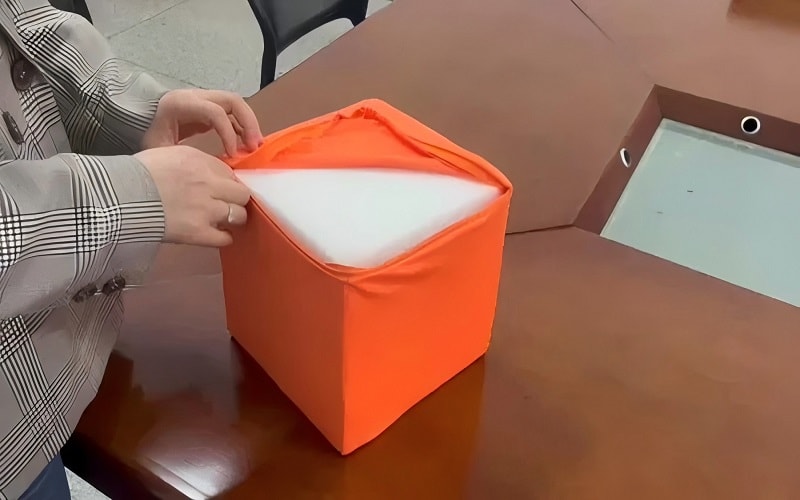

Foam Inserts

Foam inserts play a crucial role in protecting fragile items during transportation. Their benefits include:

- Snugly fitting around items to minimize damage during transit

- Being versatile and moldable into custom shapes

- Accommodating a wide range of product dimensions

The design process for foam packaging starts with detail drawings and documentation, ensuring that every aspect of the product’s protection is considered.

This meticulous approach guarantees that the final product offers the best possible protection.

Die Cutting & CNC Routing

CNC routing and die cutting allow for:

- The creation of intricate designs and shapes in foam, enhancing customization options.

- Precision and flexibility in production.

- The manufacturing of foam packaging that meets specific requirements and offers optimal protection.

Prototyping & Small Run Production

Prototyping in foam packaging allows for the rapid create of samples that can be tested for fit and protection.

This concept ensures that the final product is both high quality and cost-effective.

Small run production further enables manufacturers to meet specific needs without large-scale manufacture commitments, allowing businesses to fabricate tailored solutions along the line for companies.

Advanced Foam Packaging Techniques

Innovative foam packaging techniques can significantly enhance both performance and functionality.

These flexible techniques ensure that foams packaging solutions are not only effective but also tailored to meet specific requirements, providing the perfect packaging solution.

This section explores laminating, reticulated polyurethane, and compressed felt & phenolic honeycomb, each offering unique benefits.

Laminating

Laminating enhances foam packaging by improving its durability and protective features.

Combining foam with other materials through laminating can also improve the packaging’s aesthetic appeal. There are two main methods for laminating foam: adhesive lamination and heat lamination.

These methods ensure that the foam maintains its protective qualities while offering additional strength and resilience.

Laminated foam packaging is thus a perfect solution for products requiring extra protection and durability.

Reticulated Polyurethane

Reticulated polyurethane features an open cell structure with up to 98% void volume, enhancing breathability and performance.

It can achieve high compression ratios of up to 20:1, making it suitable for various applications that require both flexibility and support.

Compressed Felt & Phenolic Honeycomb

Compressed felt can be shaped into desired densities and thicknesses, making it versatile for various packaging applications.

This material is particularly useful in industries like food, beverage, pharmaceutical, and consumer products, where specific density requirements are crucial.

Industry-Specific Foam Packaging Applications

Foam packaging is crucial for protecting products during transport across various industries. Key features include:

- A variety of types, thicknesses, and densities tailored for specific applications, ensuring optimal protection

- Lightweight nature that helps minimize shipping costs

- Often recyclable or reusable

This section covers the specific applications of foam packaging in the aerospace & military, electronics & medical equipment, and food & beverage industries.

Aerospace & Military

Foam packaging in aerospace applications must comply with rigorous industry standards, ensuring reliability under extreme conditions.

It plays a crucial role in protect sensitive equipment and components, guaranteeing that they withstand harsh environmental factors like extreme temperatures, vibrations, and impacts.

These stringent highest standards are essential for maintaining the integrity of aerospace and military equipment during transportation, storage, safety, and ship specifications, with a minimum focus on quality that must conform to these requirements.

Electronics & Medical Equipment

Cleanroom products that meet stringent industry requirements are essential for protecting delicate electronics and medical devices.

Foam packaging for electronics is designed to prevent static damage to sensitive components, ensuring their longevity and reliability.

Food & Beverage

Foam packaging solutions for food maintain hygiene and freshness, crucial for safe consumption.

EPS is particularly advantageous for packaging temperature-sensitive items due to its lightweight nature and effective thermal insulation.

Partnering with the Right Foam Packaging Manufacturer

Partnering with the right foam packaging manufacturer is crucial for ensuring the protection and preservation of your products.

A reliable partner, experience, quality assurance, and customer support are key factors to consider when choosing a manufacturer.

Foam Packaging Specialties, with over 45 years of experience, is a leader in the industry.

Their state-of-the-art facility in Tempe, Arizona, exemplifies their commitment to high standards in design, production quality, and customer service.

Experience & Expertise

Choosing a manufacturer with extensive industry experience ensures they can meet various protective needs effectively. Conner Packaging boasts:

- Over 40 years of experience in the foam packaging industry

- Expertise available in the market

- Ability to develop effective and reliable protective solutions, which is crucial for product preservation.

Quality Assurance

Quality assurance processes are vital for maintaining high standards in foam packaging production.

These processes ensure that the packaging meets industry standards and client expectations, leading to enhanced product protection and customer satisfaction.

Customer Support & Services

Exceptional customer support is crucial in ensuring that customers receive tailored foam packaging solutions that meet their unique needs.

Designing and engineers assistance further enhance product preservation and customer satisfaction.

Summary

Foam packaging solutions are indispensable for protecting and preserving products across various industries.

From understanding the different foam materials to exploring advanced techniques and industry-specific applications, the right foam packaging can significantly enhance product safety and customer satisfaction.

Partnering with an experienced and reliable manufacturer ensures that your foam packaging meets the highest standards of quality and performance.

Embrace the benefits of foam packaging solutions and safeguard your products with confidence.

Frequently Asked Questions

What are the main types of foam used in packaging?

The main types of foam used in packaging are polyurethane foam, polyethylene foam, and expanded polystyrene (EPS). These foams offer varying levels of protection and cushioning to safeguard products during transportation.

How does laminating improve foam packaging?

Laminating significantly improves foam packaging by increasing its durability and protective qualities, while also enhancing its visual appeal. This ensures that your products are better safeguarded during transit.

Why is custom foam packaging important?

Custom foam packaging is essential as it offers specialized protection against shock, vibration, and static, safeguarding your products during transit. This tailored approach ensures items arrive in perfect condition.

What industries benefit from foam packaging solutions?

Foam packaging solutions are particularly advantageous for the aerospace, military, electronics, medical equipment, and food & beverage industries due to their protective and insulating properties. These sectors rely on foam packaging to ensure the safe transport and storage of their products.

What should I consider when choosing a foam packaging manufacturer?

When selecting a foam packaging manufacturer, prioritize their experience, quality assurance processes, and customer support to effectively meet your specific requirements.