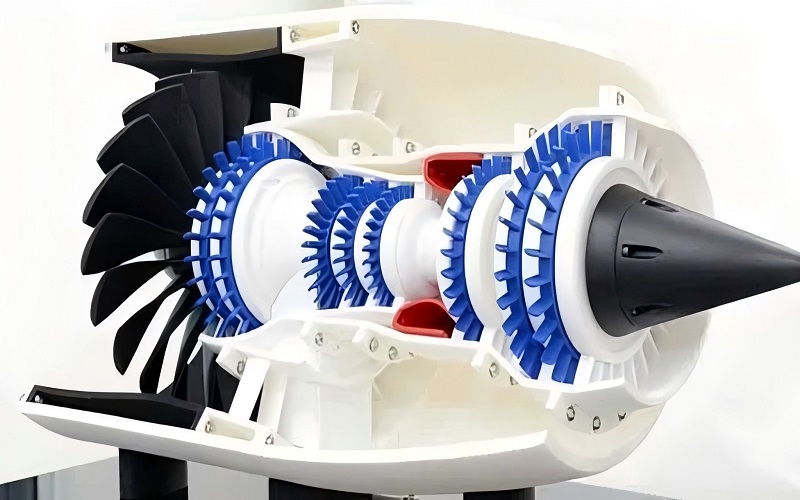

Material jetting is an advanced 3D printing method that creates highly detailed and smooth-finished parts by curing liquid photopolymer resin with UV light.

This technology is ideal for producing intricate prototypes and models.

In this article, you’ll learn how material jetting works, its main types, and its various applications and benefits.

Understanding Material Jetting Technology

Material jetting technology operates on the principle of jetting ultra-thin layers of liquid photopolymer material that are cured by UV light.

This process is akin to the familiar 2D ink-jetting technique, which enhances its efficiency and versatility. The process involves:

- Heating the photopolymer resins to optimize viscosity.

- Jetting the heated resin onto the build platform layer by layer.

- Immediately solidifying each layer with UV light, allowing for precise and detailed construction.

Material jetting stands out for:

- Its capability to produce parts with exceptionally smooth surface finish, comparable to injection molding.

- High realism at granular detail, making it ideal for creating prototypes and functional testing models.

- Controlled deposition of material managed by precise movements along the X, Y, and Z axes, ensuring accuracy and consistency in the final product.

This technology’s versatility extends to its ability to work with multiple materials simultaneously, offering a range of material properties in a single print.

This capability opens up endless possibilities for creating complex and highly detailed parts using several materials.

Types of Material Jetting

NanoParticle Jetting (NPJ) and Drop-On-Demand (DOD) are key material jetting methods.

NPJ jets tiny digital material droplets for high-resolution small parts, offering material versatility and custom deposit material properties, with dissolvable support structures for easy post-processing.

DOD selectively deposits material for flexible applications.

Drop-On Demand (DOD) is renowned for:

- Its capability to print high-resolution curves and smooth surfaces by using two print jets.

- Utilizing a diverse array of materials, including wax.

- Being particularly favored in the jewelry sector for high-precision printing and mold creation.

- The ability to print intricate details and perfectly flat surfaces, which enhances the quality of the final product.

These several techniques highlight the adaptability of material jetting technology, catering to a wide range of industries and applications.

From intricate jewelry designs to high-precision engineering components, the versatility of material jetting continues to push the boundaries of what is possible in additive manufacturing.

The Material Jetting Process

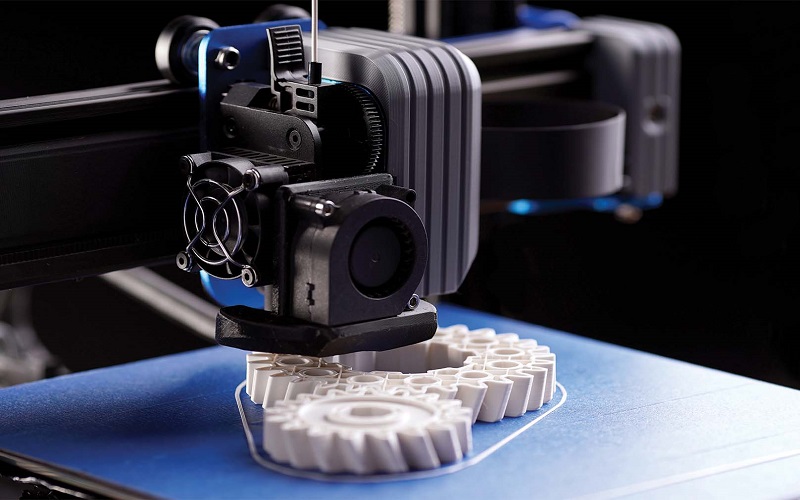

The material jetting process called involves the following steps:

- Heating the liquid resin to a temperature range of 30 to 60 degrees Celsius to ensure optimal viscosity.

- Depositing hundreds of minuscule droplets of photopolymer resin onto the build platform using a printhead.

- Immediately curing the deposited droplets with a UV light source attached to the printhead.

This layer-by-layer construction continues until the final part is complete, with the build platform lowering by one next layer height after each completed layer.

The critical aspects of printer parameters, multi-material printing, and support structures will be explored further.

Printer Parameters

Material jetting is renowned for its high accuracy, achieving dimensional accuracy within ± 0.1%.

The thin layer thickness typically ranges from 16 to 32 microns, allowing for the creation of detailed and intricate parts. This precision is crucial for applications requiring exact specifications and a smooth surface finish.

Additionally, material jetting can support large build sizes, with some industrial systems capable of dimensions up to 1000 x 800 x 500 mm.

This capability makes it suitable for producing larger components without sacrificing detail or quality.

The technology’s ability to combine these parameters ensures that it meets the diverse needs of various industries.

Multi-Material & Full-Color Printing

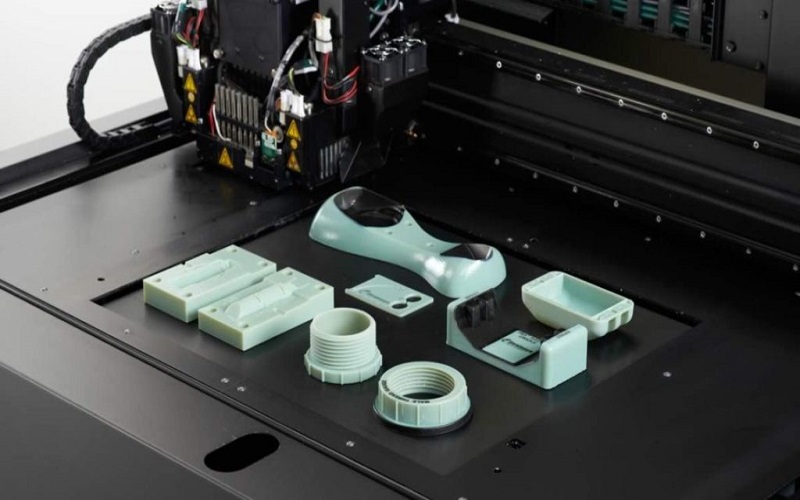

One of the most compelling aspects of material jetting technology is its ability to create multi-material and multi-color prints in a single manufacturing process, including the binder jetting process.

This means that different sections of a part can be produced using various materials or colors simultaneously, enhancing the functionality and aesthetic appeal of the final product.

Full-color prints often require files in obj or vrml file formats, specifying properties like texture and color.

This capability is particularly advantageous for creating detailed realistic prototypes and models that closely resemble the final product, making it easier to visualize and test designs before full-scale production.

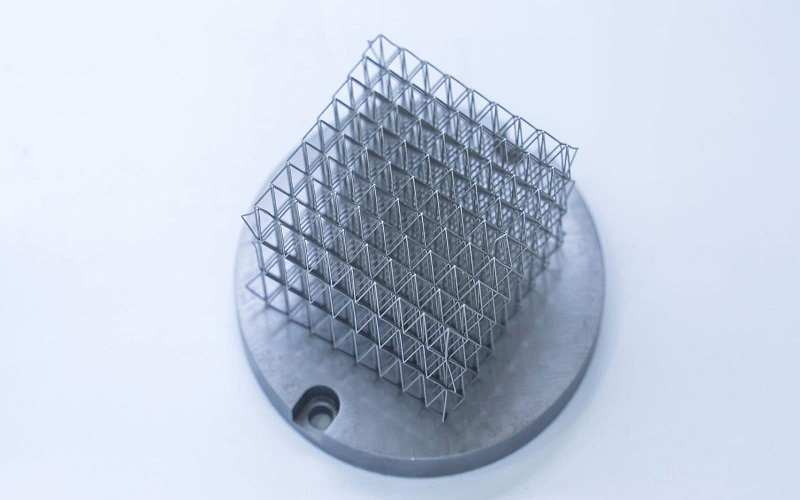

Support Structures

Support structures are essential in material jetting to maintain the integrity of complex geometries during the printing process.

These structures are printed using a secondary, dissolvable material, which can be easily removed post-printing. This allows for the creation of intricate and detailed parts without the risk of deformation or damage, supported by the use of support material.

The use of dissolvable support material facilitates the production of complex shapes and minimizes the need for additional post-processing.

After printing, support materials are either dissolved or manually removed, which impacts overall costs and efficiency, but ultimately enhances the quality and functionality of the final parts.

Advantages and Disadvantages of Material Jetting

Material jetting technology offers numerous advantages and some disadvantages.

This section will delve into the benefits such as precision, smooth finishes, and material versatility, and also discuss the drawbacks like high cost and material limitations.

Advantages

A significant advantage of material jetting is its capacity to produce intricate shapes with sharp details and smooth finishes. Key features include:

- Support for layer thickness as fine as 0.013 mm, allowing for exceptional detail and high precision

- Ideal suitability for aesthetic applications and functional prototypes

- Ability of DOD printers to print high-resolution curves and a perfectly flat surface, enhancing the quality of printed objects.

Material jetting supports the creation of items with varied material properties, such as flexibility and translucency, advantageous for specialized applications like medical devices.

The versatility in material properties and the ability to produce smooth, detailed parts are key factors that make material jetting a preferred choice for many industries.

Disadvantages

Despite its advantages, material jetting has some notable drawbacks:

- High cost associated with the technology, making it more expensive than other 3D printing methods like binder jetting.

- Material viscosity limitations.

- Potential weaknesses in printed parts, which can affect the suitability of material jetting for certain applications.

Parts produced through material jetting may have inferior mechanical properties compared to those made with stronger materials or different material, limiting their use in high-stress applications.

These disadvantages necessitate careful consideration when choosing material jetting for specific projects.

Comparing Material Jetting with Other Additive Manufacturing Technologies

Material jetting stands out among additive manufacturing technologies for producing detailed parts with smooth finishes. Compared to Fused Deposition Modeling (FDM), material jetting is generally faster, allowing for quicker production times.

While it may have slower production speeds compared to methods like SLA, the finer resolution and smoother surface finishes make material jetting particularly suited for aesthetic models and detailed parts.

Unique capabilities like multi-material printing and high precision set material jetting apart from traditional SLA and FDM processes.

These features make it a valuable tool for industries requiring detailed and complex parts, offering special properties and specific advantages over other technologies in the additive manufacturing process.

Materials Used in Material Jetting

A variety of photopolymer materials in liquid form, which solidify under UV light, are utilized in material jetting.

These resins can achieve properties like glass-like transparency and can be polished to a clear finish. Common materials include rigid opaque plastics, flexible rubber-like materials, and castable resins, each serving different applications.

Support structures in material jetting are typically made from a secondary dissolvable material, facilitating easier post-printing removal.

Advancements in material options, such as smart materials and composites, continue to improve the performance and expand the applications of material jetting.

Cost Analysis of Material Jetting

Several factors, including the orientation of the part during printing and the extensive use of support materials, influence the cost of material jetting, potentially increasing overall expenses.

The high costs associated with the materials and sophisticated machinery make material jetting less accessible for budget-conscious projects.

Compared to FDM and SLA, material jetting typically incurs higher material expenses due to the quality of resins required for printing.

Despite these costs, the precision and quality offered by material jetting often justify the investment for specialized applications.

Environmental Impact of Material Jetting

Material jetting offers a more sustainable approach to manufacturing by reducing material waste compared to traditional methods.

The precision of material jetting minimizes overall waste, contributing to effective waste management. This reduction in waste is a significant advantage in terms of environmental impact.

Research focuses on bio-based materials and biodegradable resins to further improve sustainability in material jetting. These efforts aim to reduce the environmental footprint of manufacturing processes, making biocompatible materials a more eco-friendly option.

Industry Applications of Material Jetting

Material jetting technology is employed in various industries like automotive, design, art, and healthcare to create accurate prototypes with multiple materials and colors.

High accuracy, multi-material capabilities, and faster design cycles make it a valuable tool across different sectors.

The following subsections will explore its specific applications in healthcare and aerospace/automotive industries.

Healthcare

In the medical industry, material jetting produces anatomical models with intricate detail from patient data, improving visualization and aiding surgical planning.

Stratasys enhances efficiency and precision in dental labs through multi-material, full-color 3D printing, enabling rapid prototyping and customization.

PolyJet technology accelerates design cycles by printing multiple materials simultaneously, providing patient-specific solutions that improve treatment outcomes.

Aerospace and Automotive

Material jetting, using print heads, creates high-precision components from build material essential for aerospace and automotive industries.

Increasingly utilized for prototyping, traditional tooling, and low-volume production, it deposits material in a line-wise fashion, enhancing efficiency and accuracy.

This precision makes material jetting effective for applications where accuracy and detail are critical, such as aerospace and automotive parts production.

Quality Control in Material Jetting

Quality control in material jetting ensures the precision and reliability of 3D printed objects, especially in industries that depend on accurate parts. This involves:

- Meticulous monitoring of the layer-by-layer printing process

- Ensuring accurate deposition of each droplet of material

- Employing techniques like high-resolution scanning and post-print inspections to detect and rectify any issues.

Common quality challenges in material jetting include incomplete curing and layer shifting. Poor material adhesion is another significant issue.

These issues can be mitigated by optimizing material viscosity, adjusting print speed, and ensuring proper UV curing during the printing process.

Stringent quality control measures are essential to maintain the high standards required in sectors like healthcare and aerospace.

Innovations and Future Trends in Material Jetting

Recent innovations in material jetting focus on addressing existing challenges and expanding the technology’s capabilities.

Developments aim to improve material options to enhance performance, increase printing speed, and reduce overall production costs. These advancements aim to make material jetting more accessible and efficient for a broader range of applications.

Future trends point towards the use of eco-friendly materials and biodegradable resins, significantly reducing the environmental impact of material jetting.

As research continues, more sophisticated and sustainable solutions will push the boundaries of material jetting technology.

Prominent Material Jetting 3D Printers on the Market

Several prominent material jetting 3D printers are making significant impacts across industries. The XJet Carmel 1400C, utilizing NanoParticle Jetting Technology, is ideal for applications requiring fine detail.

The Stratasys J750 Digital Anatomy, designed primarily for the medical sector, showcases its adaptability for specialized applications.

Other notable printers include the J35 Pro PolyJet printer, offering multi-material capabilities for enhanced functional design and concept modeling, and the Mimaki 3DUJ-553, providing ten million color options suitable for industries where visual fidelity is critical.

These printers exemplify the advanced capabilities and diverse applications of material jetting technology.

Summary

Material jetting technology stands at the forefront of 3D printing, offering unparalleled precision, multi-material capabilities, and smooth surface finishes.

By understanding the technology, its types, processes, and applications, we can appreciate its transformative impact on industries ranging from healthcare to aerospace.

The technology’s ability to produce detailed, high-quality parts makes it a valuable tool for prototyping, functional testing, and even low-volume production.

Frequently Asked Questions

What is material jetting technology?

Material jetting technology creates detailed 3D objects by jetting ultra-thin layers of liquid photopolymer material onto a build platform, which are then cured with UV light. This process allows for high-resolution outputs with intricate features.

What are the main types of material jetting?

The main types of material jetting are NanoParticle Jetting (NPJ), which employs tiny nanoparticles for precise manufacturing, and Drop-On Demand (DOD), which utilizes two print jets for high-resolution outputs. Each method offers distinct advantages for various applications.

What materials are used in material jetting?

Material jetting typically uses photopolymer resins, including rigid plastics, flexible rubber-like substances, and castable resins, with water-soluble support materials for easy removal.

How does material jetting compare to other 3D printing technologies?

Material jetting provides higher precision and smoother finishes compared to FDM and SLA, supports multi-material printing, and is generally faster than FDM, though slower than SLA. This makes it a compelling choice for detailed and multi-material applications.

What are the disadvantages of material jetting?

Material jetting can be costly and may produce parts with potential weaknesses, alongside limitations in material viscosity and higher material expenses compared to other 3D printing techniques.