Thin wall injection molding produces plastic parts with very thin walls, typically 0.5 to 0.8 mm thick.

It’s vital for making lightweight and cost-effective components.

This article explains the benefits, challenges, and best practices for thin wall injection molding.

Understanding Thin Wall Injection Molding

Thin wall injection molding is an innovative process that efficiently manufactures plastic parts with exceptionally thin walls. The term ‘thin wall’ in injection molding refers to the wall thickness in relation to the size of the part, typically ranging from 0.5 to 0.8 mm.

One of the significant benefits of thin wall injection molding is the substantial reduction in material usage, leading to lower production costs and lighter parts.

However, the process is not without its challenges. Achieving proper plastic flow within the mold requires high injection pressures and fast speeds, making it a delicate balance to perfect. Thermoplastics are commonly used in thin wall injection molding due to their effective filling properties.

Design considerations play a vital role in the success of thin wall molding. Maintaining uniform wall thickness helps avoid issues like warping and ensures consistent material flow.

Understanding these fundamentals sets the stage for successful injection molding.

Key Material Selection for Thin Wall Parts

Choosing the appropriate plastic material is key for successful thin wall injection molding.

High-flow properties and low melt viscosity in materials, including liquid silicone rubber, ensure effective filling of thin geometries.

These characteristics allow the molten plastic part to flow smoothly into the mold cavity, preventing defects such as weak knit lines and ensuring the production of quality parts with cross support ribs.

Polypropylene, particularly certain high-flow grades, is highly valued in thin wall applications for its excellent melt flow properties.

This material selection not only ensures the effective filling of the mold but also contributes to producing lighter parts with reduced material usage.

When comparing materials, it’s important to consider their flow characteristics to optimize the injection molding process for thin wall parts, including high density polyethylene.

Moreover, selecting materials like low density polyethylene can address cosmetic texture inconsistencies by improving surface finish, especially in specialized forms designed for specific thin wall applications.

This choice enhances the aesthetic and functional quality of the final parts.

Critical Mold Design Elements

The design of the mold plays a pivotal role in the success of thin wall injection molding.

Even material flow within the mold cavity is achieved by maintaining uniform wall thickness and strategic gate placement. A consistent wall thickness not only improves cooling but also reduces warping, leading to better results during the cooling process.

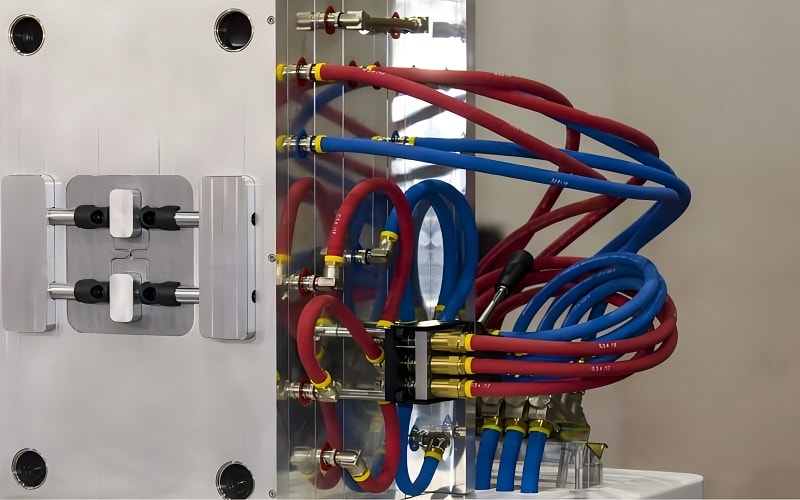

Careful gate placement is another critical aspect of mold design. Appropriately placed gates ensure uniform material flow, preventing flow lines and ensuring complete mold filling. High-hardness steel molds withstand the extreme conditions of thin wall injection molding, ensuring structural integrity and durability.

Additionally, optimizing the mold cooling system is crucial for maintaining uniform cooling and minimizing defects. Cooling systems with channels close to the molding surface enhance the cooling process, reducing cycle times and improving overall molded part quality.

Importance of Clamping Force

Clamping force is a critical factor in the injection molding process, particularly for thin wall parts.

Clamping pressure is the force needed to securely close the mold during injection, preventing defects like plastic leakage and mold flashes.

Inadequate clamping force can lead to significant issues, including excess plastic seeping out and breaks in the molded part.

Thin-walled components typically require greater clamping force due to the increased injection pressure needed to fill the mold. It is often recommended to add an additional 20% to the calculated clamping force to accommodate any adjustments during production.

This ensures that the mold remains securely closed throughout the injection process, preventing unwanted problems and ensuring the success of the molding operation.

Optimizing Injection Speed and Pressure

The correct injection speed and pressure are crucial in thin wall injection molding.

High injection speeds often exceeding 200 mm/s are needed to effectively fill the mold cavity and prevent short shots. Likewise, high injection pressures, above 20,000 psi, ensure proper packing and compensate for material shrinkage, which is crucial for the integrity of the final part.

Additionally, injection molding machines play a significant role in achieving these optimal conditions.

Flow lines, resulting from the molten plastic moving through the mold at varying speeds, can occur due to low injection speeds or pressures.

Similarly, short shots, where the plastic does not completely fill the mold, often arise from narrow gates or insufficient injection pressure.

Monitoring cavity pressure throughout the injection process helps achieve complete mold filling and minimizes defects.

Effective Cooling Processes

Uniform wall thickness is crucial in the cooling process of thin wall injection molding.

A consistent wall thickness between 0.060 and 0.120 inches helps prevent warping and ensures even cooling throughout the part. Inconsistent wall thicknesses can cause defects like warpage and incomplete filling, especially if the parts have thick sections.

Utilizing proper cooling channels in molds significantly accelerates the cooling process and helps maintain dimensional stability in thin wall parts.

Real-time monitoring of cooling processes can identify issues such as uneven cooling temperature distribution, allowing for timely adjustments and minimizing defects, ultimately improving cycle time.

Mold cooling systems with channels close to the surface minimize warping defects and ensure high-quality part production.

Optimizing the cooling process reduces cycle times and energy costs while maintaining molded part integrity in the machine.

Addressing Common Defects

Defects like weld lines, jetting, and delamination in thin wall injection molding can significantly impact product quality.

Weld lines form where two resin flows meet and fail to bond properly due to improper temperature or flow speed during injection.

Jetting happens when resin partially solidifies before the mold is filled, creating surface patterns that weaken the part.

Delamination, where layers within the part separate, can happen if contaminants prevent proper bonding, often exacerbated by excessive use of mold release agents.

Higher injection speed or pressure can resolve short shots, ensuring complete mold filling and enhancing part integrity.

Adding gussets can enhance the stability of thin rib walls, making them more robust without increasing thickness. Proper vent placement avoids defects caused by trapped air during injection.

Addressing these common defects improves the quality and reliability of thin wall plastic parts and ribs.

Advanced Design Tips for Quality Parts

Incorporating advanced design tips ensures the production of high-quality thin wall plastic parts.

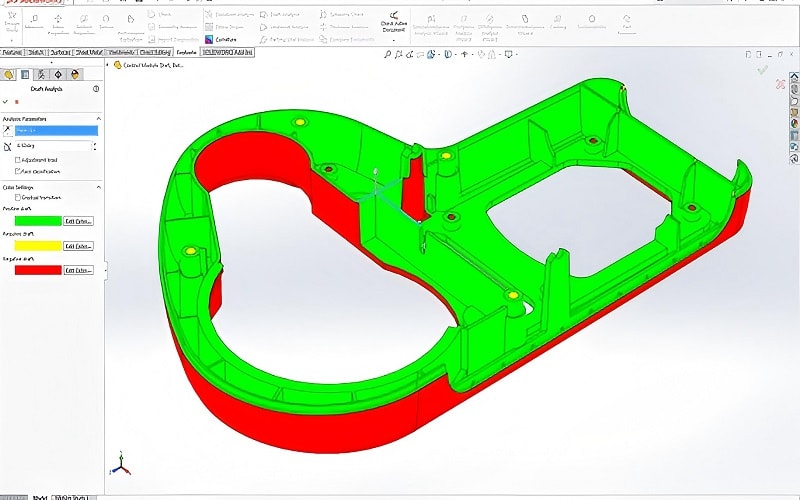

Early feedback on CAD files identifies and addresses wall thickness or geometric issues, such as sink marks, enhancing the quality and integrity of finished parts and their edges.

Addressing these issues before production avoids costly errors and ensures quality parts that meet industry standards, often by using less material to optimize efficiency.

These design principles are crucial for specifically designed thin-wall components, which can include car parts where lightweight construction is essential, showcasing the process’s versatility in automotive applications.

Incorporating these tips into mold design and production ensures that the final product features composite action and meets key considerations for desired specifications and quality standards.

Summary

In summary, mastering thin wall injection molding involves understanding the intricacies of material selection, mold design, clamping force, injection speed and pressure, and effective cooling processes.

Each of these aspects plays a critical role in producing high-quality thin wall plastic parts.

By applying the best practices and key considerations discussed in this guide, manufacturers can optimize their injection molding process, address common defects.

Embrace these insights and take your thin wall injection molding projects to the next level.

Frequently Asked Questions

What is thin wall injection molding?

Thin wall injection molding produces plastic parts with walls as thin as 0.5 to 0.8 mm by utilizing high injection pressures and speeds for efficient filling. This method is essential for creating lightweight and cost-effective components.

Why is material selection important in thin wall injection molding?

Material selection is critical in thin wall injection molding because it ensures effective filling of thin geometries with high-flow properties and low melt viscosity, leading to the production of high-quality parts.

What role does clamping force play in thin wall injection molding?

Clamping force is crucial in thin wall injection molding as it ensures the mold closes securely, preventing defects such as plastic leakage and mold flashes, which are vital for a successful molding process.

How can common defects in thin wall injection molding be addressed?

To effectively address common defects in thin wall injection molding, optimize injection speed and pressure, ensure proper vent placement, and consider adding gussets for enhanced stability. This proactive approach can significantly reduce issues like weld lines, jetting, and delamination.

What are the benefits of leveraging expert services in thin wall injection molding?

Leveraging expert services in thin wall injection molding enhances the quality of plastic parts by providing tailored solutions to specific challenges and mitigating common manufacturing issues. This results in improved efficiency and cost-effectiveness in production.