Choosing the right material is crucial for successful injection molding or 3D printing projects, and understanding the differences between PLA and TPU can make all the difference.

In this comprehensive PLA vs TPU comparison guide, we will explore the unique properties, and ideal applications of these two popular materials.

Whether you need a rigid, easy-to-print filament or a flexible, durable material, this guide will help you make an informed decision to achieve the best results for your needs.

What Is PLA?

Polylactic Acid, commonly known as PLA, is one of the most common materials.

Derived from renewable resources like corn starch and sugar cane, PLA material is biodegradable and environmentally friendly, making it a popular choice among hobbyists and professionals alike.

PLA is known for its low melting point and ease of printing, requiring relatively low printing temperatures and often not needing a heated bed, though using a heated bed or a glue stick can improve bed adhesion and print quality.

As a rigid material, PLA is ideal for producing detailed decorative prints, prototypes, and functional parts that do not require flexibility.

What Is TPU?

Thermoplastic Polyurethane, commonly known as TPU, is a flexible material belonging to the thermoplastic elastomer (TPE) family.

Unlike rigid plastics, TPU combines the durability of plastic with the elasticity of rubber, making it an ideal choice for 3D printing flexible parts that require excellent shock absorption and stretch.

Due to its rubber-like texture, TPU parts are commonly used in applications like protective phone cases, flexible joints, gaskets, and vibration dampeners.

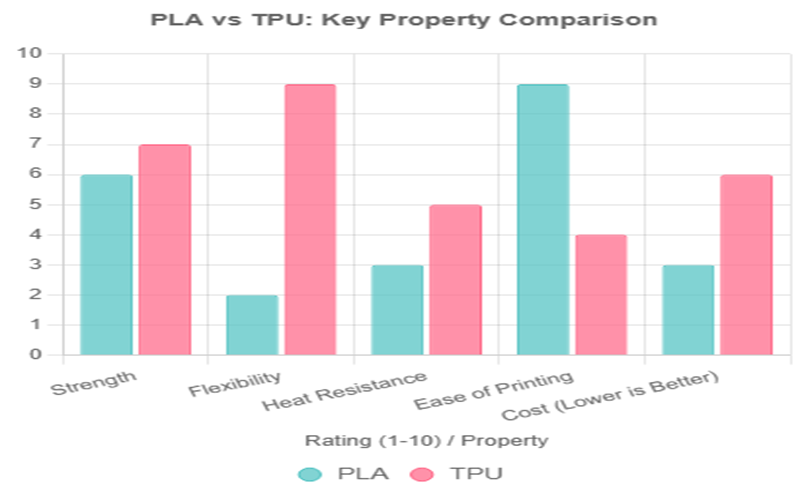

Key Property Comparison Between PLA And TPU

When comparing PLA material and TPU material, several key properties highlight their distinct characteristics and ideal applications.

PLA material, known for its rigidity and ease of printing, offers a low melting point and excellent dimensional accuracy, making it the best filament choice for detailed decorative prints and prototypes.

However, PLA material has limited temperature resistance and tends to be brittle, making it unsuitable for parts requiring flexibility or impact resistance.

In contrast, TPU material is a flexible filament belonging to the thermoplastic elastomer family, combining the durability of plastic with the elasticity of rubber.

TPU’s unique material properties include high elasticity, excellent shock absorption, and resistance to abrasion and chemicals, which make it ideal for printing flexible parts such as protective phone cases, flexible joints, and vibration dampeners.

TPU material requires higher printing temperatures and slower print speeds, along with specific retraction settings to reduce stringing, making it more challenging to print than PLA.

Differences Between TPU And PLA In Processing Methods

Due to the significant differences in the properties of PLA and TPU, their processing methods also differ.

PLA can be processed through various methods such as extrusion, spinning, biaxial stretching, injection molding, and blow molding.

In the PLA injection molding process , it is necessary to equip an appropriate cooling system to control the mold temperature between 20-30°C.

Additionally, PLA pellets need to be dried before processing to avoid degradation issues caused by moisture.

TPU, being a linear structure polymer, can be processed using the same techniques and equipment as thermoplastic plastics, such as injection molding, extrusion, blow molding, and calendering.

Among these, TPU injection molding is the most common due to its high wear resistance and elasticity, which give TPU products a wide range of applications.

Furthermore, TPU can be processed with certain polymer materials to obtain polymer alloys with complementary properties.

PLA Filament vs TPU Filament: 3D Printing

When it comes to 3D printing, choosing between PLA filament and TPU filament is a critical decision that affects the final product’s functionality and quality.

PLA, or polylactic acid, is a popular material in fused deposition modeling (FDM) due to its ease of use, low melting point, and excellent surface finish.

PLA prints well on a variety of build surfaces and requires minimal post process work, making it a convenient choice for many users.

On the other hand, TPU, a flexible filament from the thermoplastic elastomer family, offers unique properties such as high elasticity, impact resistance, and durability.

While more challenging to print than PLA, TPU enables the creation of flexible joints, shock absorbers, and protective phone cases that cannot be achieved with rigid materials.

Additionally, TPU can withstand low temperatures and harsh environments better than PLA, making it suitable for functional parts requiring flexibility and wear resistance.

Applications Of PLA Plastic

PLA plastic is widely used in various applications due to its ease of printing, biodegradability, and good surface finish.

Decorative Prints

PLA is widely favored for decorative prints due to its excellent dimensional accuracy, smooth surface finish, and ease of printing.

Its rigid and biodegradable nature makes it ideal for creating detailed figurines, vases, art pieces, and intricate models that require sharp edges and fine details.

PLA maintains its shape well during printing, ensuring high-quality results without warping.

Prototyping

PLA is an ideal material for prototyping due to its low cost, ease of printing, and ability to produce detailed, accurate models quickly.

Designers and engineers commonly use PLA filament to create rapid prototypes that help test form, fit, and function before committing to more expensive or complex materials.

Its rigidity ensures that prototypes maintain their shape well, making it easier to identify design flaws early in the development process.

Functional Parts

While PLA is known for its rigidity and ease of printing, it is best suited for functional parts that do not require flexibility or high impact resistance.

Common applications include enclosures, brackets, and holders where dimensional accuracy and surface finish are important.

Food Packaging

PLA is increasingly used in food packaging applications due to its biodegradable nature and safety.

Made from renewable resources like corn starch and sugar cane, PLA offers an environmentally friendly alternative to traditional plastics.

Its excellent surface finish and rigidity make it suitable for items such as disposable cups, containers, and wraps that require structural integrity and a clean appearance.

Applications Of TPU

TPU is widely used in various industries due to its unique combination of flexibility, durability, and resistance to abrasion and chemicals.

Protective Phone Cases

Protective phone cases made from TPU are highly valued for their excellent shock absorption and flexibility.

Unlike rigid materials, TPU offers a durable material that can withstand drops, impacts, and scratches, providing superior protection for your device.

The elastic nature of TPU allows these cases to absorb and dissipate energy effectively, reducing the risk of damage.

Seals

TPU’s excellent chemical resistance and inherent elasticity make it an ideal material for manufacturing seals used in automotive, industrial, and plumbing applications.

Its flexibility allows seals to maintain a tight fit under varying pressures and temperatures, ensuring effective prevention of leaks.

Compared to rigid materials like PLA, TPU seals can better absorb vibrations and accommodate slight deformations without cracking or losing functionality, making TPU the preferred choice when durability and flexibility are critical.

Medical Devices

TPU’s exceptional flexibility, durability, and biocompatibility make it an excellent choice for manufacturing medical devices.

It is widely used to produce custom prosthetics, orthotic supports, and flexible components that require both comfort and resilience.

While PLA is less common in medical device applications due to its rigidity, flexible PLA variants are emerging but still lag behind TPU in terms of elasticity and durability.

Automotive Parts

In the automotive industry, TPU is widely used for manufacturing parts that require both durability and flexibility.

Common applications include hoses, belts, gaskets, and protective covers that must withstand harsh environmental conditions such as extreme temperatures, abrasion, and chemical exposure.

TPU’s excellent impact resistance and elasticity make it ideal for components that experience constant movement and stress, ensuring longer service life and better performance.

Which Is Better, PLA Or TPU?

Choosing between PLA and TPU generally depends on the specific requirements of your project and the desired material properties.

PLA’s rigidity, ease of printing, and low cost make it the ideal material for applications needing precise, stiff components with good tensile strength.

It is commonly used for decorative prints, prototypes, and functional parts that do not require flexibility.

On the other hand, TPU’s flexibility, durability, and excellent impact resistance make it perfect for projects that need to add flexibility and withstand wear and tear, such as shock absorbers, flexible joints, and protective phone cases.

TPU prints maintain their shape better under high temperatures and harsh environments, offering superior temperature resistance compared to PLA.

Overall, both PLA and TPU have their strengths. If a project requires environmentally friendly and easy-to-print materials, PLA is the better choice.

Conversely, for applications that need high elasticity and durability, TPU is more suitable.

Summary

In summary, both PLA and TPU are two materials with distinct characteristics that serve different needs.

PLA is a rigid, easy-to-use material known for its low cost and eco-friendly properties, making it ideal for detailed decorative prints and functional parts that require precision and strength.

On the other hand, TPU is a soft, flexible material from the thermoplastic elastomer family, offering superior durability, elasticity, and resistance to abrasion and oil, which is perfect for applications needing impact resistance and flexibility.

While TPU stands out among other TPEs for its balance of printability and performance, it requires slower print speeds and more careful handling during printing.

Understanding these unique properties of the two materials will help you choose the best material for your specific projects, whether you prioritize ease of printing or the need for flexible, durable parts.