Acrylonitrile Styrene Acrylate (ASA) and Polylactic Acid (PLA) are two widely used thermoplastics in the fields of manufacturing and 3D printing.

This guide aims to provide a comprehensive comparison of ASA and PLA, highlighting key considerations such as Properties, Processing Methods, applications, and safety to help users select the most suitable material for their projects.

What Is ASA?

ASA, or Acrylonitrile Styrene Acrylate, is a durable thermoplastic widely used in 3D printing, particularly in fused deposition modeling (FDM).

Known for its excellent weather resistance and UV resistance, ASA material is a popular choice for outdoor applications where longevity and color stability are essential.

With a high melting point and good mechanical properties, ASA offers high impact resistance and thermal stability, making it suitable for functional prototypes and mechanical parts that require durability under stress and exposure to the elements.

What Is PLA?

Polylactic Acid is a biodegradable thermoplastic derived from renewable resources such as corn starch and sugarcane.

It is widely favored in 3D printing due to its ease of use, low printing temperature, and excellent print quality. PLA is considered a go-to material for beginners and those producing aesthetic models and prototypes.

While it offers good dimensional stability and is cost-effective, PLA has lower heat resistance and impact strength compared to ASA.

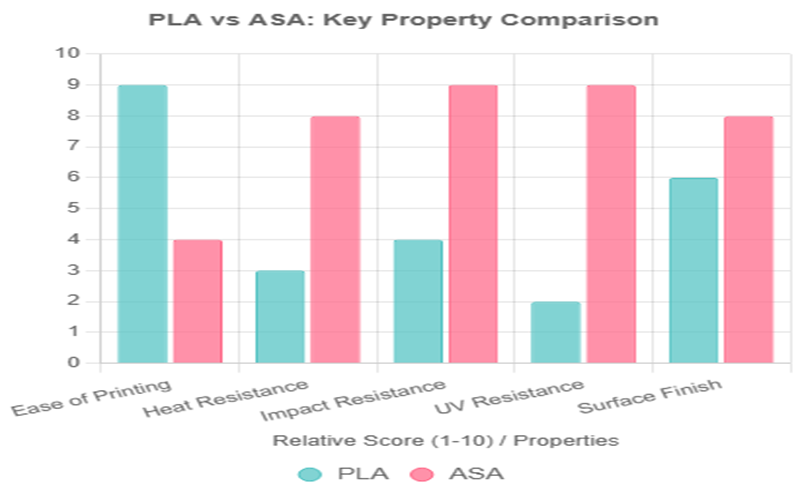

Key Property Comparison Between PLA and ASA

When comparing PLA and ASA, several key properties distinguish these materials and influence their suitability for different applications.

Heat Resistance

Heat resistance is a critical factor when choosing between ASA and PLA for applications.

ASA offers superior heat resistance due to its higher melting point and excellent thermal stability.

In contrast, PLA has a lower heat resistance and a melting point significantly below that of ASA, which means it can soften or deform at relatively low temperatures, limiting its use in high-temperature environments.

ASA material is easy to warp, PLA, being less prone to warping, generally requires less stringent measures to prevent warping.

Impact Resistance

When it comes to impact resistance, ASA clearly outperforms PLA, making it the preferred choice for applications requiring high durability and toughness.

ASA’s molecular structure provides excellent resistance to shocks and mechanical stresses, allowing printed parts to withstand heavy use without cracking or breaking.

On the other hand, PLA is more brittle and prone to cracking under impact, which limits its use to primarily aesthetic models or low-stress applications.

Weather Resistance

Weather resistance is one of the most significant advantages of ASA over PLA, especially for outdoor applications.

ASA exhibits outstanding resistance to UV radiation, moisture, and temperature fluctuations, which helps maintain the structural integrity and color stability of printed parts over time.

In contrast, PLA tends to degrade faster when subjected to prolonged sunlight and moisture, leading to brittleness, fading, and loss of mechanical strength.

Print Speed

Print speed is a crucial factor when working with ASA and PLA filaments, as it directly impacts print quality, layer adhesion, and overall success of the 3D printing process.

ASA generally requires a moderate print speed, typically between 30 to 50 mm/s, to ensure proper layer bonding and to prevent issues such as warping or poor layer adhesion.

On the other hand, PLA is more forgiving and can be printed at higher speeds, often ranging from 40 to 70 mm/s, without compromising print quality.

Differences Between ASA And PLA In Processing Methods

The processing methods for ASA and PLA differ significantly due to their distinct material properties, which affect print settings, handling, and post-processing techniques.

ASA, being a heat resistant and impact resistant material, requires higher extrusion temperatures typically between 240°C and 260°C and a heated print bed set around 90°C to 110°C to ensure good layer adhesion and to reduce warping.

Printing ASA often benefits from an enclosed printer environment to maintain consistent temperatures and prevent cracking, especially for large prints.

In contrast, PLA is easier to print with due to its lower melting point, generally between 180°C and 220°C, and does not require a heated bed, though one can improve adhesion and print quality.

PLA is less prone to warping and offers good print quality with fine layer height, making it a popular choice for aesthetic models and prototypes.

However, PLA has lower heat resistance and impact strength, limiting its use in functional prototypes or outdoor applications.

Overall, the choice of processing method varies depending on the filament’s properties and the intended application, with ASA demanding more precise printer compatibility and environmental controls, while PLA offers ease of use and flexibility for different applications.

PLA Filament vs ASA Filament: 3D Printing

When it comes to 3D printing, choosing between PLA filament and ASA filament depends largely on the specific requirements of your project.

PLA is renowned for its ease of use, printing at lower temperatures (typically between 180°C and 220°C) without the need for a heated bed, making it ideal for beginners and aesthetic models.

It offers excellent print quality with fine layer height and minimal warping.

However, PLA’s lower heat resistance and impact strength limit its suitability for functional prototypes or outdoor applications.

On the other hand, ASA filament is favored for its high durability, excellent UV resistance, and superior weather resistance, making it the go-to material for outdoor applications and mechanical parts.

Printing ASA requires higher temperatures (240°C to 260°C) and a heated bed (90°C to 110°C) to ensure proper bed adhesion and reduce warping.

While ASA can emit toxic fumes during printing, proper ventilation and fine tuning of print speed, cooling fan settings, and nozzle temperature help achieve optimal print quality.

Applications of ASA Plastic

ASA plastic is valued for its combination of durability, weather resistance, and mechanical strength, making it suitable for a wide range of applications.

Outdoor Automotive Components

ASA filament is an excellent choice for outdoor automotive components due to its superior weather resistance and UV stability.

Parts such as mirror housings, trims, and spoilers benefit from ASA’s ability to maintain color and mechanical strength even after prolonged exposure to sunlight, rain, and temperature fluctuations.

Its high impact resistance and thermal stability ensure that these printed parts can endure the stresses of daily use on vehicles without cracking or deforming.

Fixtures

ASA plastic is an ideal choice for manufacturing durable outdoor fixtures due to its excellent UV resistance and weather resistance.

These properties ensure that fixtures such as garden lights, outdoor signage, and decorative elements maintain their color vibrancy and structural integrity even after prolonged exposure to sunlight, rain, and varying temperatures.

Additionally, ASA’s high impact resistance and good mechanical properties help prevent cracking or deformation caused by physical stress or environmental factors.

Using glass beds or Kapton tape can further improve build surface adhesion, while employing soluble supports can facilitate the printing of intricate designs.

Electrical Enclosures

ASA is an excellent material choice for electrical enclosures due to its high heat resistance and dimensional stability.

Additionally, ASA’s superior weather resistance and UV resistance make it ideal for outdoor electrical applications, where exposure to sunlight and moisture is a concern.

Using a filament dryer to keep ASA filament dry further improves print quality by preventing issues such as poor layer adhesion and nozzle clogging.

Sporting Goods

ASA’s toughness and resistance to environmental stress make it suitable for manufacturing parts of sporting equipment designed for outdoor use.

Its high impact resistance and excellent weather resistance ensure that items such as bicycle components, protective gear, and outdoor accessories maintain their durability and performance even under harsh conditions.

Additionally, ASA’s UV resistance prevents color fading, keeping sporting goods looking vibrant over time.

Applications of PLA Plastic

PLA (Polylactic Acid) is widely used in various applications due to its ease of printing, biodegradability, and good surface finish.

Prototypes

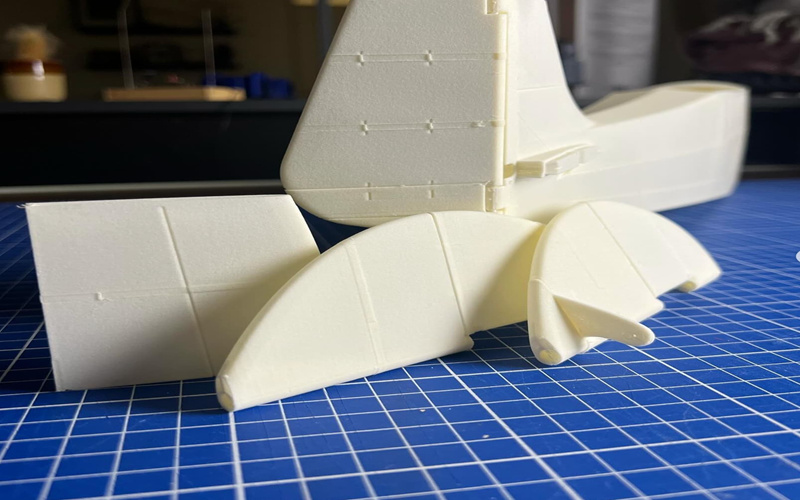

PLA is widely regarded as the go-to material for creating detailed and visually appealing prototypes.

Its ease of printing, combined with fine layer height capabilities and excellent print quality, allows designers and engineers to produce accurate scale models and concept parts efficiently.

PLA’s wide range of available colors further enhances its suitability for aesthetic models, making it ideal for presentations and design validations.

Packaging

PLA is extensively used in the packaging industry due to its biodegradability and origin from renewable resources.

It serves as an eco-friendly alternative to traditional petroleum-based plastics for producing biodegradable packaging materials, disposable cutlery, food containers, and other single-use items.

By choosing PLA for packaging applications, manufacturers can reduce environmental impact and support the shift towards greener materials in the supply chain.

Medical Devices

PLA’s biocompatibility and biodegradability make it an excellent choice for various medical applications.

It is commonly used in 3D printing of medical devices such as implants, surgical tools, and drug delivery systems.

Due to its ability to safely degrade within the human body, PLA is ideal for temporary implants and tissue engineering scaffolds that support cell growth and then gradually dissolve.

Low Temperature Functional Parts

PLA is well-suited for low temperature functional parts that operate in environments where heat resistance is not critical.

These parts include housings, casings, and lightweight fixtures that benefit from PLA’s good dimensional stability and ease of printing.

Which Is Safer, ASA Or PLA?

When considering safety between ASA and PLA materials, several factors come into play, including printing emissions, material toxicity, and environmental impact.

PLA is generally regarded as the safer option for everyday 3D printing due to its origin from renewable resources and its biodegradability.

It emits minimal toxic fumes during printing, making it suitable for indoor use and educational environments.

In contrast, ASA material, while offering superior durability and weather resistance, releases toxic fumes when heated, necessitating proper ventilation and an enclosed printing environment to ensure user safety.

Additionally, PLA’s lower printing temperature reduces risks associated with high-temperature handling.

For example, ASA’s compatibility with carbon fiber and other plastics allows for reinforced composites with enhanced mechanical strength.

For post-processing, isopropyl alcohol is commonly used to clean PLA prints, while ASA benefits from vapor smoothing techniques to improve surface finish.

However, ASA’s robustness makes it the right filament choice for outdoor applications where long-term stability is needed, provided safety precautions are followed.

Ultimately, choosing between ASA and PLA depends on balancing safety concerns with the specific performance requirements of your project.

Conclusion

In summary, the choice between ASA and PLA depends largely on the specific needs of your project and printing environment.

ASA stands out for its high durability, excellent UV resistance, and superior weather resistance, making it the ideal filament for outdoor applications and functional prototypes requiring high impact resistance and thermal stability.

However, printing ASA demands a heated bed, precise temperature control, and proper ventilation due to the emission of toxic fumes.

On the other hand, PLA offers ease of use, good print quality, and is cost-effective, making it the go-to material for beginners and aesthetic models.

Its biodegradability and origin from renewable resources add to its appeal, though its lower heat resistance and impact strength limit its suitability for demanding or outdoor uses.

Understanding these different properties and key considerations such as print bed requirements, layer adhesion, and post processing options will help you select the right filament for your project, balancing performance, safety, and environmental impact.