Insert molding and overmolding are two essential manufacturing techniques widely used in the injection molding process to create complex plastic parts with enhanced functionality and durability.

Both methods involve molding plastic over another material, but they differ significantly in their approach, applications, and benefits.

This article will explore the fundamentals of Insert molding vs overmolding molding processes, their advantages, common uses, and how they contribute to efficient manufacturing in industries ranging from medical devices to consumer products.

What Is Insert Molding?

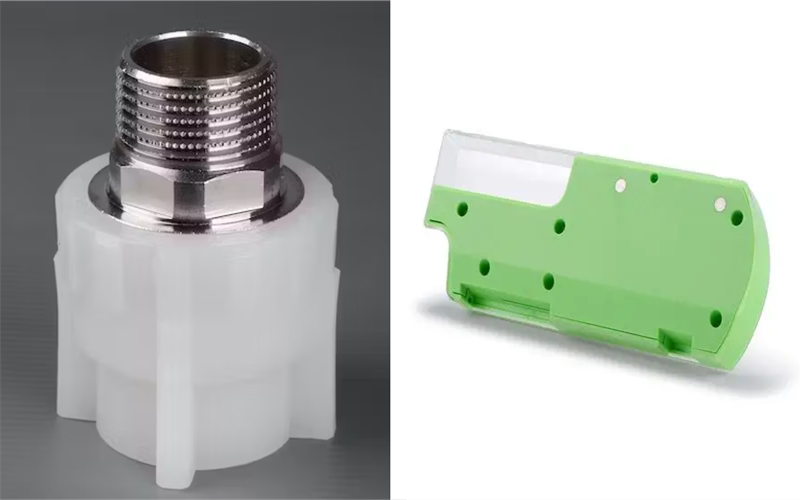

Insert molding is a specialized manufacturing process within the broader injection molding industry where molten plastic is injected into a mold cavity containing pre-placed metal components or other rigid inserts.

Typically, insert molding is used to embed metal inserts such as threaded inserts, electrical connectors, or metal components into a plastic substrate, resulting in durable parts that reduce assembly costs and improve production efficiency.

By integrating metal parts directly into molded plastic components, insert molding offers a robust solution for multi material molding challenges.

Advantages Of Insert Molding

Insert molding offers several significant advantages that make it a preferred choice in many manufacturing applications.

Durability

By molding plastic around metal inserts, insert molding creates parts with superior mechanical strength and long-lasting durability compared to parts made from a single material.

Reduced Assembly Costs

Integrating metal components directly into the plastic part eliminates secondary assembly steps such as fastening or bonding, thereby reducing labor costs and assembly time.

Suitable For Complex Parts

Insert molding can accommodate complex part geometries and intricate metal components, making it ideal for producing advanced plastic housing, medical devices, and electrical connectors.

Disadvantages Of Insert Molding

While insert molding offers many benefits, there are several disadvantages to consider.

Longer Cycle Times

The process of placing inserts into the mold cavity, whether manually or robotically, can slow down production compared to single-shot injection molding.

Insert Misalignment

Manual placement of inserts can lead to misalignment or defects, impacting the quality and functionality of the final plastic part.

What Is Overmolding?

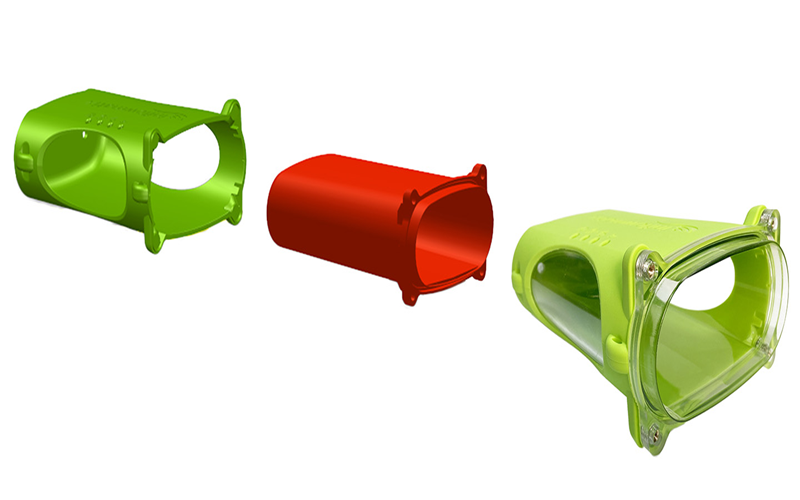

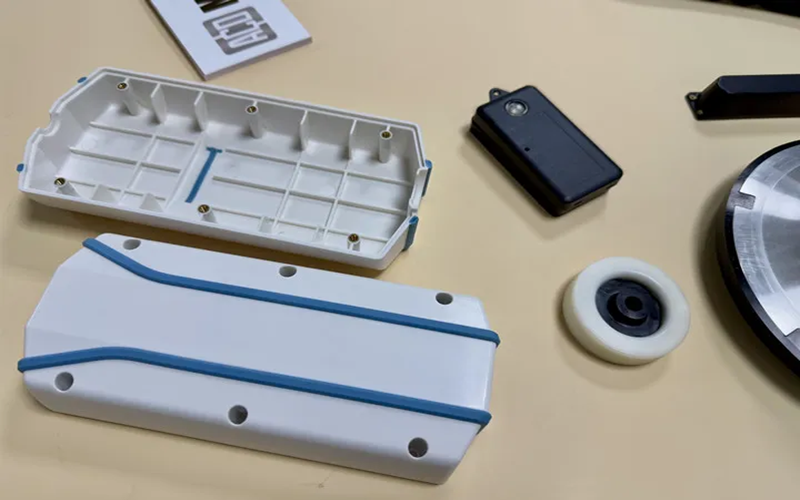

Overmolding is an advanced manufacturing process within the injection molding industry that involves molding a second material, often a softer or more flexible material, over a previously molded plastic substrate.

This two shot process uses an injection molding machine to inject the first material into a mold, forming a rigid plastic base, followed by injecting a second material over the base to enhance grip, shock absorption, or aesthetic appeal.

Overmolding allows the combination of two materials with different properties into a single, unified part without the need for assembly, making it ideal for producing overmolded parts such as plastic handles with soft seals or protective rubber coatings.

Advantages Of Overmolding

Overmolding offers several key advantages that make it a popular choice in the manufacturing industry.

Reduced Assembly Costs

Since overmolding combines multiple materials into a single molded plastic part, it eliminates the need for secondary assembly processes, reducing labor and production time.

Versatility In Material Selection

Overmolding supports a wide range of materials, including thermoplastic elastomers and silicone rubber, enabling the creation of soft seals, protective coatings, and complex two shot mold designs.

Suitability For High Volume Production

Overmolding is well-suited for high volume production runs due to its automation capabilities and efficiency, making it a cost-effective solution for large-scale manufacturing.

Disadvantages Of Overmolding

While overmolding offers many benefits, there are several disadvantages to consider when choosing this manufacturing process.

Longer Production Cycle Times

The two-step injection process can result in longer cycle times, reducing overall production speed, particularly for low volume injection molding runs.

Design Complexity

Overmolding requires careful mold design and part geometry considerations to ensure proper adhesion and avoid defects such as delamination or warping.

Increased Scrap Rates

Misalignment during the second molding stage or poor bonding between layers can lead to higher rejection rates, impacting production efficiency.

Key Differences Between Insert Molding And Overmolding

Insert molding and overmolding are two distinct yet complementary manufacturing processes, each offering unique advantages and suited for different applications.

Manufacturing Technology

Both insert molding and overmolding utilize advanced injection molding machines designed to handle multiple materials and complex mold designs.

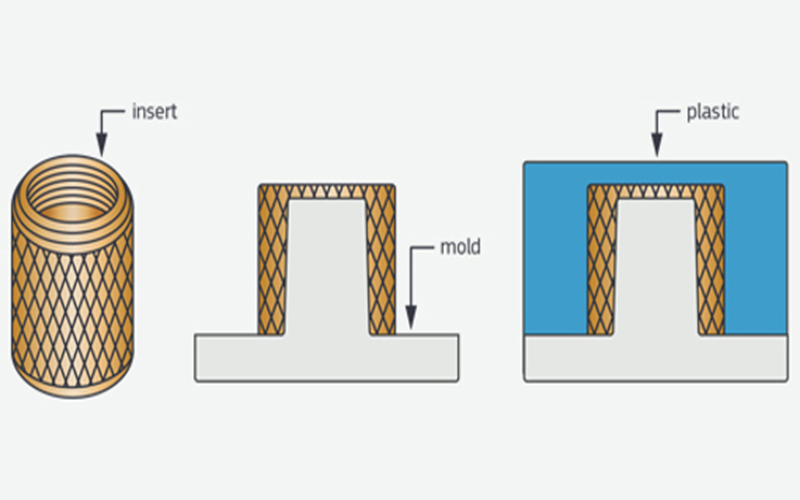

Insert molding typically involves placing pre-fabricated inserts into the mold cavity before injecting molten plastic around them, creating a strong mechanical bond without the need for adhesives.

Overmolding, on the other hand, generally uses a two shot molding process where the first material is molded and partially cooled in a single mold or a second mold, followed by injecting a second, often softer, overmolded material over the substrate.

Production Process

The production process for insert molding and overmolding involves distinct steps tailored to their specific applications.

Insert molding typically starts with placing a prefabricated insert, which is typically metal, into the mold cavity.

The mold then closes, and molten plastic is injected around the insert, forming a single solid part with a strong mechanical bond.

In contrast, overmolding involves a two-step injection molding process. First, the base component or substrate, usually a rigid plastic part, is molded and partially cooled.

Then, it is transferred to a second mold or the same mold is used in a two-shot molding machine to inject a second, often softer material such as silicone rubber or thermoplastic elastomers, over or around the substrate.

Materials Commonly Used

Both insert molding and overmolding utilize a wide range of materials to meet diverse manufacturing requirements.

The plastic materials injected around these inserts are usually rigid plastics like ABS, polycarbonate, or nylon, which provide structural support and electrical insulation.

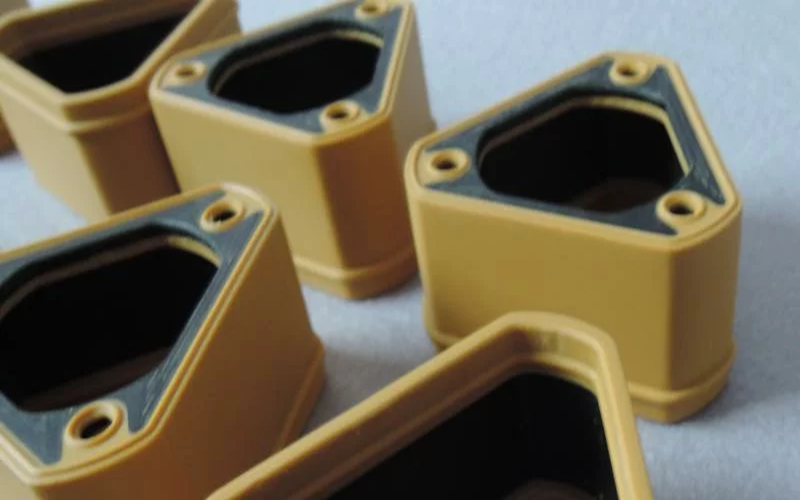

Overmolding commonly involves combining different materials to achieve specific functional properties.

The base substrate is often a rigid plastic, while the overmolded layer typically consists of softer materials such as thermoplastic elastomers, silicone rubber, or rubber material to enhance grip, shock absorption, or tactile comfort.

Insert Molding Applications

Insert molding is widely used across various industries due to its ability to combine metal components with plastic parts into a single, durable product.

Automotive Industry

Insert molding is widely employed to produce high-quality components such as dash panels, electrical connectors, and sensor housings that require both excellent electrical insulation and superior mechanical strength.

This manufacturing process offers precise integration of metal inserts within molded plastic parts, ensuring enhanced durability, reduced assembly costs, and improved performance in demanding environments.

Medical Devices

The process is ideal for manufacturing medical devices that incorporate metal parts, such as surgical instruments, implantable devices, and diagnostic equipment, ensuring durability, biocompatibility, and sterilizability.

Insert molding provides a seamless integration of metal components within a plastic housing, offering excellent electrical insulation and mechanical strength.

Consumer Products

Many hand tools, such as screwdrivers and scissors, utilize insert molding to combine metal blades or shafts with ergonomic plastic handles, resulting in improved grip, enhanced shock absorption, and lighter weight.

This manufacturing process involves injecting molten plastic around metal inserts within a mold cavity, creating a strong mechanical bond that increases durability and reduces assembly costs.

Industrial Equipment

Insert molding helps create durable components by forming strong mechanical bonds between metal inserts and molded plastic parts, significantly enhancing shock absorption, wear resistance, and overall structural integrity.

This process reduces the need for secondary assembly, lowers production costs, and ensures consistent quality in complex parts used across automotive, medical, and industrial applications.

Overmolding Applications

Overmolding is widely used across various industries due to its versatility in combining different materials to enhance product functionality and aesthetics.

Consumer Products

Overmolding is commonly used to add soft, ergonomic grips to items such as toothbrushes, power tools, and phone cases, significantly improving user comfort, grip, and overall usability.

This molding process allows manufacturers to combine multiple materials seamlessly, enhancing both the functional and aesthetic qualities of the final product.

Medical Devices

The process enables the production of biocompatible, easy-to-clean surfaces by overmolding silicone or thermoplastic elastomers onto rigid plastic parts, which is essential for medical instruments, wearable devices, and other healthcare applications.

Additionally, the use of overmolding in these applications improves the durability and chemical resistance of the final product, making it suitable for repeated sterilization and long-term use.

Automotive Industry

Overmolding provides durable, shock-absorbing components such as dashboard panels, knobs, and handles by combining rigid plastics with softer materials like thermoplastic elastomers or silicone rubber.

The process also allows for improved shock absorption and wear resistance, making these parts suitable for high volume production in automotive and industrial applications.

Electronics

Overmolding protects delicate electronic components by encapsulating circuit boards or connectors with insulating and shock-absorbing materials, significantly increasing product reliability and durability.

This process enhances electrical insulation while providing effective shock absorption and environmental protection, making it ideal for high-performance electronic devices in demanding applications.

How To Choose Between Overmolding And Insert Molding?

Choosing between overmolding and insert molding depends on several factors such as the desired material combination, production volume, part complexity, and cost considerations.

If your project requires combining multiple materials into a single part with a soft, ergonomic outer layer—like a rubber grip over a hard plastic substrate—overmolding is often the best choice.

It excels in applications needing enhanced aesthetics and tactile comfort, especially for high volume production using two-shot molding techniques.

Conversely, insert molding is ideal when embedding prefabricated components such as metal inserts, electronic parts, or fasteners directly into a plastic housing.

This process is well-suited for parts that demand strong mechanical bonds, electrical insulation, and durability, often with lower cycle times compared to overmolding.

Considering the physical geometry of the part, compatibility of materials (including issues like low surface energy surfaces), and the specific manufacturing process—whether injection molding, compression molding, or silicone molding—will help determine the most efficient and economical option.

Frequently Asked Questions

What Are The Key Differences Between Insert Molding Overmolding In the Injection Molding Process?

Insert molding involves injecting molten plastic around pre-placed metal or rigid inserts to create a single part, while overmolding involves molding a second, often softer material over a previously molded plastic substrate using a two-step injection process.

What Are The Advantages Of Combining CNC Machining With Insert Molding In Manufacturing Complex Plastic Parts?

Combining CNC machining with insert molding allows for precise fabrication of complex metal inserts that can be securely embedded into molded plastic parts.

Can Insert Molding And Overmolding Be Used Together In One Product?

Yes, these two processes can be combined to leverage the benefits of both. For example, a metal insert can be placed via insert molding, and then a soft overmolded layer can be applied for grip or protection.

What Materials Are Commonly Used In Overmolding?

Overmolding typically uses a rigid plastic substrate combined with softer materials such as thermoplastic elastomers, silicone rubber, or other rubber materials to provide enhanced grip, shock absorption, or tactile comfort.

What Are Some Common Applications Of Insert Molding?

Insert molding is widely used in automotive parts like dash panels and electrical connectors, medical devices including surgical instruments and implants, consumer products such as hand tools with metal blades.