Plastic injection molding is a fundamental manufacturing process that powers the creation of high-quality parts across multiple industries, including automotive, medical, electronics, and beyond.

The versatility of injection molding services lies in their ability to adapt to various production needs, making them indispensable in today’s competitive market.

Our approach integrates scientific molding and design for manufacturing (DFM) to optimize every molding process, while quality assurance ensures that each plastic component meets industry standards.

With a team of skilled manufacturing engineers and tooling engineers, we guide clients from injection molding design to secondary operations, enhancing product development cycles.

The following sections delve into the technical and practical aspects of our offerings, showcasing how we serve multiple industries with high quality parts that exhibit structural integrity, chemical resistance, and temperature resistance.

Understanding the Injection Molding Process

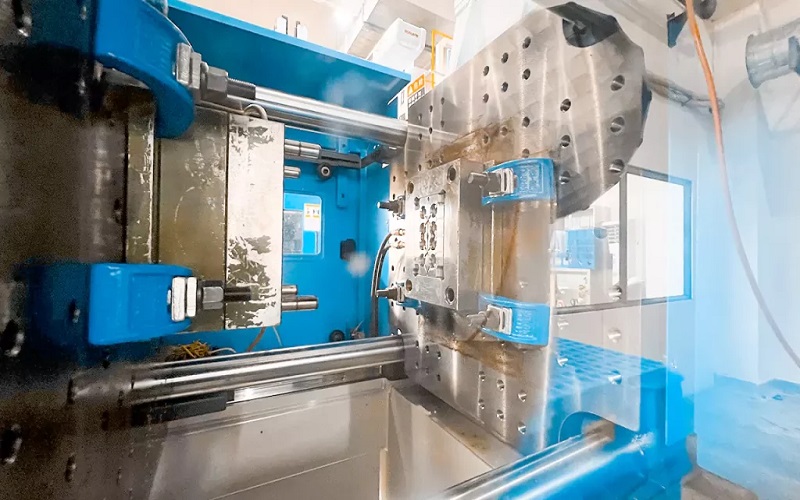

The injection molding process is a highly efficient manufacturing process that produces injection molded parts with exceptional precision, serving as a backbone for modern industrial production.

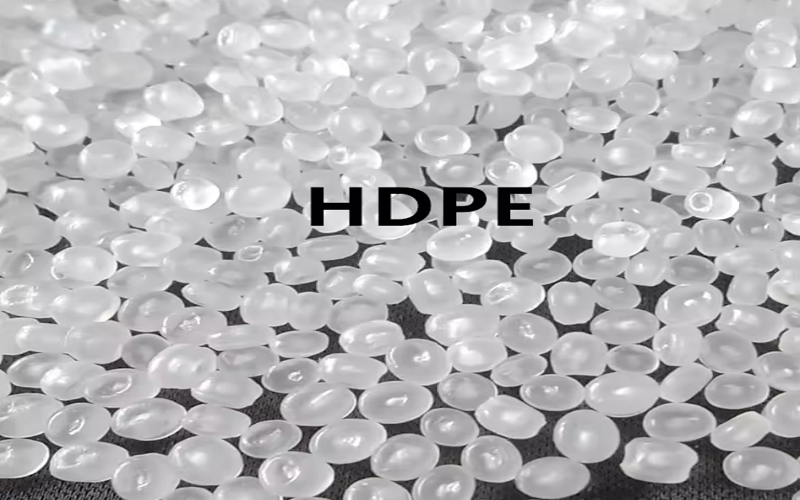

This process begins with loading raw plastic material—typically in pellet form—into the hopper of an injection molding machine. The injection unit heats the material to a molten state, with temperatures ranging from 200°C to 300°C depending on the injection molding materials, such as thermoplastic elastomer or thermoset materials.

The molten raw plastic material is then injected under high pressure, often between 10,000 and 30,000 psi, into a machined mold that shapes the molded parts.

During the cooling phase, the material solidifies, forming the final plastic part with the required structural integrity and wall thickness.

Our molding service refines this process with advanced techniques, ensuring consistency across production molding cycles.

Core Principles and Mechanics

The injection molding process relies on core principles that guarantee consistent, high-quality results.

The machined mold, crafted by tooling engineers using CNC machining, is made from durable materials like hardened steel or aluminum to withstand repeated high-pressure injections and thermal cycles.

These mold tools are designed with precise wall thickness to prevent defects such as warping or sink marks, and they accommodate complex shapes that are challenging to achieve with other manufacturing methods.

The injection unit delivers the molten raw plastic material with pinpoint accuracy, while the clamping unit applies significant force—up to several hundred tons—to secure the mold tool during injection and cooling.

This synchronized operation enables our molding service to produce plastic components for multiple industries, including medical devices and automotive components, while adhering to strict quality control standards.

Optimization Techniques

To enhance the molding process, we implement scientific molding, a data-driven approach that optimizes variables like material flow, injection pressure, and cooling time.

Sensors within the injection molding machine provide real-time data, allowing our manufacturing engineers to adjust parameters and minimize defects such as flash or short shots, thereby reducing waste and improving production efficiency.

The injection molding design phase is equally critical, where design for manufacturing (DFM) principles are applied to create mold tools that are both functional and cost-effective. This involves conducting mold flow simulations to identify potential issues like air traps or uneven cooling, ensuring the design supports high precision and reduces mold cost.

Our methodology accommodates low volume production for prototype development and high volume production for mass manufacturing, delivering cost efficiency and superior quality.

Equipment and Technology

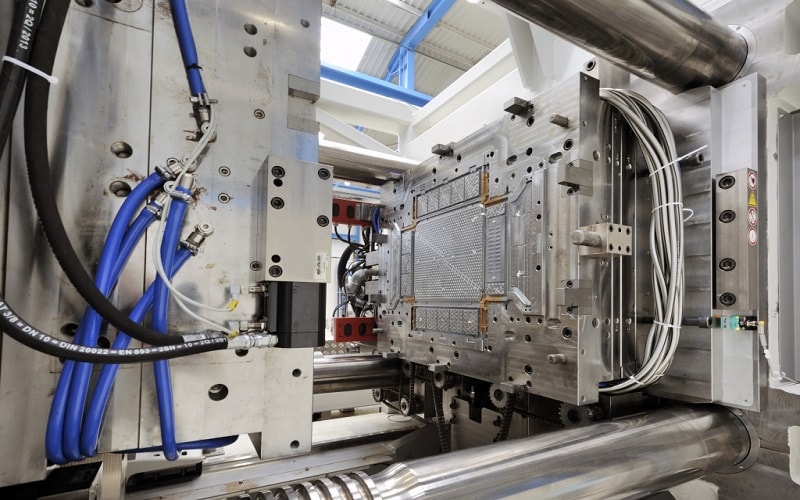

Our injection molding machine fleet is a cornerstone of our technological capability, featuring advanced injection units that offer precise control over the melting and injection of raw plastic material.

These machines vary in tonnage capacity, from 50 tons for small, intricate plastic parts to 500 tons for large automotive components requiring significant force.

We enhance this with CNC machining for mold making, producing mold tools with tolerances as tight as ±0.01 mm, which is essential for complex shapes and structural integrity.

Our tooling engineers and manufacturing engineers undergo continuous training to master this equipment, ensuring that our production processes meet the diverse needs of industrial applications.

This includes crafting medical devices with high precision or electrical connectors with electrical insulation, all while maintaining production efficiency and quality assurance.

Versatile Plastic Injection Molding Materials

The selection of plastic injection molding materials is a decisive factor in determining the final plastic part’s performance, durability, and suitability for its intended use.

Our molding service provides a comprehensive range of materials, including low density polyethylene (LDPE), thermoplastic elastomer (TPE), thermoset materials, and liquid silicone rubber for medical device applications.

Each material is chosen for specific properties such as high temperature resistance, chemical resistance, corrosion resistance, and electrical insulation, enabling us to address a wide array of industrial applications with high quality parts.

Material Options and Characteristics

Low density polyethylene (LDPE) is a lightweight, flexible material with excellent moisture resistance, making it ideal for packaging plastic components and certain consumer goods.

Thermoplastic elastomer combines rubber-like elasticity with thermoplastic processability, making it suitable for automotive components that must endure mechanical stress and repeated flexing.

Thermoset materials, such as epoxy or phenolic resins, offer superior chemical resistance and temperature resistance, positioning them as top choices for medical components and electrical insulators that require stability under harsh conditions.

High density polyethylene (HDPE), as noted in recent industry data, provides corrosion resistance, impact strength, and low moisture absorption, making it a versatile option for outdoor plastic parts and industrial containers.

Liquid silicone rubber (LSR) is a standout for medical device applications, offering biocompatibility and flexibility for the smallest medical insert.

Performance Under Harsh Conditions

These injection molding materials are engineered to perform under challenging conditions, ensuring the final plastic part meets its functional requirements.

Automotive components require temperature resistance to withstand engine compartment heat, while electrical connectors and electrical insulators depend on electrical insulation to prevent short circuits and ensure safety.

Liquid silicone rubber excels in medical device applications, providing flexibility and resistance to chemical exposure while maintaining structural integrity for medical components.

Our expertise ensures that each material is processed to maximize corrosion resistance and durability, adhering to quality control protocols that certify high quality parts for critical uses, such as medical devices in surgical environments.

Influence on Production Costs

The choice of injection molding materials directly impacts mold cost and production efficiency. Thermoplastic elastomer, for instance, is relatively easy to process, reducing cycle times and production processes costs due to its quick solidification.

In contrast, thermoset materials may require longer curing times and higher processing temperatures, increasing mold cost but providing enhanced durability and chemical resistance for long-term applications.

Our manufacturing engineers collaborate with clients to select materials that align with budget constraints and performance goals, optimizing production molding to achieve cost efficiency.

This strategic approach also supports product development cycles by minimizing waste and refining production efficiency over multiple production runs.

Applications Across Multiple Industries

Injection molding services are essential for multiple industries, delivering plastic parts tailored to specific needs with high precision and reliability.

Our molding service has a proven track record in sectors such as automotive, medical, electronics, aerospace, and consumer goods, providing solutions that enhance product performance and market competitiveness.

Automotive Industry Solutions

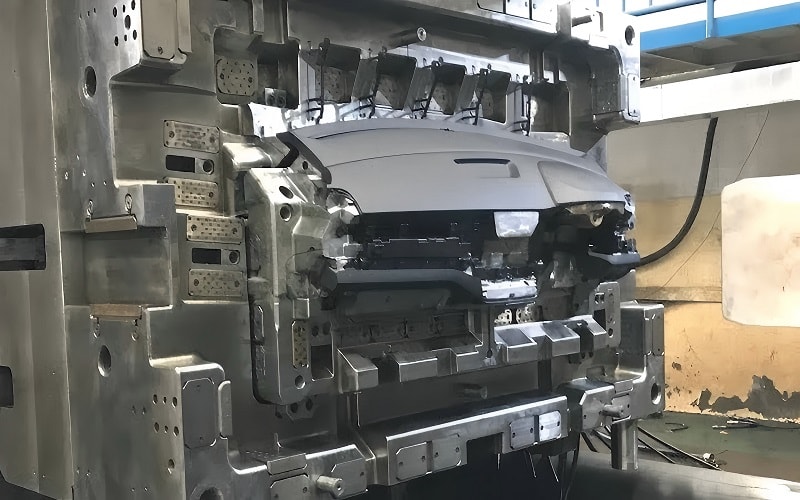

In the automotive industry, our plastic injection molding service produces a wide range of automotive components, including dashboards, bumpers, door panels, interior trim, and engine covers.

These molded parts are crafted using materials with structural integrity and high temperature resistance, ensuring they can withstand chemical exposure, mechanical stress, and the harsh conditions of vehicle operation.

Our production tooling and injection molding machines are optimized to handle the high demands of this sector, delivering high quality parts that contribute to vehicle safety, comfort, and longevity.

For example, HDPE is increasingly used for under-the-hood components due to its corrosion resistance and impact strength, reducing weight while maintaining performance.

Medical Device Manufacturing

Medical injection molding is a specialized area where we manufacture medical components and medical devices, such as surgical instruments, drug delivery systems, diagnostic equipment housings, and the smallest medical insert.

We utilize liquid silicone rubber molding to achieve high precision and biocompatibility, adhering to strict quality assurance standards and regulatory requirements, including FDA compliance.

This capability makes our molding service a trusted partner for medical device applications, where reliability and safety are paramount.

The use of liquid silicone rubber ensures that medical components can be sterilized and used in sensitive procedures, enhancing patient outcomes.

Electronics and Beyond

The electronics industry benefits from our production of electrical connectors, electrical insulators, circuit board housings, and other components that require excellent electrical insulation and durability under mechanical stress.

Our molding service supports low volume production for prototype development and high volume production for mass manufacturing, accelerating product development cycles.

Beyond electronics, we serve the aerospace industry with lightweight plastic parts that meet stringent temperature resistance requirements, and the consumer goods sector with durable plastic components for everyday products like household appliances.

This versatility underscores our ability to adapt production processes to diverse market needs.

Advanced Molding Techniques

Our molding service employs advanced techniques to enhance the functionality, quality, and versatility of molded parts, meeting the specific demands of various industrial applications.

Specialized Methods

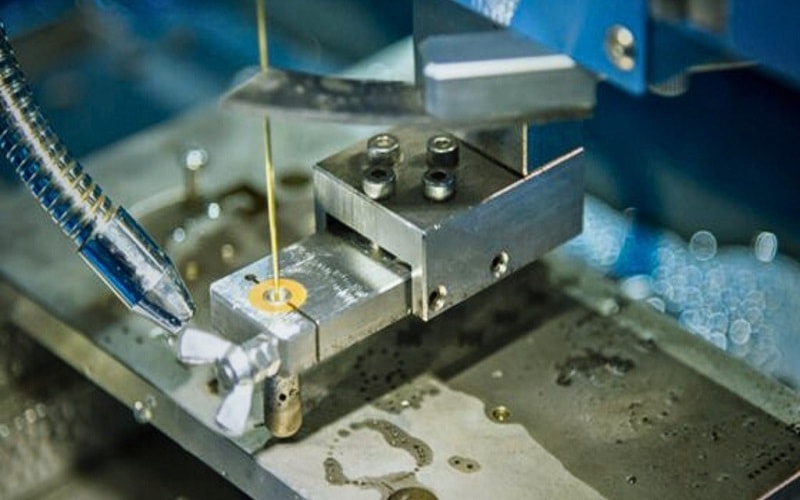

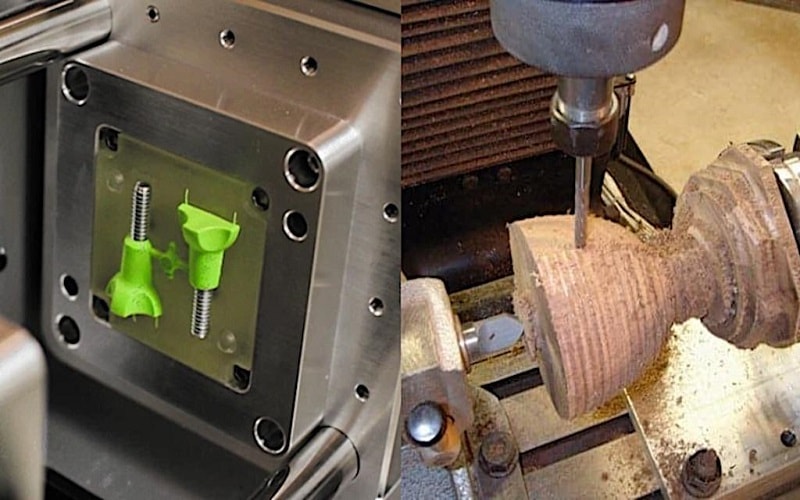

Insert molding allows us to integrate metal or plastic inserts into molded parts, improving strength and functionality for applications like electrical connectors and medical components. This technique reduces assembly steps and enhances structural integrity.

Transfer molding and liquid silicone rubber molding are used to create flexible, high precision components, particularly for medical devices where biocompatibility is essential.

Compression molding, on the other hand, is ideal for producing larger plastic parts with unique material properties, such as those requiring enhanced chemical resistance or temperature resistance.

These methods expand our capability to serve specialized sectors with tailored solutions.

Tooling and Secondary Operations

Our mold making process leverages CNC machining to produce mold tools and production tooling with exceptional accuracy and durability.

We offer bridge tooling for rapid prototyping, allowing clients to test designs before committing to full production molding, which supports large-scale runs.

This balance helps manage mold cost while maximizing production efficiency. Secondary operations, such as assembly, finishing, painting, coating, and quality testing, further enhance the final plastic part.

For instance, coating can improve corrosion resistance, while finishing ensures a polished appearance, adding value to plastic components used in automotive industry or medical device applications.

Design for Manufacturing and Quality Assurance

Optimizing Design

Design for manufacturing (DFM) is a cornerstone of our injection molding expertise, ensuring that injection molding design is both practical and economical.

Our manufacturing engineers collaborate with clients to optimize wall thickness, material flow, and mold geometry, reducing mold cost and minimizing defects like voids or burn marks.

This approach enhances cost efficiency while producing high quality parts that align with design specifications and performance goals, supporting product development cycles from concept to production.

Ensuring Quality

Every molded part undergoes rigorous quality control to verify structural integrity, chemical resistance, and temperature resistance.

We use scientific molding techniques, supported by advanced injection mold tools, to maintain consistency across production processes.

This includes dimensional checks, material testing, and performance evaluations, ensuring that plastic components meet standards whether produced in low volume production or high volume production.

Our quality assurance process is certified to industry benchmarks, providing clients with confidence in the reliability of high quality parts.

Cost Efficiency and Scalable Solutions

Reducing Costs

Our plastic injection molding service is designed to achieve cost efficiency through optimized production processes and production tooling.

By minimizing material waste, refining injection parameters, and streamlining workflows, we reduce mold cost and overall project expenses.

Clients receive detailed injection molding quotes tailored to their budgets, ensuring affordability without compromising the structural integrity or high precision of molded parts.

This cost-effective approach is particularly beneficial for smallest medical insert production or automotive components in large quantities.

Scalability Options

We offer scalability to meet diverse production needs, supporting low volume production for prototyping and small-batch runs, as well as high volume production for mass-market products.

Our tooling engineers develop bridge tooling for initial production phases and production molding setups for large-scale manufacturing, providing flexibility and cost savings.

This scalability accommodates product development cycles across multiple industries, from electronics to aerospace, ensuring that clients can scale production as their market demands grow.

Why Choose Our Injection Molding Service?

Excellence in Service

Our injection molding services set the standard for custom plastic injection molding, producing plastic components with high precision and robust structural integrity.

We excel at handling complex shapes and a diverse array of injection molding materials, from thermoplastic elastomer to liquid silicone rubber, positioning us as a leader in the industry.

Our ability to deliver high quality parts on time and within budget makes us a preferred partner for innovative projects.

Industry-Wide Versatility

Our molding service serves multiple industries with tailored solutions, producing medical devices that resist chemical exposure, automotive components that endure mechanical stress, and electrical insulators with excellent electrical insulation.

We utilize injection molding machines, CNC machining, and scientific molding to meet the unique challenges of each sector, ensuring high quality parts that perform under demanding conditions and contribute to product development cycles.

Getting Started with Your Project

Ready to bring your ideas to life? Our injection molding program offers comprehensive support, covering injection molding design, mold making, and production molding.

Clients can request an injection molding quote to explore custom plastic injection molding solutions tailored to their specifications.

Conclusion

As a leader in plastic injection molding, we provide injection molding services that empower multiple industries, including automotive, medical, and electronics.

Our profound expertise in injection molding materials, mold making, production tooling, and scientific molding ensures that every plastic part meets the highest standards of quality, high precision, and performance.

Whether you need medical components, automotive components, or electrical connectors, our molding service delivers cost efficiency, reliability, and innovation.

Contact us today to discuss how our custom plastic injection molding solutions can elevate your next project.