Plastics are an integral part of modern life, shaping everything from household items to medical devices.

The question, “What is plastic made of?” reveals a fascinating process that transforms raw materials into the extremely versatile products we use daily.

This article delves into the components, production processes, and environmental impact of plastics, incorporating key terms like crude oil, natural gas, and biodegradable plastics to provide a comprehensive understanding of the plastics industry.

The Core Components of Plastics

At their essence, plastics are made from organic polymers, which are long chains of carbon atoms connected through chemical bonds.

These organic compounds form the backbone of most plastics, enabling their flexibility, durability, and ability to be molded into various shapes.

The word “plastic” encompasses a wide range of synthetic plastic and semi-synthetic materials, each tailored for specific applications, from plastic packaging to disposable cups.

The vast majority of plastics are fully synthetic plastics, derived from fossil fuels like crude oil and natural gas. These raw materials undergo complex processing in the petrochemical industry to produce the crucial compounds that form plastics.

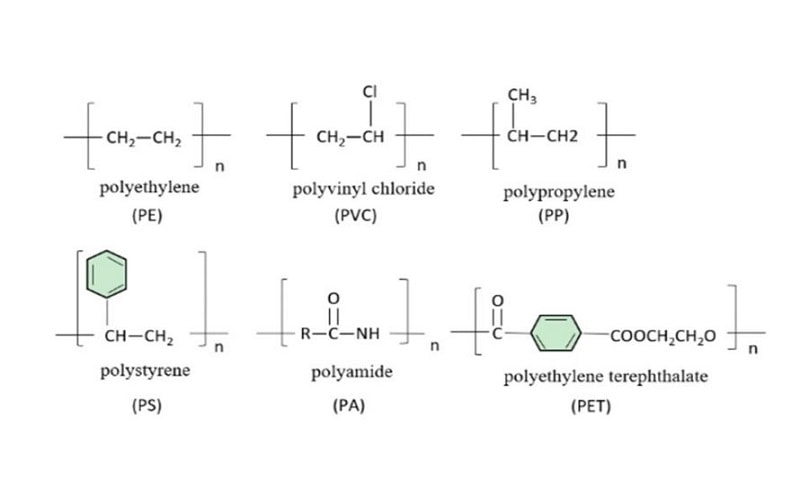

For instance, heavy crude oil is refined to extract lighter components, which are then transformed into polymers like polyethylene and polystyrene.

The Plastic Production Process

The transformation of raw materials into plastic products is a sophisticated process that combines chemistry and engineering to meet the demands of modern life.

From Fossil Fuels to Polymers

The production of plastics begins with fossil fuels, primarily crude oil and natural gas. These are refined at high temperatures to isolate organic compounds like ethylene and propylene, which serve as the building blocks for polymers.

The petrochemical industry plays a pivotal role, breaking down heavy crude oil into simpler molecules that form the basis of synthetic plastics like polyethylene terephthalate (PET) and polyvinyl chloride (PVC).

For example, polyethylene terephthalate (PET), used in plastic bottles and food packaging, is created by combining ethylene glycol and terephthalic acid.

Similarly, high-density polyethylene (HDPE), found in plastic containers and plastic bags, is produced through the polymerization of ethylene under controlled environmental conditions.

These processes require precise temperature and pressure management to ensure the formation of strong chemical bonds.

Historical Context: Early Plastics

The plastics industry has evolved significantly since its inception.

Early plastics, like cellulose nitrate and phenol formaldehyde, were among the first synthetic materials developed in the 19th and early 20th centuries.

These paved the way for modern plastics, which are now produced on a massive scale to meet global demand for plastic packaging, household items, and more.

With an understanding of how plastics are made, let’s examine the various types of plastics and their applications in everyday life.

Types and Applications of Plastic Materials

The versatility of plastics stems from the diverse range of materials available, each designed for specific purposes across industries.

Common Types of Plastics

The plastics industry produces a variety of materials, each with unique properties:

- Polyethylene Terephthalate (PET): Known for its clarity and strength, PET is widely used in plastic bottles, food packaging, and textiles.

- High-Density Polyethylene (HDPE): This heat-resistant, durable plastic is common in plastic containers, pipes, and plastic bags.

- Polyvinyl Chloride (PVC): Valued for its low cost and flexibility, PVC is used in construction, packaging, and medical devices.

- Polycarbonate Plastic: Its impact resistance makes it ideal for safety equipment and medical devices.

- Polystyrene: Lightweight and affordable, polystyrene is found in disposable cups and packaging materials.

- Low-Density Polyethylene (LDPE): Flexible and lightweight, LDPE is used in plastic bags and films.

- Phenol Formaldehyde: An early heat-resistant plastic, it’s still used in electrical components and household items.

These plastics are tailored to meet specific needs, from the rigidity of plastic containers to the flexibility of plastic packaging.

Plastics in Industry and Daily Life

Plastics are crucial in various sectors. In the automotive industry, lighter components made from plastics like HDPE reduce vehicle weight, improving fuel efficiency and lowering greenhouse gas emissions.

In healthcare, polycarbonate plastic and PVC are used in medical devices due to their durability and sterility.

Plastic packaging, including food packaging and plastic bags, ensures product safety and extends shelf life, while disposable cups and household items offer convenience and affordability.

The ability of plastics to be molded into various shapes, combined with their low cost, makes them extremely versatile, but their widespread use raises significant environmental concerns, which we’ll explore next.

Environmental Impact of Plastics

The production and disposal of plastics have profound implications for the environment, prompting a shift toward sustainable practices.

Plastic Waste and Climate Change

The reliance on fossil fuels for plastic production contributes significantly to greenhouse gas emissions. Extracting and refining crude oil and natural gas releases carbon dioxide, a key driver of climate change.

The energy-intensive processes used to produce plastics, often requiring high temperatures, further exacerbate emissions.

Plastic waste is another pressing issue. Plastic bags, plastic packaging, and other single-use plastics often end up in landfills or oceans, where they persist for centuries.

The environmental impact of plastic waste harms ecosystems, pollutes waterways, and threatens wildlife, making it a global concern.

Sustainable Alternatives and Recycling

To mitigate these challenges, the plastics industry is innovating with recycled plastic and biodegradable plastics. Recycled plastic, made from post-consumer materials, reduces the demand for virgin fossil fuels and helps manage plastic waste.

Biodegradable plastics, like polylactic acid (PLA), break down more quickly under specific environmental conditions, offering a greener alternative for packaging and disposable products.

Additionally, renewable materials, such as plant-based polymers, are being used to create plastics with a lower carbon footprint.

These innovations aim to reduce plastic consumption’s environmental toll while maintaining the functionality of plastic products.

With sustainability in mind, let’s consider how plastics continue to shape modern society and what the future holds.

Plastics in Modern Society and Future Trends

The ubiquity of plastics underscores their importance, but their future depends on balancing utility with environmental responsibility.

Plastics in Everyday Life

Plastics are indispensable in modern life. From plastic containers and food packaging to medical devices and automotive components, plastics offer unmatched versatility.

Their ability to withstand various environmental conditions, such as moisture and heat, makes them ideal for diverse applications.

For example, heat-resistant polycarbonate plastic is used in protective gear, while low-density polyethylene forms flexible packaging films.

In industries like transportation, plastics reduce vehicle weight, enhancing fuel efficiency and reducing emissions. In households, plastic products like disposable cups and storage containers are valued for their convenience and low cost.

The Future of Plastics

The plastics industry is at a turning point. Innovations like recycled plastic, biodegradable plastics, and renewable materials are driving a shift toward sustainability.

For instance, polylactic acid and other plant-based plastics reduce reliance on petroleum-based plastics, while recycling programs in other countries aim to minimize plastic waste.

Consumers also play a vital role.

By choosing products made from recycled or biodegradable plastics and supporting policies that reduce single-use plastics, individuals can help mitigate the environmental impact of plastic consumption.

Governments worldwide are implementing bans on plastic bags and promoting the use of renewable resources to produce plastics.

Conclusion

Plastics, made from organic polymers derived primarily from crude oil and natural gas, are a cornerstone of modern life.

Their versatility, low cost, and ability to be molded into various shapes make them essential in industries ranging from packaging to healthcare.

However, the environmental impact of plastic production and waste necessitates a shift toward sustainable alternatives like recycled plastic, biodegradable plastics, and renewable materials.

By understanding what plastics are made of and how they are produced, we can make informed choices to balance their benefits with the need to protect the environment, ensuring a sustainable future for the plastics industry and the planet.

FAQs About Plastics

What are the primary sources of materials used to make plastics?

Plastics are primarily made from fossil fuels like crude oil and natural gas, which are refined to produce organic polymers.

Additionally, some plastics incorporate natural materials like cellulose or starch, especially in bioplastics, while other materials such as coal derivatives or renewable sources like sugarcane can also be used to create the complex mixture of compounds in final products like plastic packaging or containers.

How do natural materials differ from synthetic materials in plastic production?

Natural materials, such as corn, sugarcane, or cellulose, are renewable and used in bioplastics, which degrade more easily.

Synthetic materials, derived from fossil fuels, form the basis of most conventional plastics, like polyethylene or other plastics such as polystyrene.

These synthetic materials often require various chemicals and processing at lower temperatures to create a complex mixture that ensures durability and versatility in final products.

What role do additives play in the composition of plastics?

Additives are various chemicals mixed into the polymer base to enhance properties like flexibility, color, or heat resistance.

These can include stabilizers, plasticizers, or flame retardants, forming a complex mixture that tailors plastics for specific uses.

For instance, other materials like UV stabilizers are added to other plastics to improve outdoor durability, ensuring the final products meet diverse performance needs.

Are all plastics made from the same elements?

No, plastics are composed of various elements, primarily carbon, hydrogen, and oxygen, derived from fossil fuels or natural materials.

Some plastics, like PVC, include chlorine, while other plastics may incorporate nitrogen or sulfur through additives.

The combination of these various elements and various chemicals results in a complex mixture that defines the unique properties of each plastic type in the final products.

Why are lower temperatures used in some plastic production processes?

Processing at lower temperatures is often employed to save energy and prevent degradation of sensitive natural materials or other materials in the production of certain plastics.

For example, bioplastics or other plastics like PLA (polylactic acid) require lower temperatures to maintain the integrity of their complex mixture, ensuring the final products retain desired qualities like biodegradability or flexibility.