Thermoplastic polyurethane (TPU) film, commonly referred to as TPU film, PU film, or thermoplastic urethane film, is a highly versatile plastic film renowned for its abrasion resistance, low temperature flexibility, and optical clarity.

Derived from thermoplastic polyurethane (TPU), it includes variants like polyester TPU films and polyether TPU films, each offering unique properties that make polyurethane films an excellent choice for applications across different industries.

This article explores the composition, benefits, manufacturing process, and wide range of uses for TPU film, highlighting why it is a preferred material for customers seeking durable, flexible, and high-performance products.

Composition and Types of Thermoplastic Polyurethane Film

Thermoplastic polyurethane TPU is a standout among plastic films due to its ability to combine elasticity with durability.

Understanding its composition and variants, such as polyester TPU and polyether TPU, is key to appreciating its versatility and functionality in modern manufacturing.

What is TPU Film Made Of?

TPU film is derived from polyurethane polymers, specifically thermoplastic polyurethane, which is formed by combining polyester or polyether compounds with other chemical components.

Polyester TPU films are known for their exceptional abrasion resistance and ability to withstand chemical exposure, making them suitable for rugged environments.

Polyether TPU films, on the other hand, excel in low temperature flexibility and resistance to moisture, ensuring performance without breaking in cold or humid conditions.

These properties make TPU film compatible with a variety of materials, unlike PVC or other plastic films, allowing it to enhance products through processes like lamination.

Polyester vs. Polyether TPU Films

The polyester TPU variant offers superior durability and resistance to abrasion and organic solvents, making it ideal for applications like protective coatings or automotive parts.

Polyether TPU, with its low temperature flexibility, is better suited for products requiring elasticity in extreme conditions, such as medical bags or outdoor fabrics.

Both types contribute to the versatility of thermoplastic polyurethane film, allowing companies to customize TPU films to match specific customer requests for colors, widths, or functionality.

Benefits of TPU Film in Manufacturing

The performance of TPU film makes it a top choice for industries seeking durable, flexible, and cost-effective materials.

Its unique properties, such as high resistance to wear and optical clarity, provide significant advantages for both manufacturers and end-users.

Durability and Resistance

Polyester TPU films are celebrated for their abrasion resistance, enabling them to withstand harsh conditions without breaking over time.

This durability makes them suitable for applications like automotive interiors or industrial covers with enhanced longevity.

Polyether TPU films offer low-temperature flexibility and moisture resistance, ensuring reliable performance in environments where PVC or other plastic films may fail.

Both types provide good chemical resistance to organic solvents, making TPU film an excellent choice for product lines exposed to oils or cleaning agents, further boosting their functional enhancements.

Optical Clarity and Aesthetic Versatility

The optical clarity of thermoplastic urethane film is a key feature for applications requiring transparency, such as display screens or packaging.

This clarity, combined with the ability to produce TPU films in a wide range of colors and widths, allows for customization to match branding or aesthetic needs.

Additives can further enhance properties like UV resistance or flame retardancy, improving the functionality of polyurethane films in consumer products or laminate fabrics.

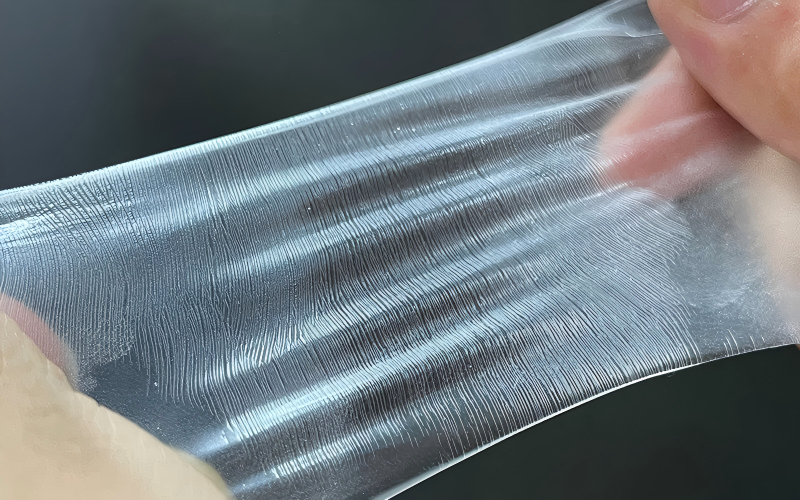

Flexibility and Elongation

The flexible nature of TPU film, particularly polyether TPU, allows for high elongation without compromising strength. This makes it ideal for products like living hinges in bags or fabrics that require bending without breaking.

The semi-crystalline nature of thermoplastic polyurethane ensures it maintains performance under stress, offering a balance of flexibility and durability that enhances product longevity.

Manufacturing Process of TPU Film

The manufacture of thermoplastic polyurethane film is a complex process that transforms polyurethane polymers into thin, durable films.

This process is critical to achieving the properties that make TPU film so valuable.

Extrusion and Film Formation

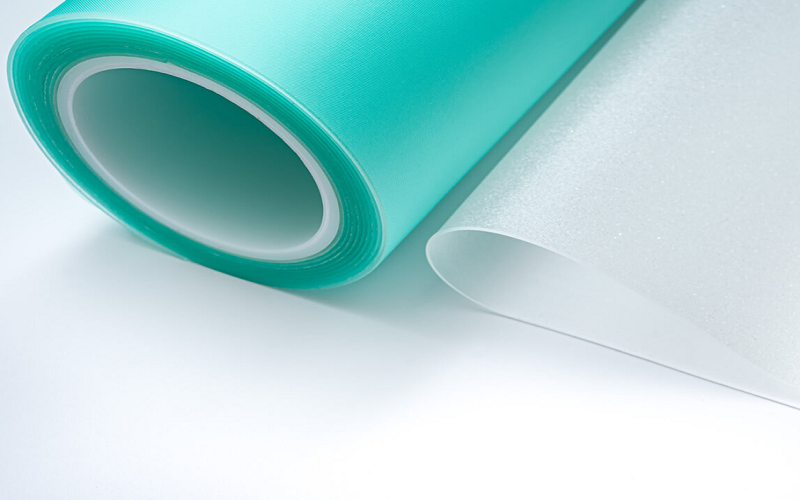

The production of TPU film begins with thermoplastic polyurethane resin, which is heated to a molten state and extruded through a flat die to form a continuous film.

The film is then cooled and wound into a roll for further processing or distribution.

During extrusion, additives are incorporated to enhance abrasion resistance, optical clarity, or low temperature flexibility, depending on whether polyester TPU or polyether TPU is being produced.

This process ensures uniform thickness and high quality in the final products.

Lamination and Customization

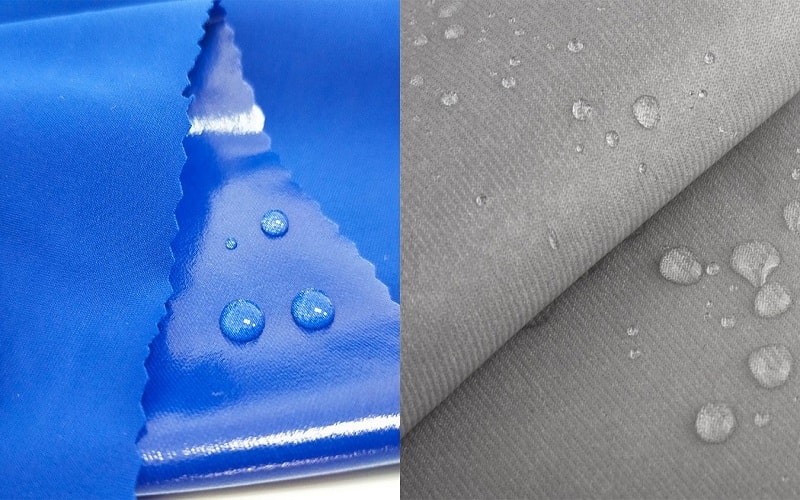

TPU film can be laminated onto fabrics or other materials to improve functionality, such as creating waterproof bags or breathable textiles.

Manufacturers can customize the film by adjusting widths, colors, or properties to match customer requests.

For example, polyester TPU films may be tailored for abrasion resistance, while polyether TPU films focus on moisture resistance.

This customization ensures TPU film meets the specific needs of different industries, from automotive to medical.

Applications of Thermoplastic Polyurethane Film

The versatility of TPU film makes it a staple in industries like automotive, medical, textile, and consumer goods. Its ability to withstand demanding conditions drives its wide adoption in products worldwide.

Automotive and Industrial Uses

Polyester TPU films are commonly used in automotive parts, such as protective coatings for dashboards or exterior components, due to their abrasion resistance and durability.

These polyurethane films can be laminated onto fabrics to enhance interior functionality and aesthetics.

Polyether TPU films, with their low temperature flexibility, are suitable for outdoor applications, such as protective covers that withstand cold climates without breaking.

Medical and Consumer Products

In the medical industry, polyether TPU is used in products like wound dressings, catheters, and air bags due to its moisture resistance and biocompatibility.

Its low temperature flexibility ensures performance in cold storage or surgical environments.

For consumer products, TPU film is found in phone cases, sportswear, and packaging, leveraging its optical clarity and durability. These polyurethane films enhance product longevity and appeal, making them a popular choice today.

Textile and Fashion Industry

TPU film is often laminated onto fabrics to create waterproof or breathable materials for jackets, shoes, or bags.

The flexible nature of polyester TPU and polyether TPU allows these products to maintain performance under stress, while customization options like colors or textures match fashion trends.

This versatility makes TPU film an excellent choice for designers looking to improve both function and style.

Challenges in Using TPU Film

While thermoplastic polyurethane film offers numerous benefits, manufacturers and customers must address certain challenges to ensure optimal performance. These considerations are critical for successful applications.

Processing and Material Compatibility

Improper processing of polyester TPU or polyether TPU can lead to material degradation or reduced abrasion resistance.

Higher temperatures during manufacture may affect optical clarity or low temperature flexibility, requiring precise control of the process.

Compatibility with other materials during lamination is also essential to enhance functionality without compromising quality.

Companies must work closely with suppliers to develop TPU films that meet specific requirements.

Cost and Supply Chain Considerations

The production of TPU film can be more expensive than PVC due to the complexity of polyurethane polymers.

Companies must maintain adequate stock to meet customer demand, offering a wide range of options in widths and types.

Partnering with a reliable company ensures timely return of high-quality TPU films, balancing cost with performance to satisfy customers.

Conclusion

Thermoplastic polyurethane (TPU) film, encompassing polyester TPU films and polyether TPU films, is a versatile, durable, and flexible material that excels in abrasion resistance, low temperature flexibility, and optical clarity.

From automotive parts to medical bags and textile laminates, polyurethane films offer unmatched performance across different industries. By understanding the manufacturing process, properties, and customization options, companies can develop products that match customer requests and enhance functionality.

Whether you’re looking to improve packaging, create durable fabrics, or innovate in consumer goods, TPU film is an excellent choice.

For more information or to request customized TPU films, contact a trusted supplier today to experience the benefits of this remarkable material.