Metal CNC machining is a cornerstone of modern manufacturing, enabling the production of precise and complex parts for industries like consumer electronics, industrial machinery, and medical device manufacturing.

Using computer numerical control (CNC) technology, CNC machining delivers high precision and tight tolerances for custom parts made from metal alloys like stainless steel, aluminum alloys, and mild steel.

This guide explores the CNC machining process, best practices, and CNC machining advantages, providing insights into creating CNC machined parts with excellent mechanical properties for high volume production or rapid prototyping.

Understanding Metal CNC Machining

Metal CNC machining leverages computer numerical control to produce custom parts with high precision.

By combining computer aided design (CAD) and computer aided manufacturing (CAM), this subtractive manufacturing process ensures consistent quality across various materials.

Understanding its fundamentals is key to optimizing production.

What is Metal CNC Machining?

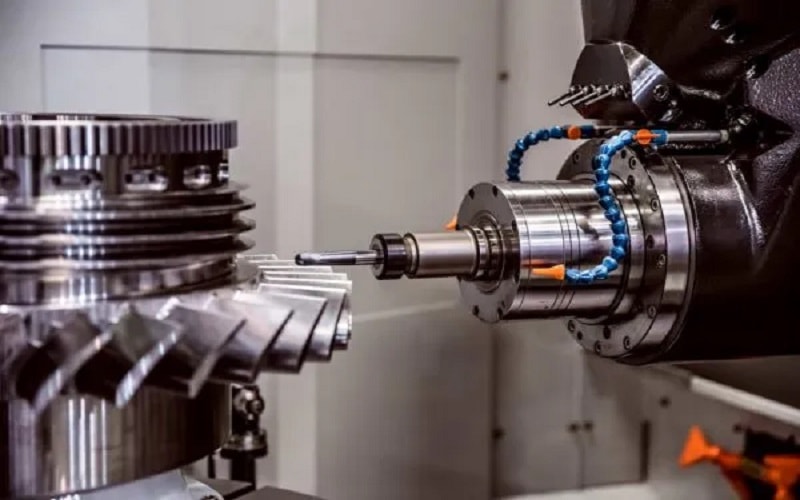

Metal CNC machining involves removing material from a material stock using machine tools like CNC lathes, CNC routers, or CNC milling machines.

CNC stands for computer numerical control, where the CNC system uses a CAD file to guide the cutting tool along a tool path, shaping metal parts into the desired shape as part of the production process.

Unlike additive manufacturing, which builds parts layer by layer, this subtractive manufacturing process ensures tight tolerances and excellent electrical conductivity for metal alloys, though results can vary widely depending on material and design.

CNC machines operate with CAM software, replacing manual control to achieve high precision for complex parts like surgical instruments.

Role in Custom Parts Production

CNC machining is ideal for custom parts in mass production or rapid prototyping, supporting industries requiring corrosion resistance or high wear resistance.

Engineers create technical drawings using computer aided design CAD to define machining parameters, ensuring CNC machined parts meet specific requirements.

The versatility of CNC technology allows manufacturers to work with various materials, from stainless steel to aluminum alloys, delivering production parts with superior surface finish and mechanical properties.

The precision and flexibility of metal CNC machining make it a preferred manufacturing process for custom tools and complex parts.

Its ability to produce precise components supports industrial and consumer applications.

Benefits of Metal CNC Machining

Metal CNC machining offers significant CNC machining advantages, making it a go-to method for custom parts production.

Its reliability and efficiency drive its adoption across industries.

Key CNC Machining Advantages

CNC machining delivers high precision, cost efficiency, and durability for metal parts. Key benefits include:

- High Precision: CNC machining works with tight tolerances, ensuring precise and complex parts for surgical instruments or consumer electronics.

- Versatility: The process supports various materials like stainless steel, aluminum alloys, and mild steel, accommodating broad range applications.

- Excellent Mechanical Properties: CNC machined parts offer tensile strength, corrosion resistance, and high wear resistance, ideal for extreme temperatures.

- Efficiency: CNC machines operate with CAM software, enabling high volume production with minimal material deformation.

Supporting Rapid Prototyping and Mass Production

CNC machining excels in rapid prototyping, allowing engineers to test custom parts before mass production.

The CNC machining process ensures consistent quality, reducing waste and costs.

For example, CNC turning and CNC milling produce production parts with excellent electrical conductivity, suitable for industrial machinery or electronics.

This efficiency makes metal CNC machining a cost-effective solution for high volume production.

These advantages position CNC machining as a reliable manufacturing process, delivering high quality metal parts for custom applications.

Key Techniques in Metal CNC Machining

The CNC machining process employs advanced techniques like CNC milling, CNC turning, and sheet metal fabrication to create CNC parts.

These methods ensure precision and durability.

CNC Milling and Turning

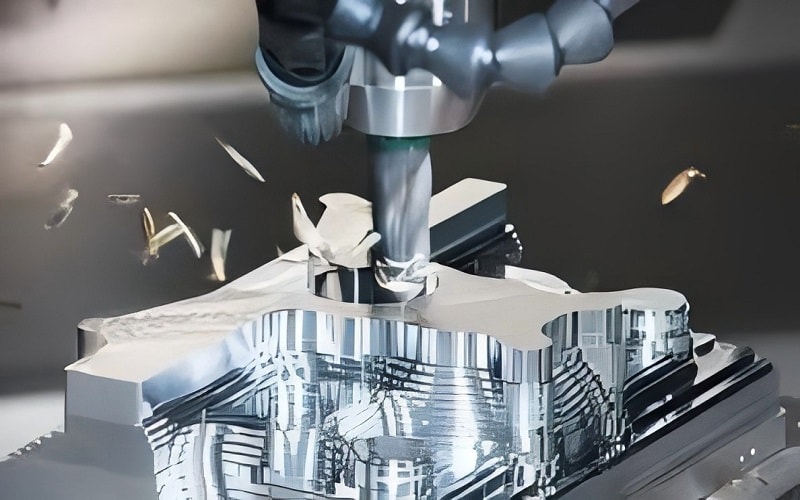

CNC milling uses a cutting tool to remove material from a stationary workpiece, creating complex parts with tight tolerances.

CNC turning, where the workpiece rotates, is ideal for cylindrical production parts like shafts.

Both techniques rely on CAM software to define the tool path, ensuring high precision and excellent mechanical properties.

CNC lathes and CNC routers enhance versatility, supporting metal alloys for industrial applications.

Sheet Metal Fabrication and Finishing

Sheet metal fabrication involves shaping metal into desired shapes using CNC technology.

Powder coating or heat treatment enhances surface finish, corrosion resistance, and heat resistance.

These finishing processes ensure CNC machined parts withstand high temperatures and harsh environments, making them suitable for surgical instruments or consumer electronics.

The techniques in metal CNC machining allow manufacturers to produce precise and complex parts, ensuring consistent quality and performance for custom parts production.

Material Selection for Metal CNC Machining

Material selection is critical in metal CNC machining, impacting mechanical properties and product quality.

Choosing the right metal alloys ensures durability and functionality.

Common Metal Alloys for CNC Machining

The following table summarizes common metal alloys used in CNC machining:

| Material | Key Properties | Applications |

| Stainless Steel | Corrosion resistance, tensile strength | Surgical instruments, industrial machinery |

| Aluminum Alloys | Excellent electrical conductivity, lightweight | Consumer electronics, aerospace |

| Mild Steel | Good mechanical properties, cost-effective | Custom tools, production parts |

Stainless steel offers high wear resistance and corrosion resistance, ideal for medical applications.

Aluminum alloys provide excellent electrical conductivity, suitable for electronics.

Mild steel ensures good mechanical properties for cost-effective production parts.

Specialty Materials and Considerations

For specific applications, alloy steels or epoxy resin coatings may be used to enhance heat resistance or surface finish.

Material selection considers machining parameters like tool access and material deformation, ensuring CNC machined parts meet tight tolerances.

Heat treatment can further improve tensile strength, making parts suitable for extreme temperatures.

Proper material selection ensures CNC parts deliver optimal performance, supporting high volume production and rapid prototyping.

Applications of Metal CNC Machining

Metal CNC machining supports a broad range of applications, producing custom parts with high precision for various industries.

Its versatility drives its adoption.

Consumer Electronics and Industrial Machinery

CNC machining produces metal parts for consumer electronics, such as housings or connectors, leveraging aluminum alloys for excellent electrical conductivity.

In industrial machinery, stainless steel CNC parts offer corrosion resistance and tensile strength, ensuring durability in harsh environments.

CNC milling and CNC turning create precise and complex parts for mass production.

Surgical Instruments and Custom Tools

Metal CNC machining is ideal for surgical instruments, using stainless steel for high wear resistance and biocompatibility.

Custom tools benefit from mild steel or alloy steels, providing good mechanical properties for rapid prototyping or production parts.

CNC routers and CNC lathes ensure tight tolerances, critical for medical and industrial applications.

The applications of metal CNC machining highlight its ability to produce precise CNC parts with consistent quality, supporting diverse industry needs.

Best Practices for Metal CNC Machining

Implementing best practices in metal CNC machining ensures high precision, efficiency, and product quality.

These strategies optimize the CNC machining process.

Optimizing CAD and CAM Processes

Engineers create technical drawings using computer aided design CAD to define machining parameters. CAM software generates the tool path, ensuring CNC machines operate with precision.

Best practices include verifying CAD file accuracy and optimizing tool access to minimize material deformation.

This ensures CNC machined parts meet tight tolerances and desired shape requirements.

Material and Finishing Considerations

Selecting metal alloys like stainless steel or aluminum alloys based on mechanical properties is essential.

Powder coating or heat treatment enhances surface finish, corrosion resistance, and heat resistance.

Manufacturers should test CNC parts to ensure they withstand high temperatures and harsh environments, maintaining consistent quality for production parts.

Challenges in Metal CNC Machining

Metal CNC machining faces challenges that require careful management to ensure product quality and efficiency. Addressing these is critical for success.

Maintaining Tight Tolerances

Achieving tight tolerances in CNC machining requires precise machining parameters and tool path optimization.

Material deformation or improper tool access can affect CNC machined parts, necessitating advanced machines and CAM software.

Engineers must monitor the CNC system to ensure consistent quality for complex parts.

Material and Cost Management

Material selection impacts costs and performance. High volume production with expensive metal alloys like stainless steel can increase costs, while mild steel offers cost efficiency.

Manufacturers must balance mechanical properties with budget, ensuring CNC parts meet industry standards without compromising quality.

Conclusion

Metal CNC machining is a vital manufacturing process for producing precise and complex parts in consumer electronics, industrial machinery, and surgical instruments.

Leveraging CNC technology, CNC milling, and CNC turning, manufacturers create CNC machined parts with tight tolerances, corrosion resistance, and excellent mechanical properties.

By optimizing computer aided design CAD, CAM software, and material selection, metal CNC machining ensures cost efficiency and high volume production.

For engineers and manufacturers seeking custom parts or rapid prototyping, partnering with a CNC machining expert guarantees consistent quality and performance.

Contact a trusted metal CNC machining provider today to explore solutions for your production needs.