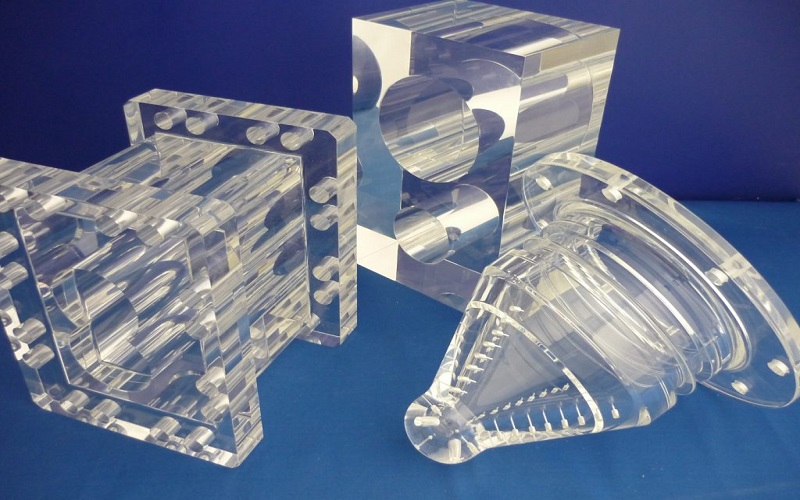

Acrylic CNC machining is a transformative process in manufacturing, enabling high precision creation of acrylic parts for industries like retail displays, automotive, and medical.

Using CNC machining, acrylic sheets—made from polymethyl methacrylate (PMMA)—are transformed into complex shapes with clean edges and smooth finish.

This guide explores CNC acrylic machining techniques, including acrylic cutting, acrylic drilling, and post processing, to achieve optical clarity, impact resistance, and durability.

By mastering CNC machining acrylic parts, manufacturers can leverage the numerous advantages of acrylic, such as high transparency and cost effectiveness, for project success.

Understanding Acrylic CNC Machining

Acrylic CNC machining involves using CNC mills or routers to shape acrylic sheets into precise acrylic pieces.

Its significant advantages make it a preferred method for many industries. Understanding the material and process is key to achieving quality results.

What is Acrylic CNC Machining?

Acrylic CNC machining, also known as CNC machining PMMA, uses a rotating cutter to cut, drill, or form acrylic into complex geometries.

The process employs CNC cutting to shape cast acrylic or extruded acrylic, ensuring high precision and clean edges.

CNC acrylic machining delivers acrylic parts with optical clarity and smooth finish, ideal for retail displays or outdoor applications.

Manufacturers control spindle speed and feed rate to prevent melting and stress cracking, ensuring minimal damage to the clear polymer.

Types of Acrylic: Cast vs. Extruded

Acrylic comes in two primary forms: cast acrylic and extruded acrylic. The following table compares their properties:

| Type | Key Properties | Applications |

| Cast Acrylic | High transparency, impact resistance | Retail displays, optics |

| Extruded Acrylic | Cost effective, easier to machine | Signage, outdoor applications |

Cast acrylic offers superior optical clarity and durability, while extruded acrylic is more cost effective and easier to machine, making it suitable for high volume projects.

Proper material selection ensures acrylic CNC cutting meets project requirements.

The versatility of CNC acrylic machining makes it ideal for many manufacturers.

By understanding acrylic types and machining techniques, you can achieve precision and quality in acrylic parts.

Benefits of Acrylic CNC Machining

CNC machining acrylic parts offers numerous advantages, from cost effectiveness to high transparency.

These benefits make acrylic CNC machining a go-to process for industries seeking durable plastic solutions.

Key Advantages of CNC Acrylic Machining

Acrylic CNC machining provides significant advantages for manufacturers:

- High Precision: CNC machining PMMA ensures tight tolerances, delivering acrylic pieces with complex shapes and clean edges.

- Optical Clarity: Acrylic’s refractive index rivals glass, making it ideal for retail displays or optics requiring high transparency.

- Impact Resistance: Acrylic is highly resistant to impacts, outperforming glass in durability for outdoor applications.

- Cost Effective: Compared to other materials like aluminum or wood, acrylic is affordable, reducing project costs.

Versatility Across Industries

The durability and aesthetic appeal of CNC machined acrylic make it suitable for many industries, including automotive, medical, and retail.

Acrylic cutting produces parts like dashboards, medical device components, or signage, while acrylic drilling supports design features like mounting holes.

The process’s cost effectiveness ensures high quality acrylic parts for diverse projects.

These advantages position acrylic CNC machining as a preferred method for creating durable, visually appealing plastic components, ensuring precision and performance.

Techniques for Acrylic CNC Machining

Mastering acrylic CNC machining requires expertise in techniques like CNC acrylic cutting, acrylic drilling, and post processing.

These methods ensure smooth finish and minimal damage.

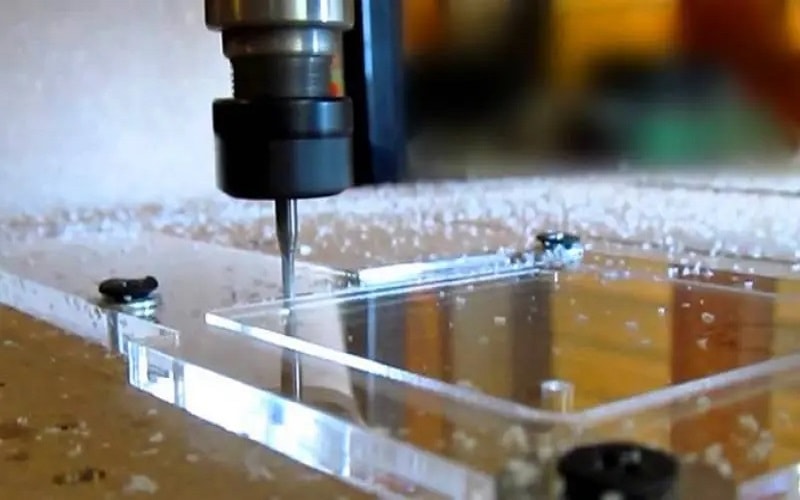

CNC Acrylic Cutting and Drilling

CNC acrylic cutting uses a specialized bit with a razor sharp edge to cut acrylic sheets at a steady rate, preventing melting or stress cracking.

Spindle speed and correct feed rate are critical to achieve clean edges and smooth ramp transitions for complex geometries.

Acrylic drilling requires just the right amount of pressure to avoid cracking, ensuring precision for design features like holes or slots.

CNC mills with specifically designed tools deliver high quality acrylic pieces for retail displays or medical applications.

Post Processing for Enhanced Quality

Post processing enhances the smooth finish of CNC machined acrylic. Techniques like flame polishing or buffing remove minor imperfections, improving optical clarity.

For outdoor applications, applying UV light-resistant coatings protects acrylic parts from degradation.

Manufacturers ensure minimal damage by controlling heat during post processing, maintaining the clear polymer’s durability and aesthetic appeal.

The techniques of CNC acrylic machining ensure high precision and quality, making acrylic parts suitable for complex projects across industries.

Material Selection for Acrylic CNC Machining

Choosing the right material is critical for acrylic CNC machining, as it impacts product quality and performance.

Acrylic’s unique properties make it a top choice for many manufacturers.

Cast Acrylic vs. Extruded Acrylic

Cast acrylic and extruded acrylic offer distinct properties:

| Type | Strengths | Best Uses |

| Cast Acrylic | High transparency, impact resistance | Retail displays, optics |

| Extruded Acrylic | Cost effective, easier to cut | Signage, mass production |

Cast acrylic provides superior optical clarity and impact resistance, ideal for acrylic parts requiring precision, such as lenses.

Extruded acrylic is cost effective, making it suitable for high volume CNC acrylic machining projects like signage.

Material selection ensures acrylic CNC cutting meets project specifications.

Comparing Acrylic to Other Materials

Acrylic outperforms other materials like glass, wood, or aluminum in cost effectiveness and machinability.

Unlike glass, acrylic is lighter and highly resistant to impacts, reducing breakage.

Compared to wood, acrylic offers a smooth finish without grain issues.

While aluminum is durable, acrylic is easier to cut and form, making it ideal for complex shapes. The clear polymer’s refractive index ensures high transparency, perfect for retail displays.

Proper material selection ensures CNC machining acrylic parts delivers durability and precision, meeting industry standards for quality.

Best Practices for CNC Machining Acrylic

Achieving high quality acrylic parts requires following tips and techniques to prevent melting, stress cracking, or damage.

These best practices optimize acrylic CNC machining.

Optimizing Spindle Speed and Feed Rate

Controlling spindle speed and correct feed rate is crucial for CNC acrylic cutting. High spindle speeds with a steady rate ensure clean edges and minimal damage.

A specialized bit, such as a single-flute razor sharp cutter, reduces heat buildup, preventing melting. The following tips help:

- Use just the right amount of pressure to avoid stress cracking.

- Adjust feed rate to maintain a smooth ramp for complex geometries.

- Keep the acrylic cool with air or coolant to prevent melting.

Post Processing and Finishing Tips

Post processing enhances the smooth finish of CNC machined acrylic.

Flame polishing or sanding removes imperfections, while UV light-resistant coatings protect acrylic parts for outdoor applications.

Manufacturers should test post processing on small acrylic pieces to ensure optical clarity and durability.

These techniques ensure acrylic CNC machining delivers high quality parts with clean edges.

The best practices for CNC machining PMMA ensure precision, durability, and aesthetic appeal, making acrylic parts suitable for many industries.

Applications of Acrylic CNC Machining

Acrylic CNC machining supports numerous applications across industries, producing acrylic parts with high transparency and impact resistance. Its versatility drives its adoption.

Retail Displays and Signage

CNC acrylic machining creates retail displays and signage with optical clarity and smooth finish.

Acrylic cutting produces clean edges for professional designs, while acrylic drilling adds design features like mounting holes.

Cast acrylic’s high transparency makes it ideal for showcases, outperforming glass in durability and cost effectiveness.

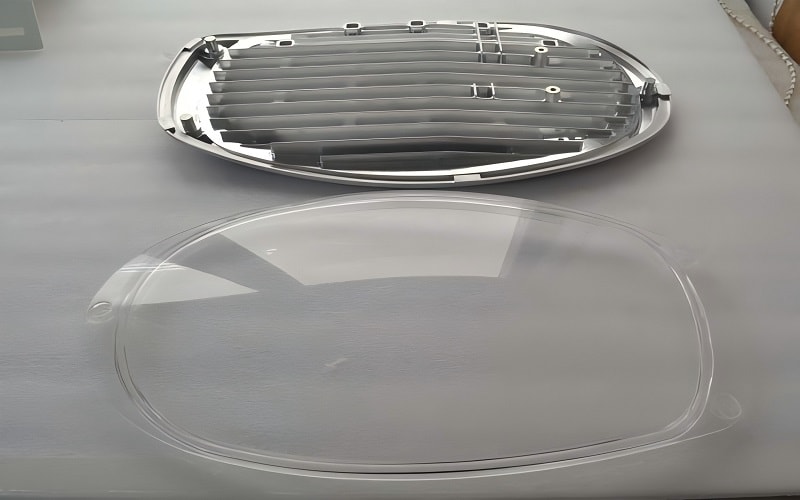

Automotive and Medical Components

CNC machining acrylic parts is used in automotive for dashboards or lenses, leveraging acrylic’s impact resistance.

In medical applications, CNC acrylic produces device components with biocompatible cast acrylic, ensuring precision and durability.

Acrylic parts withstand UV light and harsh environments, making them suitable for outdoor applications.

Industrial and Prototyping Applications

CNC acrylic machining supports prototyping for complex shapes, allowing manufacturers to test design features.

Acrylic pieces are used in industrial components like covers or panels, offering cost effective alternatives to aluminum.

The process’s high precision ensures consistent quality for project needs.

Challenges and Solutions in Acrylic CNC Machining

Acrylic CNC machining faces challenges that require expertise to ensure quality. Addressing these ensures high precision and durability in acrylic parts.

Preventing Melting and Stress Cracking

Melting and stress cracking are common issues in CNC machining PMMA. The following tips help:

- Use a specialized bit to reduce heat buildup during CNC acrylic cutting.

- Maintain correct feed rate and spindle speed to prevent melting.

- Keep acrylic cool with air cooling to avoid thermal damage.

- Test acrylic drilling on scrap acrylic pieces to minimize stress cracking.

Ensuring Precision and Quality

Achieving tight tolerances requires process control.

CNC mills must be calibrated, and post processing should avoid over-polishing to maintain optical clarity.

Injection molding experts can guide manufacturers in optimizing CNC acrylic machining for complex geometries, ensuring minimal damage and high quality.

Conclusion

Acrylic CNC machining is a versatile process that delivers high precision acrylic parts for many industries, from retail displays to automotive and medical applications.

By mastering CNC acrylic cutting, acrylic drilling, and post processing, manufacturers achieve clean edges, smooth finish, and optical clarity using cast acrylic or extruded acrylic.

The numerous advantages of CNC machining PMMA, including cost effectiveness, impact resistance, and durability, make it ideal for complex shapes and outdoor applications.