What is selective laser sintering?

Selective laser sintering (SLS) is a transformative additive manufacturing technology that uses a high-powered laser to fuse small particles of powdered materials into durable parts with complex geometries.

As a key additive manufacturing method, SLS 3D printing produces functional parts and rapid prototypes with excellent mechanical properties, thermal stability, and surface finish, making it a cost-effective alternative to traditional manufacturing methods like injection molding.

This guide explores the selective laser sintering process, its benefits, materials, and applications, providing insights into why SLS technology is a cornerstone of modern 3D printing.

What is Selective Laser Sintering?

Selective laser sintering SLS is a powder bed fusion process that sets itself apart from other additive manufacturing technologies by offering design freedom and versatility.

To understand its significance, it’s essential to examine how the SLS process works and how it compares to other additive manufacturing methods.

How the SLS Process Works

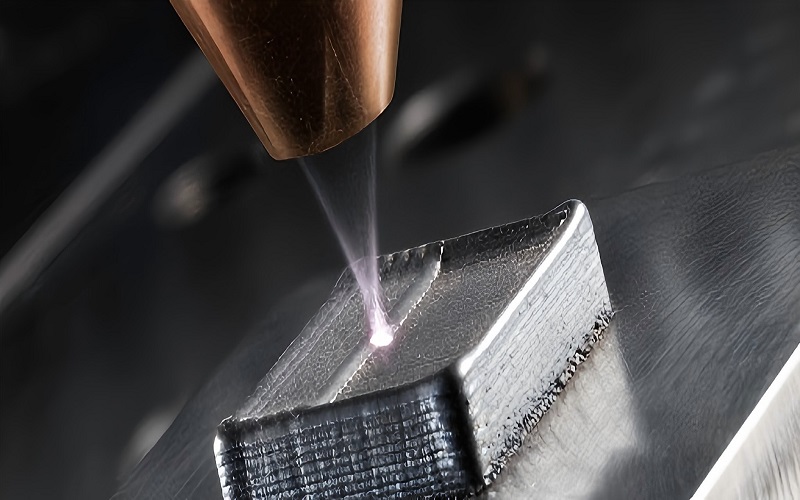

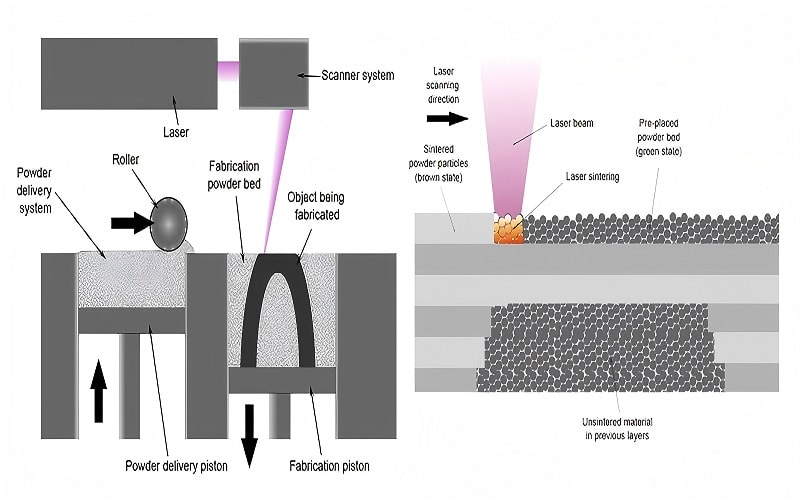

The selective laser sintering process involves a high-powered laser that selectively fuses powdered materials, such as polymer powder or thermoplastic polyurethane, in a powder bed to form a solid structure.

A thin layer of powdered material is spread across a build chamber, and the laser scans cross-sections of a digital model, fusing small particles to create SLS parts.

The process repeats for each layer thickness, typically 50-200 microns, with unsintered powder acting as support structures.

This eliminates the need for support removal, enabling complex geometries and mechanical joints in functional prototypes.

SLS vs. Other Additive Manufacturing Methods

Unlike selective laser melting or direct metal laser sintering, which fully melt powder particles to their melting point, SLS uses laser sintering to bond small particles below the melting point, preserving thermal stability.

Compared to fused deposition modeling, SLS 3D printing doesn’t require support structures due to the loose powder in the powder bed, making it ideal for producing complex SLS parts.

This distinguishes selective laser sintering from other additive manufacturing technologies and traditional manufacturing methods like injection molding, which rely on production tooling.

The SLS process leverages recycled powder, reducing waste and enhancing cost savings, making it a cost-effective alternative for rapid prototyping and medium production runs.

Its ability to produce multiple parts in a single build chamber further enhances efficiency.

Benefits of Selective Laser Sintering

The selective laser sintering SLS process offers numerous advantages, making it a preferred choice for additive manufacturing.

Its mechanical properties and design flexibility drive its adoption across industries.

Complex Geometries and Design Freedom

SLS 3D printing excels at creating complex geometries that are challenging for traditional manufacturing methods like injection molding.

The powder bed fusion process allows SLS machines to produce functional parts with intricate features, such as mechanical joints or internal channels, without production tooling.

The unsintered powder acts as support structures, enabling design freedom for end-use components and functional prototypes.

Excellent Mechanical and Thermal Properties

SLS material properties include consistent mechanical properties, isotropic mechanical properties, and excellent mechanical properties, ensuring durable parts with uniform strength.

Materials like thermoplastic polyurethane or carbon fiber-reinforced polymer powder offer chemical resistance, heat resistance, and wear resistance, making SLS parts suitable for medical devices, automotive interior components, and industrial applications.

The thermal properties provide temperature resistance, ensuring performance in high-heat environments.

Cost-Effectiveness and Efficiency

SLS printing supports medium production runs and rapid prototyping, offering cost savings over traditional manufacturing.

Recycled powder reduces material waste, while the powder bed eliminates the need for support removal, streamlining production.

SLS technology allows multiple parts to be produced in a single build chamber, making it a cost-effective alternative for low volume production and functional testing.

The Selective Laser Sintering Process

The SLS process is a sophisticated printing process that transforms powdered materials into SLS parts with high precision.

Understanding its steps is key to mastering selective laser sintering for 3D printing.

Key Stages of SLS Printing

In the selective laser sintering process, a thin layer of powdered material is spread across a powder bed in a build chamber.

A high-powered laser scans the previous layer, fusing small particles to form a solid structure. The powder bed is lowered by one layer thickness, and a new thin layer is applied, repeating the sintering process until the SLS parts are complete.

Unsintered powder supports the desired three-dimensional shape, eliminating the need for support structures.

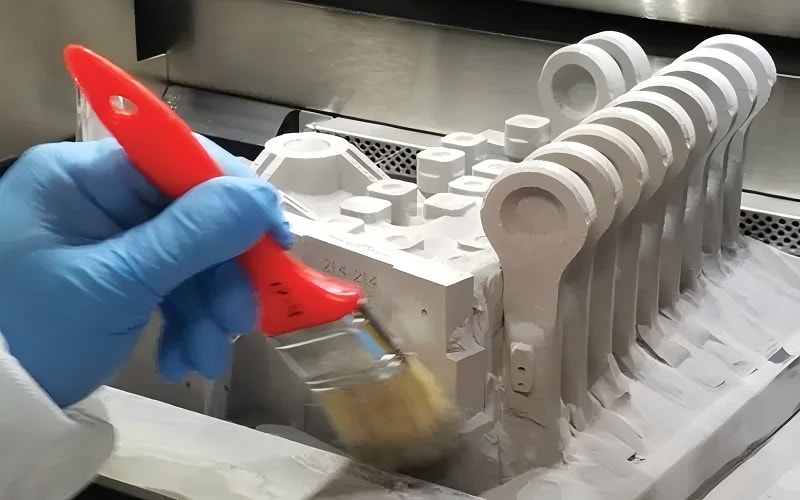

After printing, loose powder is removed, revealing durable parts with consistent mechanical properties.

Post-Processing Techniques

Post-processing solutions enhance the surface finish of SLS parts. Techniques like vapor smoothing or dyeing improve aesthetics and durability, making printed parts suitable for end-use components.

Post-processing techniques also address minor imperfections, ensuring high-quality surface finish and dimensional accuracy. The recycled powder is sieved and reused, contributing to cost savings and sustainability in the SLS process.

The SLS process’s ability to produce complex SLS parts without production tooling makes it a versatile additive manufacturing method, ideal for rapid prototyping and functional parts.

SLS Materials and Their Properties

The material diversity of selective laser sintering SLS allows manufacturers to select SLS materials tailored for specific applications.

These materials offer a range of mechanical properties to meet industry demands.

Common SLS Materials

SLS materials include polymer powder, thermoplastic polyurethane, and carbon fiber-reinforced powders, each providing distinct properties.

Thermoplastic polyurethane offers high elasticity and chemical resistance, ideal for flexible functional parts.

Nylon provides good mechanical properties and temperature resistance, suitable for automotive interior components or medical devices.

Carbon fiber enhances tensile strength and heat resistance, making it ideal for industrial applications requiring durable parts.

Material Properties and Performance

SLS material properties include isotropic mechanical properties, ensuring uniform strength across printed parts.

Chemical resistance and wear resistance make SLS parts suitable for harsh environments, while thermal stability and heat resistance support performance in high-temperature settings.

The powder form of SLS materials allows precise sintering, ensuring dimensional accuracy and excellent mechanical properties for end-use components.

Applications of Selective Laser Sintering

Selective laser sintering SLS is widely used in industries for rapid prototyping, low volume production, and end-use components.

Its versatility makes it a preferred additive manufacturing technology.

Rapid Prototyping and Functional Testing

SLS 3D printing is ideal for rapid prototyping, enabling functional testing of complex geometries without production tooling.

SLS parts can be produced quickly with dimensional accuracy, allowing engineers to test functional prototypes for medical devices, automotive interior components, or consumer goods.

The material diversity supports testing under real-world conditions, ensuring performance and reliability.

Production Parts and End-Use Components

SLS technology excels in medium production runs, producing production parts with excellent mechanical properties and high-quality surface finish.

Automotive interior components, such as dashboards, and medical devices, like prosthetics, benefit from SLS printing’s ability to produce complex plastic parts.

End-use components leverage SLS’s design freedom and durability, making it a cost-effective alternative to injection molded parts.

Industrial and Consumer Applications

In industrial applications, SLS parts are used for functional parts like gears or housings, leveraging wear resistance and heat resistance.

In consumer goods, SLS printing produces printed parts like wearables or protective cases, benefiting from high elasticity and surface finish.

The powder bed fusion process supports multiple parts in a single build chamber, enhancing efficiency for medium production runs.

Challenges in Selective Laser Sintering

While selective laser sintering offers numerous advantages, manufacturers must address challenges to ensure superior 3D printing outcomes. These considerations are critical for optimizing SLS printing.

Material Handling and Powder Management

Material handling in SLS 3D printing requires careful management of powdered materials to prevent contamination and ensure consistent powder form.

Recycled powder must be sieved to maintain quality, and improper handling can affect dimensional accuracy or surface finish.

SLS machines require regular maintenance to ensure performance in the sintering process, impacting cost savings.

Processing and Post-Processing Challenges

The selective laser sintering process demands precise control of laser sintering parameters, such as layer thickness or laser power, to avoid defects in printed parts.

Higher temperatures can cause material degradation, reducing mechanical properties or thermal stability.

Post-processing solutions like vapor smoothing add time to the production process but are necessary for high-quality surface finish and dimensional accuracy.

Managing these factors ensures durable parts for end-use components.

Conclusion

What is selective laser sintering?

Selective laser sintering (SLS) is a powerful additive manufacturing technology that uses a high-powered laser to selectively fuse powdered materials in a powder bed, creating SLS parts with complex geometries, excellent mechanical properties, and high-quality surface finish.

From thermoplastic polyurethane to carbon fiber-reinforced polymer powder, SLS materials offer chemical resistance, heat resistance, and isotropic mechanical properties, making them suitable for medical devices, automotive interior components, and consumer goods.

Compared to other additive manufacturing methods like fused deposition modeling or traditional manufacturing like injection molding, SLS 3D printing provides cost savings, design freedom, and rapid prototyping capabilities.

For companies seeking functional prototypes, medium production runs, or end-use components, selective laser sintering SLS is the best choice.

Contact an SLS printers provider today to explore SLS technology and experience its benefits for your production needs.