Injection molding short run is a cost-effective solution for low volume production, enabling many businesses to produce limited quantities of high-quality parts without the expensive tooling associated with high volume production.

By leveraging short run injection molding, industries like the automotive industry and medical devices can meet market demands with greater flexibility and faster turnaround.

This guide explores the manufacturing process, benefits of short run, tooling options, and applications of short run molding, providing insights into why it’s ideal for rapid prototyping, market testing, and niche markets.

Understanding Injection Molding Short Run

Short run injection molding is a specialized production process within plastic injection molding designed to produce limited quantities, typically ranging from a few hundred to a few thousand units.

Its ability to deliver high precision parts with lower upfront costs makes it a game-changer for various industries.

To appreciate its value, let’s dive into its core principles and how it differs from traditional methods.

What is Short Run Injection Molding?

Injection molding short run involves using aluminum molds or softer materials to create plastic parts in small batches, unlike steel molds used in large scale production.

The molding process injects molten plastic into a mold cavity, where the material cools to form a finished part.

This process is ideal for low volume runs, offering cost savings and faster turnaround compared to high volume production.

Short run molding supports rapid prototyping and market testing, allowing many businesses to refine product development without sacrificing quality.

How It Differs from High Volume Production?

Unlike high volume production, which uses steel molds to produce even millions of parts, short run injection molding focuses on limited quantities with aluminum injection molds.

These aluminum molds reduce tooling costs and lead time, making short run projects more cost-effective.

While high volume production is suited for large scale production, short run molding provides the same level of high precision for niche markets or limited edition products, offering greater flexibility in production volume.

Benefits of Short Run Injection Molding

The benefits of short run injection molding are numerous, making it a preferred choice for many businesses seeking cost-effective production processes.

Its main advantages include flexibility, cost savings, and speed, which we’ll explore in detail.

Lower Upfront Costs and Tooling Savings

One of the main advantages of short run injection molding is its lower upfront costs.

Aluminum molds are less expensive than steel molds, reducing tooling costs significantly.

This makes short run molding a cost-effective solution for small quantities, typically ranging from a few hundred to a few thousand units.

The rapid tooling process further minimizes production costs, enabling many businesses to launch new projects without heavy investment in expensive tooling.

Faster Turnaround and Market Entry

Short run injection molding provides faster turnaround times, allowing parts produced to reach the market faster.

The rapid tooling and molding process streamline production, reducing lead time compared to traditional manufacturing methods like 3D printing for production parts.

This speed is critical for market testing or limited edition products, ensuring many businesses can respond to market demands with high-quality parts at the same level of precision as high volume production.

Flexibility in Product Development

Short run molding offers greater flexibility in refining product designs and material selection.

Injection molding services allow many businesses to test functional prototypes or small batches before committing to large scale production.

This flexibility supports niche markets and product development, enabling industries like the automotive industry and medical devices to produce plastic parts tailored to specific applications without sacrificing quality.

The Injection Molding Short Run Process

The manufacturing process of short run injection molding is a streamlined version of plastic injection molding, optimized for low volume production.

Understanding its steps is key to leveraging its numerous benefits.

Key Stages of the Molding Process

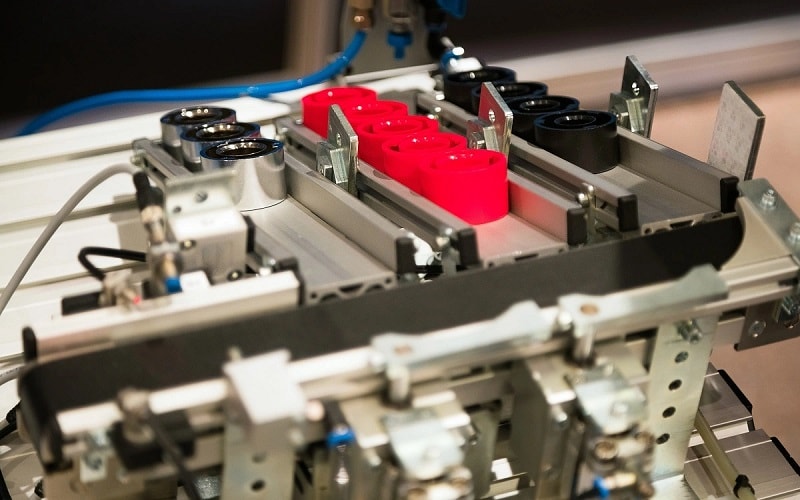

The short run molding process begins with designing an aluminum mold or using softer materials for the mold cavity.

Molten plastic is injected into the mold, where it cools to form a finished part.

The mold is then opened, and the parts produced are removed.

This process is repeated to produce limited quantities, typically ranging from a few hundred to thousand units.

The rapid tooling ensures faster turnaround, making short run injection molding ideal for rapid prototyping or low volume runs.

Material Selection and Tooling Options

Material selection is critical in short run injection molding to ensure high-quality parts.

Common plastics like thermoplastic polyurethane or nylon are chosen for their durability and flexibility.

Aluminum injection molds offer cost-effective tooling options, reducing production costs compared to steel molds.

These tooling options enable many businesses to produce small batches with high precision, supporting market testing or limited edition products.

Comparison of Short Run vs. High Volume Injection Molding

This table illustrates the main advantages of short run injection molding for low volume production and rapid prototyping, compared to high volume production using steel molds.

| Aspect | Short Run Injection Molding | High Volume Injection Molding |

| Tooling | Aluminum molds or softer materials | Steel molds |

| Production Volume | Low volume (a few thousand units) | High volume (even millions) |

| Tooling Costs | Lower upfront costs | Expensive tooling |

| Lead Time | Faster turnaround | Longer due to complex tooling |

| Applications | Rapid prototyping, market testing | Large scale production |

| Flexibility | Greater flexibility for small batches | Limited flexibility, suited for mass production |

| Cost Effectiveness | Cost-effective for limited quantities | Cost-effective for high volume production |

Applications of Short Run Injection Molding

Injection molding short run is widely used across various industries for its ability to produce high-quality parts in small quantities.

Its versatility makes it a go-to solution for niche markets and product development.

Automotive Industry

The automotive industry relies on short run molding to produce plastic parts like interior components or prototypes for market testing.

Aluminum molds enable rapid prototyping of limited quantities, allowing manufacturers to test designs before committing to large scale production.

The high precision of short run injection molding ensures parts produced meet stringent automotive standards without sacrificing quality.

Medical Devices

Medical devices benefit from short run injection molding for producing small batches of components like surgical tools or device housings.

The molding process supports material selection for biocompatible plastics, ensuring high-quality parts for medical applications.

Injection molding services provide faster turnaround, enabling many businesses to meet market demands with cost-effective solutions.

Consumer Goods and Niche Markets

In consumer goods, short run molding is used for limited edition products or niche markets, such as custom electronics or specialty packaging.

The ability to produce limited quantities with high precision supports refining product designs and market testing.

Short run plastic parts, like casings or accessories, offer the same level of quality as high volume production, making short run projects a cost-effective solution.

Challenges in Short Run Injection Molding

While short run injection molding offers numerous benefits, manufacturers must address challenges to ensure high-quality parts.

These considerations are critical for optimizing the production process.

Tooling Costs and Material Limitations

Although aluminum molds reduce tooling costs, they are less durable than steel molds, limiting their lifespan for medium production runs.

Material selection is also critical, as softer materials may not withstand high-stress applications.

Many businesses must balance cost with performance, ensuring the right material is chosen for specific applications without sacrificing quality.

Production Volume and Scalability

Short run injection molding is optimized for low volume production, typically ranging from a few hundred to a few thousand units.

Scaling to large scale production may require transitioning to steel molds, increasing production costs.

Manufacturers must plan production volume carefully to maintain cost-effectiveness and meet market demands for small batches or limited edition products.

Conclusion

Injection molding short run is a cost-effective manufacturing process that delivers high-quality parts for low volume production, rapid prototyping, and market testing.

By using aluminum molds and softer materials, short run injection molding reduces tooling costs and lead time, offering greater flexibility for various industries like the automotive industry, medical devices, and consumer goods.

The ability to produce limited quantities with high precision and faster turnaround makes short run molding a cost-effective solution for niche markets and limited edition products.

Compared to high volume production or 3D printing, short run injection molding provides the same level of quality with lower upfront costs.

Contact a trusted provider today for an instant quote and experience the benefits of short run injection molding for your new project.