Polyester is everywhere in our daily lives, from the clothes we wear to the bottles we drink from.

But have you ever wondered how this popular material gets made?

In this guide, we’ll break down the whole process step by step.

We’ll cover what polyester is, the raw materials involved, how it’s produced, its different types, properties, uses, and even its impact on the environment.

By the end, you’ll have a clear picture of how polyester goes from basic chemicals to the fabrics and products we use every day.

Let’s dive in.

What is Polyester?

Polyester is a type of synthetic fiber that’s super common in textiles and other items.

It’s known for being strong, cheap, and versatile. But to really understand it, we need to look at its basics.

First off, polyester is a polymer, which means it’s made up of large molecules formed by linking smaller ones together.

The most common type is polyethylene terephthalate, often referred to as polyethylene terephthalate PET or simply PET for short.

Polyethylene terephthalate PET is what you’ll find in most polyester clothing, polyester fabric, and even plastic bottles.

Polyester falls under synthetic materials, meaning it’s man-made rather than coming from natural sources like cotton or wool.

It’s created through a chemical reaction that combines acids and alcohols. This makes it different from natural fibers, which come from plants or animals.

There are a few types of polyester out there.

Besides polyethylene terephthalate PET, there’s PCDT polyester, which is a bit more elastic but less common. Most of what we use today is PET, though.

Raw Materials Used in Polyester Production

Before we get into how polyester is made, let’s talk about what goes into it.

The raw materials are key to the whole process.

The main ingredients are terephthalic acid and ethylene glycol. Terephthalic acid comes from crude oil, which is a fossil fuel and a non-renewable resource.

Ethylene glycol is also derived from petroleum products.

Sometimes, dimethyl terephthalate (a dimethyl ester) is used instead of terephthalic acid, but the idea is the same.

These chemicals are mixed in a process called esterification reaction or direct esterification.

It’s basically a chemical reaction where two or more molecules combine to form the polyester polymer.

In recent years, there’s been a push for recycled polyester. This uses recycled plastics, like old water bottles or plastic products, to make new polyester. It helps reduce waste and reliance on virgin polyester from fresh raw materials.

Other chemicals might be added for specific properties, but the core is always those acid and alcohol combos. Since it’s based on fossil fuels, polyester production ties into bigger issues like using non-renewable resources.

The Production Process of Polyester

Now, let’s get to the heart of it: how is polyester made?

The production process involves several steps, from creating the polymer to spinning it into fibers.

It’s done on a large scale in factories for commercial production.

The process starts with polymerization, where the raw materials turn into a thick liquid.

Then, it’s spun into fibers through methods like melt spinning.

After that, the fibers are stretched and treated to make them usable.

Step 1: Polymerization

To kick things off, we need a smooth transition into the first big step. Polymerization is where the magic begins, turning simple chemicals into the base material for polyester.

In this phase, terephthalic acid and ethylene glycol are heated together at high temperatures. This causes an esterification reaction, forming PET resin—a molten polymer.

If using dimethyl terephthalate, it’s a similar chemical reaction but with a transesterification twist.

The result is a viscous liquid that’s like hot glue. This PET production happens in big reactors, and it’s crucial for getting the right chemical structure. The polymer chains need to be long enough for strength.

Step 2: Spinning

Once we have the polymer, it’s time to shape it into fibers. This leads us naturally into the spinning process, which turns the liquid into threads.

The most common method is the melt spinning process. The hot PET resin is pushed through tiny holes called spinnerets, like squeezing toothpaste. As it cools, it hardens into continuous fibers or polyester filaments.

For staple fiber, these filaments are cut into short lengths later. This spinning creates the basic polyester fibers, ready for further processing.

Step 3: Drawing and Texturing

After spinning, the fibers aren’t quite done. We need to make them stronger and more usable, which brings us to drawing and texturing.

Drawing involves stretching the fibers to align the molecules, improving mechanical properties like strength and heat resistance. Then, texturing adds crimp or twist to make them feel more like natural fibers.

Finally, heat setting locks in these changes by applying heat. This makes the polyester highly resistant to wrinkles and stains.

The whole production process is efficient and low-cost, which is why polyester fabric cost is often cheaper than other fabrics.

Types of Polyester Fibers

Polyester comes in different forms depending on how it’s processed. This variety makes it useful for all sorts of things.

We can break it down into main categories like staple fiber and filament yarn. Each has its own uses.

Polyester staple fiber is short and fluffy, like cotton. It’s great for blending with natural fibers.

Polyester filaments are long, continuous fibers that make smooth, silky fabrics.

There’s also polyester polymer used in composite materials or industrial materials, beyond just textiles.

Properties of Polyester

What makes polyester so popular? Its properties set it apart from other fibers.

Below is a table summarizing the key characteristics of polyester with specific performance metrics.

| Property | Description | Performance Metric |

| Wrinkle Resistance | Resists creasing, stays smooth after use | 90% wrinkle recovery after 5 minutes |

| Stain Resistance | Repels spills, easy to clean | 80% stain removal with mild detergent |

| Heat Resistance | Withstands high temperatures without melting | Stable up to 250°C for short exposure |

| Color Fastness | Retains dye well, resists fading | 4-5 rating on AATCC colorfastness scale |

| Mechanical Strength | Strong and durable, resists tearing | Tensile strength of 5-7 g/denier |

| Electrical Insulation | Prevents electrical conductivity | Dielectric strength of 15-20 kV/mm |

Polyester is wrinkle resistant and has great wrinkle resistance, meaning your polyester clothes don’t crease easily.

It’s also stain resistant, so spills wipe off without much hassle. Heat resistance is another plus; it can handle high temperatures without melting right away.

Color fastness means dyes stick well, so colors don’t fade quickly.

Mechanically, it’s strong with good electrical insulation, making it useful in conveyor belts or electronics.

Compared to natural fibers like cotton, it’s more durable but less breathable.

Applications of Polyester

Polyester isn’t just for clothes; it has tons of uses.

In clothing, polyester clothing and polyester clothes are common because they’re cheap and easy to care for.

For home furnishings, think bed sheets, curtains, or home textiles—polyester fabric is soft and long-lasting.

It’s in stuffed animals, pillows, and even synthetic fabric for upholstery.

Industrially, it’s in conveyor belts, ropes, or composite materials.

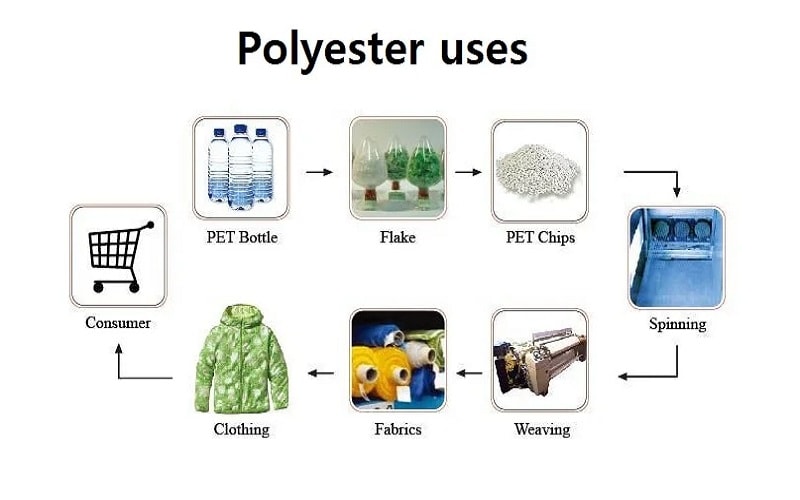

And don’t forget plastic bottles—PET polyester is recycled into water bottles or other plastics.

Polyester fabric produced worldwide goes into everything from fashion to tech.

Recycled Polyester and Sustainability

As we think about polyester’s future, recycling is a big topic. It helps address some downsides.

Recycled polyester comes from melting down old plastic bottles or recycled plastics. The process is similar to virgin polyester but uses less crude oil.

This reduces reliance on fossil fuels and non-renewable resources. It’s a step toward using renewable resources, though polyester itself isn’t fully sustainable yet.

However, polyester fabric impact includes microplastic pollution from washing synthetic fabric.

Still, advances in recycled polyester are making it better for the planet.

Environmental Impact of Polyester

Polyester has pros and cons for the environment.

On the downside, it’s made from crude oil, contributing to fossil fuel use. Production releases chemicals and uses energy.

Polyester fabric impact includes shedding tiny fibers that pollute water.

But it’s durable, so items last longer, reducing waste.

Compared to natural fibers, it uses less water in production but more energy.

Efforts like using recycled materials help, but it’s not perfect.

Comparison with Other Fibers and Fabrics

How does polyester stack up against others?

Versus cotton: Polyester is cheaper and more wrinkle resistant, but cotton is more breathable and from renewable resources.

Synthetic fiber like polyester vs. natural fibers: Synthetics are low cost but can feel less comfy.

Other fabrics like wool or silk are pricier and less versatile.

Polyester often blends with them for the best of both worlds.

In terms of making polyester vs. other fibers, it’s more chemical-heavy.

Conclusion

This guide has detailed the polyester production process, from raw materials like terephthalic acid and ethylene glycol to polymerization, melt spinning, and final processing into products like clothing, home furnishings, and plastic bottles.

The efficient manufacturing process makes polyester a cornerstone of various industries.

Despite environmental challenges tied to fossil fuel use, advancements in recycled polyester are improving sustainability.

This comprehensive overview clarifies how polyester is made and its role in everyday products.