Injection molding is a go-to method for creating high-quality plastic products used in tons of industries, from food and beverage to electronics.

It’s fast, precise, and perfect for making complex designs in high volume.

This guide dives into the top injection molding products, how the process works, and why it’s such a game-changer for manufacturing.

We’ll keep things clear and simple, so you can see how injection molding delivers innovative solutions for all kinds of projects.

What is Injection Molding?

Injection molding technology is a manufacturing process that produces precision plastic components by injecting molten plastic into a mold.

Its widespread adoption stems from its cost-effectiveness, reliability, and ability to produce products ranging from micro-components to large containers.

How Injection Molding Works?

The injection molding process starts with an injection molding machine, which melts thermoplastic resins into molten plastic.

This liquid plastic is then injected into a mold designed to match the desired part’s shape. Once the plastic cools and hardens, the mold opens, and out pops the finished part.

The process is great for tight tolerances, meaning parts come out exactly as designed, with smooth surfaces and high durability.

It’s used for both prototyping and high-volume production, making it a versatile choice for manufacturers.

Why Choose Injection Molding?

Injection molding stands out for several reasons.

It’s perfect for high volume production because it’s fast and consistent, keeping part quality high even during long production runs.

The process supports a wide range of plastic materials, so you can pick the right one for your project.

Plus, it’s cost-effective, especially for large batches, and can handle complex designs that other methods struggle with.

These advantages make it a top choice across industries.

Top Injection Molding Products

Injection molding produces a huge variety of plastic products, from everyday items to specialized components. Let’s explore some of the most common and innovative products made with this process, focusing on key industries.

Food and Beverage Industry

The food and beverage industry relies heavily on injection molding for safe, durable packaging.

Products like bottle caps, food containers, and beverage packaging are made using plastic injection molding to meet strict food contact standards.

These injection molded parts are lightweight, cost-effective, and designed with tight tolerances to ensure a secure seal, keeping food and beverages fresh.

For example, bottle caps are molded with precision to prevent leaks, while containers are made to stack neatly for storage.

The ability to produce these items in high volume makes injection molding the perfect solution for this industry.

Consumer Electronics

Injection molding electronics is a big deal in the tech world.

Plastic parts like casings, connectors, and light switches are made with this process to protect delicate circuits while keeping devices sleek and lightweight.

Electronics injection molding ensures components fit perfectly, with smooth surfaces and precise shapes that support the reliability of consumer electronics.

For instance, plastic frames for smartphones or keyboards are molded to exact specifications, balancing durability with a polished look.

The process’s ability to handle complex designs makes it ideal for the fast-paced electronics market.

Medical Devices

In the medical field, injection molding creates critical components for devices like syringes, inhalers, and diagnostic tools.

These injection molded parts must meet strict standards for safety and precision, as they’re often used in life-saving equipment.

Plastic materials chosen for medical devices are non-toxic and durable, ensuring reliability during use.

The molding process allows for tight tolerances, so parts fit together perfectly, and the cost-effectiveness of high-volume production keeps medical devices affordable.

This makes injection molding a crucial part of medical manufacturing.

Consumer Products

From toys to household goods, injection molding produces a wide range of consumer products.

Items like plastic frames, storage bins, and kitchen tools are made with this method because it’s low cost and supports high volume production.

The process allows manufacturers to create complex shapes, like intricate toy designs or ergonomic tool handles, without sacrificing quality.

These products are durable, lightweight, and often customizable with different colors or textures, making them popular in the consumer market.

The Injection Molding Process

Understanding the injection molding process is key to seeing why it’s so effective. This section breaks down the steps and tools involved, so you can grasp how manufacturers turn raw materials into finished products.

Material Selection

Choosing the right plastic materials is a big part of injection molding.

Thermoplastic resins, like polyethylene or polypropylene, are commonly used because they can be melted and reshaped multiple times.

The material selection depends on the project’s needs—some plastics are chosen for durability, others for flexibility or food contact safety.

Manufacturers work closely with designers to pick materials that balance cost, strength, and performance, ensuring the end product meets quality standards.

Tooling Design

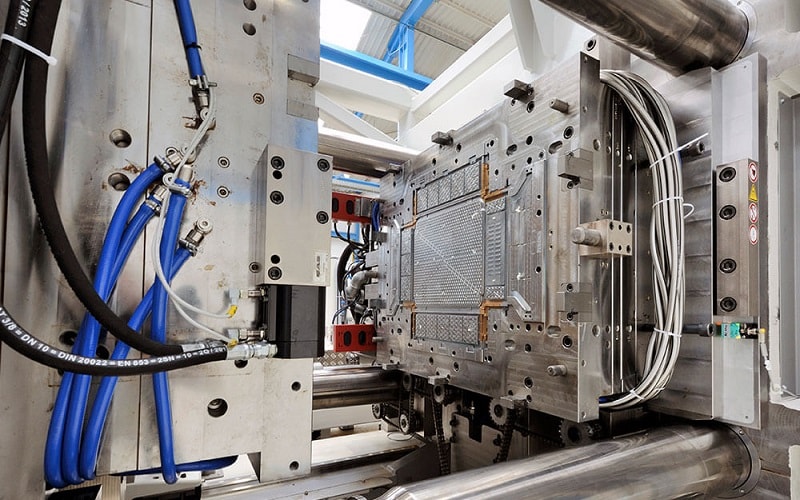

The mold, or tooling, is the heart of the injection molding process. Tooling design involves creating a mold that matches the exact shape and size of the desired part.

Molds are typically made from steel or aluminum for durability, especially for high-volume production runs.

A well-designed mold ensures tight tolerances and a smooth surface, which are critical for part quality.

Designing the mold takes time and precision, but it’s worth it for the consistent results it delivers.

Production Process

Once the mold is ready, the production process begins. The injection molding machine heats the plastic material until it becomes molten plastic, then injects it into the mold under high pressure.

The plastic fills every detail of the mold, creating precise shapes.

After cooling, the mold opens, and the part is ejected. This process is fast, often taking seconds per part, making it ideal for high volume production.

Manufacturers can produce thousands of identical parts with minimal waste, ensuring cost-effectiveness and reliability.

Benefits of Injection Molding

Injection molding offers a bunch of advantages that make it a top choice for manufacturing. Here’s why companies love this method for creating innovative products.

Precision and Quality

The injection molding process is known for its precision.

Tight tolerances mean parts come out exactly as designed, with no variation between pieces.

This is crucial for industries like electronics and medical devices, where even tiny errors can cause problems.

The process also delivers high part quality, with smooth surfaces and consistent shapes that don’t need extra finishing.

Cost-Effectiveness

Injection molding is a low-cost option for high volume production.

While the initial tooling design can be expensive, the cost per part drops significantly as production scales up.

This makes it perfect for large production runs, where thousands or millions of parts are needed. The efficiency of the process also reduces material waste, further lowering costs.

Versatility in Design

The ability to create complex designs is a major strength of injection molding.

From intricate connectors to large containers, the process can handle a wide range of shapes and sizes.

Manufacturers can also use different plastic materials to add features like flexibility, transparency, or heat resistance, making injection molding suitable for many applications.

Challenges and Considerations

While injection molding is awesome, it’s not without challenges.

The upfront cost of tooling design can be high, especially for small production runs.

Material selection also requires careful thought to ensure the plastic meets the project’s needs.

Additionally, maintaining the injection molding machine and molds is crucial to avoid defects and keep production running smoothly.

Working with experienced manufacturers helps overcome these challenges and ensures a high-quality end product.

Why Injection Molding is a Market Leader?

Injection molding is a leading manufacturing process because it combines precision, cost-effectiveness, and versatility.

It meets the demands of industries like food and beverage, electronics, and medical devices by producing reliable, high-quality plastic parts.

The ability to create complex designs in high volume makes it a perfect solution for companies looking to innovate.

Whether you’re designing bottle caps, light switches, or medical components, injection molding delivers consistent results that drive the market forward.

Conclusion

Injection molding is a powerful method for creating innovative plastic products, from food packaging to consumer electronics.

By using advanced injection molding machines and precise tooling design, manufacturers can produce high-quality parts with tight tolerances and complex shapes.

The process’s cost-effectiveness and ability to handle high volume production make it ideal for industries with big demands.

Whether you’re in the food and beverage industry, electronics, or medical field, injection molding offers the tools and flexibility to bring your ideas to life with durable, reliable components.