Designing for injection molding is critical for producing high-quality plastic parts efficiently and cost-effectively.

The injection molding process transforms plastic resin into precise molded parts used in industries like automotive, medical, and consumer goods.

However, poor design choices can lead to defects like sink marks, drag marks, or compromised structural integrity, increasing production costs.

This guide explores the essentials of injection molding design, covering material selection, wall thickness, mold cavity considerations, and more.

By following these design guidelines, manufacturers can create injection molded parts that balance cosmetic appearance, functionality, and low-cost production.

Overview of the Injection Molding Process

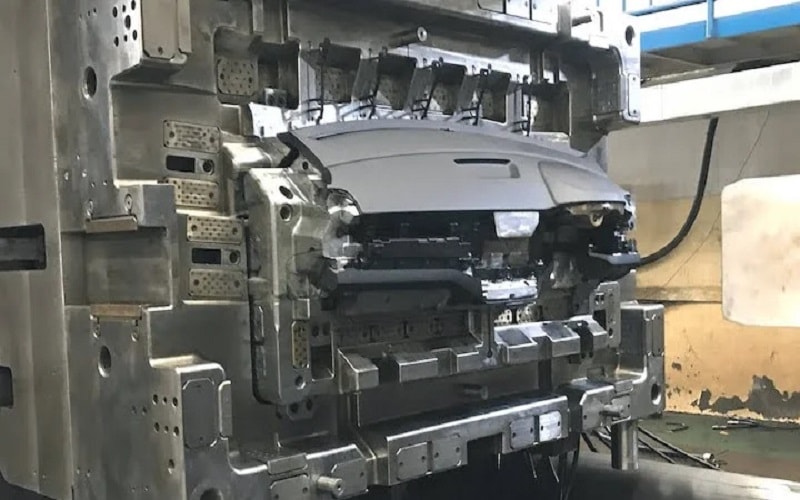

The injection molding process is a versatile manufacturing process for creating high-volume plastic parts, such as bottle caps or automotive components.

It begins with an injection molding machine heating plastic resin into melted plastic, which is then injected under high pressure into a mold cavity.

The mold, consisting of two halves (A side and B side), closes to form the part shape. Once the material cools, the mold opens, and ejector pins release the part.

This injection molding cycle, including cooling time, is optimized for efficiency, often producing tens of thousands of parts.

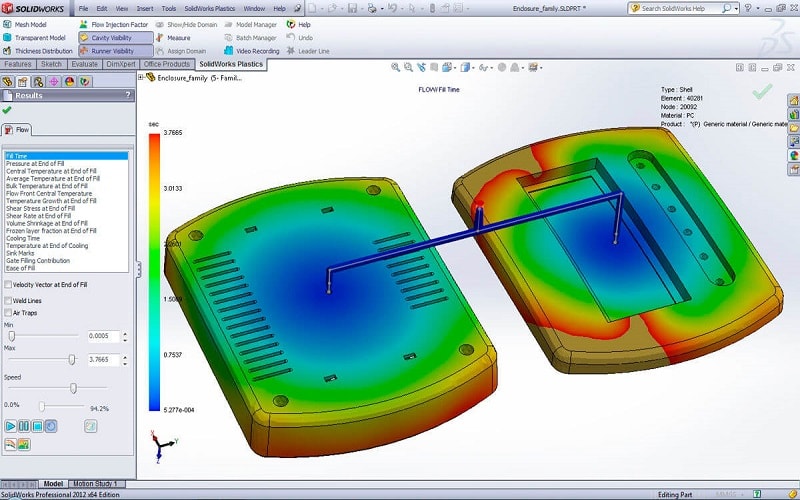

Key to success is understanding how the molding process affects part quality. Factors like material flow, cooling process, and gate position influence the outcome.

For example, improper material flow can cause defects, while a well-designed runner system ensures smooth transitions.

By mastering these elements, designers can minimize secondary operations and tooling costs, achieving cost-effective production.

Key Design Considerations for Injection Molding

Effective injection molding design hinges on several critical factors that ensure part quality and manufacturing efficiency.

These considerations guide the creation of molded parts that meet both functional and aesthetic requirements.

Proper Wall Thickness

Maintaining uniform wall thickness is essential for injection molding success.

Thick wall sections (e.g., >4 mm) can lead to sink marks or extended cooling times, while thinner walls (<1 mm) may cause incomplete filling.

A proper wall thickness, typically 2–4 mm, ensures even material flow and cooling, preserving structural integrity.

For example, designing bottle caps with consistent wall thickness prevents warping and reduces production costs.

Draft Angle and Part Ejection

A draft angle (1–2°) on vertical surfaces facilitates smooth part ejection from the mold.

Without it, drag marks can occur, damaging the mold surface or part’s cosmetic appearance.

Incorporating draft angles on both A and B sides ensures the mold opens without resistance, minimizing defects and wear on ejector pins.

Gate Position and Types

Gate position significantly impacts material flow.

Common gate types, like hot tip gates, edge gates, tunnel gates, or sub gates, must be strategically placed to avoid stress concentrations.

For instance, a tunnel gate near the main body of a part ensures even filling, while improper gate placement can cause flow marks.

Gate removal in secondary operations should also be considered to maintain surface finishes.

Common Injection Molding Defects and Their Causes

Injection molding defects can compromise the quality of plastic parts, increasing costs and delays. Understanding these issues helps designers address them early in the process.

Sink marks occur when thick sections cool unevenly, causing the plastic to shrink and form depressions. Uneven wall thickness or insufficient cooling time often triggers this defect. For example, thick walls in a medical device housing may lead to sink marks, affecting both appearance and functionality.

Drag marks appear when parts stick to the mold during ejection, often due to insufficient draft angles or poor mold surface finishes. These marks damage the cosmetic appearance and may require costly secondary operations.

Flow lines or wavy patterns result from poor material flow, often caused by low material temperature or improper gate position. These defects can weaken the structural integrity of parts, especially in high-stress applications like automotive components.

By anticipating these issues, designers can adjust wall thickness, draft angles, and gate positions to minimize defects and ensure high-quality injection molded parts.

Design Optimization Strategies

Optimizing injection molding design requires a strategic approach to mold building, process parameters, and material selection.

By addressing factors like wall thickness, material flow, and cooling process, designers can reduce defects and production costs.

The table below outlines key parameters and their recommended values for designing successful injection molded parts, serving as a practical guide for manufacturers.

| Parameter | Recommended Value | Purpose |

| Wall Thickness | 2–4 mm | Ensures uniform cooling |

| Draft Angle | 1–2° | Facilitates part ejection |

| Melt Temperature | 200–280°C (e.g., ABS: 230–260°C) | Enhances material flow |

| Mold Temperature | 50–100°C (e.g., PP: 60–80°C) | Prevents uneven cooling |

| Injection Pressure | 80–150 MPa | Ensures complete mold filling |

| Gate Size (e.g., Tunnel Gate) | 1–3 mm | Optimizes material flow |

Mold Design Best Practices

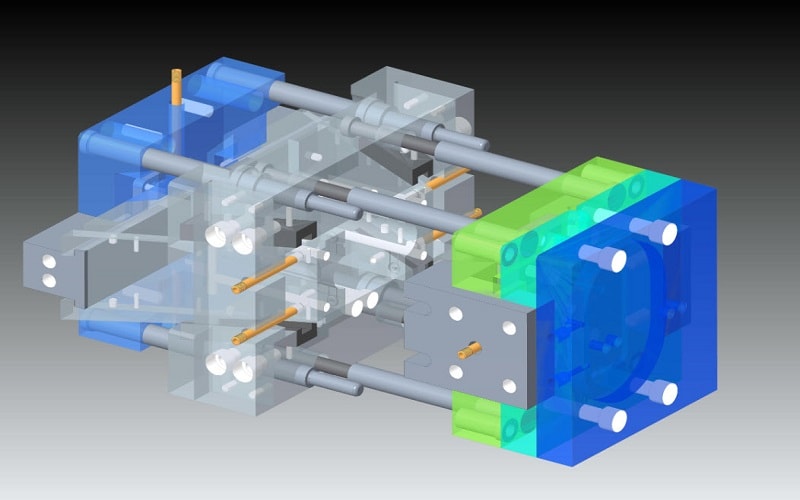

Mold design is the foundation of injection molding success. The mold cavity, formed by the A and B sides, must ensure smooth transitions to avoid stress concentrations.

Strategic gate placement, such as using hot tip gates for small parts or edge gates for larger components, enhances plastic flow.

For example, a tunnel gate in a bottle cap mold ensures even filling, reducing defects. Incorporating support ribs or design ribs in thick sections adds strength without increasing wall thickness, maintaining uniform cooling.

Using CNC machining for mold building ensures precision, creating a flat surface and consistent parting line. Polished mold surfaces or specific surface textures improve part release and cosmetic appearance, reducing the need for secondary operations.

Process Parameter Optimization

Fine-tuning the injection molding cycle is critical for quality.

The injection molding press must deliver adequate injection pressure (80–150 MPa) to fill the mold cavity completely.

Melt temperature (200–280°C) and mold temperature (50–100°C) should be tailored to the plastic resin, ensuring smooth material flow and uniform cooling.

For instance, ABS requires a melt temperature of 230–260°C for optimal flow, while polypropylene needs a mold temperature of 60–80°C to avoid warping.

The runner system and ejection system also play key roles.

A well-designed runner system minimizes material waste, while properly placed ejector pins prevent drag marks during mold opening.

Optimizing cooling time ensures the plastic shrinks evenly, preserving structural integrity.

Material Selection for Injection Molding

Injection molding materials, such as ABS, polypropylene, or polycarbonate, vary in physical properties like viscosity and shrinkage.

High-viscosity materials require higher melt temperatures to ensure smooth plastic flow, while low-shrinkage resins reduce sink marks.

For example, polycarbonate’s high strength suits automotive parts, but its viscosity demands precise temperature control.

Selecting the right material minimizes defects and supports cost-effective production.

Common Questions About Injection Molding Design

To address user search intent, here are answers to common questions about designing for injection molding:

- Why is uniform wall thickness important?

It ensures even cooling, preventing sink marks and maintaining structural integrity.

- How do draft angles affect part quality?

A 1–2° draft angle facilitates ejection, reducing drag marks and mold wear.

- What role does material selection play?

Choosing materials with optimal physical properties minimizes defects and supports cost-effective production.

Conclusion

Designing for injection molding success requires careful attention to wall thickness, draft angles, gate position, and material selection.

By optimizing mold design, fine-tuning process parameters, and choosing the right plastic resin, manufacturers can produce high-quality injection molded parts with minimal defects.

Strategic use of design ribs, proper gate types like hot tip or tunnel gates, and precise CNC machining ensures smooth transitions and cost-effective production.

Through real-world applications and continuous improvement, designers can master the injection molding process, delivering plastic parts that meet stringent aesthetic and functional requirements for high-volume manufacturing.