2 shot injection molding, also known as two shot injection molding, double shot injection molding, or dual shot molding, is a cutting-edge manufacturing process that creates complex multi-material parts in a single mold.

Unlike traditional injection molding, which uses one material, this technique combines two or more materials—such as rigid plastics and liquid silicone rubber—within the same tool, eliminating the need for post-molding assembly.

From toothbrushes with soft grip handles to medical devices with rigid and flexible components, two shot molding delivers seamless, durable products with a molecular bond, enhancing quality and efficiency.

This article explains what 2 shot injection molding is, its key differences from standard injection molding, the detailed process, its benefits, and its diverse applications.

What is 2 Shot Injection Molding?

Injection molding is a widely used manufacturing process where molten material is injected into a mold to form injection molded parts.

Two shot injection molding elevates this by using two separate injection stages to combine different materials or multiple colors in one machine.

For example, a consumer product like a power tool might feature a rigid substrate for structure and a soft touch surface for comfort, all crafted in the same mold.

The process creates a chemical bonding between the first material and the second material, ensuring a strong, durable final part without adhesives or separate tools.

This molecular bond distinguishes it from traditional methods, reducing material waste and enhancing quality for complex parts.

By integrating multiple components into one cycle, it achieves maximum production efficiency, making it ideal for producing complex geometries with varied material properties.

Key Differences from Traditional Injection Molding

Traditional injection molding relies on standard injection molding machines to produce single-material parts, suitable for simpler designs but limited when multiple materials or complex geometries are required.

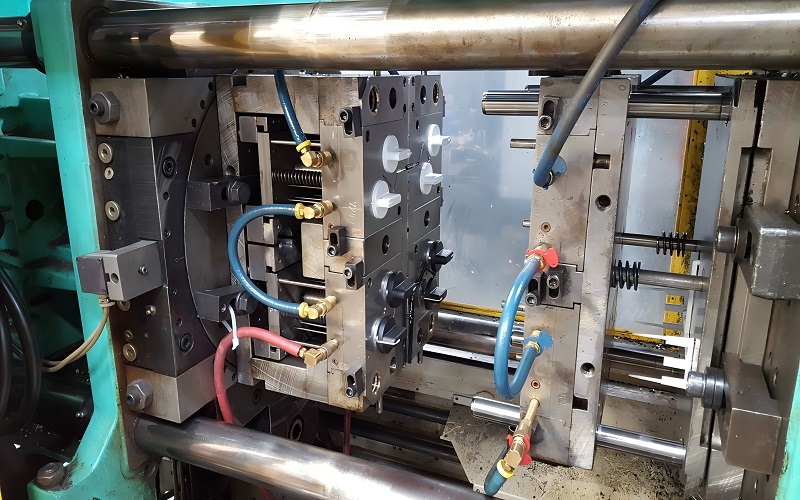

In contrast, two-shot injection molding utilizes specialized injection molding machines equipped with independent injection units, allowing two materials to be sequentially injected within the same mold.

Key differences include:

- Single vs. Multiple Materials: Traditional methods use one material, while two shot molding combines two or more materials, such as plastics and liquid silicone rubber, for multi-material parts.

- Tooling: Traditional molding may require separate tools for different components, increasing costs and time. Two shot molding uses the same mold for both shots, streamlining the process.

- Bonding: Traditional assembly often relies on adhesives or mechanical joining, which can fail. Two shot molding ensures a molecular bond for enhanced quality and durability.

- Efficiency: By eliminating post-molding assembly, two shot molding reduces labor and material waste, achieving maximum production efficiency.

While two shot molding involves process complexity, its ability to produce complex multi-material parts in one cycle makes it a cost-efficient choice for many applications.

How Does the 2 Shot Injection Molding Process Work?

The two shot molding process is a sophisticated yet efficient method for producing complex parts. It begins with the first injection, where the first material—often a rigid plastic—forms the base in a mold cavity.

After slight cooling, the mold rotates or transfers the part to a second injection station, where the second material, such as a soft grip material or liquid silicone rubber for shock absorption, is injected over or around the first.

Specialized injection molding machines, equipped with independent injection units, control injection speeds and temperatures to ensure material compatibility and prevent defects like delamination.

The process occurs in one machine, using the same mold, which reduces multiple cycles and eliminates the need for separate tools.

This shot injection molding process is ideal for both low volume production runs and high-volume needs, delivering consistent quality with minimal material waste.

Steps in Two Shot Molding

- Mold Design: Engineers create a mold with cavities for both materials, often using a rotating platen or transfer system for precise alignment.

- First Injection: The first material, typically a rigid substrate, is injected into the initial cavity to form the core.

- Mold Adjustment: The mold rotates or repositions to align the part for the second shot, maintaining precision.

- Second Injection: The second material, such as a soft touch material or another plastic for multiple colors, bonds to the first through heat and pressure.

- Ejection: The final part cools and is ejected, ready for use without further assembly.

This overmolding process ensures a seamless integration of materials, making it perfect for complex parts with varied textures or functions, like soft grips or shock absorption features.

Key Benefits of 2 Shot Injection Molding

The advantages of two shot injection molding make it a preferred choice for manufacturers seeking efficiency and quality in producing multi-material parts.

- Cost Efficiency: By using one machine and the same mold, it eliminates separate tools and post-molding assembly, reducing labor, material waste, and production time.

- Enhanced Quality: The chemical bonding between materials creates a durable, consistent final product, outperforming parts joined by adhesives.

- Design Flexibility: Manufacturers can combine multiple materials, colors, or textures—like rigid substrates with soft touch surfaces—for innovative designs in consumer products or industrial applications.

- Scalability: Suitable for low volume production runs and high-volume needs, it offsets the initial investment in specialized machines with faster cycle times.

- Sustainability: The overmolding process minimizes material waste, aligning with eco-friendly manufacturing goals.

- Versatility: It supports complex geometries and material combinations, enabling intricate designs without compromising strength.

These benefits make two shot molding a cost-efficient solution for industries requiring precision and durability, though some challenges must be addressed for optimal results.

Overcoming Implementation Challenges

The process complexity of two shot molding requires skilled operators to manage injection speeds, temperatures, and material compatibility.

Incompatible materials can lead to issues like weak bonding or defects, so selecting compatible materials is critical.

The initial investment in two shot molding machines is higher than standard injection molding machines, which may deter smaller operations.

However, with proper training, precise process control, and careful material selection, these challenges are manageable. Manufacturers can leverage the method’s efficiency to justify costs, especially for applications demanding complex multi-material parts.

Applications of 2 Shot Injection Molding

Two shot injection molding excels in industries requiring multi-material parts with enhanced functionality and aesthetics.

Consumer Electronics: Devices like smartphones or wearables use double shot molding for cases with soft touch surfaces over rigid substrates, improving comfort and durability without extra assembly.

Medical Devices: Syringes, wearable monitors, or surgical tools combine hard plastics with liquid silicone rubber for sterile seals or flexible grips, ensuring safety through strong chemical bonding.

Automotive: Components like dashboards, gear shifts, or buttons use multiple colors and textures for lightweight, aesthetic designs, reducing the need to join components separately.

Consumer Products: Kitchen tools, toys, or personal care items like razors leverage two shot molding for safe, vibrant designs with soft grips or multiple colors.

Sports Equipment: Golf club grips, helmet padding, or fitness trackers incorporate shock absorption and soft touch surfaces over rigid bases for performance and comfort.

Industrial Applications: Tools or machinery parts with ergonomic handles benefit from the overmolding process, blending strength with user-friendly textures.

The method’s ability to produce complex parts with consistent quality makes it ideal for both low and high production volumes, offering flexibility across diverse sectors.

Conclusion

2 shot injection molding is a transformative manufacturing process that combines two or more materials in one mold to create complex multi-material parts.

Its ability to reduce material waste, enhance quality through chemical bonding, and enable innovative designs with multiple components makes it a standout choice for industries like consumer electronics, medical devices, automotive, sports equipment, and industrial applications.

Despite challenges like process complexity and initial investment, the benefits of cost efficiency, scalability, and design flexibility outweigh the hurdles.

For manufacturers aiming to produce high-quality injection molded parts with complex geometries or material combinations, two shot molding offers a reliable, eco-friendly solution.

Explore compatible materials and specialized machines to unlock its potential for your next project.