In the modern landscape of manufacturing processes, the debate between 3D printing (also known as additive manufacturing) and plastic injection molding is central to any accurate cost assessment.

Whether you are developing automotive parts, car batteries, or simple milk jugs, choosing the right method is the difference between a high unit cost and achieving true economies of scale.

This guide explores the cost effectiveness of both methods, helping you estimate cost and determine when it makes sense to transition from one to the other.

Tooling Costs vs. Zero Tooling

The most significant factor in manufacturing costs is the “entry fee.”

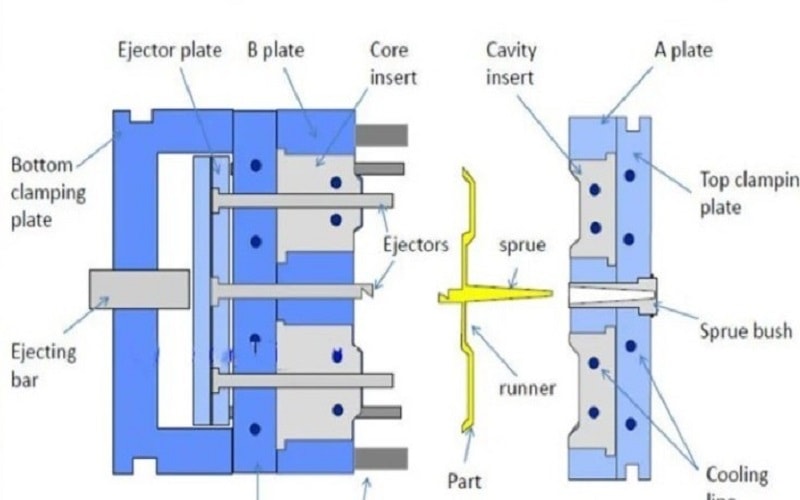

- Injection Molding: This process requires a machined metal mold. Whether you use aluminum molds for shorter runs or steel for large scale production, the injection mold cost is substantial. A typical mold involves complex mold making steps, including the creation of a cavity mold, integration of cooling lines, and the installation of ejector pins. Depending on part geometry, these tooling costs can range from $3,000 to over $100,000.

- 3D Printing: In contrast, 3D printing has near-zero tooling requirements. It builds plastic parts directly from cad drawings. For small quantities, the absence of hand costs for a physical tool makes it the most cost effective option.

The Importance of Volume

To understand the cost comparison, we must look at the production runs.

3D printing is a good process to prototype in and confirm ‘proof of concept.’

It allows for on-demand production, which drastically reduces the financial risk of unsold inventory and the cost of warehouse storage.

For low volumes, the total cost of 3D printing is significantly lower.

However, injection molding becomes more cost-effective over large production runs.

- The Critical Quantity: The breakeven point between 3D printing and injection molding typically falls between 250 and 2,000 parts.

- The Power of Scale: At 10,000 pieces, injection molding can cost approximately $12,900, while 3D printing could exceed $70,000. This is because injection molding uses cheaper bulk raw material pellets, while 3D printing materials (like those used in selective laser sintering) can range from $20 to over $300/kg.

Design Flexibility vs. Production Speed

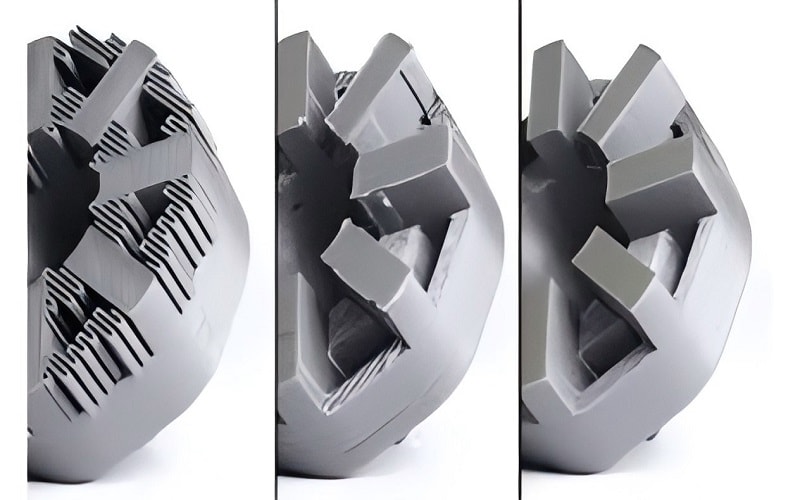

3D printing allows for more design flexibility and easier iterations compared to injection moulding.

If you need to make design changes throughout the production process, 3D printing is your best friend.

It can create complex geometries that might be difficult or impossible to achieve with a physical mold.

Injection molding, however, has stricter design requirements. Factors like thin walls, draft angles, and the placement of more cavities in a multi cavity or family mold must be meticulously planned during mold design. Once the same tool is cut, changes are incredibly time consuming and expensive.

But once the mold is ready, the cycle time for plastic injection is unbeatable.

It can produce high-quality parts in seconds, supporting high production rates that 3D printing simply cannot match for mass production.

Material Capabilities and Functional Performance

The decision between these two methods also hinges on specific material requirements.

Injection molding utilizes industrial raw material pellets that are cost-effective in bulk, enabling significant economies of scale.

This process uses molten plastic under high pressure to produce high-strength components such as car batteries, milk jugs, and critical automotive parts that require consistent structural integrity.

While 3D printing is a cost effective option for testing thin walls or living hinge designs, the specialized materials carry a much higher price tag per kilogram.

These material costs can significantly increase the total cost as production volume grows.

Furthermore, the multi cavity mold process ensures tight tolerances across thousands of parts, a level of precision and material density that 3D printing often cannot replicate for final functional use.

Part Quality and Post-Processing Expenses

When calculating the piece part price, you must account for post processing:

3D Printing: Often requires labor-intensive support removal and surface smoothing. Visible layer lines can affect the surface finish, making it less ideal for consumer-facing plastic parts without extra work.

Injection Molding: Typically results in cleaner, more polished injection molded parts. It can achieve tight tolerances and a professional finish straight out of the machine, which is why it is preferred for high volume consumer goods.

Key Technical Comparison: 3D Printing vs. Injection Molding

| Feature | 3D Printing | Injection Molding |

| Tooling Cost | $0 (No mold needed) | High ($3,000 – $100,000+) |

| Unit Cost | High (remains constant) | Low (decreases with volume) |

| Lead Time | Fast (1-3 days) | Slow (4-12 weeks for mold making) |

| Ideal Quantity | 1 – 500 units | 1,000+ units (Mass production) |

| Design Flexibility | Infinite (Easy iterations) | Limited (Mold is hard to change) |

The Bottom Line

- 3D Printing is cheaper for: Rapid prototyping and low volumes (<500 parts). It eliminates high upfront mold costs and allows for fast design changes.

- Injection Molding is cheaper for: Large scale production (1,000+ parts). It achieves massive economies of scale, offering the lowest unit cost and professional surface finish.

Family Molds and CNC Machining

For those looking to save money on injection mold cost, engineers often use a family mold.

This involves placing different parts into only one mold, allowing you to produce multiple components of the same part assembly in one cycle, rather than investing in two molds for separate pieces.

Additionally, for lower quantities where 3D printing might not offer the right material properties, CNC machining or vacuum forming are often considered.

However, for true high volume production, nothing beats the efficiency of a multi cavity injection tool.

The cost of injection molding is ultimately influenced by the total part quantity, part size, bounding box dimensions, and the specific material.

Conclusion: Which Is Right For Your Project?

Is 3D printing cheaper than injection molding?

YES for low volume production, rapid prototyping, and products requiring frequent design changes. It offers a cost effective way without the burden of high upfront mold costs.

NO for mass production. Injection molding is the superior choice for producing high-quality parts at scale, as the high tooling investment is quickly offset by the low unit cost and faster cycle times.

For a truly accurate cost assessment, you should evaluate your anticipated quantities and the complexity of your part geometry.

Would you like us to help you calculate a specific cost estimation for your CAD drawing, or should we look into the best specific material for your production run?