In the modern manufacturing process, TPE has become a absolute superstar.

Common applications of TPE include soft grips for toothbrushes, weather seals in automotive, and cable coatings in electronics.

It bridges the gap between hard plastics and traditional rubber, offering the best of both worlds.

But how do we turn this raw polymer into the products we use every day? The answer lies in the TPE injection molding process.

In this guide, we’ll break down everything you need to know,so you can understand why TPE material is taking over many industries.

What is TPE?

To truly understand TPE injection moulding, we must first comprehend the material itself. Thermoplastic elastomers (TPE) are unique compounds that exhibit rubber-like properties yet are processed in a manner akin to plastics, allowing them to be used for items requiring a soft-touch feel.

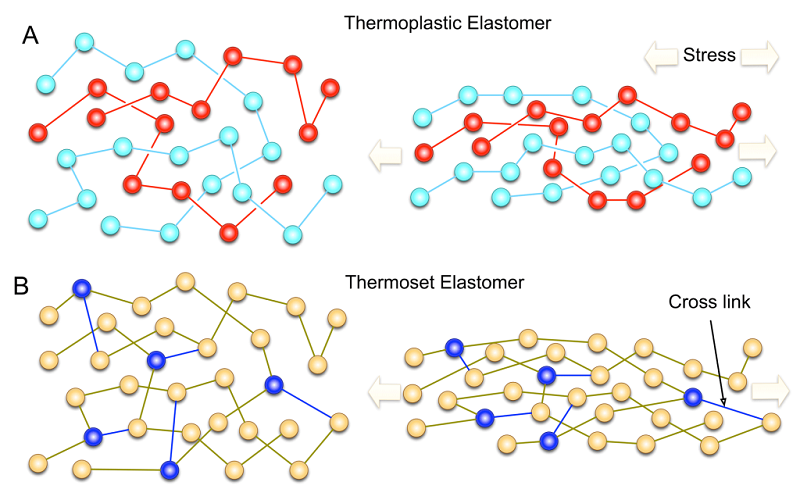

We can draw the most straightforward comparison between TPE and traditional rubber:

Traditional rubber (thermoset elastomers): Much like boiling an egg. Once cooked (cured), you cannot revert it back to liquid form to boil again.

TPE material: Like chocolate. It is thermoplastic. You can melt it into liquid plastic, inject it into a mould, and once cooled and hardened, if you dislike the result, you can remelt it and start again.

Unlike TPU or those rigid plastics, TPE feels elastic and is highly flexible.

In the injection molding process, this characteristic means you can recycle excess material back into the machine for reprocessing.

For factories, this translates to faster production, less waste, and cost savings.

The Chemical Composition

The chemical composition of TPE is what gives it its “superpowers.”

It is usually a block copolymer—a mix of two or more different types of polymers.

One part is hard, and the other part is soft. When these styrenic block copolymers or styrene block copolymers are mixed, you get a material that is suitable for tough jobs but feels soft to the touch.

Different Types

TPEs can be broken into six primary categories based on their chemical composition and structure.Not all thermoplastic rubbers are created equal. Depending on the specific applications, you might run into different types:

- TPE-S: These are the most common. Made of styrene block copolymers, they are used for everything from soft grips to children’s toys.

- TPE-O: TPO is a hard polyolefin blended with soft non-crosslinked rubber regions, yielding a tough product with high impact strength.Great for outdoor applications because they handle UV rays and weather extremely well.

- TPE-V: TPV is a hard thermoplastic material with regions of softer cross-linked rubber dispersed throughout its polymer matrix.These have even better physical properties and are often found in automotive seals.

- TPE-E: Known for excellent mechanical properties and high tear strength.

- TPE-A:TPE-A is made from polyamide, featuring excellent mechanical properties.

How the TPE Injection Molding Process Works?

The injection molding process for TPE is very similar to how you’d mold standard plastic, but with a few specialized tweaks to handle its flexible nature.

Melting the Material

The process starts with TPE pellets being fed into the injection molding machine.

Inside, a large screw creates friction and heat.

Because every TPE has a specific melting point, the barrel must be heated to just the right temperature. If it’s too hot, the material degrades; too cool, and it won’t fill the mold cavity.

The Injection Phase

Once the TPE becomes a liquid plastic, the screw slams forward. This forces the molten material under high pressure into the mold.

The liquid plastic flows through channels called runners until it reaches the mold cavity.

Because TPE is thick, the machine needs to maintain high injection pressure to ensure it fills every corner of complex shapes.

Cooling and Ejection

This is where TPE shines compared to liquid silicone rubber.

While silicone needs heat to “cure” (a chemical reaction), TPE just needs to cool down.

The cooling time is a huge factor in production speed. Once it’s cool enough to hold its original shape, the mold opens, and the finished part is ejected.

Why Choose TPE Over Other Materials?

When engineers look at material selection, they often compare TPE to thermoset elastomers, liquid silicone rubber, or other materials. Here’s why TPE often wins:

Less Waste and Energy: Because it is a thermoplastic, any leftovers can be reground. This leads to less waste and less energy usage compared to traditional manufacturing.

Chemical Resistance: It can withstand oils, acids, and cleaning agents, making it perfect for harsh conditions.

Physical Properties: TPE offers good elasticity, high tensile strength, and great abrasion resistance.

Durability: Whether it’s tpe s, tpe o, or tpe e, these materials provide long-term durability for consumer goods.

Design Tips for TPE Injection Molding

To ensure your injection-molded parts achieve both an exquisite appearance and flawless functionality, it is essential to adhere to certain fundamental rules of TPE injection molding.

Watch Your Wall Thickness

In the injection process, consistency is king. If your wall thickness varies too much, the part will cool unevenly, leading to warping or sink marks.

For tpe material, keeping walls uniform helps the molten flow fill complex shapes easily.

Surface Finish and Grip

One of the biggest advantages of TPE is the surface finish. You can make it feel silky smooth, or give it a “soft-touch” matte texture.

This is why it’s so popular for consumer products like tool handles—it provides a comfortable grip even in harsh conditions.

Real-World Applications of TPE

Because thermoplastic elastomer tpe is so flexible and safe, it’s used in various applications.

Medical Products: In the healthcare world, medical devices must be biocompatible. TPE is perfect for medical products because it can be sterilized.

Consumer Products: From the seals in your kitchen containers to the wheels on a suitcase, TPE is everywhere in consumer goods.

Outdoor Applications: Thermoplastic olefins are used for car bumpers and gaskets because they don’t crack under high heat or high temperatures.

Quality Control: How to Achieve Success?

To ensure every finished part is perfect, quality control is vital.

Since TPE can be sensitive to moisture, the pellets often need to be dried before they go into the injection molding machine.

Manufacturers also monitor the injection speed.

If you push the liquid plastic too fast, you might get “burn marks.”

If you go too slow, the material might cool before it fills the entire mold cavity.

It’s a delicate balance that requires a skilled injection molder to meet specific requirements.

Summary

As we look for more efficient ways to build components, TPE injection molding stands out as a clear winner.

It combines the excellent mechanical properties of rubber with the fast, recyclable manufacturing of plastic.

Whether you are making medical devices, consumer products, or rugged outdoor applications, TPE provides the durability and flexibility needed to achieve success.

By understanding the unique properties of styrenic block copolymers and other TPE types, you can choose the right material for your next big project.

FAQs

Can TPE be Injection Moulded?

Yes, absolutely. In fact, TPE is designed specifically for the injection molding process. Because it is a thermoplastic, it melts when heated and solidifies when cooled, making it much faster and easier to mass-produce than traditional rubber. Today, it is a leading material for creating everything from medical products to consumer goods.

TPE vs. TPU: What’s the Difference?

While thermoplastic polyurethane (TPU) is technically a type of TPE, it is much harder and has higher abrasion resistance. TPE is generally softer and more “rubbery.”

Choose TPE if: You need a soft grip, a bouncy toy, or a flexible seal.

Choose TPU if: You need something that can survive being dragged across concrete or exposed to heavy oils.

When is TPE’s Tear Resistance Most Important?

For certain applications like medical tubing or heavy-duty seals, TPE is the right material because its high tear resistance and tensile strength allow it to be stretched and stressed in harsh conditions without snapping or losing its original shape.

Is TPE a Plastic Or Rubber?

It’s actually both! TPE (thermoplastic elastomer) is a polymer that has rubber like properties (it’s stretchy and flexible) but possesses the manufacturing DNA of a plastic.

This means you get the performance of rubber with the recycling advantages and speed of thermoplastics.