The toy industry is worth billions of dollars, with new toy products being developed constantly by everyone from creative individuals to large companies.

However, having an amazing idea is just the beginning. To realize that vision and turn a concept into a real product, you must master the design process.

Creating a prototype for a toy design is an iterative process that moves from rough illustration to a tangible model used for safety testing and manufacturing.

Simply put, rapid prototyping is creating your physical product quickly to obtain information about its design and functionality.

It allows you to physically hold, touch, and move your product to understand it better.

In this comprehensive guide, we will explain the practical steps to building your own toy prototypes, ensuring you meet safety standards and find the perfect market fit.

Defining the Concept: Before the First Prototype

Before you pick up a craft knife, you need to find a way to articulate your idea.

This includes clarifying what your toy is, who it is for (the kids), and what makes it better than existing consumer products.

Market Research and Market Fit

Every business starts with market research.

A simple competitive matrix can help identify where your toy concept fits in the world.

Toy designers use this to ensure they aren’t just copying large companies. You need to realize your Unique Selling Proposition (USP) early in the stage.

Sketching and Graphic Design

Sketching out your idea is a crucial first step before creating a prototype.

Use graphic design and illustration to create a visual plan.

Once the idea is developed, you should define the draft specifications, including key features, size, material selection, and safety considerations.

Building the First Prototype

Moving to the prototyping phase early is very advantageous due to the amount of information you can obtain.

You don’t need professional tools to begin.

A quick, “rough and dirty” first prototype is created to check the basic concept and scale without investing in expensive molds.

The initial rapid prototypes should be made with the most readily available material. Common materials for initial toy prototypes include:

- Cardboard, paper, and foam board.

- Wood, clay, or even LEGO bricks.

- Fabric scraps, stuff like foam, and hot glue.

Tools such as craft knives, steel rulers, and hand saws are commonly used.

Note that designers and students should practice using tools safely before constructing their toy prototypes.

The model does not need to be 100% functional; it should be a proof-of-concept that conveys the product’s purpose.

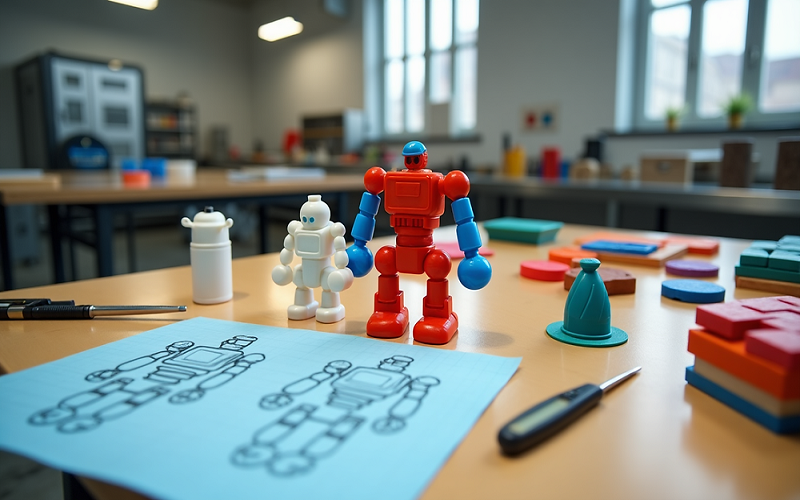

From Sketch to Scale: A Practical Example

When you begin to create your physical model, start with a clear example of your toy’s proportions.

If you are designing an action figure, for instance, you might use a range of different materials to block out the basic silhouette.

A common trick is to use a small ball of clay or even a wooden bead to represent the head, as this helps you determine if the rest of the body’s construction feels balanced.

By building a simple figure in this way, you can quickly see if your illustration translates well into the 3D world.

Feedback and Playtesting

The process of prototyping and learning is repeated numerous times at a rapid pace when new information is learned.

All information, good or bad, obtained from prototyping is valuable to move the product design forward.

Playtesting with Kids

Playtesting involves conducting sessions with children to observe interactions and identify functional flaws.

Testing your prototype with kids and gathering feedback is essential to understand what they like or dislike. Parents are also a great source of feedback regarding safety and value.

Refining the Design

Testing can happen at any stage of the prototyping process to gather feedback.

Prototyping allows you to identify issues before full-scale production.

This is where you fix potential problems such as small parts or complex mechanisms that don’t work in the real world.

Creating the Digital Blueprint

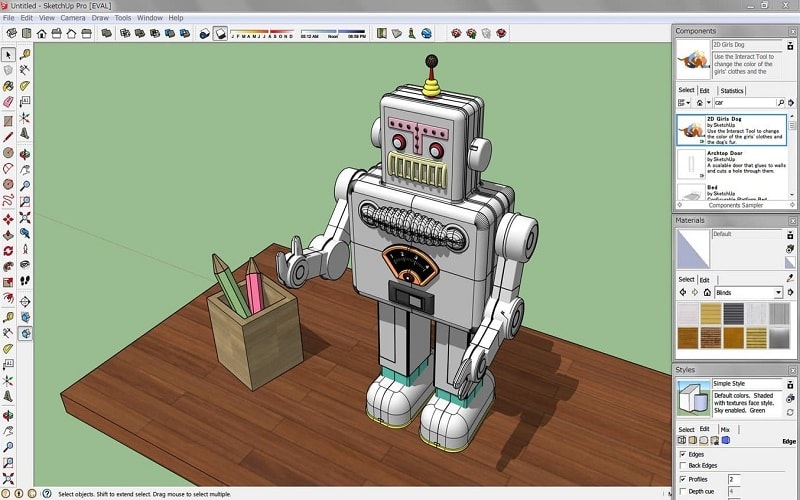

Once you have a physical model that works, you need to create a digital blueprint. This is an important thing to do before building refined, high-fidelity toy prototypes.

3D CAD Modeling

3D CAD modeling software like Zbrush or SolidWorks is used to create a detailed 3D model for visual inspection and engineering analysis. An industrial designer or engineering specialist can help you create this file. This digital construction ensures precision before manufacturing.

Modern Prototyping and 3D Printing

In 2026, modern prototyping prioritizes durability, non-toxicity, and sustainability. 3D printing commonly uses materials such as PLA, PETG, or SLA/resin.

PLA Filaments: Used for visual models.

ABS or Tough PLA: Used for functional toy prototypes that need durability.

Silicone Molding: This involves creating a master, creating a mold box, and casting resin into the silicone mold for different materials testing.

Sourcing and Manufacturing in a Global Market

Most toys sold in the global market are produced in China due to competitive pricing, flexible minimums, and fast lead times. Transitioning from a prototype to a final product requires a strong manufacturing plan.

If the tasks seem overwhelming, many companies offer access to expert services:

Brand New MD™ LLC: A full-service toy development company that designs, develops, and sources high-tech toys. They provide prototyping, branding, manufacturing, and logistics.

Klugonyx: Offers end-to-end toy development services, including ideation, engineering, factory audits, and quality control.

Cad Crowd: Provides a selection of design professionals and manufacturing contacts to help turn concept ideas into toy prototypes.

Toy development companies often require a tech pack that lists dimensions, materials, and colorways before factories can provide quotes.

The toy sourcing team at these firms helps find the right manufacturers and suppliers.

The Final Prototype and Pre-Production

Prototyping a toy from scratch involves transitioning from initial low-cost models to more durable, refined versions suitable for testing.

A high-fidelity prototype resembles the final product and is created once the design is finalized.

The final prototype is the version that looks and functions exactly like the final product. It is often called a “looks-like, works-like” model.

Before you commit all your money to a full production run, you need pre-production samples.

These are high-quality samples made using the same molds and manufacturing techniques that will be used in the factory.

Take this prototype and talk to your target audience. Give it to kids and watch them play.

Do they find it fun? Do parents think it’s worth the price? Their feedback is the most important thing you can get before moving to the next stage.

Safety Testing and Quality Control

In the toy industry, safety is the number one priority. No brand can survive a recall.

Your toy prototypes must undergo strict safety testing.

This includes:

Drop tests to ensure no small parts break off.

Chemical testing to ensure the materials are non-toxic.

Torque and tension tests for complex mechanisms.

If you are manufacturing in China or other international hubs, make sure your manufacturers are familiar with the safety standards of the country where you plan to sell.

Companies often hire third-party labs to review and certify their toys.

Scoring a Deal in the Toy Industry

Once your toy is developed, designed, and produced, you have to get it in front of potential customers.

Pitching to Toy Companies The better your prototype and presentation, the higher your chances of scoring a deal.

However, toy companies often deal with established inventors, making it challenging for new inventors to get their products to market.

You may have to hire someone who specializes in getting meetings with toy companies if you cannot get in on your own.

Conclusion

The prototyping step is crucial in turning a conceptual idea into a physical product.

It is the heart of product design. Prototyping helps refine ideas before full-scale production and helps in obtaining quick and clear information on the product and how the initial market views it.

The prototyping process is iterative, involving multiple rounds of design and feedback.

Whether you are using fabric scraps and a craft knife or high-end 3D CAD modeling, the goal remains the same: to create something fun, safe, and amazing.

Prototyping allows you to see your conceptual idea as a real product.

With the right plan, the right materials, and a focus on safety, you can realize your vision and find success in the global toy industry.