In the competitive world of modern manufacturing, selecting the most efficient plastic manufacturing method is not just a technical choice—it’s a critical business decision.

Whether you are developing medical devices or heavy-duty automotive components, the debate usually centers on two heavyweights: extrusion molding vs injection molding.

While both rely on the transformation of plastic pellets into a desired shape, the mechanical journey from plastic granules to a finished extruded product or injection molded parts is fundamentally different.

This article provides an exhaustive deep dive into extrusion and injection molding, helping you navigate mold tooling injection molding, material flow, and high volume production strategies.

The Mechanics of Injection Molding

Plastic injection molding is a discrete manufacturing method designed for creating individual, often highly complex parts.

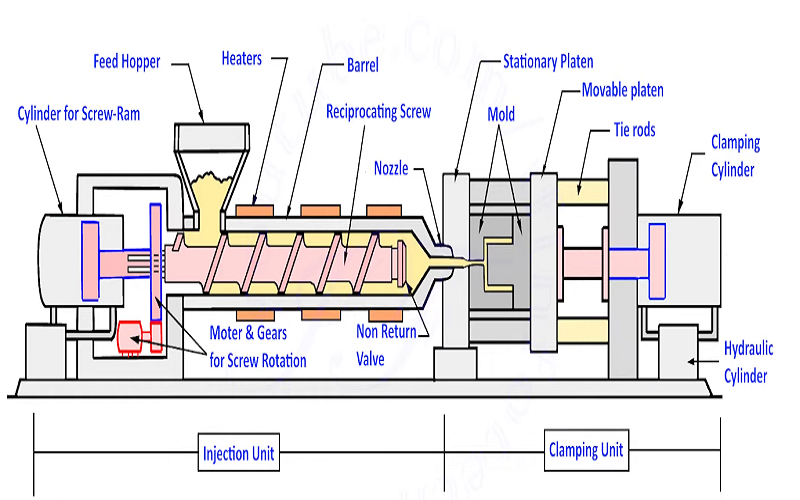

The injection molding process begins when raw plastic granules are fed into a hopper and funneled into the injection unit of an injection molding machine.

The Clamping and Injection Unit

Inside the machine, a reciprocating screw subjects the material to intense frictional heat.

This heat, combined with the machine’s heater bands, transforms the solid pellets into a molten plastic material—specifically, a thick liquid or liquified plastic.

Once the molten plastic reaches the required viscosity, the injection unit rams it under high pressure into a custom-engineered mold cavity.

At this stage, the clamping and injection unit is vital; it exerts tons of force to keep the mold tooling shut, preventing leaks.

Once the plastic cools inside the water-cooled mold cavity, the part solidifies, the clamp opens, and a finished part with complex geometries is ejected.

Why Industries Rely on Injection Molding?

Complex Shapes: It is the only choice for complex parts with internal ribs, bosses, or complex cross sections.

Tight Tolerances: It excels at maintaining precise dimensions, often within +/- 0.005 inches, making it ideal for medical devices.

Surface Texture Options: From high-gloss to specific surface texture options, the mold design determines the final aesthetic.

Mass Production: While it has high mold creation costs, it is the most cost effective route for large quantities (often exceeding 5,000 units).

The Mechanics of Extrusion

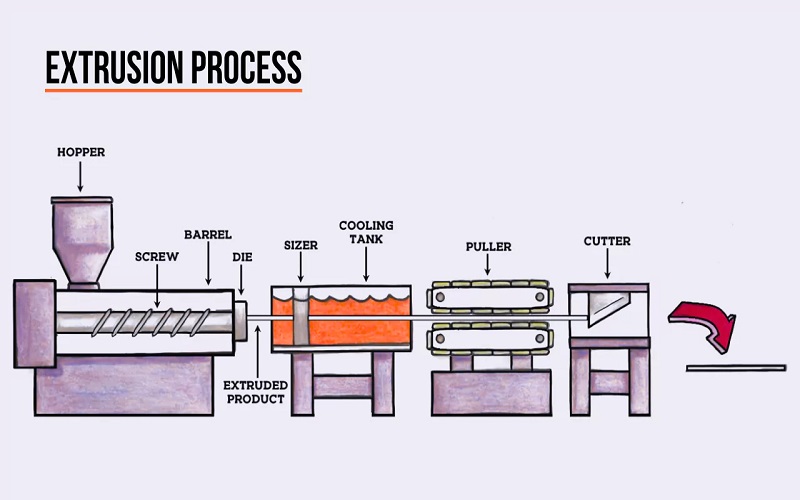

Unlike injection molding, which is a “one-and-done” batch process, the plastic extrusion process is a continuous process. Think of it as a high-industrial version of a pasta maker.

The Plastic Extrusion Method

In the extrusion process, the molten material is pushed through a metal die to create uniform cross-sectional shapes.

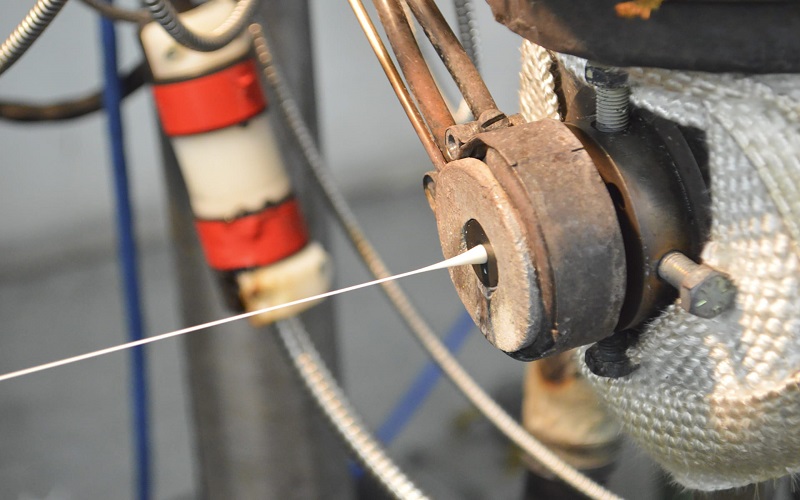

As the extruded plastic emerges from the die, it is pulled through a cooling vacuum or water tank. This continuous production allows for the creation of miles of product without stopping.

Extrusion Processes: Hot Extrusion and Cold Extrusion

Depending on the engineering plastics used, manufacturers may employ hot extrusion or cold extrusion.

Extrusion offers a unique advantage for the construction industry, where uniform shapes like pvc frames, window frames, and cable insulation are required in vast lengths.

Tooling and Setup: A Cost Comparison

One of the most significant differences lies in the mold tooling injection molding costs versus extrusion die costs.

Injection Molding Costs: The mold creation process for injection molding is labor-intensive. It involves CNC machining of complex molds from hardened steel.

Consequently, it has high initial setup costs. However, for high volume production, the cost-per-part drops significantly.

Lower Tooling Costs in Extrusion: Because extrusion dies only need to define a 2D profile rather than a 3D volume, they are much simpler to manufacture.

This leads to lower tooling costs, making it more viable for smaller, simpler production runs.

Design Flexibility: 2D vs. 3D Geometries

The choice between injection molding and extrusion often boils down to the geometry of the plastic components.

Extrusion is limited to 2D shapes that are extended into a third dimension.

It is the perfect plastic molding choice for continuous shapes with a consistent cross section.

Injection molding produces solid parts but cannot easily create extremely long, hollow profiles like a 100-meter pipe.

However, it is the superior choice for complex 3D shapes that require tight tolerances and intricate internal structures.

Material Versatility and Waste

In modern manufacturing, sustainability and material waste are top priorities.

Material Efficiency: The plastic extrusion process is incredibly efficient. Since it is a continuous process, there is very little scrap. Any “off-cuts” can often be reground and fed back into the non rubber extruder.

Material Flow in Injection Molding: During plastic injection molding, material often remains in the “runners” (the tunnels leading to the mold cavity). While these can be recycled, it adds a step to the plastic processing cycle.

Engineering Plastics: Injection molding supports a wider range of engineering plastics, including most thermoplastics and thermosets. Extrusion is primarily suited for thermoplastics with high melt strength like PVC, PE, and PP.

Surface Finish and Post-Processing

A smooth surface finish is often a requirement for automotive components and consumer electronics.

Injection Molding: The surface finish is determined by the texture of the mold cavity. You can achieve anything from a mirror polish to a leather-like grain.

Extrusion: While it produces a clean finish due to the high pressure in the die, it lacks the ability to add intricate 3D textures or logos onto the surface without secondary stamping processes.

The Power of Mold Flow Analysis

We don’t start mold creation without a thorough mold flow analysis. This digital simulation tracks the material flow of the liquid plastic as it enters the complex molds.

By analyzing how the molten plastic fills the mold cavity, we can:

Predict and prevent air traps.

Ensure uniform shapes and wall thicknesses.

Optimize the cooling phase so the plastic cools evenly, preventing warping.

Achieve the desired product characteristics on the first try, reducing material waste.

Injection Molding vs. Extrusion Molding: A Direct Comparison

Detailed comparison of injection molding and extrusion molding.

| Feature | Injection Molding | Extrusion Molding |

| Production Type | Discrete / Batch | Continuous process |

| Complexity | Complex geometries (3D) | Uniform cross sections (2D) |

| Tooling Cost | High Initial Investment | Lower tooling costs |

| Production Volume | Ideal for mass production | Ideal for high volume linear parts |

| Material Waste | Moderate (Runners/Sprues) | Very Low |

| Common Products | Medical devices, plastic parts | Extruded films, pvc frames |

Choice of Different Industries

Given the differences between these two injection molding methods, this suggestion can be referenced when producing different products.

Construction and Infrastructure

If you are producing window frames, pvc frames, or cable insulation, the plastic extrusion method is your best bet. The ability to produce continuous shapes with a consistent cross section makes it the most cost effective solution for this sector.

Automotive and Medical

For automotive components or medical devices that require complex parts and must maintain precise dimensions, injection molding is the industry standard. The ability to use specialized engineering plastics and achieve tight tolerances ensures the safety and functionality of these critical plastic components.

Packaging and Consumer Goods

Extruded films are the backbone of the packaging industry, created through a specialized extrusion process. Meanwhile, the containers and caps for those packages are almost always injection molded parts.

Conclusion

Choosing between extrusion molding vs injection molding requires a deep understanding of your product’s desired shape, budget, and scale.

Extrusion offers a path to high-speed, continuous production with lower tooling costs, while injection molding provides the precision and complexity required for modern manufacturing’s most demanding tasks.

Both extrusion and injection molding are capable of producing large quantities of high-quality products. The decision ultimately rests on whether your part is a standalone 3D object or a continuous 2D profile.

We specialize in both mold design and plastic processing. We help you evaluate material versatility, perform mold flow analysis, and manage the entire manufacturing processes from mold creation to mass production.