Polycarbonate (PC) is an excellent material with high transparency, durability and heat resistance. Widely used in injection molding, Polycarbonate (PC) can meet complex design requirements while providing excellent mechanical properties and impact resistance.

In this article, we’ll take a closer look at the entire Polycarbonate injection process, focusing on the technology, benefits, and common challenges. Whether you are new to plastic injection molding or a seasoned expert, this article will provide you with valuable information and practical advice.

What is Polycarbonate(PC) Materials?

Polycarbonate, commonly called PC, is considered a “universal material” due to its unique physical and chemical properties. This material is very popular in many industries. First of all, PC is very transparent, similar to the plastic version of “clear glass”, has a light transmission of 80-90% and is stable even at high temperatures. In addition, the computer is very strong and resistant to shocks. These properties make it an indispensable high-quality material for automotive lighting, medical equipment and various daily necessities.

Properties of Polycarbonate(PC)

| Property | Value |

| Density | 1.2 – 1.22 g/cm³ |

| Shrinkage | 0.5 – 0.7 % |

| Yield Tensile Strength | 60 – 70 MPa |

| Elongation at Break | 100 – 150 % |

| Flexural Modulus | 2.0 – 2.4 GPa |

| Flexural Strength | 90 – 100 MPa |

| Drying Temperature | 110 – 120 ℃ |

| Drying Time | 3 – 4 hours |

| Melting Temperature | 250 – 270 ℃ |

| Mold Temperature | 80 – 100 ℃ |

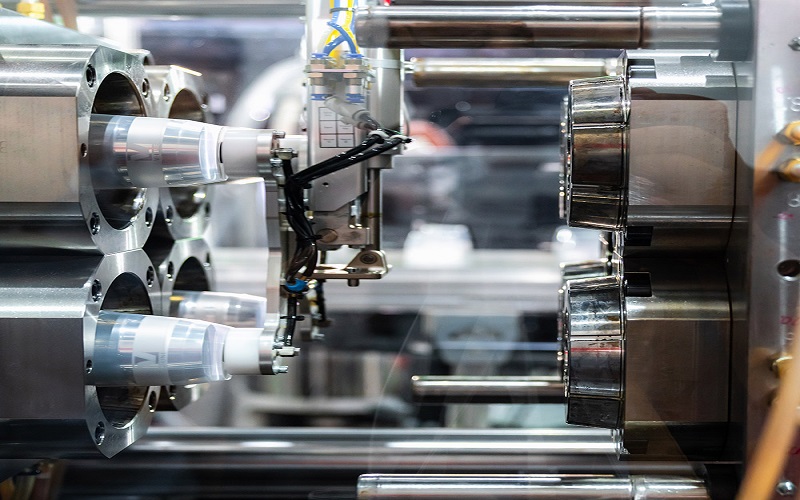

What is Polycarbonate Injection Molding?

Injection molding is a common production method that is particularly suitable for large-scale production of parts. Because it is fast, accurate and reusable, it is popular for making a variety of plastic products.

An example of this method is the injection of polycarbonate (PC). In this process, PC plastic is heated until it melts and then injected into a mold at high temperature and pressure to produce a series of complex plastic parts. The process is simple.

What Are the Technologies for Polycarbonate Injection Molding?

There are several common technologies for polycarbonate (PC) injection molding, and below is a detailed description of the various PC injection molding technologies.

The first is co-injection molding. This technology involves creating composite parts by injecting two or more plastics into a mold. This not only makes the parts stronger and more durable, but also allows different colors or functional layers to be combined. For example, a layer of soft rubber can be injected into a solid PC base to increase comfort and anti-slip properties.

Then there’s gas-assisted injection molding. This technology creates hollow structures by injecting gas during the injection process. This reduces the weight of the part and saves material. This method is particularly suitable for automotive parts and home appliance housings as it improves surface quality while reducing shrinkage and distortion.

Finally, there is hot runner injection molding. This technology uses a heating system to maintain the temperature of the plastic melt, which can reduce material waste and increase production speed. This method makes it possible to fill molds very efficiently, which makes it very suitable for mass production and also reduces the cost of production and waste disposal.

Finally, there is the very powerful extrusion technology that adds new layers of material to existing parts. This method allows you to combine different materials in one part. For example, adding a soft rubber layer to a hard PC matrix can not only increase feel, but also improve slip resistance or provide additional protection. This technology is often used to create housings for electronic devices, tool handles and car interiors. Because these things need a nice touch and better functionality.

Therefore, these injection molding technology is generally used to create a variety of high-performance and multi-functional products.

What Are the Applications of Polycarbonate Injection Molding?

Polycarbonate (PC) is used in many industries due to its strength, transparency and heat resistance. Here are some of the main uses:

Glasses and lenses:

PC is highly transparent and blocks UV (if treated with sunscreen), making it ideal for eyeglass lenses. It is also very impact resistant, making it particularly useful for children’s and sports glasses.

Building materials:

The computer is transparent and durable, which makes it useful in the construction industry. It is often used to create transparent or translucent roof panels, skylights and greenhouse panels that allow light to pass through while resisting weather changes. It can also be used to make bulletproof glass and safety shields.

Consumer products:

The strength and transparency of PC, as well as the fact that it is food safe, make it particularly useful for kitchen utensils such as mixing bowls, beverage bottles and food storage containers. It can also be opaque to appliances, toys and tools.

Car products:

Polycarbonate is very durable and resistant to UV radiation, high and low temperatures and impacts, so it is often used in interior parts such as lights and car dashboards.

Hospital equipment:

Polycarbonate is often used in medical devices such as catheters, syringes and incubators because it is resistant to corrosion, heat and sterilization.

Electronic and electrical products:

Polycarbonate has excellent impact and heat resistance, making it suitable for packaging electronic products such as laptops and mobile phones. It is also used in electrical insulators and circuit breaker covers.

Simply put, polycarbonate is important in many applications because of its versatility and performance.

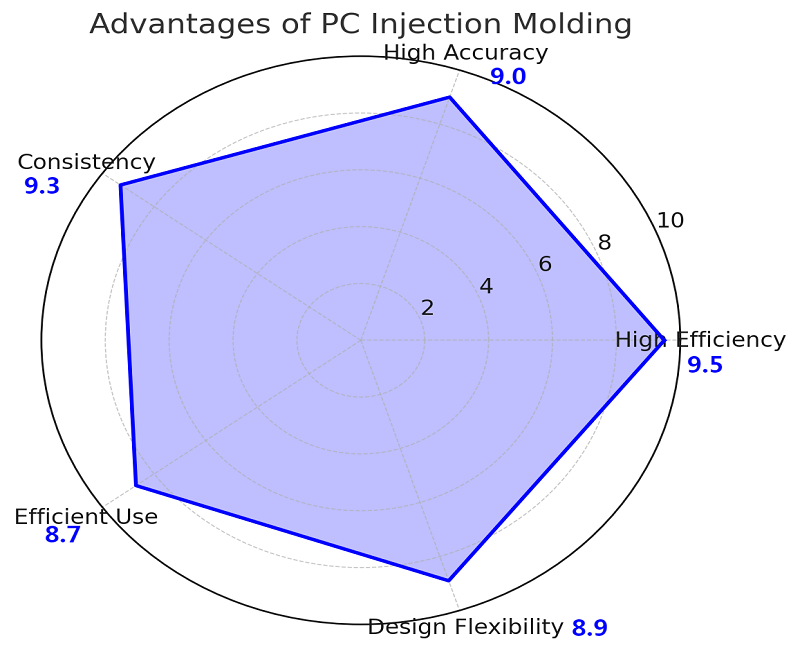

What Are the Advantages of Polycarbonate Injection Molding?

high efficiency: Injection molding is fast and suitable for mass production.

High accuracy: The precision of the parts is high and the tolerances are at the millimeter level.

Consistency: Ensure that the quality and performance of each product is consistent.

Efficient use: Maximizes material use, reduces waste and promotes waste recycling.

Design flexibility: Enables flexible design of complex shapes and structures.

Common Problems and Solutions in Polycarbonate Injection Molding

In PC injection molding, several problems can occur that affect the quality of the product. For example, shrinkage is a problem. PC shrinks as it cools, making product dimensions inaccurate. The solution is to adjust the construction of the mold, reduce the temperature and increase the holding time.

There is also the problem of warping. Sometimes uneven cooling or excessive internal pressure can cause product deformation. The solution is to ensure uniform cooling, design cooling channels and perform heat treatment after forming.

Burns are also a common problem. If the temperature is too high or the injection speed is too high, the material will burn. To avoid this problem, you can reduce the temperature, reduce the injection speed and ensure good ventilation of the mold.

Finally, there is the question of hydrolysis and degradation. PC is sensitive to moisture and high temperatures and is prone to degradation. The solution is to thoroughly dry the material, control the temperature and use additives appropriately.

By understanding these issues and solutions, you can achieve better PC injection results.

Key Process Parameters for Polycarbonate(PC) Injection Molding

| Process Parameters | Value | Explanation |

| Barrel Temperature | 240 – 270 ℃ | |

| Front Zone | 240 – 250 ℃ | |

| Middle Zone | 250 – 260 ℃ | |

| Rear Zone | 260 – 270 ℃ | |

| Mold Temperature | 80 – 100 ℃ | Reduces internal stress and warping |

| Injection Pressure | 70 – 140 MPa | Ensures full cavity filling |

| Injection Speed | Medium to high speed | Prevents premature cooling and defects |

| Holding Pressure | 50 – 100 MPa | Maintains shape and dimensions |

| Holding Time | 5 – 15 seconds | Maintains shape and dimensions |

| Cooling Time | 10 – 30 seconds | Prevents deformation |

| Cooling Efficiency | Efficient cooling channels and media (such as water or oil) | Improves cooling effect |

Key Equipment Requirements for Polycarbonate(PC) Injection Molding

To ensure smooth polycarbonate (PC) injection molding and produce high-quality products, your injection molding machine must have several important features:

First, the injection molding machine must have a precise control system that can accurately control the temperature and pressure to ensure uniform melting of the PC material. Second, the temperature control system must be reliable, and it is important that the cylinder and mold maintain a stable temperature.

The injection machine must also be able to deliver high injection pressures of 70 to 140 MPa, as PC materials require very high pressures for molding. Controlling the injection speed is also important to ensure that the material fills the mold quickly to avoid problems during the molding process.

The pressure maintenance system cannot be ignored either, which must be able to maintain a pressure of 50 to 100 MPa to prevent product deformation during cooling. In addition, an effective cooling system is needed to ensure uniform cooling of molds and products to increase production efficiency.

The screw and cylinder must have good resistance to high temperatures. This is because PC materials require high temperatures to melt. Finally, the machine must have sufficient clamping force to handle high injection pressures to avoid mold problems.

Simply put, as long as the injection machine meets these conditions, the PC injection process can run smoothly and produce high-quality products.

Environmental Aspects of Polycarbonate(PC) Injection Molding

Polycarbonate (PC) injection molding has environmental benefits such as easy recycling and durability of the material, which reduces waste, but it also has some challenges. This process requires high temperatures and pressures, leading to high energy consumption and increased carbon emissions.

In addition, hazardous substances can be released during the production process, flue gases and waste water must also be cleaned. Overall, PC injection molding has advantages in terms of waste reduction and recycling, but still requires improved technology and management to cope with high energy consumption and environmental impact.

Conclusion

This article introduces polycarbonate (PC) material and its injection molding process. Because PC materials are highly resistant to impact and heat, they are widely used in fields such as eyeglass lenses, medical equipment, household goods, and auto parts.

Although some PC materials can be difficult to process, their advantages are very clear. Overall, PC injection molding is an excellent technology for producing high-performance products.

If you need this material for your project, it is definitely worth considering.