| No. | Company Name | Year Established |

| 1. | Proto Labs | 1999 |

| 2. | Star Rapid | 2005 |

| 3. | HLH Prototypes | 2008 |

| 4. | 3ERP | 2010 |

| 5. | Shapeways | 2007 |

| 6. | Xometry | 2013 |

| 7. | FOW Mould | 1978 |

As prototyping technology advances rapidly, vacuum casting is becoming the top choice for producing prototypes and small batches because of its accuracy, cost-effectiveness, and fast turnaround. Many exceptional vacuum casting companies have emerged, offering expert services and high-quality products.

For example,Proto Labs, Star Rapid,are leading company in this field, boasts a broad client base and offers tailored vacuum casting solutions.

In this article, we will present a list of the top 7 vacuum casting companies globally, highlighting their technical strengths, service features, and market influence to give you comprehensive industry insights.

What Is Vacuum Casting?

This is a casting process for elastomers which uses a vacuum to draw any liquid material into the mold. Vacuum casting is used when air entrapment is a problem with the mold. Additionally, the process can be used when there are intricate details and undercuts on the mold.

Also, it is applied if the material used to make the mold is fiber or a reinforced wire. The process is sometimes called thermoforming because the manufacturing process involves rapid prototyping where the plastic sheets are preheated. The materials are preheated in an automated vacuum casting machine until they are soft and pliable.

How Does Vacuum Casting Work?

Vacuum casting is a super cool way to make high-quality prototypes and small batches of parts, almost like magic! Here’s the lowdown:

- Create a master model: First, use a 3D printer or CNC machine to make a super detailed “template.”

- Make a silicone mold: Pour liquid silicone over your master model. Once it sets, you’ve got a “soft mold” that picks up every little detail.

- Inject the material: Cut open the silicone mold, pop out the master model, and pour in some liquid material like polyurethane resin.

- Cure and remove: Let the material harden, then take out your finished parts from the mold.

Parts made this way come out smooth and detailed, kind of like making a fine sculpture—fast and precise.

Advantages of Vacuum Casting

Vacuum casting is popular in industry, especially for making small batches of prototypes and parts. It has several distinct advantages over other manufacturing methods:

Detail: Vacuum casting can produce very detailed parts because its molds are 3D printed. 3D printing can create intricate details that appear accurately on the final casting, just like a painting with fine brushstrokes.

Money saving: Vacuum casting is cheaper than other methods. It only takes a few hours to make a mold and it can be reused, unlike other processing methods that require expensive tools and materials.

Dimensional accuracy: Parts made with vacuum casting are so accurate that they rarely require sanding or drilling, and fit perfectly like a puzzle.

Design freedom: It has high design flexibility because 3D printing can create almost any shape. This makes it easy to make even complex parts that cannot be made by other methods with vacuum casting.

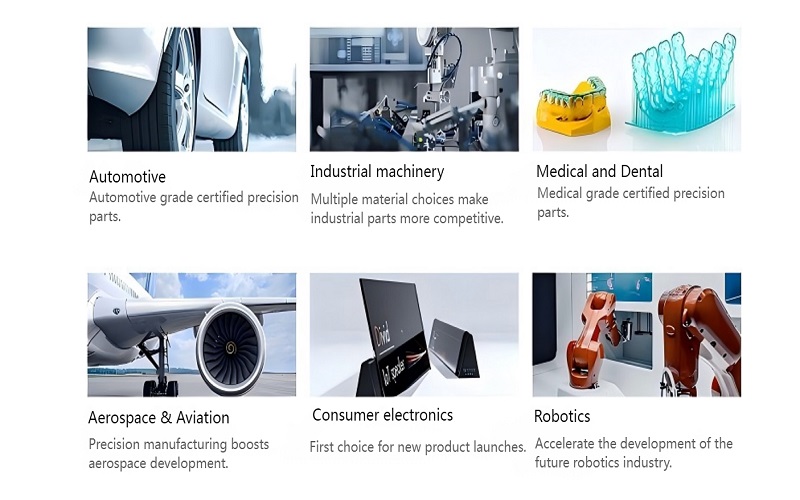

Cross-Industry Application Of Vacuum Casting Services

The following are examples of vacuum casting applications in different industries:

Top 7 Vacuum Casting Companies Profile

Proto Labs

Proto Labs specialize in rapid prototyping and small-batch production, using technologies such as injection molding, CNC machining, 3D printing and vacuum casting.

Especially in vacuum casting, Proto Labs is very professional. They can use this technology to make very precise and complex parts, which are very suitable for testing functions or checking appearance. Vacuum casting is also particularly suitable for producing small batches of plastic and rubber parts, which can well simulate the materials and performance of the final product.

The big advantage of Proto Labs is their digital manufacturing platform, which allows customers to upload design files directly online and get design analysis and quotes immediately. This fast service makes them a super important partner for new product development in industries such as medical devices, automobiles, and aerospace.

Employee Size: 2,145

Address: 5540 Pioneer Creek Dr, Maple Plain, MN 55359, United States

Contact: +1-877-479-3680

Website: https://www.protolabs.com

Star Rapid

Started in 2005, Star Rapid is a top-notch prototype maker in China. They’ve got all sorts of services like vacuum casting, CNC machining, and injection molding. Their vacuum casting game is top-tier, using advanced tech to make super realistic prototypes.

With high-quality silicone molds and advanced vacuum techniques, they’re great at handling all sorts of needs from different industries,they can create super realistic prototype parts for everything from medical gear to electronics and auto parts.

The company uses vacuum casting technology to effectively remove air bubbles in the material, thus ensuring the perfect quality and finish of each part.

Star Rapid accelerates the product listing process by having a dedicated engineering team that helps customers quickly transform design concepts into actual products. With excellent craftsmanship and efficient service, Star Rapid has built a high reputation in the global market and has become a reliable partner for many companies.

Employee Size: 280

Address: 15 Huan Mao 1 Road, Zhongshan Torch Development Zone, Guangdong Province, 528437, China

Contact: +86-760-2222-2550

Website: https://www.starrapid.com

HLH Prototypes

HLH Prototypes is a major player with over 500 folks on their team, including top-notch engineers, designers, and manufacturing experts. Since 2008, they’ve mastered rapid prototyping.

With all the latest tech—like CNC machines, injection presses, 3D printers, and vacuum forming gear—they’ve got everything needed to whip up prototypes quickly and smoothly. It’s like they have a full toolbox for creating prototypes quickly and efficiently.

This advanced equipment and professional teams enable HLH prototypes to serve a variety of industries including automotive, aerospace and medical.

The company provides efficient manufacturing solutions to customers around the world. Due to its quick response, flexible manufacturing methods and highly customized services, HLH prototypes are highly recognized in the global market.

Employee Size: 500+

Address: Building A, 315-317 Hongmei Road, Dalang, Bao’an, Shenzhen, China

Contact: +86-755-8256-9129

Website: https://www.hlhprototypes.com

3ERP

3ERP is a new company that has quickly gained acclaim for its on-time delivery and affordable prices. Since 2010, they have been shining like a rising star in the global manufacturing industry.

The company uses advanced technology and flexible services to meet various manufacturing needs one by one. Whether it is the automotive or aerospace field, 3ERP’s business covers a wide range.

When it comes to vacuum casting, 3ERP’s services are particularly suitable for making small batches of plastic parts. It is like carving a detailed work of art with high-precision tools, which can produce very fine and high-quality parts that perfectly meet customer requirements.

In addition to manufacturing, 3ERP also provides a variety of surface treatment services such as painting, anodizing and screen printing to ensure that each part meets the customer’s high standards.

3ERP works closely with customers around the world, whether they are big brands or just starting companies, and they can always provide tailor-made solutions to meet the special needs of each project. This customer-first strategy has made 3ERP stand out in the fiercely competitive market and become a trusted partner for various industries.

Employee Size: 200+

Address: No. 78 Wanjiang North Road, Wanjiang District, Dongguan City, Guangdong Province, China

Contact: +86-769-2329-4842

Website: https://www.3erp.com

Shapeways

Shapeways is a top 3D printing company that’s known worldwide. They’ve got tons of materials and technologies, plus a really solid supply chain. With their vacuum casting service, you can pick from different materials, get super high-quality castings, and have them made really fast.

It’s like having a magic wand for creating awesome parts.The company has helped more than 1 million customers make more than 21 million parts, using 10 technologies and 90 materials, and has sold its products to 160 countries.

Shapeways started in the Netherlands and later expanded to the United States, and has now become a superstar in digital manufacturing. Its online platform allows you to easily upload design files and choose the right materials and processes. No matter if you need a prototype or tons of parts, Shapeways has got you covered. They’re great for all kinds of stuff—like consumer products, medical gear, jewelry, and industrial stuff.

Shapeways isn’t just about tech; they’ve also built a global community where designers can share and sell their creations. This helps spread the word about digital manufacturing.

The company is all about turning customers’ creative ideas into reality with top-notch 3D printing tech and great service. They’ve really made a name for themselves in the global market.

Employee Size: 152

Address:44 W 28th St FL 12, New York, NY 10001-4212, USA

Contact: 1-844-438-7427

Website: https://www.shapeways.com/

Xometry

Xometry is a major player in on-demand manufacturing. They’ve been around since 2013 and are based in Maryland, USA. They do all sorts of things—like CNC machining, 3D printing, injection molding, sheet metal work, and vacuum casting. It’s pretty much a one-stop shop where you can get almost anything made!They use a huge global network and cutting-edge digital tools to get the job done.

In terms of “vacuum casting”, Xometry focuses on the production of high-quality plastic parts in small batches, especially suitable for manufacturing those parts with rich details and complex parts.

It is like tailor-made for each part, especially suitable for projects that require high precision and perfect surface, such as prototyping or small production. Xometry’s vacuum casting service can quickly turn design drawings into actual products to meet the needs of various industries.

Xometry’s super power lies in its online platform, where customers can upload design files, get manufacturing feasibility analysis and quotation immediately, and then place orders directly.

It has established operations in many parts of the world and has rapidly expanded its influence.

Employee Size: 1,000+

Address: 6116 Executive Blvd, Suite 800, North Bethesda, MD 20852, United States

Contact: +1-240-252-1138

Website: https://www.xometry.com

FOW Mould

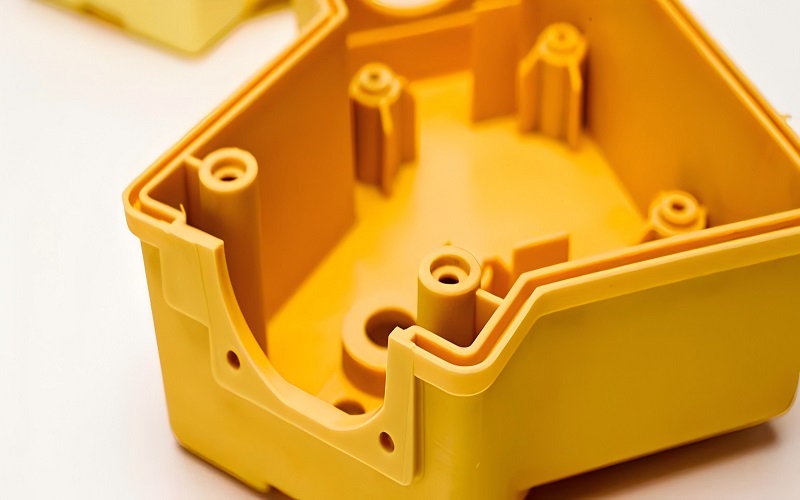

“FOW Mould”, founded in 1978 and headquartered in Huangyan District, Taizhou City, Zhejiang Province, China, is a company specializing in molds. Over the years, they have accumulated rich experience and top technology in plastic injection molds, but their best skill is “vacuum casting”.

FOW Mould’s vacuum casting is great for making small batches of top-notch plastic parts. It can handle tricky shapes and tiny details like a pro. This tech is used in all sorts of fields—like cars, home appliances, electronics, and medical stuff—helping customers get spot-on prototypes and functional parts.

Through strict quality control and efficient production processes, FOW Mould can serve global customers from design to manufacturing in one step. Their products and services are widely praised in the international market and are a trusted partner in all walks of life.

Employee Size: 992

Address: No.328 Xiaoliqiao Village, Beiyang Town, Huangyan, Taizhou, Zhejiang, 318024, China

Contact: +86-576-84288218

Website: https://www.immould.com

| Proto Labs | Star Rapid | HLH Prototypes | 3ERP | Shapeways | Xometry | FOW Mould | |

| Established | 1999 | 2005 | 2008 | 2010 | 2007 | 2013 | 1978 |

| Design | ●●●●● | ●●●● | ●●●● | ●●● | ●●●●● | ●●●●● | ●●●● |

| Quality | ▲▲▲▲ | ▲▲▲▲▲ | ▲▲▲▲▲ | ▲▲▲▲ | ▲▲▲▲ | ▲▲▲▲ | ▲▲▲▲ |

| Delivery Time | ★★★★ | ★★★★ | ★★★★★ | ★★★★★ | ★★★★ | ★★★★ | ★★★★ |

| Service | ★★★★ | ★★★★★ | ★★★★ | ★★★★ | ★★★★ | ★★★★ | ★★★★★ |

| Price | ♥♥♥♥ | ♥♥♥♥♥ | ♥♥♥♥♥ | ♥♥♥♥ | ♥♥♥♥ | ♥♥♥♥♥ | ♥♥♥♥♥ |

Summary

After understanding these seven top vacuum casting companies, we can see their unique advantages in rapid prototyping and small batch production. From Proto Labs’ quick response and high-quality delivery to FOW Mould’s fine processing and international services, these companies are focused on providing customers with efficient and precise solutions.

Whether it is medical devices, electronic products or automotive parts, they can use advanced vacuum casting technology to help customers achieve design innovation and product optimization.

By comparing these companies, we can not only find the most suitable partners, but also have a deeper understanding of how vacuum casting technology promotes the development of various industries.