| No. | Company Name | Year Established |

| 1. | Jones Plastic & Engineering | 1961 |

| 2. | Fathom Digital Manufacturing | 1984 |

| 3. | Proto Labs, Inc. | 1999 |

| 4. | American Tool & Mold Inc. | 1978 |

| 5. | MSI Mold | 2005 |

| 6. | Britech Industries | 1984 |

| 7. | Plastek Group | 1956 |

| 8. | Nicolet Plastics | 1986 |

USA, as the whole largest economy of the world demand a lot from plastic products especially injection molded. With the growing subset of sectors as medical, consumer goods and automotive applications is raising demand for more precise high-precision injection mold components.

It is rooted in the powerful industrial system established by United States since the mid-19th century which promotes the development of injection molding industry. Currently, there are over 800 plastic injection molding companies in the United States with most of them located in the states like California, Texas, Ohio, Michigan Illinois and Pennsylvania.

Through constant exploration and serving customers from all walks of life, these companies enable everyone to transition smoothly from design to production by offering ever-evolved innovative products and services.

If you are in need of a company that will be able to produce the products via injection mold, then this is your place. Well next we will give you a list of 8 rather representative American injection molding companies, these occupy the top positions in their own market with their advantages.

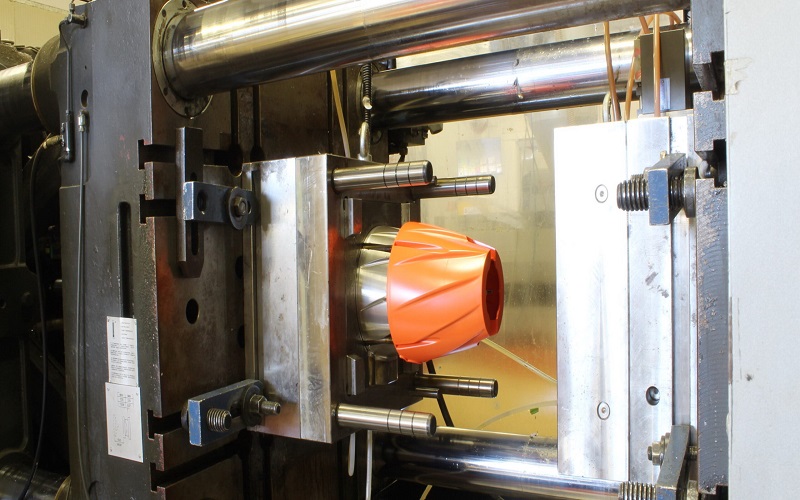

Jones Plastic & Engineering

- Location: 801 South 21st Street, Louisville, Kentucky 40211, USA

- Number of Employees: Approximately 1,200

- Specializes: High-volume precision injection molding, mold design and fabrication, assembly and finishing services. They specialize in the automotive, appliance, and industrial markets, with advanced manufacturing technologies including robotic automation and in-mold labeling.

- Website: www.jonesplastic.com

Harry Jones, along with Larry Jones founded JONES PLASTIC & ENGINEERING in 1961. With about 1,200 employees today Jones Plastic & Engineering are currently headquartered in Louisville, Kentucky.It is a world leader in high volume, precision injection molding which is widely regarded throughout the worlds automotive and appliance industries.

From complex mold design to automated production line, they offer insulation solutions in conjunction with high-quality and cost effective range of services. Jones employs modern technology and equipment to satisfy with large-scale requirements, also guarantees product quality.

By now, Jones Plastic & Engineering is already one of the world’s leading automotive and appliance mold injection molding company. They have 5 plants in the USA and offices in Europe and Asia. Jones has the professional technology and fast production capability, which saves customers’ shipping cost manpower costs, laying a solid foundation for their leading position.

Fathom Digital Manufacturing

- Location: 1050 Walnut Ridge Drive, Hartland, Wisconsin 53029, USA

- Number of Employees: Approximately 400

- Specializes: On-demand digital manufacturing services, including 3D printing, CNC machining, injection molding, and additive manufacturing. They serve industries such as aerospace, medical, automotive, and consumer products with a focus on rapid prototyping and low- to mid-volume production.

- Website: www.fathommfg.com

Fathom is perfect destination for 3D printing, additive manufacturing (AM), CNC machining, and injection molding technologies from prototyping through production. Fathom has excelled within aerospace, medical, automotive and consumer products.

Their advanced technology and commitment to quick services lead them to provide customers faster times of making products, more efficient designs, improved production efficiency.

Fathom is also a very professional injection molding company.They enable the production of complicated and precise parts while also providing faster tooling times which results in shrinking lead times.

Fathom uses conventional injection molding methods alongside the latest digital technologies in order to deliver low-cost, high-quality production solutions that cater for anything from small batch prototyping through to large scale manufacture.

Learn more about how Fathom can speed up prototype building across all project scales with additive manufacturing and 3D printing for a rapid early-stage development process, moving to injection molding ideal for volume production parts that are ordered in high quantities—allowing our customers to get products quickly to market without sacrificing quality.

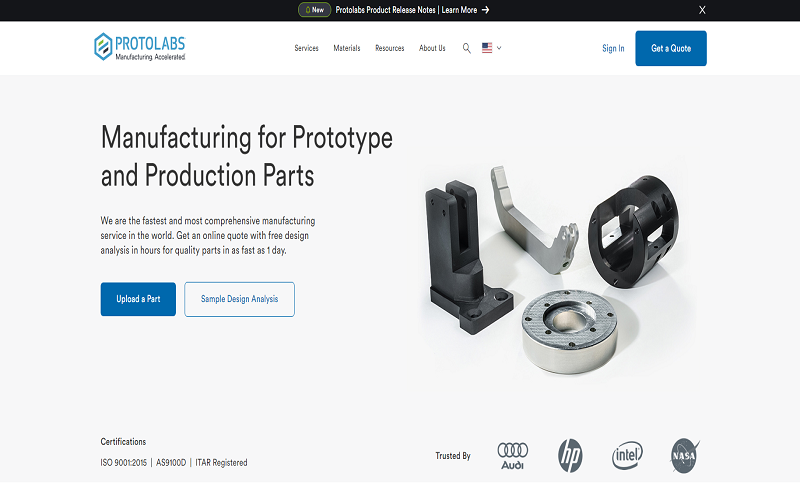

Proto Labs, Inc.

- Location: 5540 Pioneer Creek Drive, Maple Plain, Minnesota 55359, USA

- Number of Employees: Approximately 2,500

- Specializes: Rapid prototyping, low-volume production, CNC machining, injection molding, and 3D printing. They cater to industries such as medical, aerospace, automotive, and consumer electronics.

- Website: www.protolabs.com

Proto Labs: Based in Maple Plain, Minnesota,this digital manufacturing company was founded on 1999 The company specializes in processes such as injection molding, 3D printing and CNC machining to deliver rapid prototyping and low-volume production.

Proto Labs provides industries such as medical, aerospace, automotive and consumer electronics with rapid production times and short-term contract manufacturing capabilities.

Proto Labs provides injection-molding services to quickly turn designs into parts. By using automated systems they can achieve a rapid time from design to production, enabling customers access to high-quality injection-molded parts in just few days.

Such fast production method is not only getting to market and make products available quicker but also cost efficient way of doing so. Proto Labs has a wide selection of materials and tight tolerances especially when it comes down to production.

Web-enabled technology and global manufacturing capabilities allows Proto Labs to quickly provide injection molding options, saving customers time in their product development processes as well improving production models.

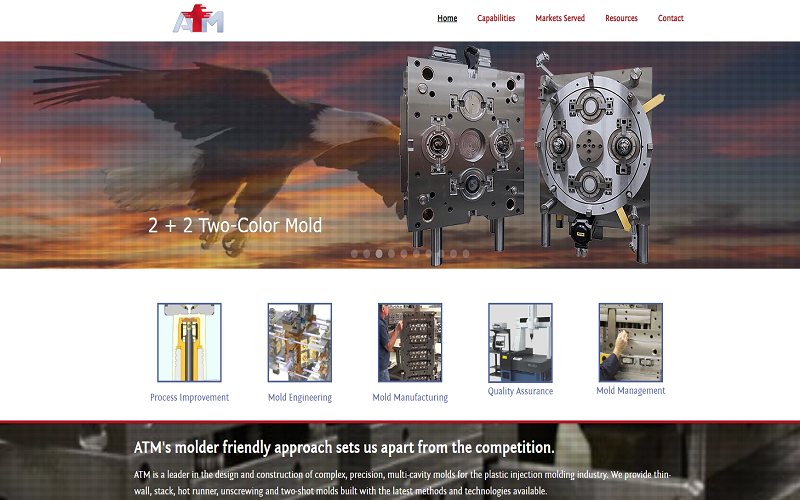

American Tool & Mold Inc.

- Location: 11850 62nd Street North, Largo, Florida 33773, USA

- Number of Employees: Approximately 200

- Specializes: High-precision injection mold manufacturing, including multi-cavity molds, stack molds, and complex mold designs. They serve the medical, packaging, and consumer products industries.

- Website: www.americantool.com

American Tool & Mold Inc.Founded in 1977, American Tool is uniquely positioned to manufacture complex multi-cavity molds up to and exceeding Class 101 specifications. It also makes multi-cavity molds, custom plastic 3D printing and assembly services.

American Tool & Mold is an industry leader for Plastic Injection Molds with advanced technology tooling and a commitment to quality.

Design and production turnkey services to guarantee the quality of product and improve efficiency in production; They have been able to quickly manufacture complex molds and deliver excellent service because of their innovative methods, rich experience.

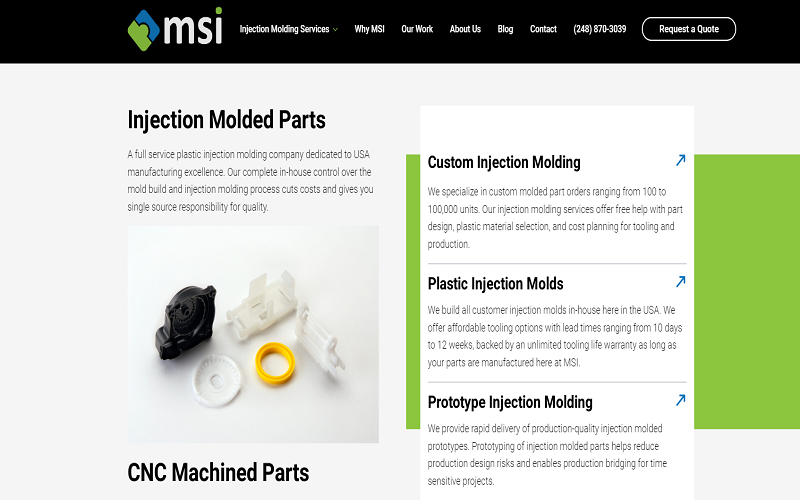

MSI Mold

- Location: 1201 East Lincoln Avenue, Madison Heights, Michigan 48071, USA

- Number of Employees: Approximately 50

- Specializes: Custom plastic injection molding, mold design and manufacturing, and short-run production. They focus on automotive, electronics, and consumer products.

- Website: www.msi-mold.com

Founded in 2005, MSI Mold is based in Madison Heights Michigan. They are a custom plastic injection molding facility and mold designer with specialization in soft tooling / short-run production follow up on small volume productions.

It operates mostly in the automotive, electronics and consumer products industries and is recognised for its quick deliveries and nimble production capabilities.

In the beginning, MSI Mold helped Detroit automotive companies with sales and technical support, as well providing mold design expertise to production processes.

What changed for 2009, that’s when the company opened a new facility specific to engineering changes on injection molds and trialblacks. The increasing demand made them grow and become better at their services, coupling this with the improvements in their technology.

This company has a comprehensive service portfolio, ranging from design to manufacturing. They use advancedThey use advanced technology and precision mold manufacturing to ensure high quality for each project.

They also do prototyping and small-volume production to help customers quickly verify their designs. The company has won the trust of many customers because of its excellent service and manufacturing capabilities.

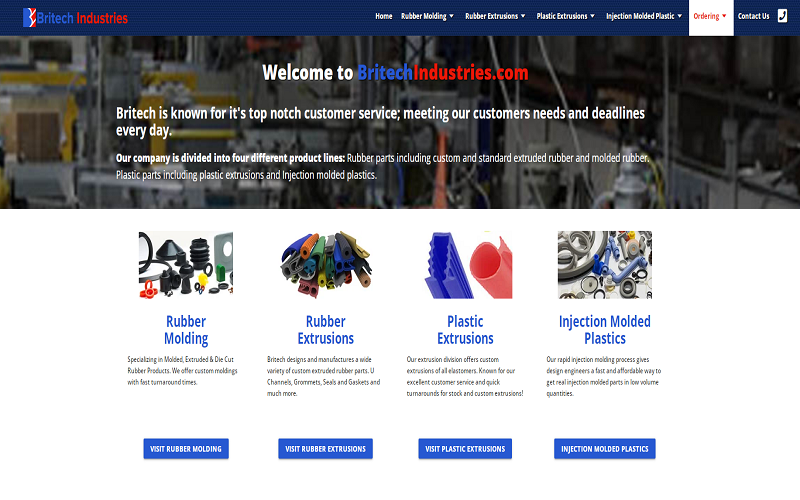

Britech Industries

- Location: 2202 Industrial Boulevard, Sarasota, Florida 34234, USA

- Number of Employees: Approximately 25

- Specializes: Custom plastic injection molding, rubber molding, and extrusion services. They specialize in producing parts for the electronics, medical, and aerospace industries.

- Website: www.britechindustries.com

Company Britech Industries was founded in 1984 and is an American company located at Sarasota, Florida. Their specialty is custom plastic and rubber molding with expertise in injection, compression and especially extrusion; they are pervasive throughout electronics, medicalierifestyle aerospace).

Britech offers the complete services from design to production, and guarantee that your project is developed under strict quality standards. The Company has the ability to address complex manufacturing programs and leverages state-of-the-art technology available in thoughtful solution design for customers.

No matter the size of your order, whether you’re seeking small or large batch production they deliver advanced products fast — keeping customers competitive edge in a rapidly shifting market.

Meanwhile, Britech makes available quick delivery as well technical support and maintenance services to help ensure that theprojects are completed on time.With rich experience and professional technology, Britech has become a trusted partner for many customers.

Plastek Group

- Location: 2425 West 23rd Street, Erie, Pennsylvania 16506, USA

- Number of Employees: Approximately 2,000

- Specializes: Custom injection molding, mold design, and manufacturing for packaging, personal care, and consumer products industries. They are known for their expertise in high-volume production and complex mold designs.

- Website: www.plastekgroup.com

Plastek Group specializes in plastic injection molding and mold design, serving the food and beverage, automotive parts, cosmetics and personal care industries. Plastek is known for its high-quality plastic packaging and innovative product design.

The company provides a full range of services from design to production, excelling in handling complex molds and precision injection molding while using automation to improve efficiency. Plastek is particularly creative in packaging, helping customers stand out in the market.

In addition to the United States, Plastek also has factories in the United Kingdom, Mexico and Brazil to serve customers around the world. With strong manufacturing capabilities and international operations, Plastek has become an industry-leading company.

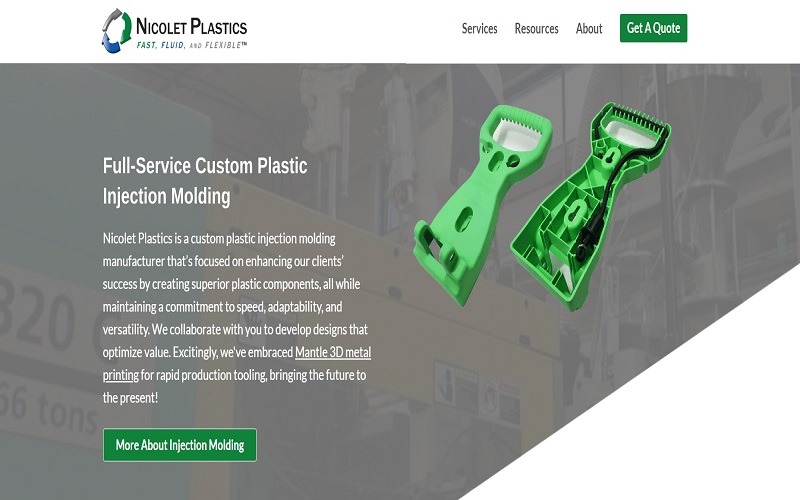

Nicolet Plastics

- Location: 16685 State Highway 32, Mountain, Wisconsin 54149, USA

- Number of Employees: Approximately 100

- Specializes: Low to moderate volume injection molding, complex part design, and post-molding services. They focus on medical, industrial, and consumer products markets.

- Website: www.nicoletplastics.com

Nicolet Plastics is a company that specializes in custom plastic injection molding, with a particular focus on low- to medium-volume production and complex parts manufacturing. The company excels in the medical, industrial, consumer goods, and electronics sectors, and is known for its high-quality workmanship and efficient production capabilities.

They offer a full range of services from product design and mold development to final production, capable of handling a variety of complex geometries and precision manufacturing requirements. Using advanced injection molding technology and automation equipment, Nicolet Plastics ensures product quality and consistency while improving production efficiency and reducing costs.

In addition, Nicolet Plastics also focuses on flexibility, can quickly respond to customer needs, and provide tailor-made solutions. With their expertise and quality services, they have earned a good reputation in the injection molding industry and are a trusted partner for many customers.

| Jones Plastic & Engineering | Fathom Digital Manufacturing | Proto Labs, Inc. | American Tool & Mold Inc. | MSI Mold | Britech Industries | Plastek Group | Nicolet Plastics | |

| Established | 1961 | 1984 | 1999 | 1978 | 2005 | 1984 | 1956 | 1986 |

| Design | ●●●●● | ●●●●☆ | ●●●●☆ | ●●●●☆ | ●●●●● | ●●●●● | ●●●●☆ | ●●●●☆ |

| Quality | ▲▲▲▲☆ | ▲▲▲▲▲ | ▲▲▲▲▲ | ▲▲▲▲☆ | ▲▲▲▲▲ | ▲▲▲▲☆ | ▲▲▲▲☆ | ▲▲▲▲☆ |

| Delivery Time | ★★★★★ | ★★★★☆ | ★★★★☆ | ★★★★★ | ★★★★☆ | ★★★★★ | ★★★★☆ | ★★★★☆ |

| Service | ★★★★☆ | ★★★★★ | ★★★★☆ | ★★★★☆ | ★★★★☆ | ★★★★☆ | ★★★★☆ | ★★★★☆ |

| Price | ♥♥♥♥☆ | ♥♥♥♥♥ | ♥♥♥♥♥ | ♥♥♥♥☆ | ♥♥♥♥☆ | ♥♥♥♥♥ | ♥♥♥♥☆ | ♥♥♥♥☆ |

Conclusion

It is really not easy to find a reliable manufacturer nowadays, because there are many new companies constantly emerging. I hope this list can help you find the injection molding manufacturer that is right for you.

Before choosing, it is best to do some background research, because a good partner is important for the success of your business. You can contact these companies, tell them your requirements for plastic injection molding, and then wait for them to provide high-quality molds.

Finding the right manufacturer can not only ensure the quality of your products, but also improve production efficiency. I hope this guide can help you find the right partner smoothly and promote the success of your project.