When you’re first getting started with 3D printing, choosing the appropriate materials is essential to getting the results you want from your print project.

Two of the more popular materials for 3D printing are PLA (Polylactic Acid) and PETG (Polyethylene Terephthalate Glycol-modified). Each has unique properties that are tailored to particular kinds of prints.

Knowing the subtle differences between PETG and PLA can help you make the best decision for your needs, whether they be strength, ease of printing, or environmental considerations.

Understanding PLA

What is PLA?

PLA, an acronym for polylactic acid, is a thermoplastic that is biodegradable and therefore ideal for aid in 3D printing.

PLA derives from renewable sources like corn starch and sugarcane, which makes it an advantage over traditional plastics derived from petroleum-based sources. PLA’s environmental advantages, along with its ease of use, have made it the filament of choice by many professionals seeking a filament that is both easy-to-use and effective.

PLA is unique due to its biodegradability. PLA is compostable under industrial composting conditions, which lowers the environmental impact of this material in the long run and is specifically attractive to people looking for sustainable 3D printing materials.

Properties of PLA

PLA possesses unique mechanical properties that enable its application for various purposes. The longitudinal tensile strength of this polymer is around 57.4 MPa, which has enough strength to create rigid objects while still providing reasonable stiffness and dimensional integrity.

However, PLA lacks flexibility and is prone to cracking under stress which maybe be less of an issue with other, less rigid polymers.

One outstanding feature of PLA is its low melt temperature at around 150-160°C. Due to this, it can be printed at a much lower temperature, reducing the chances for warping, and rendering it conducive for printing items using smaller desktop printers.

PLA prints tend to exhibit a nice surface finish, producing models that look very nice and aesthetically appealing, which add a unique quality to display models or prototype type models or any items where aesthetics play a greater role than functionality.

| Property | PLA |

| Tensile Strength | 57.4 MPa |

| Elongation at Break | 6% |

| Young’s Modulus | 3.5 GPa |

| Density | 1.24 g/cm³ |

| Melting Temperature | 150-160°C |

| Glass Transition Temp | 60-65°C |

| Impact Resistance | Low (brittle, prone to cracking) |

| Print Temperature | 190-220°C |

| Bed Temperature | 20-60°C (Optional, for adhesion) |

| UV Resistance | Low |

| Water Resistance | Low |

| Biodegradability | High (biodegradable under conditions) |

Applications of PLA

PLA material is frequently utilized in prototypes, consumer goods, and educational settings, where fast and reliable prints are necessary.

PLA’s biodegradable properties make it suitable for short-term applications like disposable products, food-safe procedures, and surgical models.

Finally, PLA is also used for biomedical scaffolds in drug delivery systems due to its safe properties for biosorption.

Overall, PLA has very low heat resistance, so it is not useful for industrial applications, nor is it useful in high heat applications. This limits its usefulness associated with functional parts and outdoor use due to its ability to degrade in moist environments and low heat.

Understanding PETG

What is PETG?

PETG, or glycol-modified PET, combines the best of both worlds, matching the strength and flexibility of PET with the ease of printing of PLA.

This means that when you choose to print with PETG, the glycol added to PET will increase its impact resistance and improve printability, making it a very effective option for functional and strong prints.

While PETG is not biodegradable like PLA, it does have the advantage of being recyclable.

PETG’s versatility, strength, and durability makes it a solid alternative for prints that will require a little more tensile strength or those which will exposed to the elements, like mechanical parts and/or outdoor signs.

Properties of PETG

PETG boasts a tensile strength of around 50 MPa, slightly lower than PLA but with greater flexibility. This makes it more impact-resistant and less prone to cracking under pressure.

It also has a higher melting temperature, typically between 220-260°C, which allows it to withstand higher temperatures during printing without warping or deforming.

Another notable feature of PETG is its chemical resistance, making it ideal for parts exposed to water, chemicals, or sunlight.

It is highly UV-stable, meaning it won’t degrade as quickly in outdoor environments compared to PLA.

PETG also offers excellent layer adhesion, resulting in strong, durable prints with a smooth, glossy finish.

| Property | PETG |

| Tensile Strength | ~50 MPa |

| Elongation at Break | 25% |

| Young’s Modulus | 2.1 GPa |

| Density | 1.27 g/cm³ |

| Melting Temperature | 220-260°C |

| Glass Transition Temp | 80°C |

| Impact Resistance | High (better flexibility, less brittle) |

| Print Temperature | 220-260°C |

| Bed Temperature | 70-90°C |

| UV Resistance | Moderate to High (better than PLA) |

| Water Resistance | High |

| Biodegradability | Low (recyclable, not biodegradable) |

Applications of PETG

Due to its durability and FDA-approved safety, PETG is widely used in the food industry for containers and utensils, as well as in medical devices where chemical resistance and cleanability are critical. Its ability to handle functional parts, such as mechanical components or outdoor objects, makes PETG a versatile material for projects requiring both strength and longevity.

PLA vs. PETG: Which Should You Choose?

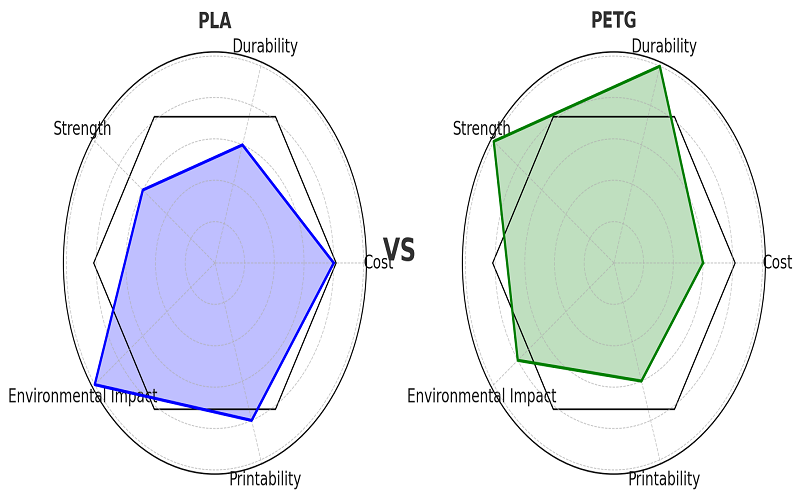

The following aspects should be taken into account when deciding between PETG and PLA filaments for 3D printing: cost, mechanical qualities, printability, and environmental effect.

Every filament has benefits and drawbacks that influence the output in the end. Regardless of your level of skill, knowing the benefits and drawbacks of each filament can help you make a better informed decision.

PLA vs. PETG: Printability and Ease of Use

PLA is regarded as one of the most user-friendly filaments available to new users and is easy to print. The material has a low melting temperature in the range of 190°C to 220°C; this makes it compatible with a wide array of printers, including entry-level or less expensive printers available on the market.

PLA also has a much lower incidence of warping during the print process, so a heated bed is not usually a necessity. Additionally, because PLA cools fast after extrusion, it is able to hold its shape while continuing to print, making it an excellent filament for more detailed models.

There is also a lot of variety with regards to the smooth surface finish found with PLA as well as the variety of colors to choose from.

In contrast, PETG have a higher melting temperature (between 220° and 260°C), which can be a challenge to achieve. PETG usually has to have a heated bed setup on the printer at a temperature of about 70 to 90°C for proper adhesion and warping prevention.

Overall, while PETG may take a little more attention to detail to know your printer settings, PETG has an operational advantage over PLA in that it is longer lasting durability.

PLA vs. PETG: Mechanical Properties

When discussing the mechanical features of PLA and PETG, it is worth considering the properties of tensile strength, flexibility and resistance to impact.

PLA has a higher value of tensile strength, with a nominal of about 57.4 MPa, indicating that it can endure higher stresses prior to failure during the loading of the material.

However, the downside of PLA’s strength is its brittleness. While PLA can hold its form well in static loads, it has a propensity to crack or snap upon any impact or bending loads. This brittleness diminishes its application in parts needing mechanical durability and use over time.

Conversely, PETG has a slightly lower value of tensile strength of about 50 MPa, but provides a better degree of flexibility and impact resistance. PETG may bend or deform slightly under loading without failure and in general can be a better fit for more functional parts that require a level of resilience.

As far as heat resistance is concerned, PETG outperforms PLA. PLA has a glass transition temperature (the temperature when the material starts softening) which is necessary around 60-65°C and PETG is higher at about 80°C.

Therefore, PETG may be a more reasonable option for functional parts or outdoor use.

PLA vs. PETG: Environmental Impact

Environmental impact is an important consideration to take into account when determining whether to use PLA or PETG.

PLA is biodegradable. It is derived from renewable sources such as corn starch or sugarcane, making it a more environmentally friendly alternative to plastics produced by petrochemicals. Industrial composting systems under proper conditions can break down PLA after a number of months, meaning its environmental impact can be diminished.

PETG, while it is not biodegradable, is recyclable. This offers a different avenue for environmentally considerate users to follow. Once printed, PETG waste can be sent to recycling facilities and processed into other plastic products, which further reduces its environmental impact as long as the plastic is appropriately disposed of. Limits in recycling facilities for PETG may also differ from location to location, which further complicates its overall sustainability.

Overall, PLA will be preferable for your application should you desire the biodegradability. PETG, however, may work better in applications that require long-term durability and some method of recyclability.

PLA vs. PETG: Cost Analysis

PLA and PETG are more affordable than some more advanced filaments such as abs or nylon.

PLA is usually cheaper and costs about $12-20 per kilo. As PLA is cheap, easy to use and easy to find, it is a good choice for prints that are not too demanding.

The price of PETG generally varies between $15 and $30 per kilo. Although the price difference is not important, PETG is more durable and elastic, which means less printing breakdowns and longer service life of parts.

If your project requires a stronger and more durable part, PETG may be more profitable in the long run, even if its price is slightly higher.

Conclusion

In the end, the choice between PLA and PETG comes down to the specific needs of your project:

Choose PLA if you need an easy-to-print, biodegradable, and affordable material.

Choose PETG if your project requires durability, impact resistance, and heat resistance, especially for functional parts, mechanical components, or outdoor applications.

Ultimately, both materials have their place in 3D printing. By understanding the strengths and limitations of each, you can make an informed choice that ensures your next print is a success.