ABS (acrylonitrile-butadiene-styrene) plastic is an extremely common thermoplastic in everyday life due to its strength, durability, and low price; it is extensively used in injection molding, 3D printing, and the production of auto parts and household products.

As ABS continues to be ubiquitous in normal life, people have begun to worry about its safety, especially related to health and environmental concerns.

Next, we will briefly talk about the characteristics of ABS plastic, the health risks it may bring, and how to use it safely.

At the same time, we will also look at its applications in different fields, including its impact on the environment. We hope these contents will give you a clearer understanding of ABS plastic and let you know how important it is in modern industry.

What is ABS?

ABS is one of the most cost-effective thermoplastic polymers.

It exhibits excellent mechanical properties, such as high-temperature resistance (approximately 110 to 125ºC) and high impact resistance without distortion.

ABS is easy to process, easy to work with in a facility, can be molded into a variety of complex shapes, and has high “processability.”

The Secret Recipe: What’s Inside ABS Plastic?

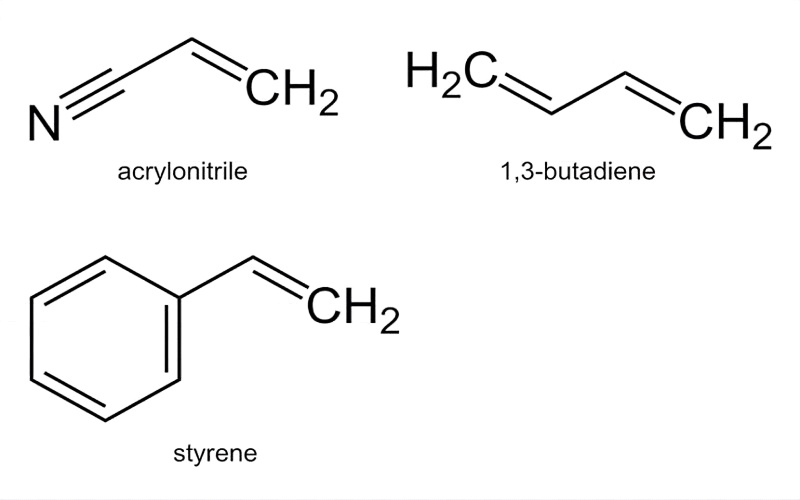

It consists of three different chemical components: acrylonitrile, butadiene and styrene.

- Acrylonitrile gives ABS plastic good chemical and thermal resistance.

- Butadiene increases its toughness and impact resistance.

- Styrene makes it harder and easier to work with.

These features make abs a very practical material that can be used in many different situations.

Properties of ABS

Resistance to shock: ABS is incredibly strong and can absorb a lot of shock without breaking.

Resistance to heat: ABS is stable at high temperature and will not melt until it reaches 105ºC (221ºF).

Resistance to chemicals: ABS has good chemical resistance to a variety of chemicals like acid, alkali, salt, and so on.

Rigidity: ABS is relatively hard, which allows it to retain its shape after treatment and not be easily deformed.

Easy to process: ABS is easy to process and can be made into different shapes using injection molding, 3D printing, etc.

Below is a concise rating table of the physical properties of the ABS material itself, with 1 indicating very poor performance on that property and 10 indicating very good performance.

For example, the “heat resistance” rating of ABS is 8, which means it can withstand certain high temperatures in conventional applications, but because it is not suitable for extreme high temperature environments, the disadvantage rating is 6.

| Attribute | Advantages Score (1-10) | Disadvantages Score (1-10) | Explanation |

| Strength and Toughness | 9 | 4 | Strong and durable, but may become brittle in cold conditions. |

| Heat Resistance | 8 | 6 | Handles heat well, but not ideal for very high temperatures. |

| Chemical Resistance | 8 | 5 | Resists many chemicals, but can be damaged by strong acids or bases. |

| Density (1.04-1.06 g/cm³) | 7 | 5 | Moderate weight, balances strength without being too heavy. |

| Ease of Processing | 9 | 3 | Easy to mold, but can release fumes during processing. |

| Electrical Insulation | 8 | 3 | Great for electrical insulation, but may degrade in humidity. |

| Water Absorption (0.3%) | 6 | 6 | Absorbs little water, but performance can drop if it does. |

| UV Resistance | 5 | 7 | Breaks down under UV light without protection. |

| Hardness (Rockwell Hardness: R100) | 8 | 4 | Hard material, but can lose hardness in extreme conditions. |

Applications of ABS Plastic

ABS plastic is widely used in many industries due to its versatility:

1.Automobile:

ABS is popular in Automobile industry. It is mainly used in components such as dashboards, door friezes and bumpers due to its shock and heat resistance.

2.Consumer electronics:

Many electronic products are made of ABS for their robustness, beauty and ease of manufacture.

3.Toys:

ABS is a commonly used material in the toy industry. Durable and safe, ideal for making all kinds of toys.

4.Medical devices:

ABS is also used in medical devices, especially in enclosures and 3D printed models. But beware, medical abs must meet strict standards to be safe.

The Relationship Between ABS and BPA: Is There BPA?

In fact, ABS plastic does not contain BPA. You may have heard of BPA. Some water bottles and food packaging contain this chemical. People are worried that it will be bad for the body, especially affecting our hormones. Don’t worry, ABS plastic has nothing to do with BPA. BPA is not used in its manufacturing process.

Many things in our lives are made of ABS plastic, such as toys, kitchen appliance shells, etc. Because it does not contain BPA, it is relatively safe to use, especially in food contact or children’s playthings, which is more reassuring.

Is ABS Plastic Really Safe? Let’s Find Out

About ABS plastic, many people often ask: “is ABS plastic non-toxic?” According to research, ABS plastic is generally non-toxic in the solid state.

Therefore, its use in consumer products is generally safe, particularly if it meets relevant regulatory standards. Here are some important things to watch out for:

ABS Toys: Are They Safe for Your Little One?

ABS plastic is very durable, so many children’s toys are made of it, such as building blocks, dolls, toy cars. ABS plastic is not easy to break or deform, can withstand strong impact.

When it comes to safety, agencies like FDA and CPSC have strict rules to ensure ABS plastic toys are safe. These rules require that toys do not contain substances dangerous to children, such as lead. These harmful substances can be dangerous if ingested or inhaled by children. ABS plastic does not easily break into sharp pieces, reducing the risk of injury to children.

The ABS surface is smooth, therefore it is unlikely to have sharp edges, making it safer for children. Also, the toy would not leach harmful chemicals, even if it were wet with saliva, an ideal characteristic of toys that kids may put in their mouth.

So long as safety standards are met, toys made of ABS plastic are as safe as possible. ABS plastic durability and stability should help provide reassurance to manufacturers and parents alike.

Food Containers and ABS: Can They Coexist Safely?

ABS plastic is used occasionally for food packaging but is generally not suitable for contact with hot food.

Although ABS itself does not allow prolonged contact with food or hot liquids, it can be used in a number of low-risk food applications, such as kitchen utensils, storage containers, and coffee machine components.

Manufacturers must use FDA approved materials of ABS type, so it has been tested to not leach harmful chemicals into food.

However, it’s important to note that ABS should still be used within the recommended temperature limits to ensure safety. Consumers are advised to avoid using ABS-based products for cooking or heating food to minimize any potential risks.

ABS in Healthcare: Safe for Medical Applications?

ABS plastic has many uses in the medical field, especially for manufacturing medical device housings and 3D printing of certain medical models.

However, not all ABS are in direct contact with the body. Normal ABS may not be suitable for direct contact with the body. To solve this problem, there is a special ABS called medical grade ABS. It is specially treated and sterilized and does not contain harmful substances, so it can be used with confidence in places where contact with the patient is required.

As ABS is easy to machine, robust and chemical resistant, it is suitable for medical instruments that are not in direct contact with the body, such as blood pressure monitors, hospital furniture and a few simple tool cases.

In general, abs is safe for many medical uses. Keep in mind that normal ABS is different from medical grade ABS, which is manufactured under stricter conditions to ensure its safe use in medical environment.

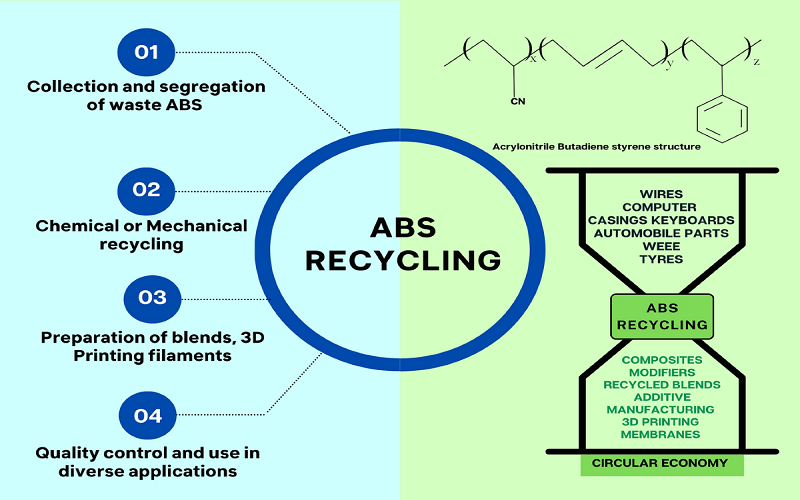

Environmental Impact: The Challenges of ABS Plastic and Recycling

Like most ordinary plastics, ABS plastic is mainly made from petroleum. Plastics such as PLA, on the other hand, are derived from organic materials such as corn or sugar cane. Since ABS is made from oil, this affects its “durability”.

ABS plastic does not break down naturally easily, which means that if disposed of in the environment, it stays for a long time and can contaminate soil and water sources. This plastic requires large quantities of petrochemical products for its manufacture, which also increases energy consumption and greenhouse gas emissions, and has a negative impact on the environment.

When disposing of ABS plastic waste, common methods are:

- Landfills : some used ABS plastics are sent to landfill. These plastics do not naturally degrade in landfills and can have long-term effects on the environment.

- Incineration: another method of disposal is incineration. However, when ABS is burned, harmful chemicals such as styrene and butadiene are released. These substances are dangerous to the air and the environment.

Since ABS plastic is made from petroleum and does not degrade easily, both of these production and disposal processes have an impact on the environment.

To protect the environment, we need to recycle these plastics better. The process of recycling ABS plastic is actually quite simple, like this:

First, collect the plastics you don’t need, such as old toys, electronic housings, and car parts. Then, wash the plastics clean and remove the dirt on them. Then cut the plastics into small pieces, which makes it easier to handle. Finally, heat the small pieces, melt them, and then make them into plastic pellets again, which can be used to make new products. This way, you don’t have to make new plastics, and you can also reduce waste.

In addition to recycling, exploring alternatives such as biodegradable plastics or renewable materials can further help protect the environment by reducing dependency on oil-based plastics.

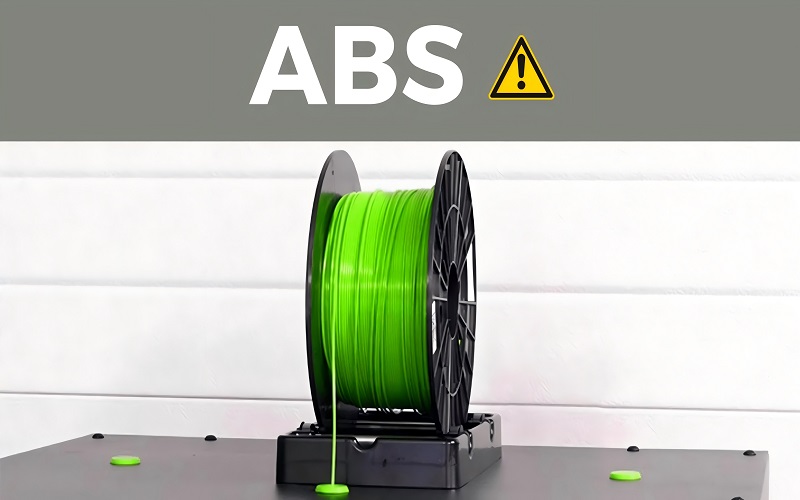

How to Safely Handle and Process ABS Plastic?

Be careful when using ABS plastic, especially when doing 3D printing. Because 3D printed ABS releases harmful smoke.

For security reasons, you can do the following:

Keep ventilation: make sure that air circulates well in the work area and use a fan or window to evacuate smoke.

Wear protective equipment: it is best to wear a mask and gloves when printing. Avoid inhalation of harmful fumes and direct contact with plastic.

Avoid contact with hot materials: do not touch hot ABS materials directly. Use tools to handle these materials to avoid burns.

Keep the work area clean: clean the work area, keep the environment clean and reduce the accumulation of hazardous substances.

Follow operating instructions: follow operating instructions of equipment and materials to ensure safety.

This will help you reduce your exposure to harmful gases and protect your health.

Conclusion: Is ABS Safe to Use?

In general, ABS plastics are generally considered safe, especially when used as toys and food containers.

It does not release harmful substances in its solid state. However, some volatile organic compounds may be produced during the manufacturing process, and ABS cannot be naturally degraded, which has a certain impact on the environment.

As long as we comply with the relevant safety regulations and handling methods, ABS plastic remains a versatile and reliable material that can be used in many industries.