If you’ve ever drunk bottled water or soda, chances are you’ve been using a type of plastic called PET.

PET is one of the most common plastics in the world. Whether it’s in beverage bottles, food packaging, or clothing, PET is almost everywhere.

But as concerns grow about plastics and their impact on health and the environment, many people are beginning to ask: Is PET really safe?

In this article, we’ll uncover the truth about PET and look at whether it’s safe for everyday use and its impact on the environment.

What is PET Plastic?

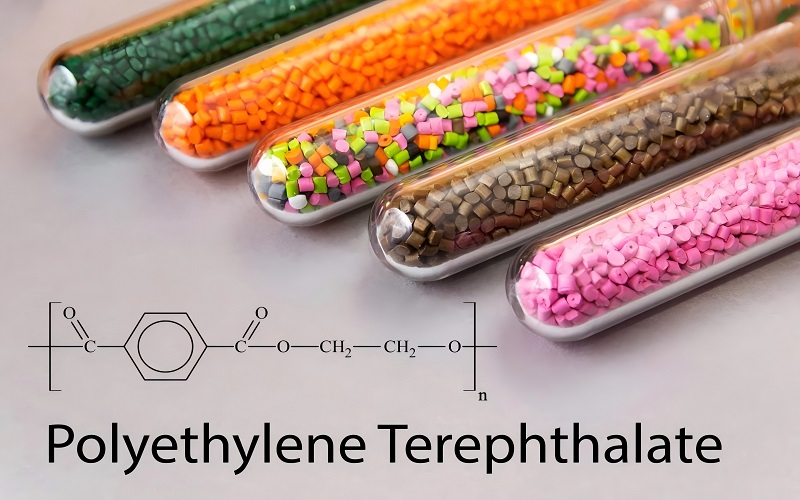

The full name of PET is Polyethylene Terephthalate; it is a very common plastic belonging to the polyester category.

PET is produced by chemical reactions between ethylene glycol (EG) and terephthalic acid (TPA), which eventually form a long polymer chain. There are many ester bonds in this molecular chain, and this structure gives PET very good physical and chemical properties.

In other words, because of this unique structure, PET is very strong, durable, and can resist corrosion from some chemicals.

| Property | Value |

| Density | 1.38 g/cm³ |

| Tensile Strength | 55-75 MPa |

| Melting Point | 250-260°C |

| Water Absorption | 0.1-0.4% |

| Elongation at Break | 50-150% |

| Thermal Conductivity | 0.24 W/m·K |

| Specific Heat Capacity | 1.0-1.2 J/g·K |

| Impact Strength | 2.7-4.5 kJ/m² |

| Dielectric Strength | 16-22 kV/mm |

| Glass Transition Temperature | 70-80°C |

PET Plastic Applications

PET plastic is used in many places, and it can be found in many things we come into contact with every day, such as:

Packaging: food and beverage packaging, such as water bottles and food boxes.

Fiber materials: PET can also be made into polyester fibers, such as clothes, carpets, and other household items.

Industrial and medical: Engineering parts, electronic product shells, and even some medical equipment also use it.

3D printing: There is a modified version of PET called PETG, which is particularly suitable for 3D printing. Many engineering models and prototypes will use it.

Automotive industry: PET is also used in cars, such as doors and dashboards.

Environmentally friendly products: For example, recycled fibers made from old PET bottles can be made into clothes, shoes, and even some home decorations.

PET Manufacturing Process

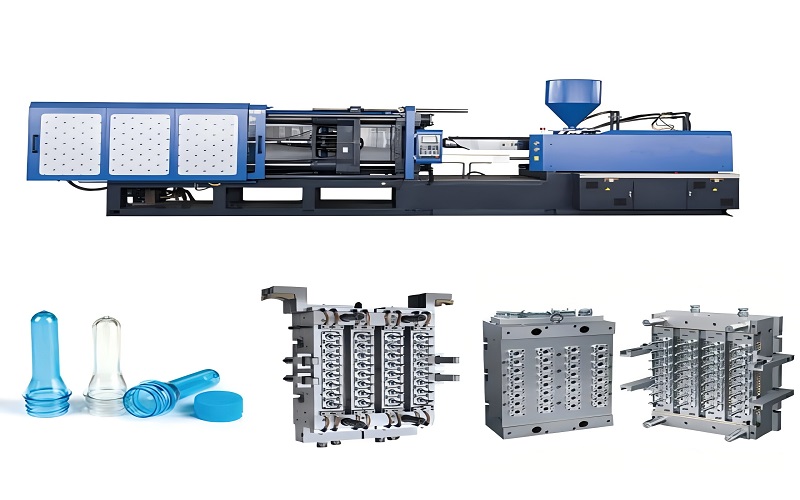

There are two common processes for producing PET plastics: “extrusion” and “injection molding.

Extrusion is the process of melting PET and squeezing it out before cooling and cutting it. This process is simple and efficient, making it ideal for mass production.

Injection molding is used to make complex-shaped products such as PET bottle preforms and food containers. By heating and melting the PET and injecting it into a mold and cooling it to shape, injection molding can achieve high precision and is suitable for products with high detail requirements.

Is PET Plastic Safe for Food and Drinks?

PET is generally considered a safe food and beverage packaging material and has been approved by regulatory agencies such as the FDA and the European Food Safety Authority (EFSA).

PET does not contain phthalates and does not contain BPA, which is an important advantage for consumers who are generally concerned about bisphenol A.

However, when PET is exposed to certain conditions, such as high temperatures, there may be a risk of chemical leaching.

Chemical Leaching: Should You Be Worried?

When chemicals from plastics get into food or drinks, we call it “leaching,” especially when the plastic is exposed to high temperatures.

For example, if a PET bottle is left in the sun for a long time in a car, harmful substances may seep into the drink in the bottle.

A chemical called antimony is used in the PET production process, and studies have shown that antimony can enter drinks when PET bottles are heated or used repeatedly.

Although the amount is small, it is still a bit worrying if exposed for a long time.

PET in Textiles: Is It Safe for Your Skin?

PET is a very common synthetic fiber material used to make clothes and other textiles.

Generally speaking, PET is safe, and its chemical structure is stable, so it will not easily release harmful substances. However, some people who are sensitive to the fiber may find it uncomfortable in hot or humid environments.

Although PET has low air permeability and low moisture absorption, some polyester fibers are now specially treated to help perspiration and reduce discomfort.

In general, PET is safe to use in clothing as long as it is used and washed properly.

Safety of PET in Medical Use

PET is very common in the medical field and is used for drug packaging and disposable devices because it is stable, does not release harmful substances, and does not have adverse reactions with the human body.

Agencies such as the FDA have recognized its safety.

Although there may be a small amount of chemical migration under extreme conditions, there is almost no risk in normal use, so you can use it with confidence.

Environmental Impact of PET Plastic

In addition to health issues, the impact of PET plastic on the environment cannot be ignored.

First, PET plastic is difficult to decompose naturally. Although it will break into tiny particles, these microplastics may remain in the environment for many years.

Although PET is recyclable, in fact, only a small part is actually recycled. A large amount of PET plastic ends up being discarded or even flows into the ocean, adding to the problem of plastic pollution.

In addition, even if PET is recycled, it is usually downgraded to lower-quality products and cannot be reused like glass.

Tips for Reducing Your Exposure to PET Plastic

If you’re concerned about the safety of PET plastic and its environmental impact, here are some simple tips to minimize your exposure and reduce your use of plastic:

- Use Reusable Bottles: Invest in a stainless steel or glass water bottle to reduce the number of single-use PET bottles you consume.

- Avoid Heat: Don’t leave PET bottles in hot cars or expose them to high temperatures, as this can increase the risk of chemical leaching.

- Choose Fresh Produce: Whenever possible, opt for fresh, unpackaged food rather than items wrapped in plastic. This reduces your exposure to PET plastic and cuts down on plastic waste.

- Recycle Properly: Make sure to recycle your PET bottles and packaging. Look for products made from recycled PET to support the recycling industry.

Conclusion: Is PET Plastic Safe?

PET plastic is generally safe to use.

It does not contain harmful chemicals such as BPA and phthalates, and has been certified by authoritative organizations such as FDA and EFSA. Under normal use, PET poses no threat to health or the environment.

Although a small amount of chemical migration may occur at high temperatures or during repeated use, this is actually rare and the amount is extremely low, and the impact on the human body is almost negligible.

In general, PET is a safe, reliable, and environmentally friendly material choice.

FAQs

Is PET Plastic Safe to Use in the Microwave?

It is not recommended to heat PET plastic in the microwave.

Although it can withstand a certain temperature, some chemicals can be released at high temperatures.

For safety reasons, it is preferable to heat food in containers labelled “microwave safe” rather than in bottles or PET-containers.

What are the Alternatives to PET Plastic?

In fact, there are several materials that can replace PET plastic, especially if you care more about environmental protection and health:

- Glass: glass is an excellent choice, especially for food and beverage packaging. It does not have to worry about chemical leaching and can be recycled many times. However, the glass is heavy and can easily break.

- Stainless steel: stainless steel is very durable and particularly suitable for water bottles and food containers. High temperature resistance, easy to clean; do not worry about harmful substances immersed in food.

- Lactic polyacid (PLA): PLA is made from plant materials that degrade naturally and are therefore environmentally friendly. However, it is less heat-resistant and less durable than PET and is better suited for disposables.

Is PET Plastic Biodegradable?

Strictly speaking, PET plastic does not degrade as naturally as organic materials.

But it can be recycled and transformed into other products, such as fibres and packaging materials.

Therefore, recycling reduces the impact on the environment.

What are the Advantages of Using PET Plastic?

PET plastic has many advantages, such as lightness, moisture resistance, and so on. It is particularly suitable for packaging food and beverages.

In addition, it is recyclable and has great potential for environmental protection.

And compared with glass, a pet bottle is not easy to break, more convenient, and safer for transportation.