| No. | Company Name | Year Established |

| 1. | Hi-tech moulds Co.,Ltd | —— |

| 2. | FOW Mould | 1978 |

| 3. | Silver Basis | —— |

| 4. | Ideal Mould Tech (ShenZhen) Co., Ltd | 1997 |

| 5. | Kelon mould Co., Ltd | 1995 |

| 6. | TK GROUP (HOLDINGS) LIMITED | 1965 |

| 7. | SINO MOULD | 1999 |

| 8. | Saihao Industrial Co., Ltd | 1975 |

| 9. | Yahong Moulding Co., Ltd | 1997 |

| 10. | WIT MOLD | —— |

Introduction to China’s Injection Molding Industry

China has become a global leader in the injection molding industry, with a large number of reliable mold manufacturers offering high-quality plastic injection molding solutions.

The country’s injection molding industry has experienced rapid growth, driven by increasing demand from various sectors, including automotive, medical, and consumer electronics.

China’s mold manufacturers have invested heavily in advanced technology and equipment, enabling them to produce high-precision molds and injection molded parts.

Top 10 Reliable China Molds Manufacturers

Hi-tech moulds Co., Ltd: A leading mold manufacturer with expertise in automotive mold design and production.

FOW Mould : A high-tech company founded in 1978, they work closely with customers around the world to design and manufacture superior quality molds for industries such as buckets, warehouses and storage, baby products, furniture, appliances, automotive and more.

Silver Basis: A professional mold manufacturer with expertise in automotive and consumer electronics mold design and production.

Ideal Mould Tech (ShenZhen) Co., Ltd: They have a complete set of mold design, manufacturing and inspection standards that meet the quality requirements of Europe, the United States and Japan. Potential manufacturing defects can be predicted and avoided and enable you to anticipate and resolve manufacturing problems at the earliest stage.

Kelon mould Co., Ltd: A professional mold manufacturer producing over 1,000 sets of stamping molds, 600 sets of injection molds, and 80 sets of thermoforming foam annually.

TK GROUP (HOLDINGS) LIMITED: A leading global one-stop injection molding solution provider with expertise in consumer electronics, personal care, and medical mold design.

SINO MOULD: A professional mold manufacturer with an excellent design team, providing high-quality die-casting molds and plastic injection molding solutions.

Saihao Industrial Co., Ltd: A well-established mold manufacturer with over 40 years of experience in automotive mold design and production.

Yahong Moulding Co., Ltd: A professional mold manufacturer with expertise in automotive and home appliances mold design and production.

WIT MOLD: A well-established Chinese mold manufacturer with over 10 years of experience, specializing in high-quality injection mold production for various sectors, including automotive and electronic devices.

Injection Molding Fundamentals

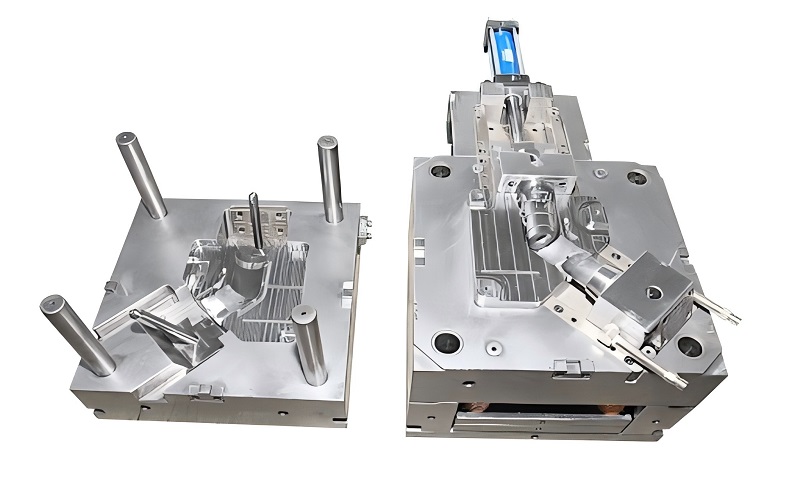

Injection molding is a manufacturing process used to produce plastic parts by injecting molten plastic into a mold.

The process involves several stages, including mold design, plastic injection mold tooling, and production. Designing lifters for injection molding is crucial as they create internal undercuts in molded parts and facilitate ejection. Material selection for lifters is essential to ensure durability and efficiency in the tooling process.

Injection molding is widely used in various industries, including automotive, medical, and consumer electronics.

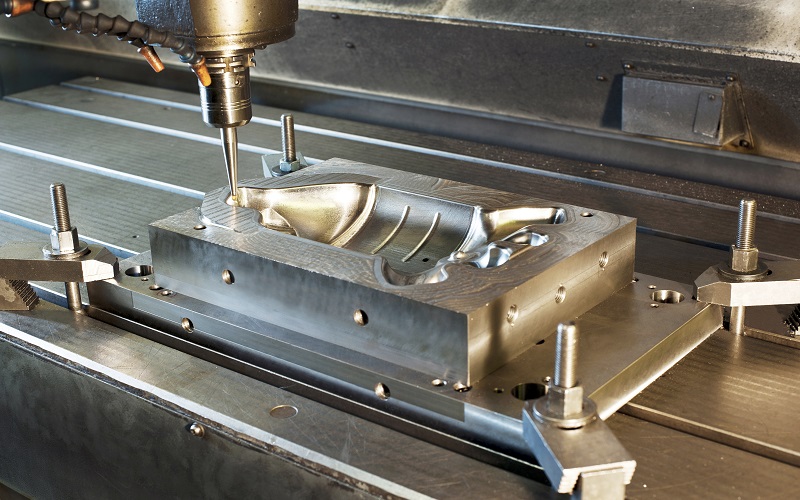

The Importance of Precision in Injection Molding

Precision is critical in injection molding to ensure the production of high-quality plastic parts.

A reliable mold manufacturer must have expertise in mold manufacturing, including the production of precision molds and injection molds tailored to specific industries such as automotive and medical, to ensure precision and accuracy.

Precision molds are essential for producing complex plastic parts with tight tolerances.

Designing for Plastic Injection Mold Success

Mold design is a critical stage in the injection molding process.

A well-designed plastic mold ensures the production of high-quality plastic parts with precise specifications and minimal defects.

A reliable mold manufacturer must have expertise in mold design and production to ensure success.

Overcoming Common Challenges in Injection Molding

Common challenges in injection molding include mold design, material selection, and production process optimization.

A reliable mold manufacturer must have expertise in overcoming these challenges to ensure successful production.

Industry experience and expertise are essential for overcoming common challenges in injection molding.

Why Choose a China Molds Manufacturer for Your Plastic Injection Mold Needs?

China’s mold manufacturers offer high-quality plastic injection molding solutions at competitive prices.

Industry experience and expertise in mold design and production ensure precision and accuracy.

Quality control and assurance ensure defect-free products.

After-sales service and support ensure customer satisfaction.

Industry Experience and Expertise

A reliable mold manufacturer must have industry experience and expertise in mold design and production.

Expertise in various industries, including automotive, medical, and consumer electronics, is essential.

A professional mold manufacturer in the plastic mold business must emphasize their commitment to quality control and efficient production processes. This includes having a strong technical team with expertise in mold design and production.

Quality Control and Assurance

Quality control and assurance are critical in injection molding to ensure defect-free products and high-quality mold production.

A reliable mold manufacturer must have a robust quality control system in place.

Industry certifications, such as ISO 9001, ensure compliance with international quality standards.

Competitive Pricing and Effective Supply Chain

Competitive pricing is essential for a reliable mold manufacturer to ensure customer satisfaction.

Effective supply chain management ensures timely delivery of high-quality plastic injection molding solutions.

A professional mold manufacturer must have a well-established supply chain to ensure success.

Sustainability Practices in Injection Molding

As a responsible injection molding company, China Mold prioritizes sustainable practices in our operations. Below are some of the sustainable practices we have implemented:

Energy-efficient equipment: We use energy-efficient injection molding machines and equipment to minimize energy consumption and reduce greenhouse gas emissions. This not only helps in conserving energy but also lowers operational costs.

Recycling programs: Our recycling programs for plastic waste and scrap materials are designed to reduce the amount of waste sent to landfills. By recycling, we conserve natural resources and contribute to a circular economy.

Sustainable materials: We offer sustainable material options for our customers, such as bioplastics and recycled plastics. These materials help in reducing the environmental impact of our products and support our commitment to sustainability.

Water conservation: Implementing water-saving measures in our manufacturing process is crucial. We focus on reducing water consumption and minimizing wastewater generation, ensuring that our operations are as eco-friendly as possible.

Waste reduction: We strive to minimize waste generation in our operations. By implementing waste reduction and recycling programs, we aim to significantly reduce the amount of waste sent to landfills.

Technological Innovations in Injection Molding

The injection molding industry is constantly evolving, with new technological innovations emerging regularly.

- Advanced mold design software: Utilizing advanced mold design software allows us to create complex mold designs and simulate the injection molding process. This reduces the risk of errors and significantly improves product quality, ensuring that our plastic injection molds meet the highest standards.

- 3D printing: We leverage 3D printing technology to create prototype molds and parts. This innovation reduces the time and cost associated with traditional mold making methods, allowing for faster turnaround times and more efficient production processes.

- Robotic automation: Implementing robotic automation in our manufacturing process has improved efficiency and reduced labor costs. Robots handle repetitive tasks with precision, ensuring consistent quality and freeing up our skilled workforce for more complex tasks.

- In-mold labeling:Our in-mold labeling services enable the creation of complex labels and designs directly in the mold. This reduces the need for secondary operations, streamlining the production process and enhancing the aesthetic appeal of the final product.

- Micro-injection molding: Investing in micro-injection molding technology allows us to produce small, intricate parts with high precision and accuracy. This is particularly beneficial for industries requiring detailed and miniature components, such as medical and electronics sectors.

Conclusion

Partnering with a reliable China molds manufacturer is essential for accessing high-quality plastic injection molding solutions and precision molds.

Industry experience and expertise, quality control and assurance, and competitive pricing ensure customer satisfaction.

A professional mold manufacturer must have a strong technical team, robust quality control system, and well-established supply chain to ensure success.