In our daily lives, plastic usually gives the impression of being an insulator. For example, the outer skin of electrical cords and outlet housings, plastic serves to stop current from passing through and avoid electrocution, making it a reliable insulator. However, with the rapid advances in materials science, scientists have developed plastics that can conduct electricity.

So, is plastic a conductor or not, and can it conduct electricity?

Join us and learn about the conductivity of plastic.

Conductivity of Plastics

The conductivity of plastics can be classified into three types: conductors, semiconductors, and insulators.

In the field of electronics, traditional plastics are typically considered insulators.

For this reason, plastics are very useful in situations where current needs to be isolated. For example, plastics like polyethylene (PE) and polyvinyl chloride (PVC) are commonly used as insulation layers for electrical wires and in the packaging of electronic components, helping to prevent electrical leakage. As a result, they are indispensable materials in modern electrical engineering.

Why Doesn’t Plastic Conduct Electricity?

1.Super High Resistivity

Plastic has extremely high resistivity, like polyethylene (PE) and polyvinyl chloride (PVC) at 10¹²-10¹⁸ Ω·m, billions of times higher than metals (e.g., copper). This means electricity can’t pass through easily.

2.No Free Electrons

Plastic is made of long-chain polymers linked by covalent bonds, locking electrons in place. Unlike metals with free electrons moving between atoms, plastic has no “path” for electricity to flow.

3.Poor Heat Conduction

Since electrons can’t move, heat can’t transfer either. Plastic blocks both electricity and heat, making it a double insulator.

4.Composition Features

Most plastics are organic polymers with carbon and hydrogen, some with chlorine (PVC) or oxygen and nitrogen (nylon). These tightly bonded chains trap electrons, so whether thermosetting (shaped once) or thermoplastic (reshapable), they don’t conduct.

5.Breakdown Voltage

Normally, plastic doesn’t conduct, but if the voltage gets too high (reaching breakdown voltage), it loses its insulating ability and starts conducting. This rarely happens in daily life, though.

What is Conductive Plastic?

In fact, some plastics are conductive.When electricity is mentioned, the first thing that comes to mind is probably wires.

We’re used to thinking of metal as the best material for conducting electricity, and there’s no doubt about it – it’s found in almost every electronic device, from light bulbs to cell phones, computers, and televisions.

But surprisingly, certain non-metallic materials, such as conductive plastics, can also act as conductors, showing no less potential.

Electricity is actually electrons traveling between atoms. Metals conduct electricity because their electrons move easily. But by tweaking the structure in plastic molecules, some plastics can also conduct electricity like metals.

The discovery came from the laboratory of Hideki Shirakawa, who discovered in a misguided experiment that polyacetylene was surprisingly conductive, and that he added conductive additives or changed the molecular structure in order to improve the conductivity.

Common Types of Conductive Plastics

1. Polyaniline (PANI)

Polyaniline is usually an insulator, but when mixed with a “doping agent,” it can conduct electricity — and even switch between insulating and conductive states. It’s cheap and stable, often used for anti-static coatings. For example, it can be applied to metal surfaces to prevent rust and stop static buildup, protecting electronic components from damage.

2. Polypyrrole (PPy)

Polypyrrole is soft and biocompatible, meaning it’s safe to interact with the human body. That makes it great for wearable devices and medical applications. For instance, it can be made into skin patches to monitor heart rate and blood pressure or even used as neural electrodes to help study brain signals.

3. Polyacetylene (PA)

Polyacetylene was the first conductive plastic ever discovered — kind of like the “ancestor” of conductive polymers. It was accidentally found by scientist Hideki Shirakawa during an experiment gone wrong. Although it’s not widely used today, its discovery sparked a wave of research into conductive plastics.

4. Polythiophene (PT)

Polythiophene is conductive and responds to light, making it perfect for solar cells. It can be turned into flexible solar panels sewn into clothes or backpacks to charge devices in the sun. Plus, it’s heat- and corrosion-resistant, so it lasts a long time.

5. PEDOT

PEDOT is transparent and conductive, ideal for touchscreens and smart textiles. The touch-sensitive layer on your phone screen might be made of PEDOT, allowing it to detect your fingers while still displaying clear images. It’s also used in sportswear to monitor heart rate and body temperature, turning regular clothes into wearable health trackers.

Where Can Conductive Plastics Be Used?

The following are some of the most widely used areas for conductive plastics:

Static Protection (ESD Protection)

- Where it’s used: Electronic packaging, semiconductor trays, production tools.

- Why: Conductive plastic gets rid of static electricity, protecting phone and computer parts from damage.

Electromagnetic Shielding (EMI Shielding)

- Where it’s used: Phone, computer, and car electronic casings.

- Why: Blocks electromagnetic interference to keep devices running smoothly.

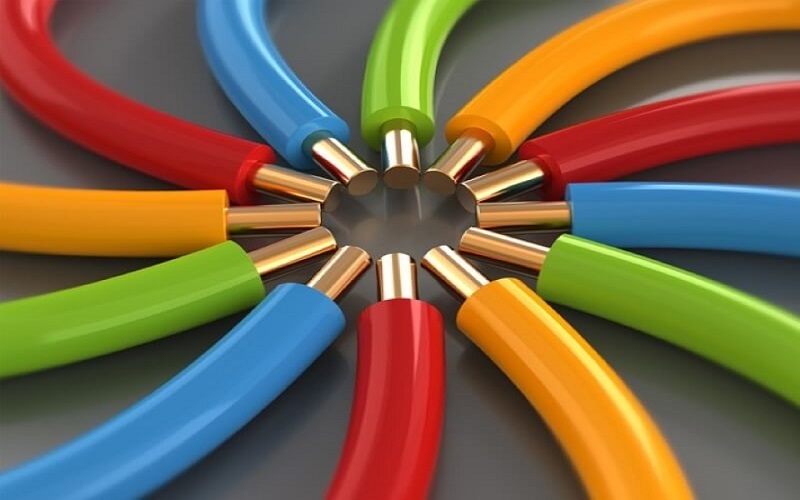

Wires and Cables

- Where it’s used: Cable coatings, conductive layers, high-voltage lines.

- Why: Conducts electricity and insulates, reducing leaks and interference.

Sensor Technology

- Where it’s used: Pressure sensors, touchscreens, wearable devices.

- Why: Flexible and conductive, perfect for making small sensors.

Energy Field (Batteries and Supercapacitors)

- Where it’s used: Battery electrodes, supercapacitors, solar panels.

- Why: Boosts charge transfer for better renewable energy devices.

Conclusion:Is Plastic A conductor?

Plastics have long been considered insulators, but with advancements in technology, scientists have discovered that certain plastics can conduct electricity. By altering the molecular structure or adding conductive fillers, some plastics can even rival metals in conductivity. These conductive plastics are lightweight, flexible, and corrosion-resistant, and are widely used in wearable devices, flexible electronics, solar cells, and anti-static packaging.

For Otivic, leveraging the properties of conductive plastics can provide customers with more diversified solutions to meet the growing demands in industries like electronics, power, and healthcare.