If you’re embarking on a product development journey, selecting the right prototyping 3D printers is key. This guide will help you understand how to choose the best model for your needs, explaining different printing technologies and their applications.

By the end, you’ll know which 3D printer will best support your prototyping efforts.

Understanding Rapid Prototyping with 3D Printers

apid prototyping is a manufacturing technique that utilizes computer-aided design (CAD). It employs advanced manufacturing processes, such as direct metal laser sintering, to quickly create 3D parts. This approach emphasizes time efficiency and cost savings, allowing for faster innovation and a reduced time to market.

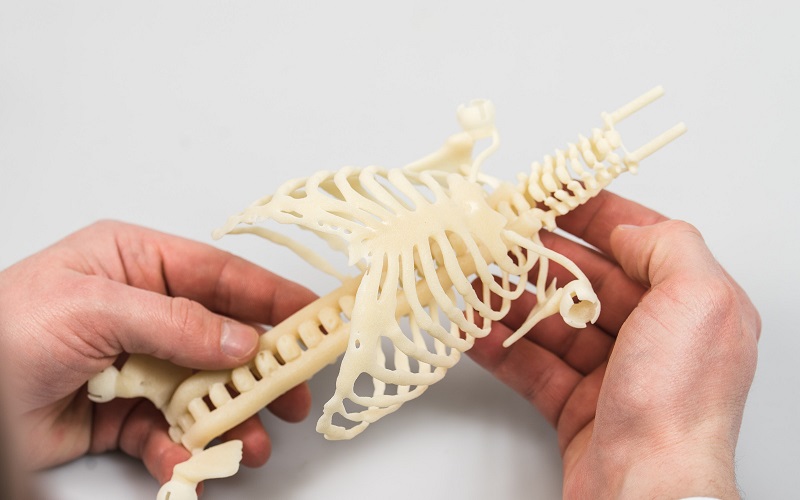

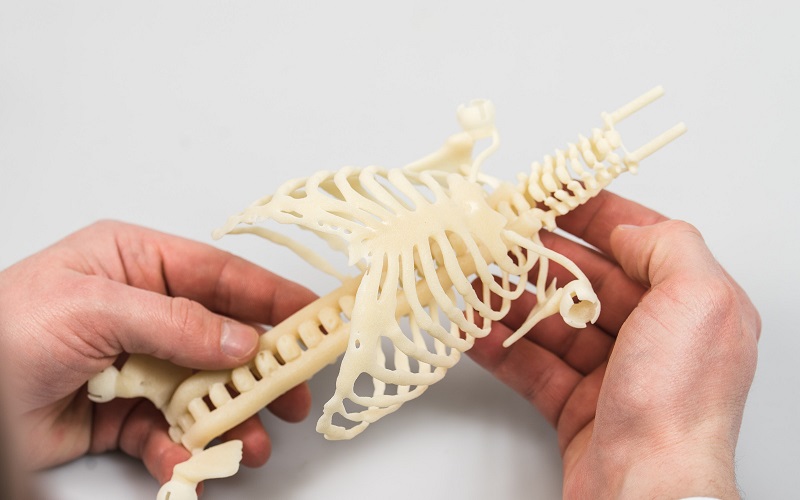

Producing prototypes rapidly allows companies to test and refine designs more effectively, leading to faster manufacturing and scaling. Visual prototypes created through this process enable the testing of various visual factors, improving communication among team members and aiding in the demonstration and validation of a product’s appearance.

The rapid prototyping process, including techniques like direct metal laser sintering, is primarily used for quick-turn, small to medium runs of industrial-strength parts and prototypes. This method is integral to both rapid prototyping and functional prototyping, bridging the gap between initial design and full-scale production.

Understanding rapid prototyping highlights its role in creating functional and visually accurate prototypes, enhancing the overall process.

Definition and Benefits

Rapid prototyping utilizes digital technologies and 3D printing to create prototypes swiftly without relying on traditional tooling. Traditionally, prototyping involved lengthy lead times, but with 3D printing, this can be reduced to hours or days.

This enhancement in speed not only accelerates the design cycle but also improves cost efficiency by eliminating the need for specialized labor and custom tooling.

Enabling multiple iterations of rapid design, 3D printing reduces the product development timeline, offering cost savings and faster market faster readiness.

Key Applications

Rapid prototyping finds extensive applications across various industries, including automotive, medical, aerospace, and electronics. In the medical field, it is used for developing devices, surgical tools, and diagnostic equipment. The automotive sector benefits from rapid prototyping for creating functional parts and testing new designs.

Engineers, designers, startups, and established businesses alike utilize 3D printing for prototyping, enabling them to innovate faster and meet their prototyping needs efficiently, attracting potential investors.

Types of 3D Printing Technologies for Prototyping

3D printing, an additive manufacturing technology, produces parts layer by layer from a 3D model. The main types of 3D printing technologies used for prototyping include Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Multi Jet Fusion (MJF). Each of these additive technology methods has unique capabilities, making them suitable for different prototyping needs. For instance, SLA, SLS, and MJF are particularly suitable for creating complex prototypes due to their advanced capabilities and precision. In contrast, injection molding is often used for producing high-volume, precise parts, complementing 3D printing by bridging prototyping and mass production. Consumer electronics benefit significantly from these technologies as they allow the production of intricate designs that traditional manufacturing methods struggle with.

After: The main types of 3D printing technologies used for prototyping include:

- Fused Deposition Modeling (FDM)

- Stereolithography (SLA)

- Selective Laser Sintering (SLS)

- Multi Jet Fusion (MJF)

Each of these technologies has unique capabilities, making them suitable for different prototyping needs. For instance, SLA, SLS, and MJF are particularly suitable for creating complex prototypes due to their advanced capabilities and precision.

Consumer electronics benefit greatly from these technologies as they allow the production of intricate designs that traditional manufacturing methods struggle with, including complex components.

Knowing the different 3D printing technologies helps in selecting the right one for your prototyping needs. Each technology offers distinct advantages, whether it’s the affordability and ease of FDM, the precision of SLA, the robustness of SLS, or the efficiency of MJF. Selecting the right technology ensures that the prototypes produced meet your specific requirements and aid in faster and more effective product development.

Fused Deposition Modeling (FDM)

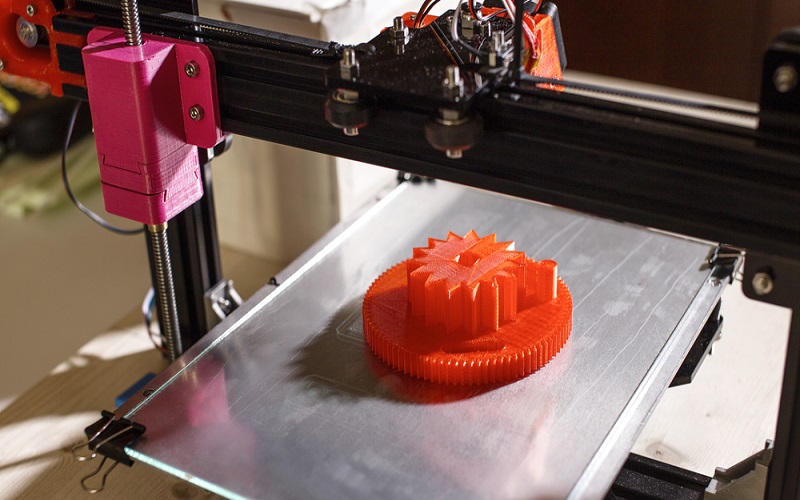

Fused Deposition Modeling (FDM) is a widely used 3D printing technology. It constructs parts by heating and extruding thermoplastics in a layer-by-layer approach. This method is often utilized for creating basic prototypes due to its affordability and ease of operation.

However, FDM has some design limitations and requires support structures, which can complicate certain projects. Additionally, FDM can only produce one part at a time, which may hinder volume production efforts.

Despite these drawbacks, FDM remains a go-to choice for many due to its cost efficiency and ability to produce functional prototypes quickly.

Stereolithography (SLA)

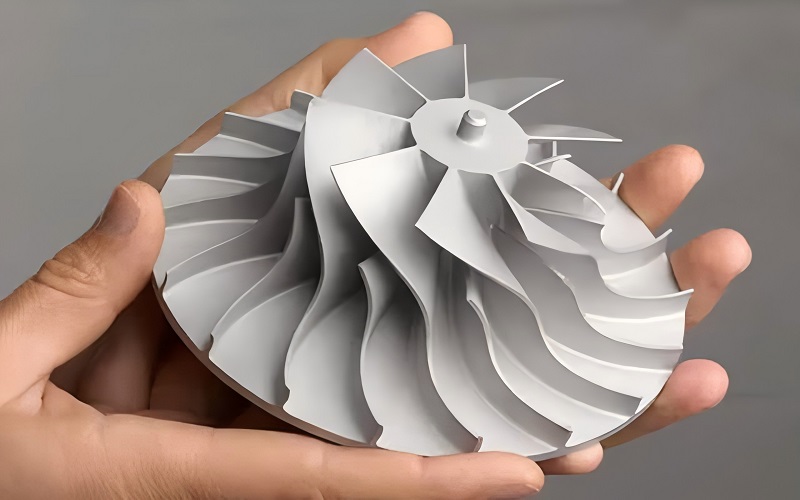

Stereolithography (SLA) is renowned for its exceptional ability to create visually appealing and intricate parts. This technology uses an ultraviolet laser to cure liquid resin, building parts layer by layer. SLA is particularly known for producing complex geometries with superior detail and smooth finishes. Its high detail and precision make it ideal for applications requiring intricate features.

However, users must consider the removal time for support structures when using SLA for detailed features.

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a preferred 3D printing technology for producing functional polymer parts. SLS employs a CO2 laser to fuse nylon-based powder, layer by layer, to create parts. This technology excels in producing robust parts suitable for functional testing without needing support structures.

Post-processing for SLS parts typically involves cooling and cleaning to enhance the final part quality.

Multi Jet Fusion (MJF)

Multi Jet Fusion (MJF) technology is known for its efficiency in producing parts rapidly. MJF applies fusing and detailing agents to nylon powder, then fuses layers with heat.

This technology is utilized for building both prototyping and end-use parts quickly, making it an excellent choice for those looking to accelerate their prototyping process with durable parts.

Selecting the Right 3D Printer for Your Prototyping Needs

Before: Selecting the right 3D printer for your prototyping needs involves matching the printer with your specific requirements to ensure it meets your prototyping needs. Consider factors such as application intent, priorities, budget, and the balance between functionality and appearance when selecting the best 3D printing technology. Assess the capacity needed for part production, whether it is for small batch or production level volumes. Additionally, ensure someone on your team learns how to operate the 3D printer you select for effective use.

After: Selecting the right 3D printer for your prototyping needs involves matching the printer with your specific requirements. Consider the following factors:

- Application intent

- Priorities

- Budget

- Balance between functionality and appearance

Assess the capacity needed for part production in the manufacturing process, whether it is for small batch or demanding applications level volumes.

Additionally, ensure someone on your team learns how to operate the 3D printer you select for effective use.

The decision-making process involves evaluating various factors to ensure the chosen technology aligns with your prototyping needs. By considering budget, material selection, and the required accuracy and precision, you can make an informed choice that enhances your prototyping process and accelerates product development.

Budget Considerations

Budget considerations play a crucial role in selecting the right 3D printer. Post-print operations typically contribute the largest portion of the cost associated with 3D printing. This is especially true when manual labor is involved. You can see cost implications for your 3D print by getting real-time cost based on material choice and resolution level.

You can receive an instant quote for 3D printing design by uploading a 3D CAD file. This process allows for quick and efficient pricing. Laser powder bed sintering processes like SLS and MJF are considered economical for producing end-use parts.

Material Selection

Material selection is critical in 3D printing as it affects the final product’s mechanical strength, rigidity, and heat resistance. The main groups of materials used in 3D printing include the best materials: polymers, metal parts, ceramics, composites, and different materials.

Thermoplastics are characterized by their ability to be melted and remolded multiple times, enhancing their sustainability in manufacturing. Engineering thermoplastics are commonly utilized in the manufacture of end-use components. These materials are specifically designed for various industrial applications. The choice of materials can also impact properties like dimensional accuracy and color in prototypes.

Accuracy and Precision

Accuracy and precision are paramount in 3D printing, especially for producing high-quality prototypes. Factors such as infill density and layer resolution significantly impact the overall precision of the printed models. Dimensional accuracy and tight tolerances are crucial for ensuring that the prototypes meet the required specifications and perform as expected in real-world applications.

Selecting a 3D printer that can achieve these tight tolerances is essential for producing precise and reliable prototypes.

Benefits of Using 3D Printers for Prototyping

Using 3D printers for prototyping offers numerous benefits, including speed, cost savings, and design flexibility. Rapid prototyping enables engineers to test and refine product designs quickly, significantly reducing lead times and costs. The ability to create precise iterations faster than traditional methods allows for quick adjustments and improvements. Overall, rapid prototyping reduces time and costs in product development, allowing quick iterations and saving on mistakes and rework.

3D printing accelerates innovation by enabling rapid design iterations and testing in physical form, allowing for manageable development expenditures. In consumer electronics, rapid prototyping allows companies to quickly test and refine product designs, reducing development cycles and costs.

The flexibility in design and production that 3D printing offers enables the creation of intricate and customized models. Utilizing 3D printing reduces the need for custom molds, therefore leading to easier modifications during the design process.

Speed and Efficiency

One of the most significant advantages of 3D printing in rapid prototyping is its speed and efficiency. New prototypes can be created in a single day, with turnaround times for parts as little as 24 hours. This rapid production capability allows for faster iterations and quicker failure to achieve optimal designs.

Design optimization in 3D printing can accelerate production and reduce overall costs. The overall advantages of speed and efficiency in 3D printing lead to significant benefits in the prototyping process.

Cost Savings

Cost savings are another major benefit of using 3D printers for prototyping. Utilizing 3D printing for small batch prototypes often results in lower overall costs compared to traditional manufacturing methods. Effective optimization of CAD files can lead to significant reductions in production costs during 3D printing.

By enabling designers to produce parts quickly without the high initial investment typical of traditional manufacturing, 3D printing offers a cost-efficient approach to rapid prototyping. Overall, 3D printing not only reduces costs associated with material waste and production time but also enhances flexibility in design iterations.

Design Flexibility

3D printing offers exceptional design flexibility, allowing for the creation of intricate parts that traditional manufacturing cannot easily fabricate. This flexibility enables the creation of complex designs that would be challenging or impossible to achieve with conventional manufacturing methods.

Prototyping with 3D printing also allows for the creation of patient-specific devices, enhancing customization in medical treatments. The ability to produce prototypes with tight tolerances and varied material options further enhances the overall design cycle.

Integrating 3D Printing into Your Prototyping Process

Integrating 3D printing into your prototyping process can significantly enhance product viability, successful production, and finishing. Whether you choose in-house printing or outsourcing, optimizing CAD designs and employing post-processing techniques are essential steps to ensure the best results. In-house printing often offers faster turnaround times and cost efficiency, while outsourcing can be beneficial for larger-scale projects or when specialized expertise is required.

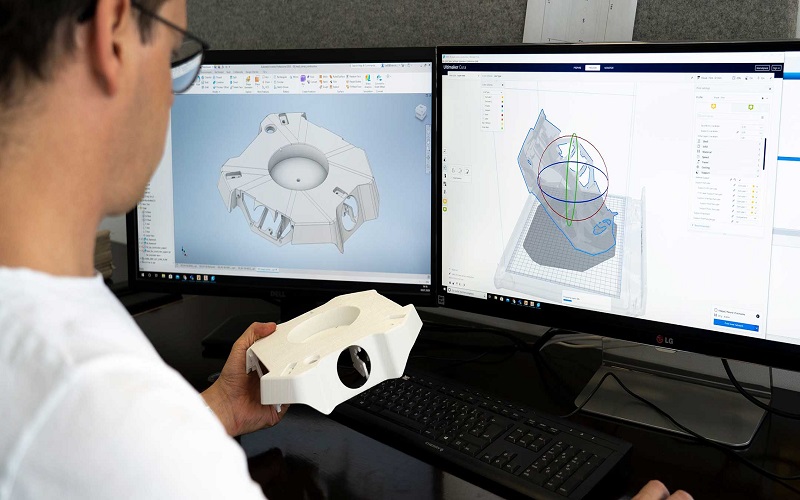

By optimizing CAD designs and incorporating post-processing techniques, you can improve the quality and functionality of your 3D printed prototypes. This integration allows for seamless transitions from design to production, ensuring that your prototypes meet the required specifications and are ready for full-scale manufacturing.

In-House Printing vs. Outsourcing

In-house 3D printing often allows for same-day delivery of prototypes, significantly enhancing speed in the prototyping process. Companies with ongoing prototyping needs often find investing in in-house 3D printers more cost-effective in the long run. In-house printing allows medical device manufacturers to significantly cut costs and accelerate their time to market.

However, outsourcing 3D printing can lead to longer turnaround times due to shipping requirements. Balancing in-house capabilities with outsourcing can help manage costs and ensure timely delivery of prototypes.

Optimizing CAD Designs

Optimizing CAD designs is crucial for achieving the best 3D printing results. The build direction of a model affects accuracy and build time, so it’s essential to consider this during the design phase.

Adding radii to corners can enhance the strength and accuracy of 3D printed parts. Maintaining uniform wall thickness helps mitigate issues related to material shrinkage during printing.

Self-supporting surfaces at a 45-degree angle or steeper reduce the need for additional support material. Ensuring a suitable file resolution when exporting CAD data to STL files is crucial for capturing design details without significantly increasing file size. Additionally, adjusting the interior structure of parts can optimize strength, weight, and cost.

Post-Processing Techniques

Post-processing techniques are critical for improving both the visual appearance and mechanical properties of 3D printed prototypes. Common methods to enhance the visual appearance include sanding, painting, and applying surface finish coatings, which also contribute to the overall surface quality.

Enhancing the excellent mechanical properties and physical properties of 3D printed parts can involve techniques like annealing, chemical resistance smoothing, and reinforcement. These techniques ensure that the final product meets the required specifications and is ready for practical use.

Case Studies: Successful Prototyping with 3D Printers

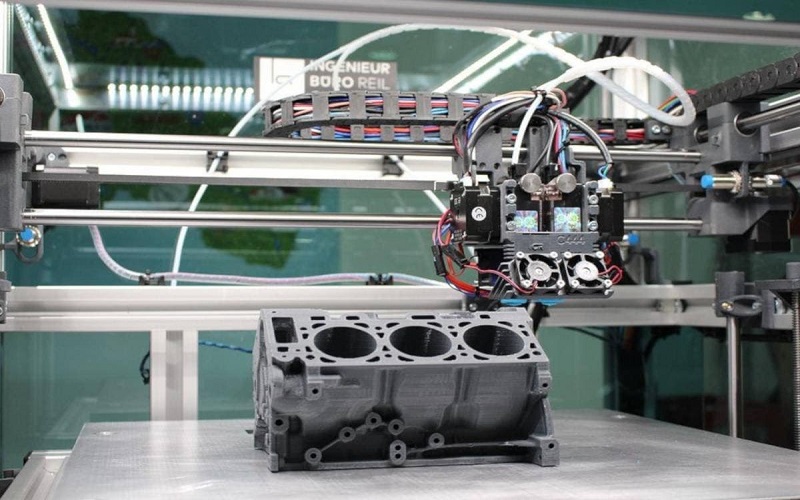

3D printing has revolutionized rapid prototyping across diverse industries, allowing companies to speed up their design processes and reduce production costs.

For instance, an automotive company successfully reduced its time to market by utilizing rapid prototyping through 3D printing, enabling quicker design iterations and testing. A medical device manufacturer leveraged 3D printing for functional prototyping, facilitating rigorous testing and validation of their designs before full-scale production.

In the consumer electronics sector, a company enhanced its product design and functionality by adopting rapid prototyping via 3D printing, resulting in innovative solutions and faster development times. These case studies illustrate the transformative impact of 3D printing on prototyping processes across different industries.

Learning how different companies have successfully integrated 3D printing into their workflows provides insights into potential applications and benefits for your own projects.

Automotive Innovations

GM Australia’s Design Studio was recognized for its innovative use of rapid prototyping in creating the Buick Avenir concept car, significantly improving the speed of prototype production. Creating the Buick Avenir concept car involved innovative use of advanced 3D printing techniques.

3D Systems’ Quickparts reduced the production time of a prototype grill for the Buick Avenir from two weeks to just three days using state-of-the-art SLS technology. The utilization of rapid prototyping technologies enabled GM Australia to expedite the process of bringing new vehicle concepts to market.

Medical Device Development

3D printing has been pivotal in developing functional prototypes for medical devices, enabling efficient testing and validation. A notable medical device manufacturer utilized rapid prototyping to create complex geometries that allowed for better functionality and performance testing of their products.

This technology has also enabled the creation of complex prosthetic devices tailored to individual patients, enhancing functionality and comfort. The acceleration of the prototyping phase in medical device manufacturing allows for quicker iterations and testing, ultimately leading to faster market readiness.

Consumer Electronics

An electronics company incorporated rapid prototyping to test new designs swiftly, enhancing both user experience and product functionalities before market launch. This integration allowed the company to refine their products efficiently, ensuring they meet consumer expectations in terms of design and functionality.

3D printing has led to significant improvements in the customization options available for electronic devices, catering to specific consumer needs, including the creation of a custom part.

Summary

In summary, rapid prototyping with 3D printers offers numerous benefits, including speed, cost savings, and design flexibility. By understanding the different 3D printing technologies and selecting the right one for your prototyping needs, you can significantly enhance your product development process.

Integrating 3D printing into your workflow, whether through in-house printing or outsourcing, optimizing CAD designs, and employing post-processing techniques, ensures high-quality prototypes that meet your specifications.

The case studies demonstrate the transformative impact of 3D printing across various industries, highlighting its potential to revolutionize your prototyping process. Embrace this technology to innovate faster, reduce costs, and bring your products to market more efficiently.

Frequently Asked Questions

What is rapid prototyping, and how does it benefit my manufacturing process?

Rapid prototyping is a manufacturing technique that leverages CAD and advanced processes to swiftly create 3D parts. It enhances your manufacturing process by significantly reducing lead times and costs, while enabling quicker innovation and design adjustments.

Which 3D printing technology should I choose for my prototyping needs?

For your prototyping needs, consider FDM for cost-effectiveness and ease of use, SLA for high precision, or SLS for functional parts. Each technology serves different purposes, so align your choice with your specific requirements.

How do I optimize my CAD designs for 3D printing?

To optimize your CAD designs for 3D printing, focus on the build direction, incorporate radii in corners, maintain uniform wall thickness, and ensure appropriate file resolution. These strategies will significantly improve the accuracy and strength of the final prints.

What are the benefits of using 3D printers for prototyping?

Using 3D printers for prototyping significantly enhances speed and efficiency, reduces production costs, and offers design flexibility.

This technology allows for rapid iterations and the development of intricate, customized designs, making it an invaluable tool in product development.

Should I invest in an in-house 3D printer or outsource my prototyping needs?

Investing in an in-house 3D printer is advisable for companies with frequent prototyping needs, as it provides cost savings and quicker turnaround. Conversely, outsourcing may be preferable for larger projects or specialized requirements.