PLA stands for Polylactic Acid, a biodegradable plastic derived from renewable resources like corn starch and sugar cane.

Unlike traditional plastics made from fossil fuels, PLA is environmentally friendly. In this article, we’ll explore what is PLA, how it’s produced, its applications, and its environmental impact.

Understanding PLA Plastic

Polylactic Acid, often referred to as PLA, is a polyester thermoplastic. It is made from renewable resources like corn starch and sugar cane. Unlike conventional plastics that rely heavily on fossil fuels, PLA plastic is made from natural materials, including lactic acid monomers and linear and cyclic oligomers, making it an eco-friendly alternative. The primary component of PLA plastics is polylactic acid, which is obtained through the fermentation of plant starches and contains ester groups in its structure.

Using renewable resources to produce PLA significantly reduces dependency on non-renewable fossil fuels and minimizes the carbon footprint associated with plastic production, despite challenges like degradation under uv radiation.

This shift not only promotes sustainability but also aligns with global efforts to combat environmental degradation caused by traditional plastics, thanks to the biodegradable nature of PLA’s ester groups.

How is PLA Produced?

Producing PLA begins with the extraction of carbohydrates from renewable resources such as corn, sugar beet, and potatoes. The primary source of the main monomers used to produce PLA is fermented plant starch, typically obtained from crops like corn, cassava, sugarcane, or sugar beet pulp. Interestingly, agricultural by-products like stems and straw can also serve as alternative sources for producing PLA.

Bioconversion transforms sugars from renewable materials into lactic acid through fermentation. This lactic acid undergoes polymerization, often enhanced by crystallizing the crude polymer from the melt to encourage polycondensation.

In some cases, a one-step process can be used by contacting lactic acid in a condensation reaction with a zeolite. Additionally, direct condensation and the use of cyclic di-ester, such as lactide, are crucial methods in the production of PLA.

This process of transforming plant-based sugars into a solid polymer like PLA is not only innovative but also environmentally beneficial. Unlike conventional plastic production, which is energy-intensive and polluting, producing PLA requires less energy and results in lower greenhouse gas emissions.

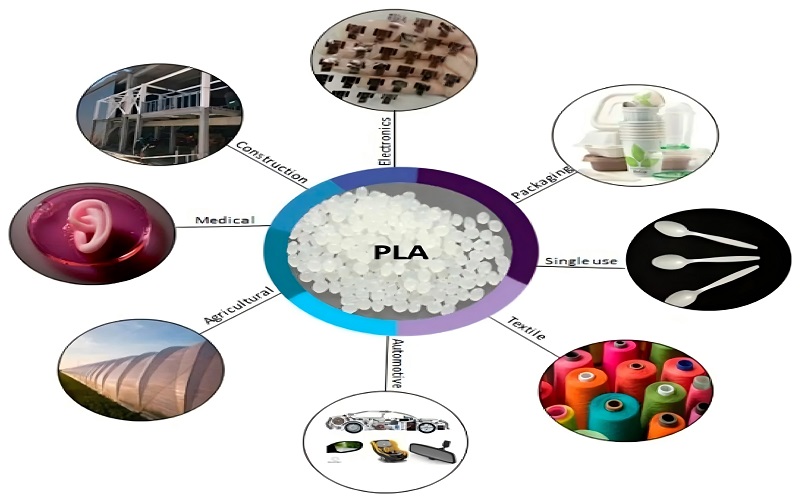

Key Applications of PLA Plastics

PLA plastics have found their way into a variety of industries, thanks to their versatility and eco-friendly profile. One of the most prominent applications of PLA is in the food packaging industry, where it is used for making food containers, wraps, and compostable packaging.

The use of PLA in packaging helps reduce the environmental impact of disposable plastics and supports sustainable waste management practices. Additionally, PLA is highly effective in compost bags due to its compostability and potential for decomposition in industrial composting environments.

In the medical field, PLA is utilized for applications such as sutures and drug delivery systems. Its biocompatibility and biodegradability make it an ideal material for medical implants and devices that are designed to break down naturally within the body.

Additionally, PLA’s low toxicity and ease of use have made it a popular choice for 3D printing, especially among hobbyists and professionals. PLA is also used in nonwoven fabrics for feminine hygiene products, highlighting its role in sustainable practices and environmental benefits in product design.

Beyond packaging and medical applications, PLA is also used in manufacturing biodegradable utensils, agricultural films, and other compostable materials.

The growing demand for sustainable products across various sectors underscores the importance of PLA as a material that aligns with environmental goals while meeting functional requirements.

Environmental Impact of PLA

PLA has become a key player in addressing environmental concerns and promoting a circular economy. Its production from renewable resources and biodegradable nature offer measurable benefits over conventional plastics. One of the most significant advantages of PLA plastics is their ability to biodegrade and compost, thereby reducing the accumulation of plastic waste in the environment.

However, studies have shown that PLA shows minimal degradation when submerged in seawater at 25°C, highlighting the challenges of its degradation in conventional waste management settings due to ambient temperatures.

However, the environmental impact of PLA is not without its challenges. The increasing demand for PLA, particularly its reliance on corn production, could affect global corn prices and food supply. Additionally, the infrastructure required to facilitate proper disposal, such as industrial composting facilities, is often lacking, which can limit the environmental benefits of PLA.

On a positive note, PLA plastic biodegrades without leaving residues of heavy metals, which underscores its clean decomposition and positive impact on reducing pollution compared to traditional packaging materials.

Understanding the environmental impact of PLA requires considering its lifecycle from production to disposal. This includes recycling, composting, and the implications of incineration and landfill disposal, which are further explored in the following subsections.

Recycling PLA

Recycling PLA plastics is achievable through both chemical and mechanical processes. Chemically recycled recycling involves breaking down PLA into its monomers, which can then be purified and repolymerized, effectively closing the loop in a circular economy.

This process can produce high-quality virgin PLA from recycled sources. Mechanical recycling, on the other hand, involves physically processing the PLA waste into new products without altering its chemical structure.

Despite its recyclability, the current recycling infrastructure for PLA is not as developed as it is for other plastics. This limitation means that much of the PLA waste does not get recycled efficiently, highlighting the need for advancements in recycling technology and infrastructure to maximize the environmental benefits of PLA.

Composting PLA

PLA is compostable, and under the right conditions, it breaks down into non-toxic byproducts such as compost, CO2, and water. Effective composting of PLA requires industrial conditions that facilitate chemical hydrolysis and microbial digestion. These conditions typically involve maintaining a temperature of 140°C for ten days.

However, the lack of accessible industrial composting conditions poses a significant challenge to the composting of PLA plastics. Without these facilities, the environmental benefits of PLA’s compostability are not fully realized, as PLA may end up in landfills where it does not decompose effectively.

Incineration and Landfill

Incineration of PLA can be a viable disposal method, generating energy without releasing harmful toxins. In fact, incinerating PLA produces 19.5 MJ/kg of energy, which can be harnessed for various applications. This method of disposal is particularly beneficial in waste-to-energy plants where waste material recovery is a priority.

However, disposing of PLA in landfills is less favorable. PLA has a significantly slower decomposition rate in landfills compared to traditional plastics, taking anywhere from 100 to 1,000 years to decompose. This slow degradation process negates many of the environmental benefits that PLA offers, making proper disposal methods crucial.

Types of PLA Filaments

PLA filament are widely used in 3D printing due to their low melting point and ease of handling. These filaments come in various types, each tailored for specific applications. For instance, wood filaments made from PLA can incorporate materials such as bamboo, cedar, and walnut, providing a unique aesthetic and texture.

Metal-enhanced PLA filaments are another innovative type, incorporating metals like brass, bronze, and copper to improve the functional properties of printed parts. The high surface energy of PLA enhances its printability, allowing for stronger printed objects and effective bonding during the 3D printing process.

Additionally, solvents like acetone can soften the PLA surface, enabling effective welding between two PLA surfaces. These enhancements make PLA filaments versatile and suitable for a wide range of 3D printing projects, from decorative items to functional components, including metal filaments.

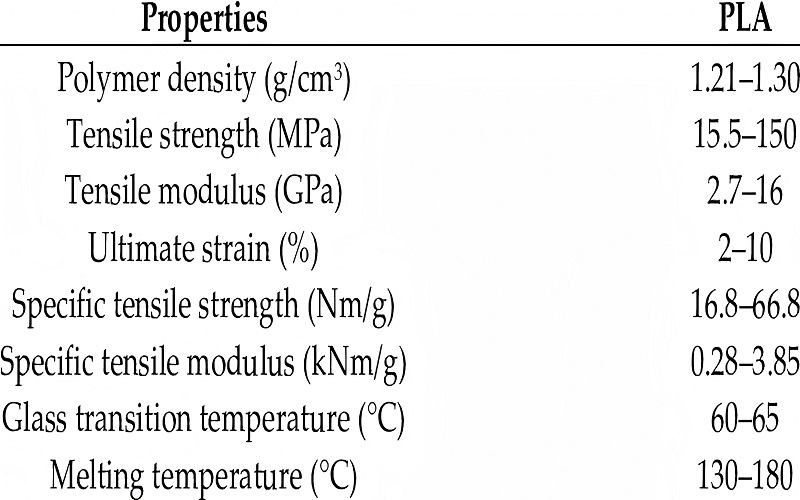

Physical and Mechanical Properties of PLA

PLA exhibits a range of physical and mechanical properties, including basic mechanical properties, that make it suitable for various applications. Here are some key properties:

- Flexural strength: around 85 MPa

- Elongation at break: ranging from 41.3% to 63.8%, indicating a balance of strength and flexibility

- Density: ranges from 1.08 to 1.12 g/cc

- Low glass transition temperature: approximately 53 °C

As an amorphous glassy polymer, PLA has distinct mechanical properties compared to its semi-crystalline and highly crystalline forms. Additionally, the heat deflection temperature of PLA can be significantly increased when blended with PDLA, enhancing its thermal properties. Heat resistant PLA can withstand temperatures of up to 110 °C, making it suitable for applications requiring higher thermal stability.

These properties contribute to the versatility of PLA in several distinct forms of different compounds applications, including l enantiomers.

PLA’s low thermal shrinkage rate and limited solubility in organic solvents further enhance its usability in different environments. Physically blending PLA with other polymers can improve its properties. For example, PLA-TPE blends are designed for shock-absorbing applications, while PLA-TPU blends create a semi-flexible material suitable for specific projects.

Composites of PLA with ABS or PP enhance its strength and flexibility, making it ideal for parts that require durability and repeated use. These blends and forming composites demonstrate the versatility of PLA and its potential to replace conventional plastics in many applications.

Advantages of Using PLA

One of the primary advantages of PLA is its significant environmental benefits. By reducing reliance on fossil fuels and lowering carbon emissions, PLA promotes a more sustainable approach to packaging and manufacturing. Derived from renewable materials like corn starch, PLA supports sustainable practices and contributes to a lower carbon footprint compared to traditional plastics.

PLA’s ease of processing through methods like extrusion and injection molding makes it highly applicable across various industries. Its ease of processing and environmental benefits make PLA a compelling choice for manufacturers looking to manufacture more sustainable materials that are manufactured responsibly.

Challenges and Limitations of PLA

Despite its many advantages, PLA also faces several challenges and limitations. One significant limitation is its brittleness, with an elongation at break of less than 10%. PLA also has a relatively low heat resistance, with a melting temperature range of 130-180 °C, which can limit its use in high-temperature applications that require materials to withstand temperatures.

Additionally, while PLA can be recycled, the current recycling infrastructure is not widely efficient or scaled up, which hinders its overall adoption. The production of PLA from crops also raises concerns about potential impacts on food supply and land use, highlighting the need for further technological advancements to address these issues.

Innovations in PLA Production

Recent innovations in PLA production techniques aim to enhance the integration of bioplastics into the traditional plastics industry. These advancements focus on improving the properties of PLA and making its production more energy-efficient.

The production of PLA requires significantly less energy than that of fossil-based plastics, further reinforcing its environmental benefits. Additionally, the use of L-lactide, a cyclic di-ester derived from lactic acid, in ring-opening polymerization is critical for producing poly-L-lactide (PLLA) with specific properties.

Innovations such as the use of stereospecific catalysts and the development of faster crystallization processes are helping to produce PLA with improved mechanical properties, higher performance, and a highly crystalline polymer. These advancements are crucial for increasing the adoption of PLA in various industries and reducing the environmental impact of plastic production.

Future Prospects of PLA

The future of PLA looks promising, with its potential to significantly reduce greenhouse gas emissions compared to traditional petroleum-based plastics. The increasing cost-effectiveness of PLA, driven by rising oil prices, makes it an attractive alternative to conventional plastics.

Government policies and consumer demand for eco-friendly products will play a significant role in the future adoption of PLA. As more industries and consumers prioritize sustainability, the demand for PLA and other bioplastics is expected to grow, fostering a more sustainable and environmentally friendly future.

Summary

In summary, PLA represents a significant step forward in the quest for sustainable materials. Its production from renewable resources, biodegradability, and compostability offer substantial environmental benefits over conventional plastics. PLA’s versatility and applicability across various industries further underscore its potential to replace traditional plastics and reduce our environmental footprint.

As we move toward a more sustainable future, the continued innovation and adoption of PLA will be crucial. By embracing PLA and other bioplastics, we can work towards a circular economy that prioritizes sustainability and reduces the impact of plastic waste on our planet.

Frequently Asked Questions

What is PLA plastic made from?

PLA plastic is derived from renewable resources such as corn starch and sugar cane. This makes it an eco-friendly alternative to conventional plastics.

How is PLA different from conventional plastics?

PLA differs from conventional plastics in that it is made from natural materials and boasts biodegradability and compostability, making it a more environmentally friendly option.

Can PLA be recycled?

Yes, PLA can be recycled through chemical or mechanical processes; however, the existing infrastructure for its recycling is less developed compared to other plastics.

What are the main applications of PLA?

The main applications of PLA include packaging, medical devices, and 3D printing, showcasing its versatility and relevance in modern industries.

What are the environmental benefits of using PLA?

Using PLA significantly reduces reliance on fossil fuels and lowers carbon emissions, making it an environmentally responsible choice. Its biodegradability and compostability further enhance its sustainability benefits.