Polyurethane film medical is widely used in medical applications for its biocompatibility, flexibility, and durability. This material plays a crucial role in enhancing the performance and safety of medical devices, including wound dressings, catheters, and implants.

This article will discuss the advantages, properties, and innovative uses of polyurethane film medical in the medical field.

Advantages of Polyurethane Film in Medical Applications

Polyurethane film stands out in medical applications due to its exceptional biocompatibility. This means it significantly reduces the likelihood of body rejection, making it a safe choice for implantable devices, thanks to its versatile material properties.

Bionate® polyurethanes, for example, offer remarkable flexibility, enhancing the resilience and adaptability of medical devices. This flexibility ensures that devices can conform to the body’s movements at body temperature without compromising their structural integrity.

Another significant advantage is the antimicrobial properties of polyurethane film, which play a critical role in infection control. These properties make polyurethane an excellent choice for surgical applications, where maintaining a sterile environment is paramount.

Moreover, biostable polyurethanes with high oxidative stability resist degradation in long-term implant applications, such as artificial heart components, thereby improving the longevity and overall performance of medical devices.

The ease of working with polyurethane film cannot be overstated. Its strength and dependability ensure that it performs reliably in various medical environments. This reliability is crucial for medical professionals who depend on the consistent performance of their tools and devices.

In summary, the benefits of polyurethane in medical device applications are manifold. Its:

- biocompatibility

- flexibility

- antimicrobial properties

- durability

Make polyurethane an ideal material for a wide range of medical applications. Polyurethane makes the next section delve deeper into the key properties that make medical grade polyurethane tubing and films so effective.

Key Properties of Medical Grade Polyurethane Film

Medical grade polyurethane tubing and films are celebrated for their exceptional properties. Medical-grade Tuftane® TPU films, for instance, are both flexible and elastomeric, exhibiting remarkable physical and mechanical characteristics.

This flexibility is crucial as it allows the material to conform to various shapes and movements within the human body, ensuring comfort and effectiveness. Tubes made from this material further enhance its versatility in medical applications.

The molecular structure of polyurethane is composed of elastomers that resemble human proteins, particularly thermoplastic polyurethanes (TPUs). This similarity to human proteins enhances biocompatibility, making polyurethane a suitable material for medical applications. Bionate® polyurethanes stand out for their oxidative biostability, abrasion resistance, and toughness. These properties ensure that the material can withstand the rigors of medical use without degrading over time.

Moreover, these TPU films demonstrate excellent durability against abrasion, tear, and puncture, even in low-temperature environments. This durability is essential for medical devices that need to perform reliably under various conditions.

The formulation of these films also provides low permeability to air and water, which is crucial for maintaining hygiene and comfort in medical applications. These films are also resistant to various environmental factors.

In essence, the proven properties of medical grade polyurethane make it an indispensable material in the medical field. Its flexibility, durability, and biocompatibility ensure that medical devices not only perform effectively but also last longer. Let’s move on to explore the common medical device applications of polyurethane film.

Common Medical Device Applications of Polyurethane Film

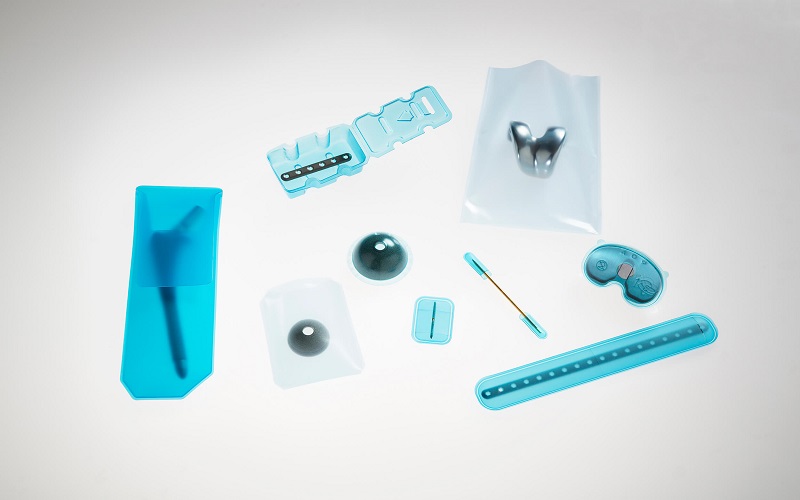

Polyurethane films are incredibly versatile and are used in a wide range of medical device applications. They are commonly found in catheters, medical gloves, wound dressings, medical bags, and organ retrieval bags. Each of these applications benefits from the unique properties of polyurethane, such as flexibility, biocompatibility, and compatibility with materials like silicone, plastic, and rubber.

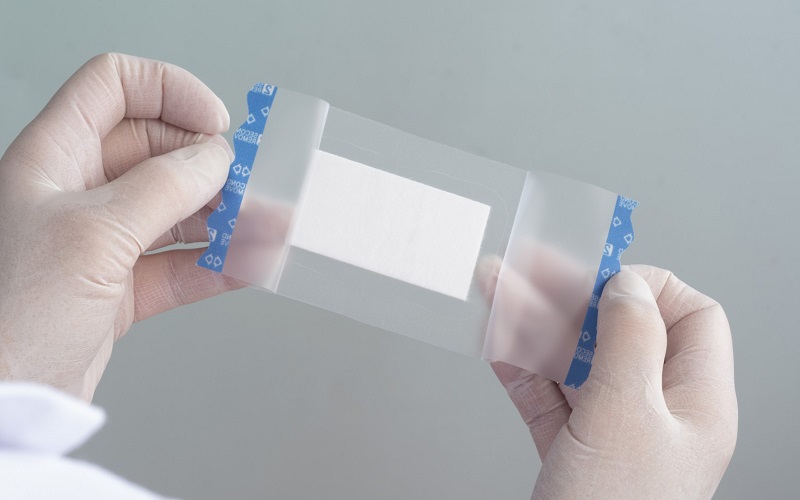

One of the most notable uses of polyurethane film is in wound dressings. Breathable polyurethane films, often combined with silicone for enhanced adhesion, allow for effective moisture management while promoting healing. Innovations in this area have further enhanced moisture control, making these dressings more effective in various wound care scenarios.

Drug delivery systems have been revolutionized by polyurethane films. These films, sometimes integrated with plastic components, enhance therapeutic efficacy by enabling the controlled release of medications through their coating. Patients receive the right dosage over an extended period through this controlled release mechanism, improving treatment outcomes.

Additionally, polyurethane’s mechanical properties and compatibility with human tissue make it suitable for orthopedic implants and prosthetics, often used alongside rubber for added flexibility. The material’s excellent antithrombotic properties make it ideal for cardiovascular devices. These applications highlight the versatility and effectiveness of polyurethane in medical device applications.

Manufacturing and Processing of Polyurethane Film

The manufacturing and processing of polyurethane film involve various methods, each suited to different medical applications.

Processing methods for polyurethanes include extrusion, injection molding, and dip molding. These methods allow for the production of diverse medical devices, each tailored to specific needs.

Batch or continuous processes are used to produce thermoplastic polyurethanes, offering flexibility in manufacturing and design. This flexibility is crucial for creating customized medical solutions that meet the unique requirements of different medical procedures. For dip-molding applications, polyurethanes are favored for their lack of extractable chemicals, enhancing safety in medical environments.

Achieving optimal curing properties requires proper processing of two-part liquid polyurethanes that combine careful conditioning to eliminate dissolved gases and ensure the right mixture ratios. These meticulous forms ensure that the final products meet the high standards required for medical use, creating a combination of quality and reliability.

Innovations in Polyurethane Film for Medical Devices

Innovations in polyurethane film technology have significantly enhanced its performance and applications ranging in the medical field. One notable advancement is the enhancement of antibacterial qualities for better wound dressing applications. Reducing the risk of bacterial infections and improving patient outcomes are benefits of this innovation.

The development of bio-based polyurethane offers environmentally friendly options for biodegradable medical devices. Meeting the functional requirements of medical devices and addressing environmental concerns, these biocompatible bio-based materials offer a sustainable choice for future medical applications.

These innovations in polyurethane film technology enhance the performance of medical devices and improve patient outcomes. Continuously evolving, polyurethane remains at the forefront of medical material science, offering solutions that meet the ever-changing needs of the medical industry.

Regulatory Compliance and Safety Standards

Ensuring the safety and effectiveness of medical grade polyurethane films requires strict adherence to regulatory compliance and safety standards. The FDA establishes regulations for polymers used in medical devices to ensure they are safe for their intended application, particularly in the market for healthcare products.

Materials designated as FDA approved must meet specific standards regarding composition and extractable substances, ensuring their suitability for medical construction.

To ensure biocompatibility, medical-grade polyurethane films are manufactured to comply with ISO 10993. Extensive testing is required by this standard to ensure materials are safe for medical applications and compatible, especially for devices used by surgeons. USP Class VI standards also require extensive biological testing of materials in contact with human cells to assess safety.

Gamma irradiation or ethylene oxide can be used to sterilize these films, making them suitable for medical applications. ASTM provides voluntary standards for materials used in medical applications, which become enforceable when referenced by regulatory bodies. A comprehensive regulatory framework ensures recognized medical grade polyurethane films are reliable, approved, and safe for various medical applications in the market.

Contact Us for Custom Polyurethane Film Solutions

Our team is dedicated to offering expert support throughout the customization process. We ensure rapid response times for inquiries, whether you need medical grade polyurethane tubing or specialized films supplied by manufacturers, allowing for quick project turnaround and availability.

We encourage you to reach out for tailored solutions that meet your specific medical device needs. We guarantee quick turnaround times for quotes and samples of customized polyurethane films. Contact us today to discover how our expertise can enhance your medical applications.

Summary

Polyurethane film offers a unique combination of biocompatibility, flexibility, durability, and antimicrobial properties, making it an ideal material for various medical applications.

From wound dressings to drug delivery systems, its versatility is unmatched. The continuous innovations and stringent regulatory compliance further solidify its position as a cornerstone in medical material science.

In conclusion, polyurethane film is a proven solution that meets the demanding requirements of the medical industry. Its ability to enhance the performance and longevity of medical devices ensures better patient outcomes and supports the ongoing advancements in medical technology.

Reach out to us for customized solutions that can elevate your medical applications to the next level.

Frequently Asked Questions

What makes polyurethane film suitable for medical applications?

Polyurethane film’s biocompatibility, flexibility, and durability render it highly suitable for medical applications like wound dressings, catheters, and drug delivery systems. These properties ensure safety and effectiveness in healthcare settings.

How does polyurethane film enhance infection control in medical settings?

Polyurethane film enhances infection control in medical settings due to its antimicrobial properties, which make it highly effective in surgical applications and wound dressings. This helps maintain a sterile environment and reduces the risk of infection.

What are the common manufacturing methods for polyurethane film?

Common manufacturing methods for polyurethane film include extrusion, injection molding, and dip molding, each tailored for specific applications. Understanding these processes can help you choose the right method for your needs.

Are polyurethane films environmentally friendly?

Yes, bio-based polyurethane films are environmentally friendly and biodegradable, making them suitable for medical devices. Such innovations reflect a positive trend towards sustainability in material development.

How do polyurethane films comply with regulatory standards?

Polyurethane films adhere to regulatory standards such as FDA, ISO 10993, and USP Class VI, confirming their safety and efficacy for medical applications. This compliance is crucial for ensuring user trust and product reliability in healthcare settings.