Searching for top-tier 3D printing services? Fowmould 3D print delivers rapid prototyping and production using cutting-edge technologies.

This article explores how Fowmould can transform your digital designs into high-quality parts swiftly and efficiently, whether you need a single prototype or mass production.

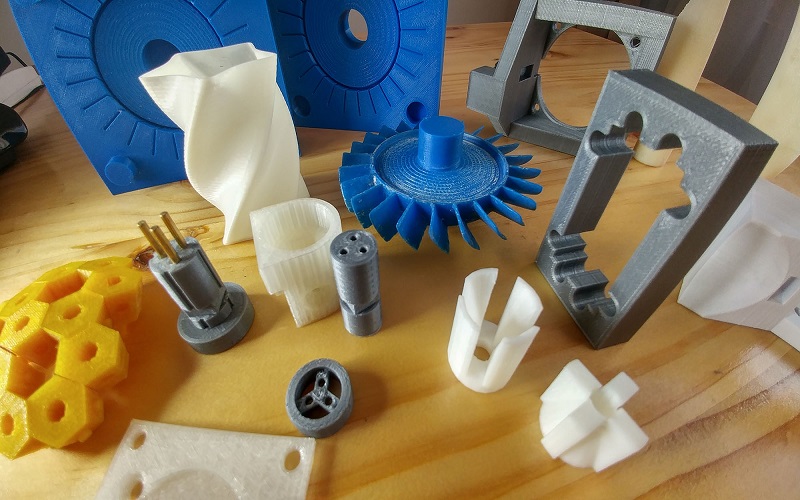

3D Printing Services Overview

Fowmould is a leader in online 3D printing services, providing custom parts on demand using cutting-edge additive manufacturing technologies. These technologies enable the creation of parts layer by layer from a digital model, opening up design possibilities previously unattainable with traditional manufacturing processes, such as enhanced heat resistance and the integration of carbon fiber for added strength and durability.

The key trends highlighted in Fowmould’ 3D Printing Trend Report include the growth in emerging applications, the transition from prototyping to production, and the expansion of material options. This comprehensive service, combined with Fowmould’ digital manufacturing and engineering expertise, facilitates the entire process from prototyping to production.

Fowmould’ manufacturing services are renowned for their expedited manufacture capabilities, often producing manufactured parts in as little as one day. Combining in-house factories with a vetted global network allows Fowmould to offer volume pricing, tighter tolerances, and the production of more complex parts.

Additionally, various post-processing options enhance the cosmetic or mechanical properties of 3D printed parts, further leveraging materials with heat resistance and carbon fiber to meet diverse industry needs.

Additive Manufacturing Technologies at Fowmould

Fowmould employs a variety of advanced additive manufacturing technologies for rapid prototyping and production services, complemented by other manufacturing methods such as CNC machining and injection molding to offer a comprehensive suite of solutions:

- Stereolithography (SLA): Employs an ultraviolet laser to create parts from liquid resin, offering high precision and fine details.

- Selective Laser Sintering (SLS): Uses a CO2 laser to fuse nylon-based powder into solid parts, making it ideal for functional prototypes and end-use components.

- Multi Jet Fusion (MJF): Applies fusing and detailing agents to nylon powder, which are then heated to form solid components, resulting in high-strength and detailed parts.

Technologies like Direct Metal Laser Sintering (DMLS), CNC machining, and injection molding, along with various post-processing techniques, enable Protolabs to cater to a wide array of 3D printing and manufacturing applications.

Producing complex geometries and high-quality 3D printed parts quickly and efficiently highlights the versatility of Fowmould’ additive manufacturing and complementary technologies.

Material Options for 3D Printing

Fowmould provides a wide range of 3D printing materials, including plastics, metals, and elastomers. These materials include commercial-grade thermoset resins, thermoplastics, and metal powders, each selected for their suitability in various applications. For example, Fowmould’ thermoset resins offer varying hardness levels, suitable for diverse applications.

The future of 3D printing looks promising with the continuous expansion of materials and related technologies. Additional services that further enhance the mechanical properties and aesthetic appeal of 3D printed parts include 3d printing processes such as:

- Heat treatment

- Secondary machining

- Plating

- Painting

- Dyeing

This comprehensive range of materials and services ensures that Fowmould can meet diverse manufacturing needs.

Metal 3D Printing with Fowmould

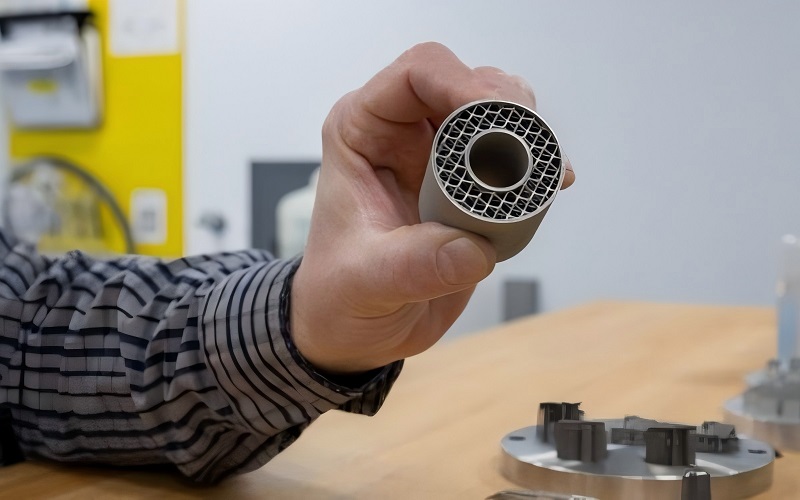

Metal 3D printing at Fowmould is revolutionized by Direct Metal Laser Sintering (DMLS), a technology that creates fully dense metal components using a fiber laser to melt metal powders layer by layer. This process allows for the production of complex metal parts quickly and with high precision, making it ideal for both prototyping and production.

DMLS offers the strength and durability needed for high-performance aerospace, medical, and industrial parts, aligning with emerging trends in additive manufacturing that drive innovation in these sectors.

Stainless Steel and Its Applications

Stainless steel, particularly 17-4 PH, is highly regarded for its high hardness and excellent corrosion resistance at high temperatures, like advanced high temp. This suitability extends to demanding applications in aerospace, medical devices, and industrial equipment, including NASA assembly CNC machining processes that require precision and durability.

Its durability, strength, and versatility further enhance its popularity in 3D printing applications, providing robust solutions for specific applications, such as NASA assembly CNC machining, that require these mechanical properties.

Titanium for High-Performance Parts

Titanium, especially Ti6Al4V, is celebrated for its unique strength-to-weight ratio, making it ideal for high-performance parts. This material’s exceptional strength-to-weight performance is crucial for applications needing high durability and resistance to extreme temperatures.

Due to its remarkable properties, titanium is widely used in industries such as aerospace and medical, where both strength and lightweight characteristics are paramount. In contrast, materials like translucent clear Accura 60, a resin often used in stereolithography (SLA), and PP-like translucent white, a polypropylene-like material, provide high clarity and precision for prototyping, offering a different set of benefits for applications requiring transparency, fine detail, and a white translucent finish.

Other Metal Materials

In addition to stainless steel and titanium, Fowmould offers a variety of other metal materials for 3D printing, including aluminum, cobalt chrome, and tool steel. These metals provide excellent mechanical properties and corrosion resistance, making them suitable for diverse 3D printing applications.

These materials expand the possibilities for creating durable and functional 3D printed lightweight metal components or high-strength parts, while non-metal options like ABS-like translucent clear and like translucent clear Accura resins offer additional versatility for applications requiring transparency and precision in prototyping.

Plastic 3D Printing Capabilities

Technologies such as PolyJet use liquid photopolymer droplets to create high-resolution parts that power 3D printing in plastics. This technology allows for the production of complex and detailed parts for prototypes, end parts, and more.

The flexibility and precision of plastic 3D printing opens up endless possibilities for a wide range of industries.

Thermoplastics in 3D Printing

Thermoplastics, such as ABS and PA 12, are commonly used in 3D printing for their robustness and versatility. ABS-like materials are favored for prototyping because of their excellent mechanical properties and ease of processing, while PC-like translucent clear materials provide additional options for applications requiring transparency and high impact resistance.

Additionally, 40 glass filled black, a reinforced thermoplastic with 40% glass fiber for enhanced strength and rigidity, offers a robust alternative for demanding applications. The use of carbon DLS (Digital Light Synthesis with carbon reinforcement) further enhances material performance with superior strength and lightweight properties.

Widely used in functional prototypes, end-use parts, and consumer products, these materials, including PC-like translucent clear, 40 glass filled black, and those produced with carbon DLS, are indispensable in 3D printing.

Elastomers for Flexible Parts

Elastomeric materials in 3D printing provide high tensile strength and resilience, ideal for components that withstand repeated bending and stretching. Achieving a range of hardness levels, these materials create durable and flexible parts for applications like seals, gaskets, and soft-touch grips.

Their unique properties make them invaluable for both prototype parts and end-use parts.

Custom Finishing Options

Custom finishing options enhance both the aesthetic and functional properties of 3D printed parts. Techniques available to improve the surface finish of 3D printed components include:

- Painting

- Clear coatings

- Decaling

- Metal plating

Surface finishes enhance visual appeal and functional performance, increasing the value and versatility of the parts.

Prototyping to Production with Protolabs

Protolabs excels at streamlining the process from prototyping to production, ensuring a seamless client transition. Key features include:

- On-demand 3D printing services capable of producing parts within 24 hours to support a fast-paced product development cycle.

- A focus on cost minimization and high quality.

- Comprehensive quality control to ensure all parts meet rigorous standards.

Rapid Prototyping Services

Rapid prototyping services enable customers to receive functional parts within a single day. Such quick turnaround enables rapid iterations, significantly shortening product development timelines. In industries like automotive, 3D printing is used for rapid prototyping, enabling quick testing and modifications of design concepts.

Creating multiple prototypes simultaneously facilitates efficient design comparison and iteration.

Scalable Production Solutions

Offers scalable production solutions that can accommodate both small batch and large-scale manufacturing requirements. Flexible solutions that adapt to varying order sizes enable customers to benefit from volume pricing and significant cost savings as production scales.

This adaptability allows to meet diverse manufacturing needs, from initial prototyping to full-scale production.

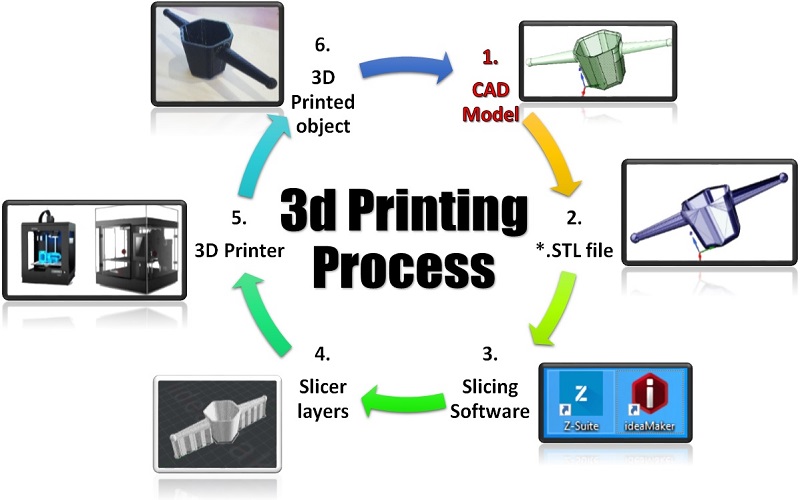

Instant Quotes and Ordering Process

Starting the ordering process on the official website is easy and convenient. Start by uploading your CAD file directly onto the quoting platform. Confirm the specifications to receive an instant quote for your project. The quoting platform supports various file formats, including STEP, STP, IGES, and more, making it accessible and convenient for users.

Real-Time Pricing Updates

Quoting platform offers real-time pricing updates, allowing users to see how changes in material selections or specifications affect pricing instantly. This feature provides immediate feedback on cost implications, enabling users to make informed project decisions.

Adjustments to choices can be made easily, and the impact on overall cost is displayed in real-time.

Quality Control and Assurance

Implements stringent quality checks throughout the manufacturing process to ensure that all parts meet specified standards and function properly. Quality control in 3D printing upholds product standards and ensures reliability.

This commitment ensures that every 3D printed part delivered meets the highest standards of manufacturing excellence.

Common Applications of Protolabs 3D Printing

3D printing services are utilized across various industries, including:

- Aerospace

- Medical

- Automotive

- Consumer products

The versatility of 3D printing materials and technologies enables a wide range of applications, from functional prototypes to end-use parts.

This broad applicability highlights the transformative potential of 3D printing in modern manufacturing.

Aerospace and Defense

In the aerospace and defense industries, 3D printing is used to produce lightweight and high-strength components, which are critical for aircraft efficiency. Materials like titanium alloys and cobalt chrome offer excellent strength-to-weight ratios and corrosion resistance, making them ideal for aerospace applications.

Creating complex geometries quickly and efficiently further enhances the performance and efficiency of aerospace components.

Medical and Healthcare

3D printing plays a crucial role in the medical field by enabling the creation of personalized prosthetics and custom medical devices. PA 12, known for its strength and flexibility, is commonly used for functional prototypes and end-use parts in medical applications.

This technology enables rapid development of patient-specific devices, enhancing treatment personalization and improving patient outcomes.

Automotive Industry

The automotive industry has fully embraced 3D printing, integrating it into both prototyping and production processes. Major manufacturers like Volkswagen, BMW, and Ford are using 3D printing to produce end-use components, contributing to the sector’s expected revenue growth to USD 9 billion by 2029.

Quickly producing prototypes and final car parts helps these companies maintain production continuity and reduce reliance on external manufacturing partners. This integration of additive technology into automotive factories highlights the transformative impact of 3D printing on the industry.

Summary

In summary, Fowmould’ 3D printing services offer a comprehensive solution for rapid prototyping and scalable production. Utilizing advanced additive manufacturing technologies, Fowmould provides a wide range of materials, including metals and plastics, to meet diverse industry needs.

The streamlined process from prototyping to production, coupled with instant quotes and rigorous quality control, ensures high-quality, cost-effective manufacturing solutions.

As industries like aerospace, medical, and automotive continue to adopt 3D printing, the potential for innovation and efficiency in manufacturing is boundless. Embrace the future of manufacturing with Fowmould and unlock new possibilities for your projects.

Frequently Asked Questions

What types of materials can use for 3D printing?

Utilizes a diverse selection of materials for 3D printing, including plastics, metals, and elastomers, to meet a wide array of industry applications. This versatility ensures that clients can find suitable materials for their specific project requirements.

How quickly can produce 3D printed parts?

3D printed parts can typically be produced in as little as one day, effectively meeting the requirements of rapid prototyping and emergency production.

What are the benefits of using titanium in 3D printing?

The benefits of using titanium in 3D printing include its exceptional strength-to-weight ratio, high durability, and resistance to extreme temperatures, making it suitable for high-performance applications in sectors such as aerospace and medical.

How do I ensure the quality of my 3D printed parts?

Ensures the quality of its 3D printed parts through rigorous quality checks conducted at various stages of the manufacturing process, ensuring that all components meet specified standards and function as intended.

Can Fowmould handle large-scale production?

Fowmould can indeed handle large-scale production, offering scalable solutions that cater to both small batches and extensive manufacturing needs, thus ensuring flexibility and cost efficiency as production increases.