Slot milling is the process of cutting precise slots or grooves in materials, vital for manufacturing complex parts. This article explains the techniques, tools, and essential tips you need for successful slot milling.

Understanding Slot Milling

Slot milling, also known as groove milling, is a machining process that employs rotating cutting tools to create slots or grooves in various materials such as metals, plastics, and hardened materials. This versatile technique is pivotal in modern manufacturing, enabling the production of intricate geometries with high precision using a CNC machine.

From creating keyways and T-slots in automotive and aerospace components to forming airflow channels in electronic enclosures, machining deep slots and slot milled techniques, often with a T slot milling cutter, are indispensable across multiple industries, especially in a slot milling operation.

The beauty of slot milling lies in its ability to produce complex workpieces with specific design requirements, including closed or open slots of various shapes and sizes.

Rotating cutting tools like end mills or slot cutters allow manufacturers to achieve the desired slot geometry with remarkable accuracy. This process is essential for applications ranging from cooling vents in brake rotors to pockets in semiconductor wafers.

Types of Slot Milling Techniques

The versatility of slot milling is evident in the numerous slot milling techniques available, each tailored for specific slot shapes and machining requirements. These techniques include:

- End milling

- Side milling

- T-slot milling

- Woodruff key slotting

- Gang milling

Each offers unique advantages in the slot milling process.

End Milling Technique

End milling is a slot cutting process that employs endmill cutters to create closed slots with variable depths and non-linear profiles. End mills excel in profiling, contouring, and face milling in multiple directions.

End mills come in various designs such as flat, ball-nose, or corner radius, and an end mill is capable of withstanding high cutting forces while creating intricate slot profiles.

Side Milling Technique

Side milling utilizes the cutter’s periphery to create precise and stable slots. This technique is effective for machining both flat and contoured surfaces, providing high stability and efficiency in slot formation.

Cutting predominantly with the tool’s edge, side milling ensures accurate and reliable slot machining.

T-Slot Milling Technique

T-slot milling is a specialized method for creating ‘T’ shaped slots, primarily used in industrial machinery and machining beds. A T-slot cutter can directly cut open slots, while an initial groove machining is necessary for closed T-slot machining.

T-slot milling provides precise and robust slot formations along the slot axis, enhancing the overall functionality and performance of components.

Woodruff Key Slotting Technique

Woodruff key slotting is essential for creating keyways that enable efficient load transfer in mechanical assemblies. This technique involves machining keyways specifically designed for key and slot joints, facilitating effective load sharing in rotating components.

Keyway slots lock load-sharing components in place.

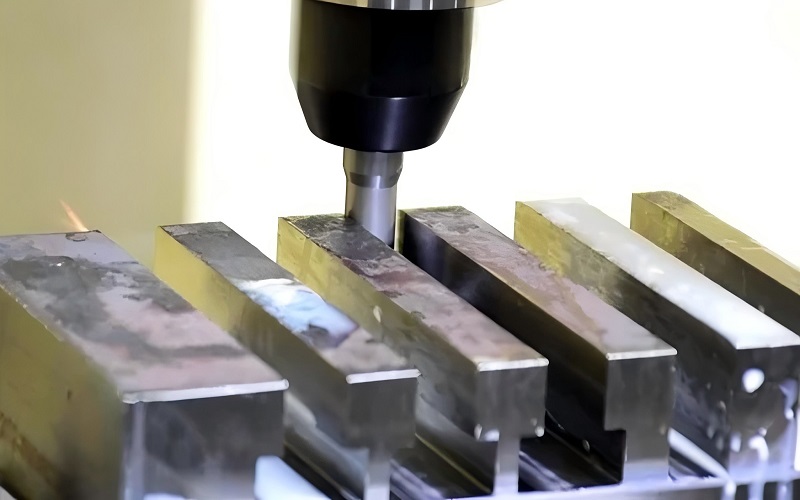

Gang Milling Technique

Gang milling enhances efficiency by using multiple cutters mounted on the same arbor for simultaneous machining on a horizontal milling machine. It boosts productivity and saves time by allowing several parallel slots to be machined at once.

Gang milling cutters are designed to create slots efficiently with multiple groove cutters, making it ideal for high-volume production tasks. A face milling cutter is essential in this process, especially when users prefer larger cutter diameters. Face milling cutters are also valuable for achieving precise finishes.

Essential Slot Milling Cutters

Slot milling requires a variety of specialized cutters, each designed for specific tasks to enhance efficiency in creating diverse slot geometries. Choosing the right tool materials and coatings based on the workpiece extends tool longevity and improves machining performance with a slot milling cutter.

End Mills

End mills are versatile tools capable of creating closed slots, non-linear profiles, and variable dimension slots. They are particularly effective for intricate profiles and can operate efficiently at varying depths and angles.

Their performance in slot milling can be impacted by their unique center ‘dead’ zone and limited cutting teeth.

Side Milling Cutters

Side milling cutters are designed for precise slots, offering high stability and efficiency. These cutters are highly effective in handling long, deep slots while maintaining precision, making them ideal for various slot milling operations.

T-Slot Cutters

T-slot cutters are specialized tools designed for creating inverted ‘T’ shaped grooves in various materials during milling. Their primary function is to machine lateral slots beneath the surface, essential for component alignment and functionality in industrial machinery.

Woodruff Key Slotting Tools

Woodruff key slotting cutters are crucial for creating semicircular keyways that secure components in machinery. Woodruff slot cutters produce keyway slots essential for key and slot joints.

Gang Milling Cutters

Gang milling cutters are designed to operate with multiple groove cutters mounted on a single arbor, allowing for simultaneous machining of multiple grooves, a process called groove milling. This setup significantly increases throughput and reduces setup time, ideal for high-volume production.

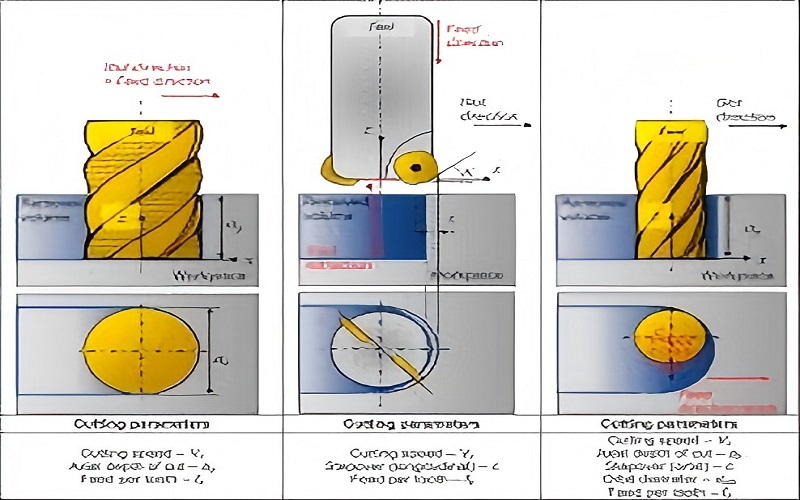

Toolpath Techniques for Slot Milling

Efficient toolpath planning in slot milling is crucial for improving the overall quality of the process, part, and machine tool health. Common toolpaths include conventional, trochoidal, and plunging, each serving different purposes depending on the application.

Conventional Toolpath

The conventional milling toolpath in slot milling uses linear paths with entry from one side, making it suitable for shallow slots. It is productive, easy to program, and compatible with most cutting tools, but faces challenges such as high vibrations and heat generation for deeper slots and non linear slot profiles.

Trochoidal Toolpath

Trochoidal milling is an advanced toolpath technique using circular paths for slot cutting. It offers more stability, cooler cutting edges, and efficient chip evacuation, making it ideal for hard materials like stainless steel or inconel.

Plunging Toolpath

The plunging technique focuses on axial cuts, providing stability during the slotting process. It reduces tool deflections, vibrations, and high radial forces, enhancing overall tool stability, allowing the tools to withstand high cutting forces.

However, it often requires additional finishing cuts to ensure high-quality surface finishes.

Best Practices for Optimal Slot Milling

Adhering to best practices in slot milling, such as utilizing ramp-down entry, ensuring effective chip evacuation, and maintaining consistent spindle load, can significantly enhance efficiency and machining performance.

Ramp Down Entry

A ramp-down motion for entry in slot milling prevents tool overload and excessive vibrations, especially at a 45° angle, improving the quality of the machined surfaces.

Effective Chip Evacuation

Effective chip evacuation is crucial to prevent deterioration of surface quality, tool life, and part tolerances. Specialized cutting tools with chip breakers and high-pressure coolant significantly aid in efficient chip removal.

Maintaining Spindle Load

Continuous engagement with the workpiece optimizes tool performance and improves machining quality, preventing interruptions and enhancing surface finish.

Advantages and Disadvantages of Slot Milling

Slot milling offers significant advantages in manufacturing, such as speed, precision, and consistency when creating slots and grooves. However, it also presents challenges like substantial tool wear and limitations in compatible materials, particularly with slot milling technology.

Advantages

Slot milling offers speed and precision in creating intricate slots and grooves. Efficient slot milling and proper chip evacuation preserve machining accuracy and prolong tool lifespan.

Disadvantages

Despite its benefits, slot milling can lead to substantial tool wear and has limitations in compatible materials, particularly harder materials, which can affect longer tool life.

Conventional toolpaths can cause high vibrations and instability during deeper cuts, especially with long tool overhangs and tool deflection.

Common Applications of Slot Milling

Slot milling is essential in various industries, enabling the crafting of accurate grooves and channels in manufacturing and carpentry. Its applications include:

- Aerospace: creating structural slots in components like ribs and spars to minimize weight.

- Automotive: cutting oil galleries in engine components.

- Electronics: creating slots in printed circuit boards for component insertion, as well as produce slots for enhanced functionality.

Precision slots are also machined into medical devices, including tracks for lead screws in insulin pumps. Slot milling is crucial for producing clearance slots on sliding shafts in machinery and making alignment slots in various components and fixtures in general manufacturing.

The T-slot cutter’s design enables it to cut through materials to form T-shaped grooves, essential for component alignment. Additionally, slot milling is vital in gear manufacturing by milling internal teeth into blanks.

Summary

Slot milling is a versatile and indispensable machining process that plays a crucial role in various industries. By understanding the different slot milling techniques, essential cutters, toolpath techniques, and best practices, manufacturers can achieve optimal slot milling performance and efficiency.

With the knowledge gained from this guide, you are now equipped to tackle slot milling challenges and excel in creating precise slots and grooves. Embrace these techniques and tools to elevate your machining processes and drive innovation in your industry.

Frequently Asked Questions

What materials can be machined using slot milling?

Slot milling can effectively machine metals, plastics, and hardened materials. This versatility allows for precise fabrication across various industries.

What are some common applications of slot milling?

Slot milling is commonly applied in industries such as aerospace, automotive, electronics, and medical devices to manufacture structural slots, oil galleries, component slots, and precision tracks. This versatility demonstrates its importance in precision engineering and component fabrication.

What is the primary tool used in end milling?

The primary tool used in end milling is the end mill, which is versatile and effective for creating closed slots and non-linear profiles. This tool’s adaptability makes it essential in various machining applications.

How does trochoidal milling benefit the slot milling process?

Trochoidal milling significantly enhances the slot milling process by providing greater stability, reducing heat at the cutting edges, and ensuring efficient chip evacuation. This makes it particularly effective for machining hard materials.

What are the challenges of conventional toolpaths in slot milling?

Conventional toolpaths in slot milling are challenged by issues such as high vibrations and excessive heat generation, particularly in the case of deeper slots. These factors can compromise the quality and efficiency of the milling process.