Composite materials are made by mixing different substances to create materials that are stronger, lighter, and more durable.

They play a vital role in aerospace, automotive, and construction industries. This article explores their benefits, types, and uses, showing how they transform engineering.

Understanding Composite Materials

Composite materials are a marvel of modern engineering, defined as combinations of two or more materials with distinct properties. Merging materials like polymers, metals, and ceramics results in composites that enhance base properties such as strength, weight, and durability. Unlike traditional materials, composites provide tailored solutions that meet specific performance requirements.

Composite materials combine the best attributes of their base materials, offering higher strength-to-weight ratios and improved resistance to environmental factors.

Common components include carbon fibre, glass fibre, and pine resin, which are combined to create materials with superior structural and functional performance. Let’s explore the historical background and the key bulk components of these versatile materials.

Historical Background

The use of composite materials dates back to ancient times when civilizations sought to enhance the properties of natural resources available to them. The earliest known composites were made from straw and mud, a technique documented in ancient Egyptian art. These early composites were used to create mud bricks, combining the tensile strength of straw with the compressive strength of mud and clay.

Over the centuries, advancements continued with the Mesopotamians developing techniques to bond thin layers of wood using natural glues, resulting in stronger and more durable materials. This method laid the foundation for creating composite bows, which combined different materials to achieve flexibility, strength, and superior performance in warfare and hunting.

The early 20th century saw a significant leap with the development of Bakelite, a synthetic resin that paved the way for modern composite materials and other materials. This historical evolution underscores the continuous quest for materials that outperform traditional alternatives.

Key Components of Composites

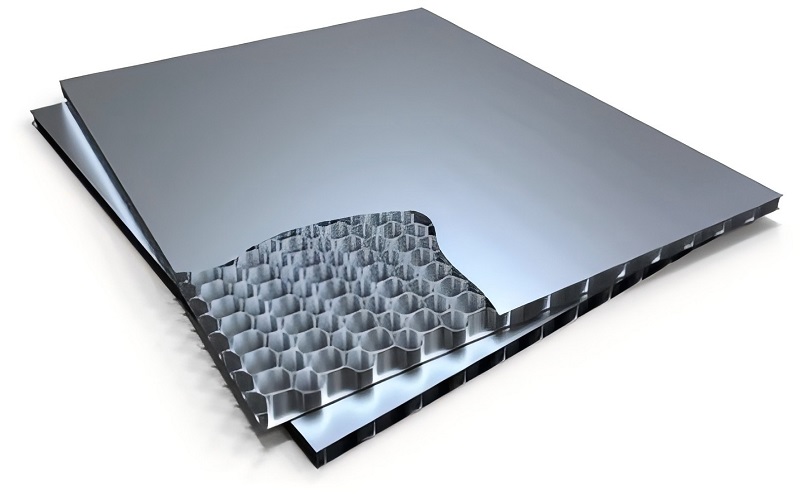

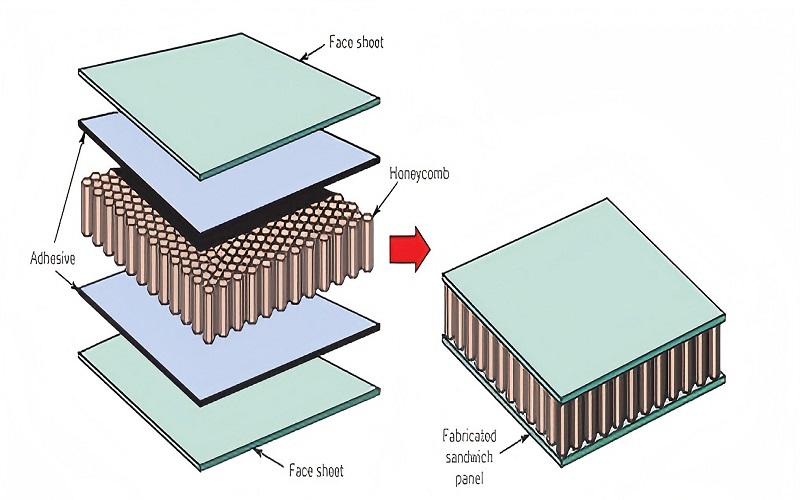

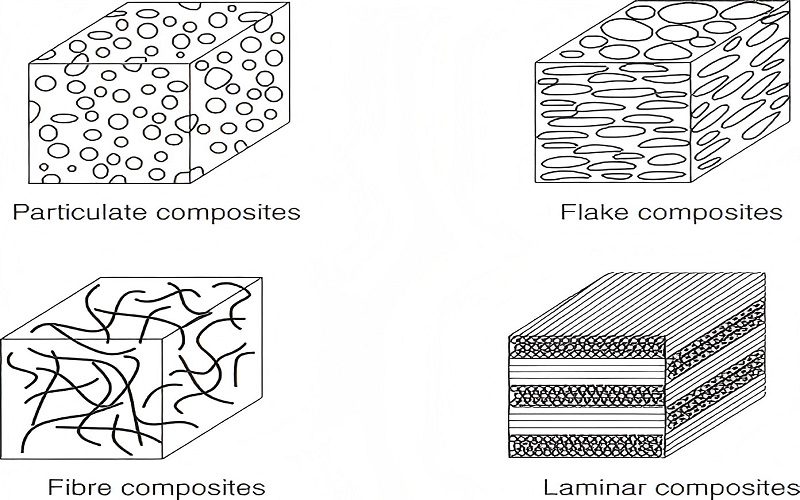

Composite materials primarily consist of two materials: the matrix composite and the reinforcement material, which are both considered constituent materials. The matrix material, often a polymer, metal, or ceramic, binds the reinforcement, shapes the composite, and protects it from environmental damage. This binding not only gives the composite its form but also distributes loads and stresses across the reinforcing fibers.

Reinforcement materials like carbon fibers, glass fibers, or aramid fiber reinforced polymers provide the load-bearing capability of fiber reinforced composites. A classic example of early composite design is the use of thin wood veneers to create plywood, improving strength and dimensional stability.

Modern innovations include carbon fibre reinforced polymers used in aerospace and automotive industries for their exceptional strength-to-weight ratios, as well as carbon nanotubes, which offer extraordinary stiffness and electrical conductivity at the nanoscale.

Composite materials are versatile, allowing for the selection and combination of different matrix and reinforcement materials. This customization enables the development of materials that can withstand extreme conditions, whether it’s high temperatures, corrosive environments, or mechanical stresses. The synergy between the matrix and reinforcement materials is what makes composites uniquely powerful.

Types of Composite Materials

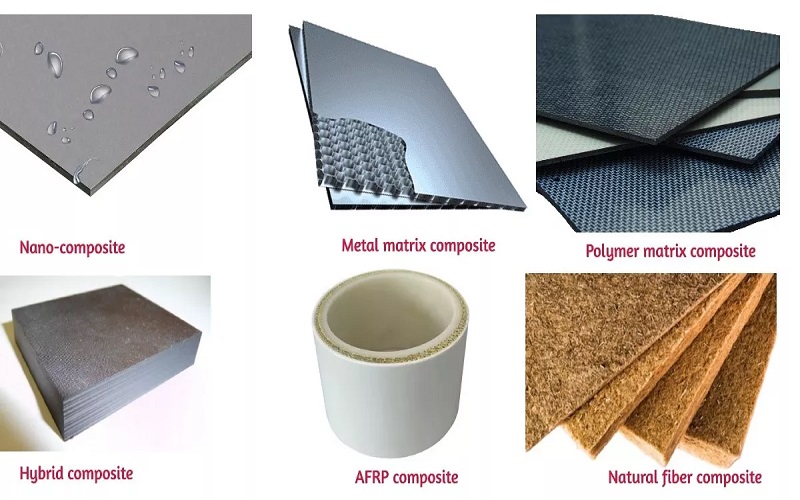

Composite materials come in various forms, each designed to meet specific performance criteria. The main categories include:

- Polymer matrix composites (PMCs)

- Metal matrix composites (MMCs)

- Ceramic matrix composites (CMCs)

- Natural fiber composites (NFCs)

- Hybrid composites

These categories represent a broad spectrum of applications, from aerospace and automotive to construction and sporting goods.

Each type of composite material offers unique properties and benefits:

- PMCs are known for their high strength and lightweight characteristics, making them ideal for various applications.

- MMCs and CMCs offer superior temperature and wear resistance, suitable for high-stress environments.

- NFCs focus on sustainability.

- Hybrid composites focus on performance.

Let’s delve deeper into each type.

Polymer Matrix Composites (PMCs)

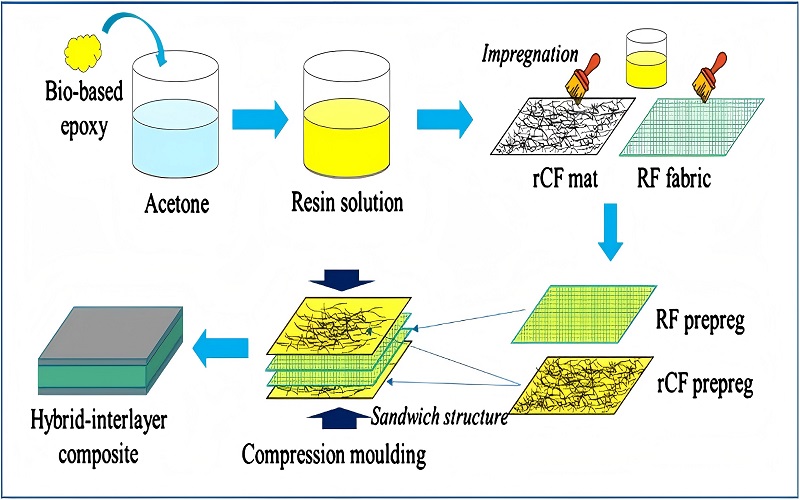

Polymer Matrix Composites (PMCs) are among the most commonly used composites, consisting of a polymer matrix reinforced with fibers like glass or carbon. The matrix materials used in PMCs include polyester, epoxy, and other synthetic resins, which provide the necessary bonding and shape to the composite. The reinforced polymer reinforcing fibers, such as glass fiber and carbon fiber, contribute to the composite’s strength and stiffness.

Glass Fiber Reinforced Polymers (GFRPs) and Carbon Fiber Reinforced Polymers (CFRPs) are prime examples of PMCs. GFRPs utilize glass fibers, which offer high strength and durability, making them suitable for applications like boat hulls and car bodies. CFRPs, on the other hand, use carbon fibers epoxy bonded with polyester or epoxy resins, providing exceptional strength-to-weight ratios ideal for aerospace and sports equipment.

In addition to synthetic options, natural composite materials—such as those made with bio-resins and natural fibers—are gaining interest for their sustainability and biodegradability, expanding the scope of PMCs in eco-conscious industries.

Manufacturing processes for PMCs, such as curing and lay-up quality, are crucial in achieving the desired material properties. Techniques like woven roving enhance lay-up quality in GFRPs, ensuring uniform strength and performance. PMCs’ versatility and adaptability make them a go-to choice for diverse industrial applications.

Metal Matrix Composites (MMCs)

Metal Matrix Composites (MMCs) combine metal matrices, such as aluminum or magnesium, with reinforcing fibers and metal fibers to enhance their mechanical properties. These composites offer increased strength, stiffness, and elevated temperature resistance compared to their pure metal counterparts. MMCs are extensively used in aerospace, automotive, electronics, and sporting goods due to their superior performance under high-stress conditions.

Reinforcements in MMCs may include ceramic fibers, carbon fibers, or silicon carbide particles, providing strength and wear resistance. In some experimental or hybrid designs, wood fibers are also being explored to reduce weight and environmental impact. Additionally, thermally activated resins may be used as part of the processing aids or hybrid matrix systems, improving the bonding and thermal stability during fabrication.

Combining metal matrices with high-strength fibers results in composites that can withstand extreme environments and mechanical stresses, making them indispensable in advanced engineering applications.

Ceramic Matrix Composites (CMCs)

Ceramic Matrix Composites (CMCs) consist of a ceramic matrix composite combined with reinforcing fibers, offering exceptional heat resistance and mechanical properties. These composites are capable of withstanding extreme temperatures without losing their structural integrity, making them ideal for high-temperature applications.

CMCs are commonly used in gas turbine blades, specialist rocket components, and heat exchangers for their ability to endure harsh thermal environments. However, their high cost and fragility are notable limitations. Ongoing research aims to improve their properties and make them more cost-effective for broader applications.

Natural Fiber Composites (NFCs)

Natural Fiber Composites (NFCs) are gaining popularity due to their environmental benefits and sustainability. Made from renewable resources like jute, hemp, and flax, NFCs offer reduced carbon emissions and biodegradability, making them an eco-friendly alternative to traditional composites.

In the automotive industry, NFCs are commonly used for interior panels, providing both structural integrity and aesthetic appeal. Research into bio-based resins and natural fiber reinforcements continues to enhance NFCs’ performance and sustainability, contributing to a greener future for composite materials.

Hybrid Composites

Hybrid composites combine two or more different reinforcing fibers to achieve enhanced performance characteristics. For instance, combining carbon fiber and glass fiber can result in a fibre reinforced composite that benefits from the high strength of carbon fiber and the flexibility of glass fiber. This synergy allows hybrid composites to meet specific performance requirements that single-fiber composites cannot.

Despite their advantages, hybrid composites face challenges related to fiber compatibility and extensive testing. Nevertheless, their superior performance potential makes them valuable for advanced applications.

Properties of Composite Materials

The properties of composite materials make them stand out in various applications. They are designed to combine the strengths of their constituent components, resulting in enhanced performance characteristics. These physical properties include other mechanical properties and chemical properties:

- High strength

- Lightweight

- Durability

- Thermal stability

- Chemical resistance These properties are crucial for their functionality in demanding environments.

Composite materials offer lower costs, reduced production time, design flexibility, and extreme strength compared to traditional materials. This section will explore the key properties that make composites highly desirable in multiple industries.

Strength and Stiffness

Composite materials offer superior strength and stiffness by combining different material properties, distinguishing composites from conventional materials like metals and plastics. Compared to these conventional materials, composites exhibit significantly higher specific strength and stiffness, making them ideal for high strength to weight applications.

Aerospace composites are highly regulated for strength and weight, leading to improved performance and efficiency in aircraft. Similarly, high-performance sporting goods benefit from composites that offer a favorable balance of strength and low weight. Composites’ primary advantage is their ability to provide strength and stiffness while remaining lightweight, contributing to an excellent strength to weight ratio.

Lightweight

Composites are highly valued for their lightweight nature, which is essential in applications where weight reduction is crucial. In vehicles, most composites and all the composites help achieve better fuel economy and reduced emissions by lowering the overall weight.

High-performance bicycles use composite materials for lightweight frames, significantly enhancing speed and maneuverability.

Durability and Impact Resistance

Durability and impact resistance enable composites to withstand forceful impacts without failure. Unlike metals, composites are less likely to completely break under stress and can prevent crack widening, maintaining their integrity under repetitive mechanical shocks and vibrations.

The use of composites in sporting goods contributes to improved performance and enhanced durability. For example, the resilience of composite materials in tennis rackets and bicycles allows athletes to perform at their best without worrying about equipment failure.

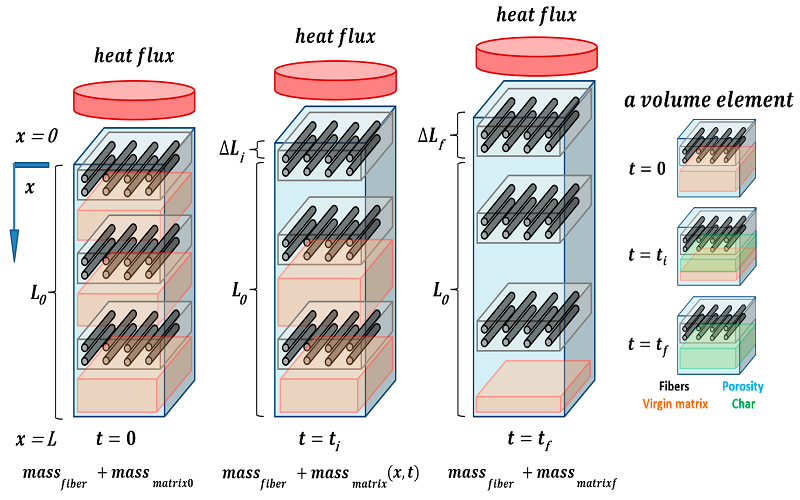

Thermal Stability

Thermal stability in composite materials means resistance to deformation under high temperatures. The composition of many composites allows them to endure extreme temperatures without losing structural integrity, making them suitable for high-temperature applications like rocket nozzles and turbine blades.

Oxide composites, in particular, possess high-temperature superconducting properties, demonstrating their effectiveness in such environments.

Chemical Resistance

Composite materials are designed to resist corrosion in harsh chemical environments, making them suitable for equipment in chemical processing.

Their resistance to harsh chemicals and environments ensures effectiveness in various chemical applications, contributing to their versatility and reliability.

Manufacturing Processes for Composite Materials

Manufacturing processes for composite materials are as diverse as the materials themselves. Chosen based on intended material properties and applications, these processes transform raw material reinforcement and resin matrix constituents into finished composite structures. Common methods include:

- Resin transfer molding

- Spray-up

- Pultrusion

- Autoclave processing

- Filament winding

Each manufacturing process requires skilled labor and precise curing control to achieve the desired properties. For instance, pre-impregnated carbon fiber involves strands pre-impregnated with heat-activated resin and laid in a mold.

The initial step in making an object from a composite material involves placing the reinforcing material in a mold, followed by the curing process to solidify the structure.

Prepreg and Vacuum Bagging

Prepreg and vacuum bagging are crucial techniques in advanced composite manufacturing. Prepreg materials, developed in the early 1900s, utilize artificial plastics and thermosetting resins essential for creating high-performance composites. The process involves pre-impregnating fibers with resin and then laying them into molds.

Once the prepreg is in place, a vacuum bagging process is used to remove air and ensure even distribution of the resin, resulting in high-quality, void-free composite structures.

Filament Winding

Filament winding involves wrapping continuous fibers around a rotating mandrel to create hollow structures. This method produces high-strength, lightweight components by precisely controlling the placement and orientation of the fibers. The process is especially beneficial for applications that require robust, cylindrical structures, such as pressure vessels and tanks.

Filament winding’s strength and lightweight properties make it popular in aerospace components, where performance and efficiency are paramount. Producing complex shapes with consistent quality allows for components that meet stringent industry standards.

Pultrusion

Pultrusion is ideal for producing continuous composite sections with consistent cross-sectional shapes. This method allows for high output and efficiency, making it suitable for manufacturing straight products like rods, beams, and panels.

Pulling fibers through an unsaturated polyester resins bath and heated dies ensures thorough impregnation and curing, resulting in strong, durable composite structures.

Industrial Applications of Composite Materials

Composite materials are used across a wide range of industries due to their versatile properties. From reducing the carbon footprint to enhancing performance and durability, composites exist significantly impact sectors such as aerospace, automotive, construction, and sporting goods. Their lightweight and durable characteristics make them indispensable in modern engineering and design.

Composite materials can be tailored for specific applications, such as creating lightweight car components or high-strength aerospace parts. Let’s explore the various industrial applications of composites and how they are transforming different sectors.

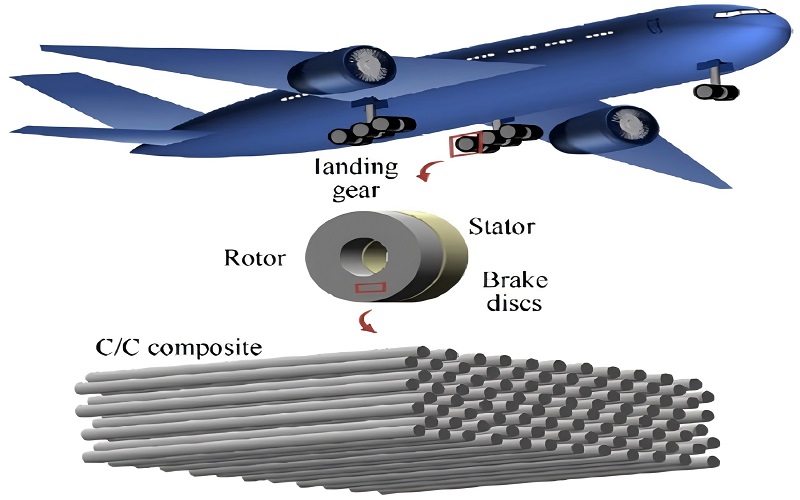

Aerospace

In the aerospace industry, composites are critical for achieving efficiency and performance. The Boeing 787 Dreamliner, for example, utilized composites for 80% of its overall volume, significantly reducing weight and improving fuel efficiency. Functionally graded composites are also beneficial for making lighter spacecraft and aircraft components, such as rocket nozzles and turbine blades.

Using engineered composites to reduce weight translates into better fuel economy and lower emissions, making aerospace travel more sustainable. Their ability to withstand extreme conditions without compromising performance makes composites essential in modern aerospace engineering.

Automotive

The automotive sector is another industry where composites are making a significant impact. Using lightweight composites, manufacturers can create vehicle components that enhance overall performance and fuel efficiency. Reducing weight positively affects vehicle efficiency, allowing cars to achieve higher speeds and better fuel economy.

Lighter vehicles require less energy to accelerate and handle better, resulting in improved driving dynamics and lower emissions. Using composites in automotive components results in vehicles that consume less fuel and produce fewer emissions, contributing to a greener automotive industry.

Construction

In construction, composites are valued for their durability and flexibility. These materials are suitable for bridges and facades, offering enhanced durability against wear and environmental factors. Their design flexibility allows architects and engineers to create innovative structures with aesthetic and functional benefits.

Composite materials improve the lifespan of structures and offer design versatility for composite structure modern composites architectural projects. Using composites in construction enhances durability and provides opportunities for creative and sustainable building solutions.

Sporting Goods

Composite materials have revolutionized the sporting goods industry by enhancing performance and durability. High-performance sporting goods like bicycles, tennis rackets, and skateboard decks significantly benefit from the lightweight and high-strength properties of composites.

The use of natural fiber composites in skateboard decks showcases the versatility of these materials in sporting equipment. Providing lighter, stronger, and more durable products, composite materials allow athletes to perform at their best without compromising equipment reliability.

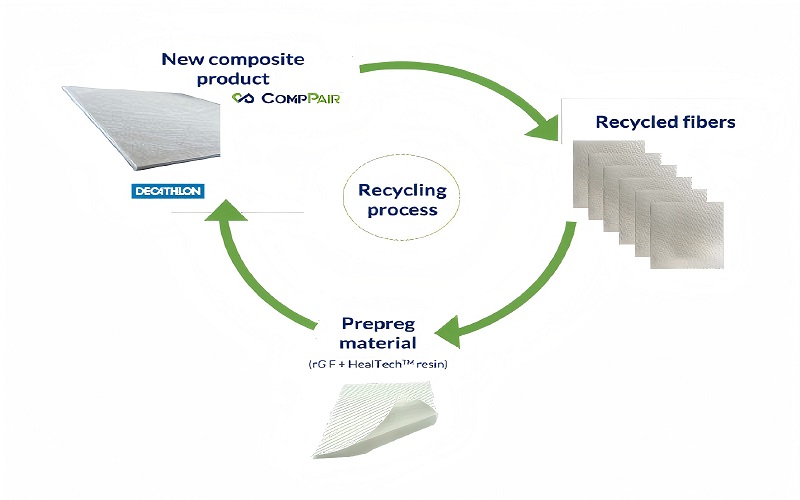

Environmental Impact and Sustainability

Most composite materials are environmentally friendly, featuring less waste and recycling potential. However, conventional composites often rely on non-renewable resources and generate significant waste. A significant shift towards a circular economy is needed in the composite materials sector to minimize waste and promote sustainable sourcing.

Environmental impact and sustainability are crucial considerations in the development and use of composite materials. Let’s explore the challenges of recycling composites and the sustainable alternatives being developed.

Recycling Challenges

The complexity of composite materials, made from multiple components, complicates recycling efforts compared to simpler materials. Separating matrix and reinforcement components in composite materials is a significant challenge, making recycling less efficient.

Recycling composites is complicated by their complex compositions, which often involve materials that are hard to separate. Developing efficient recycling methods is essential to reduce the environmental impact of composite materials and promote sustainable use.

Sustainable Alternatives

Natural Fiber Composites (NFCs) reduce environmental impact by utilizing sustainable materials made from natural fibers like jute and flax. These composites offer an eco-friendly alternative to traditional composites.

Research into bio-based resins and natural fiber reinforcements continues to enhance the sustainability of composite materials. Developing plant-based resins can minimize the environmental impact of composites, contributing to a greener future for the industry.

Summary

Composite materials are transforming industries with their unique properties, offering unparalleled strength, lightweight, durability, thermal stability, and chemical resistance. From ancient mud bricks to modern aerospace components, composites have come a long way, consistently pushing the boundaries of material science.

The journey through the world of composite materials reveals their potential to revolutionize various sectors, from aerospace and automotive to construction and sporting goods.

As research and development continue to enhance the performance and sustainability of composites, their applications are set to expand even further. Embracing composite materials can lead to a future where products are not only high-performing but also environmentally friendly.