Polyurethane injection molding involves injecting molten polyurethane into molds to create durable and versatile parts. Common in industries like automotive and medical, this process delivers components known for their strength and flexibility.

In this article, you’ll learn how polyurethane injection molding works, its benefits, and its wide-ranging applications.

Understanding Polyurethane Injection Molding

Polyurethane injection molding is a sophisticated manufacturing process where molten polyurethane is injected into a precisely engineered mold under high pressure. This process involves injecting a urethane polymer system into a mold to create components that are essential in various industries, including automotive, aerospace, and medical sectors. The versatility and durability of polyurethane moldings make them indispensable in these fields.

The history of polyurethane molding is rich and transformative. Key milestones include:

- Since the 1960s, molded urethane has been a cornerstone in automotive design, significantly influencing car interiors.

- The introduction of reaction injection molding (RIM) by Bayer in 1969 marked a pivotal moment, enabling the production of durable thermoset polyurethane parts.

- This technique has since evolved, leading to advanced methods like structural reaction injection molding (SRIM) and reinforced reaction injection molding (RRIM).

One of the standout features of polyurethane injection molding includes:

- Ability to achieve color matching and textured finishes, enhancing the aesthetic appeal of the final products.

- Particularly beneficial in consumer goods and automotive applications, where visual quality is paramount.

- Allows for the creation of complex shapes and high-quality components.

- Preferred choice in the medical, automotive, aerospace, and consumer goods industries.

Polyurethane molding is not limited to solid parts; it also includes the production of flexible foams and elastomeric components through processes like injection molding urethane casting and rim molding.

This flexibility in material properties is due to the urethane polymer system, which comprises urethane carbamate linkages, organic polymer characteristics, and elastic polymer characteristics. These linkages provide the necessary elasticity and durability, making an elastomer material called polyurethane an ideal material for various applications.

In essence, polyurethane injection molding, including injection molding urethane casting and rim molding, differs from traditional plastic injection molding in several ways. While both processes involve injecting molten material into a mold, polyurethane moldings offer superior performance characteristics, such as enhanced durability, chemical resistance, and flexibility.

This makes polyurethane moldings suitable for a wide range of applications, from automotive polyurethane bushing to medical devices and consumer goods.

The Polyurethane Injection Molding Process

The polyurethane injection molding process, a specialized plastic forming process, is a meticulously controlled operation that involves heating and injecting molten polyurethane, sometimes combined with silicone elastomer, into a mold under high pressure.

This process ensures that the material fills every nook and cranny of the mold cavity, resulting in components with precise dimensions and detailed features, including those used in creating hollow plastic products. The process can be divided into three main stages: material preparation, mold design and setup, and injection and curing.

Each of these stages plays a crucial role in determining the quality and performance of the final product, whether solid or hollow plastic products. From the careful preparation of raw materials, potentially incorporating silicone elastomer, to the intricate design of molds tailored for the plastic forming process, and finally, the injection and curing process, every step is optimized to produce high-quality polyurethane moldings.

Material Preparation

Material preparation is the first step in the polyurethane injection molding process. This stage utilizes:

- Thermoplastic materials as the primary raw material, produced by mixing diisocyanate compounds with polyol compounds.

- Additives, including polyurethane and additive resins, to enhance the performance and durability of the polyurethane products.

- Fillers like sulfur, which acts as a gradual vulcanizing agent, to improve mechanical properties and reduce manufacturing costs. Additive resins are essential for optimizing product quality.

Before injection, the polyurethane resin is mixed with catalysts and colorants to achieve the desired formulation. Maintaining the correct temperature and precise mixing of the resin and curative is critical in this stage. This ensures that the pre-polymer solution is well-prepared for the subsequent injecting polyurethane and curing process.

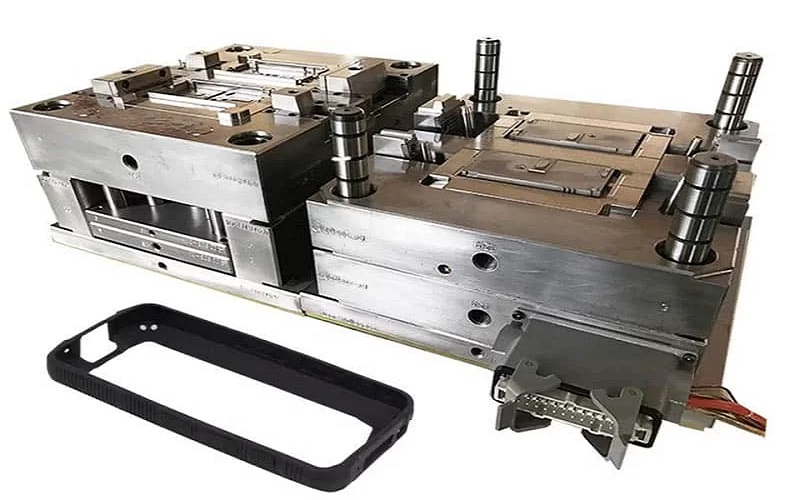

Mold Design and Setup

Mold design and setup are pivotal to the success of the polyurethane injection molding process. Key aspects include:

- Injection molds are typically made from steel or aluminum, with steel providing enhanced durability for long-term use. Metal molds can also be utilized for specific applications.

- Molds can incorporate components like universal frames known as MUD inserts, which hold removable inserts for versatile production.

- Proper cooling channels are designed into the molds to mitigate warping and shrinkage issues during the cooling phase.

Ejection mechanisms, such as lifters and sliders, are required to manage undercuts, which complicate mold removal. The core and cavity of injection molds are defined, with the core being the convex part and the cavity the concave part filled with molten material. Utilizing appropriate mold release agents can help prevent surface defects caused by material sticking to the mold.

Injection and Curing

The injection and curing stage is where the magic happens. Key points of this stage include:

- Molten polyurethane is injected into the mold cavity under heat and pressure, ensuring that it fills the mold completely.

- The mixture can be introduced into the mold cavity either driven by pressure or heat.

- Polyurethane can be cured by applying heat.

- Alternatively, it can cure by allowing curatives to react with the prepolymer system.

- Most urethane resins cure at room temperature, resulting in a solid, semi-solid, or cellular state after curing.

Once the closed mold is filled and the polyurethane cools and solidifies, the mold is opened, and the finished part is ejected. Proper venting is crucial to avoid air traps and voids during the injection process, which can lead to defects in the final product.

Properties of Polyurethane Moldings

Polyurethane parts made through both urethane casting and injection molding are renowned for their lightweight yet durable nature. These plastic components exhibit high resistance to wear, making them ideal for applications that demand longevity and resilience, such as cylindrical rollers covered with polyurethane.

The material can be engineered to possess varying hardness levels, ranging from very soft to very hard, providing versatility in its applications, including components like the inner roller core.

Polyurethane also boasts exceptional flexibility, allowing it to be shaped and molded into intricate configurations, such as cylindrical rollers covered with an inner roller core, without compromising its mechanical properties.

This flexibility, combined with excellent processability through both urethane casting and injection molding, enables manufacturers to achieve precise tolerances and intricate shapes, making polyurethane moldings suitable for a wide range of applications, including polyurethane resins.

Hardness and Durability

The hardness of polyurethane significantly impacts its performance, with harder materials showing greater resistance to wear. This property is crucial in applications that require durability, such as guide rollers and bushings.

The Shore Hardness Number, measured on the Shore A or D scale, is used to quantify the hardness of polyurethane materials. However, two materials with the same Shore Hardness Number can have different properties, affecting their suitable applications.

Polyurethane’s tear strength allows it to withstand tensile forces without ripping, showcasing its durability. This, coupled with good resilience and energy absorption, makes polyurethane suitable for high-impact applications. The material’s ability to maintain its properties over time without deteriorating further underscores its durability.

Chemical and Abrasion Resistance

Polyurethane exhibits high resistance to various chemicals, making it suitable for use in harsh industrial settings. The type of polyester polyols used in the formulation significantly influences the chemical resistance of polyurethanes. New polyurethane materials are being developed to provide superior mechanical and chemical resistance, improving the performance of molded products.

Polyurethane’s outstanding abrasion resistance makes it suitable for demanding applications, such as in wheels and rollers. Cast urethanes, characterized by high tear strength and low coefficients of friction, contribute to their excellent abrasion resistance and sliding abrasion. This combination of properties enhances polyurethane’s applicability in various harsh environments, including automotive and industrial settings.

Flexibility and Machinability

Polyurethane’s flexibility allows it to be molded into intricate shapes without losing its mechanical properties. This property is particularly valuable in the medical field, where biocompatibility and the ability to form complex shapes are essential. Urethane casting is known for its flexibility and forgiving nature with design requirements, facilitating precise shaping.

The combination of flexibility and machinability in polyurethane allows for the production of high-quality, customized components in various industries. This machinability includes processes like:

- machining

- drilling

- cutting

- CNC machining

- milling These processes enable the creation of components with precise geometries and tight tolerances.

Types of Polyurethane Injection Molding Techniques

Polyurethane molding techniques encompass various methods, each suited to different applications and material properties. These techniques include open cast molding, compression molding, centrifugal molding, foaming, and injection methods.

Among these, reaction injection molding (RIM), structural reaction injection molding (SRIM), and reinforced reaction injection molding (RRIM) stand out for their specific advantages in producing high-quality polyurethane components.

Each of these methods offers unique benefits. RIM, for instance, uses liquid prepolymer components, making it distinct from traditional injection molding techniques. SRIM and RRIM further enhance the strength and durability of polyurethane moldings, making them suitable for demanding applications.

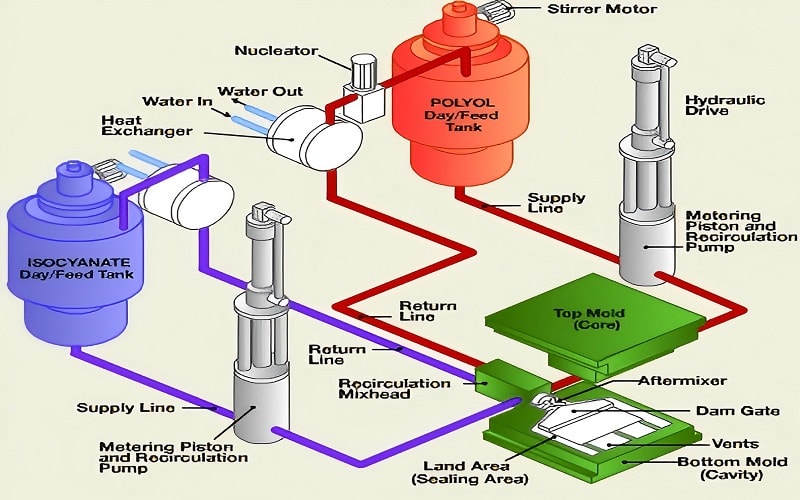

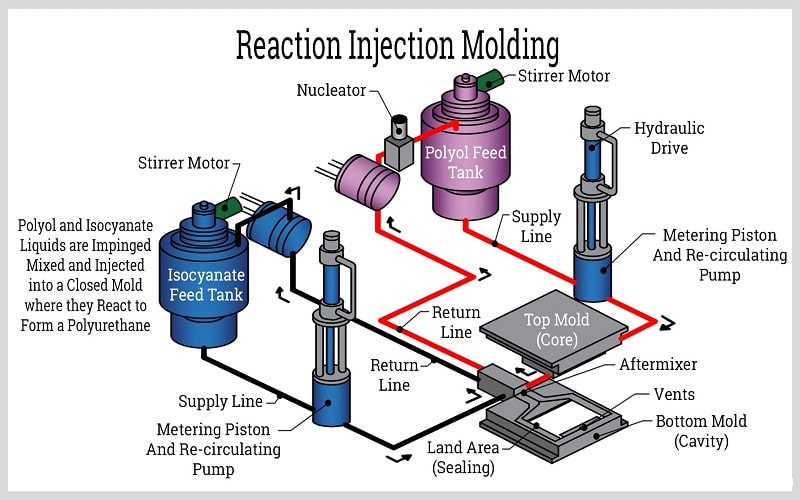

Reaction Injection Molding (RIM)

Reaction Injection Molding (RIM) differs from traditional injection molding techniques in the following ways:

- It utilizes liquid prepolymer components in liquid form instead of solid raw materials.

- The RimStar Compact machine is specifically designed for the RIM process, controlling both temperature and pressure to ensure consistent results.

- The liquid components in RIM exhibit low viscosity, allowing for easier injection into molds.

One of the significant advantages of RIM is the reduction in tooling costs. This technique allows for the use of less robust molds compared to traditional methods, making it suitable for small to medium-scale production runs. This cost efficiency, combined with the ability to produce high-quality components, makes RIM a valuable technique in modern manufacturing.

Structural Reaction Injection Molding (SRIM)

Structural Reaction Injection Molding (SRIM) is a specialized technique used for producing reinforced polyurethane components. This method enhances the strength and performance of polyurethane moldings, making them suitable for demanding applications such as automotive and aerospace industries. SRIM is one of the key types of reaction injection molding, alongside reinforced reaction injection molding (RRIM).

The applications of SRIM are varied and include industries requiring lightweight yet strong components. The process involves injecting a mixture of polyurethane and reinforcing materials into a mold, resulting in components that offer superior structural integrity and durability.

Reinforced Reaction Injection Molding (RRIM)

Reinforced Reaction Injection Molding (RRIM) is particularly effective for producing lightweight parts that require high durability.

This technique involves reinforcing polyurethane with additives, enhancing the material’s strength and longevity. The durability of parts produced using RRIM makes them suitable for various applications that demand long-lasting performance.

The application of RRIM in modern manufacturing underscores its importance in enhancing the strength-to-weight ratio of components. This process is crucial for industries like automotive and aerospace, where the combination of lightweight and durable materials is essential for performance and efficiency.

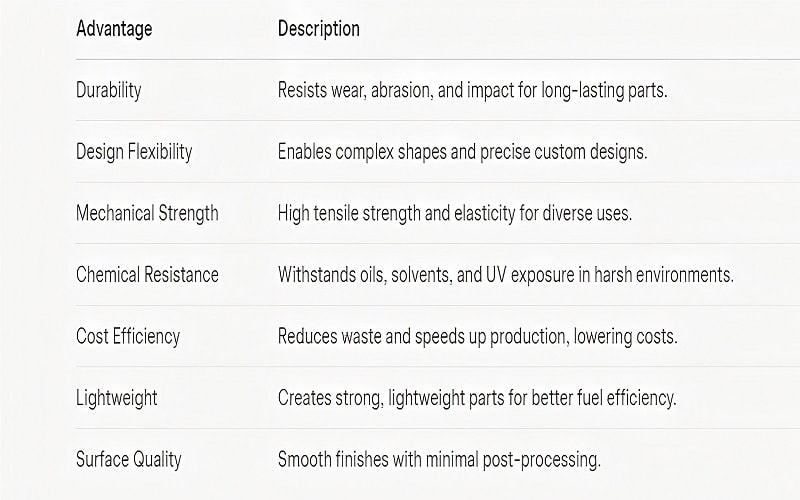

Advantages of Polyurethane Injection Molding

Polyurethane injection molding offers several advantages that make it a preferred choice in various industries:

- Efficiency in producing accurately shaped, durable components with complex designs.

- Support for rapid parts production, even at high volumes, ensuring timely delivery of components.

- Generation of less waste, as defective parts can be regrinded and reused, contributing to cost savings and environmental sustainability.

One significant advantage is the excellent machinability of advanced polyurethane grades. This allows for various processes such as:

- Machining

- Drilling

- Cutting

- CNC machining

- Milling

This capability allows for the production of components with finer details, tighter tolerances, and a range of surface finishes. The versatility of polyurethane injection molding makes it suitable for both low-volume and high-volume production, catering to diverse manufacturing needs.

Cost Efficiency

Managing tooling costs in injection molding is crucial due to the significant investment required for creating hard molds. Key points include:

- Using aluminum molds in polyurethane injection molding can significantly decrease tooling costs compared to traditional steel molds.

- Investing in high-quality molds can reduce long-term tooling costs by improving the durability and lifespan of the molds.

- Automation and AI are increasingly utilized to optimize injection molding processes, resulting in improved production speeds and reduced waste.

The cost efficiency of polyurethane injection molding is further enhanced by the ability to produce large components with varying wall thicknesses, fulfilling specific performance requirements. This flexibility in design and manufacturing ensures that the process remains cost-effective while meeting the stringent demands of various industries.

Design Flexibility

Polyurethane injection molding offers several advantages that enhance design flexibility:

- Allows for the creation of complex geometries and features.

- Excels in shaping parts without requiring drafts or accommodating undercuts, improving design quality.

- Enables the creation of intricate and uniquely shaped components, contributing significantly to overall design flexibility.

Flexible silicone molds and flexible foams further enhance the design possibilities, allowing manufacturers to produce components with tight tolerances and high precision. This flexibility is particularly valuable in industries that require customized and detailed parts, such as automotive, aerospace, and medical devices.

High-Quality Components

Polyurethane injection molding can achieve extremely tight tolerances, with a precision of +/- .005” for the first inch and +/- .002” for every subsequent inch. This precision enables the production of components designed without the need for drafts or undercuts, which enhances the integrity and functionality of the design. The result is high-quality components that meet the rigorous standards of various industries, including automotive, aerospace, and consumer goods.

The ability to produce high-quality components with tight tolerances and excellent surface finishes makes polyurethane injection molding a preferred choice for manufacturers seeking to deliver superior products. The process ensures that each component meets the specific requirements of the application, providing reliability and performance.

Applications of Polyurethane Injection Molding

Polyurethane injection molding is crucial in industries like automotive, medical, consumer goods, and industrial applications due to its high-performance capabilities. The material’s versatility allows it to be customized into various forms, including foams and rigid plastics, enhancing its applicability across different sectors. Common products produced using polyurethane molding include:

- seals

- gaskets

- rollers

- bumpers

- bespoke components.

Recent advancements in polyurethane technology, such as the polyurethane flooding technique, have further expanded its applications. This technique allows for in-mold painting that enhances the surface quality and durability of parts, making polyurethane moldings even more attractive for various industries.

Automotive Industry

Polyurethane injection molding is utilized extensively in the automotive industry, particularly for dynamic sealing elements and other components that require fatigue resistance. Polyurethane is used to manufacture various automotive components, including:

- bumpers

- spoilers

- gaskets

- seals

- interior trim parts

The fatigue resistance of polyurethane makes it ideal for applications in automotive components, ensuring reliability and longevity with its durable material and friction reducing component.

The RimStar Compact machine is known for producing high-precision automotive parts, further highlighting the importance of polyurethane injection molding in this industry.

Medical Devices

Polyurethane’s biocompatibility allows for its use in various medical applications, ensuring it does not provoke an adverse reaction when in contact with body tissues. This biocompatibility is a critical factor in the development of medical devices, ensuring they are safe and effective for patient use. The use of polyurethane in medical devices can lead to improved patient outcomes due to its compatibility with biological systems.

Medical devices made from polyurethane include catheters, surgical drapes, and implantable medical device, showcasing the material’s versatility and importance in the healthcare sector.

Consumer Goods

Many consumer products, like sporting goods and toys, benefit from polyurethane molding due to its durability and versatility. Urethane wheels, commonly used in skateboards and rollerblades, are made of molded urethane (polyurethane). The roller core of polyurethane rollers can endure damage such as:

- scratches

- dents

- corrosion

- other types of wear and tear.

The use of polyurethane in consumer goods ensures high durability, making products like sporting goods more resilient and long-lasting. This durability is particularly valuable in products subjected to frequent use and harsh conditions, ensuring they remain functional and reliable over time.

Choosing the Right Polyurethane Injection Molding Machine

Selecting the right polyurethane injection molding machine is crucial for ensuring efficiency and quality in the manufacturing process. For high-volume injection molding operations, hardened steel tooling is required to withstand the demands of production. Molded polyurethane can produce various products such as conveyor wheels and urethane bushings.

When discussing with suppliers, it’s vital to address aspects such as machine specifications and delivery timelines to ensure that the chosen equipment meets the specific needs of the production process.

Machine Specifications

A key feature of the C-Frame Compression Press is its robust design, which ensures stability and precision during the molding process. Key specifications to consider when choosing a polyurethane injection molding machine include design stability and precision features.

These specifications are essential for producing high-quality components with tight tolerances and consistent performance. Ensuring that the machine meets the specific requirements of the application will optimize the manufacturing process and enhance product quality.

Maintenance and Upkeep

Proper lubrication according to the manufacturer’s guidelines is crucial for the smooth operation of injection molding machines. Regular maintenance ensures optimal operation and longevity of the equipment, preventing unexpected downtimes and maintaining production efficiency.

Operators should be trained on maintenance procedures to enhance their capability to identify issues and perform necessary upkeep. Regular inspections and replacing worn components such as seals and nozzles can prevent significant operational issues and ensure consistent product quality.

Challenges and Solutions in Polyurethane Injection Molding

Polyurethane injection molding, like any manufacturing process, comes with its own set of challenges. These include managing viscosity and mixing issues, controlling temperature during curing, and preventing air traps that can lead to defects. Addressing these challenges is crucial for ensuring the quality and consistency of the final products.

Implementing precise mixing equipment, optimizing temperature management, and ensuring proper mold venting are essential solutions to these challenges, especially under extreme temperatures. Regular maintenance and operator training also play a significant role in mitigating these issues and maintaining smooth production operations.

Shrinkage and Warping

Warping and shrinkage of polyurethane can occur, especially in thicker components. These issues can lead to internal stresses that distort the shape of the final product, affecting its performance and appearance. Proper cooling channel design in molds and maintaining uniform cooling conditions can help mitigate these problems.

By addressing these factors, manufacturers can produce components by producing components with tight tolerances and consistent quality, ensuring that they meet the specific requirements of their applications.

Surface Defects

Common surface defects in polyurethane moldings include blemishes, bubbles, and uneven surfaces, which can impact the aesthetic and functional properties of the final product. Preventive solutions include optimizing the temperature and humidity during the molding process and using high-quality molds.

Implementing rigorous quality control measures throughout the injection molding process is crucial to detect and rectify potential surface defects early on. This ensures that the final products meet the desired quality standards and perform reliably in their intended applications.

Tooling Costs

Injection molding can typically produce between 100 to 100,000 parts, which directly influences tooling costs as larger volumes can spread the expenditure over more units. Effective management of tooling costs is essential to maximize profitability and ensure the sustainability of mass production manufacturing plastic parts production processes.

To reduce tooling costs, manufacturers often streamline production runs to optimize the number of parts produced per cycle. Investing in high-quality molds and maintaining them properly can also enhance their lifespan, reducing long-term tooling costs and improving overall production efficiency through soft tooling.

Innovations in Polyurethane Injection Molding

Innovations in polyurethane injection molding technologies lead to enhanced efficiency, reduced costs, and improved product quality. Historical advancements, such as the development of polyether polyols (PTMEG) in 1956, have paved the way for newer innovations in material sciences and molding techniques. These advancements have revolutionized the polyurethane industry, leading to the creation of more durable and versatile products.

Recent innovations include the use of automation and artificial intelligence to streamline operations and improve the precision of injection molding processes and manufacturing processes. These technologies enhance operational efficiency and reduce the learning curve for operators, making the process more user-friendly and productive.

Advanced Materials

Advanced polyurethane materials are designed to enhance performance in various applications through improved properties. The A205 model has advanced mixing and foaming capabilities. This feature enables a uniform cell structure and density. These materials are particularly valuable in industries that require high-performance components, such as automotive, aerospace, and medical devices.

The development of new polyurethane formulations continues to push the boundaries of what is possible with this versatile material. These advancements ensure that polyurethane remains a preferred choice for manufacturers seeking to produce high-quality, durable components.

Automation and AI

Automation and artificial intelligence play a crucial role in enhancing injection molding processes by streamlining operations. User-friendly interfaces in certain injection molding machines enhance operational efficiency and ease of use. These interfaces allow operators to control complex processes more effectively, reducing the learning curve and increasing productivity.

By incorporating automation and AI, manufacturers can achieve greater precision, consistency, and efficiency in their production processes. This technological integration ensures that polyurethane injection molding remains at the forefront of modern manufacturing techniques.

Summary

In short, polyurethane injection molding technology can bring many benefits to a wide range of industries. From the efficiency of producing precisely shaped, durable parts, to the flexibility of design and high quality output, this process is essential in modern manufacturing.

The ability to create complex geometries, coupled with the durability and resilience of polyurethanes, makes them the preferred choice for automotive, medical and consumer product applications.

Frequently Asked Questions

What is polyurethane injection molding?

Polyurethane injection molding is a high-pressure manufacturing process that involves injecting molten polyurethane into engineered molds to produce durable and intricate components. This method allows for the creation of high-quality parts with precise specifications.

What are the advantages of polyurethane injection molding?

Polyurethane injection molding offers significant advantages such as cost efficiency, design flexibility, high-quality output, reduced waste, and the capacity to create complex geometries with high precision. These benefits make it an attractive option for various manufacturing applications.

What industries benefit from polyurethane injection molding?

Industries such as automotive, aerospace, medical devices, and consumer goods derive substantial advantages from the versatility and durability of polyurethane injection molding. This process enhances product performance and longevity across various applications.

What are common challenges in polyurethane injection molding?

Common challenges in polyurethane injection molding involve managing viscosity and mixing issues, controlling curing temperatures, preventing air traps, and addressing tooling costs. These factors are crucial for achieving high-quality results.

How do innovations in materials and technology impact polyurethane injection molding?

Innovations in materials and technology significantly enhance polyurethane injection molding by improving efficiency, precision, and overall product quality through the use of advanced materials and automated processes. This results in more reliable and sophisticated molding capabilities.