Thermoplastic injection molding is a process used to produce precise plastic parts efficiently. It involves melting plastic, injecting it into a mold, and cooling it into a solid shape.

This method is essential in industries like automotive and healthcare. This article explores its process, benefits, and applications.

Understanding Thermoplastic Injection Molding

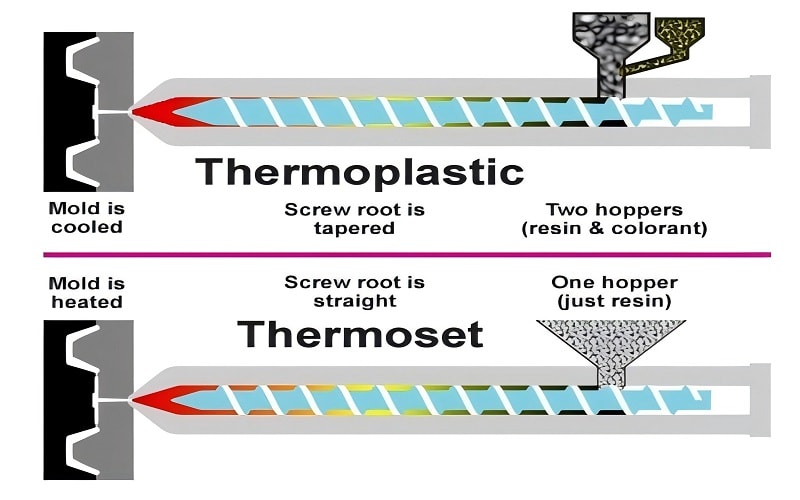

Thermoplastic injection molding, also known as plastic injection molding, is a versatile method for mass-producing plastic parts through the thermoplastic molding process, distinct from processes involving thermosetting polymers that require a curing process.

The process involves three main steps: melting the polymer, injecting it into a mold, and cooling it to create solid shapes, unlike thermosetting polymers which solidify through a curing process.

This method caters to various industries’ industrial needs through variations like rapid and production injection molding. Specialized machines transform raw plastic pellets, typically thermoplastics rather than thermosetting polymers, into manufacturing plastic parts with precision and efficiency, benefiting the plastics industry without the need for a curing process.

What is Thermoplastic Injection Molding?

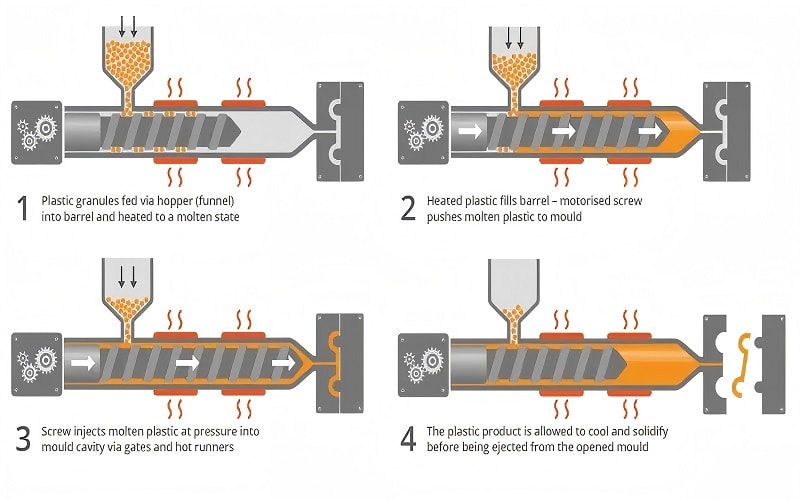

Thermoplastic injection molding involves the following steps:

- Feeding pellets into a hopper

- Melting the pellets in a heated barrel

- Controlling temperature to ensure the desired viscosity and flow characteristics

- Injecting the melted polymers into a mold

- Cooling the polymers to form solid shapes

The molten plastic is injected into a mold at a specific shot size. Factors like part thickness and material type determine the cooling time needed to solidify the part.

This versatile process can inject molten plastic to produce a wide range of products, including cold runner molds, from household items to complex automotive components.

Why Use Thermoplastics in Injection Molding?

Thermoplastic and thermosetting plastic material are pliable when heated, solid when cooled, and highly versatile.

They can withstand high temperatures, be reheated and reshaped, making them suitable for recycling and reusability in injection molding.

The thermoplastic injection molding process is versatile enough to create both tiny and large molds, offering the accuracy needed for complex shapes.

The Thermoplastic Injection Molding Process

The thermoplastic injection molding process converts raw plastic materials, such as polyvinyl chloride, into finished plastic parts through methodical steps in the production processes of the injection process. Each stage, from material preparation to the creation of a fully functional part, is crucial.

The design and quality of the mold tool significantly impact the final characteristics of the part, including those made from polyvinyl chloride, and the efficiency of the production process.

Mold design can support single-cavity or multi-cavity designs for increased productivity, with family molds offering cost savings and flexibility for materials like polyvinyl chloride.

Material Preparation

Preparing plastic pellets ensures high-quality results in injection molding. This includes drying the pellets to remove moisture before loading them into the machine’s hopper.

Moisture removal is crucial, as retained moisture can adversely affect the melting process and the quality of the final part.

Melting and Injection

The injection molding machine melts thermoplastic pellets, such as engineering grade resins, under temperature and pressure, injecting the molten plastic into molds. Temperature control in the barrel ensures the suitable melting point for various plastic materials, including engineering grade resins.

Injection pressure, typically ranging from 500 to 1500 bar, defines the part’s shape and surface finish for engineering grade resins. The nozzle temperature maintains flow and consistency, preventing premature cooling.

Applying back pressure improves color dispersion and removes air from the material, while injection speed influences the filling pattern and part appearance for engineering grade resins.

Cooling and Ejection

Cooling the molten plastic impacts overall part quality and integrity. Key points about cooling include:

- Cooling time is determined by part thickness and material type.

- Cooling begins when the plastic contacts the colder mold surfaces.

- Efficient cooling minimizes cycle times.

- Efficient cooling enhances part quality.

The mold opens, and ejector pins push the finished part out, concluding the injection molding cycle. Timing is essential during the ejection process. Proper timing helps to avoid damage to the molded part in insert molding.

Post-Processing

Post-processing techniques enhance the final product’s functionality and appearance, addressing issues like excess material and surface finish. Methods include trimming, polishing, and painting.

Trimming involves:

- Removing excess materials to create accurate, customer-ready components.

- Ensuring clean trimming, which is critical for aesthetics and functional tolerances in industries such as medical, automotive, or consumer products.

- Re-grinding leftovers and mixing them with virgin pellets.

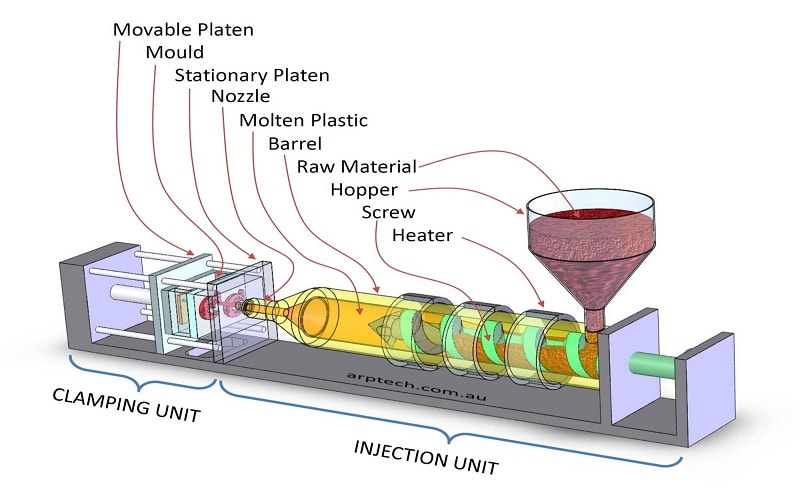

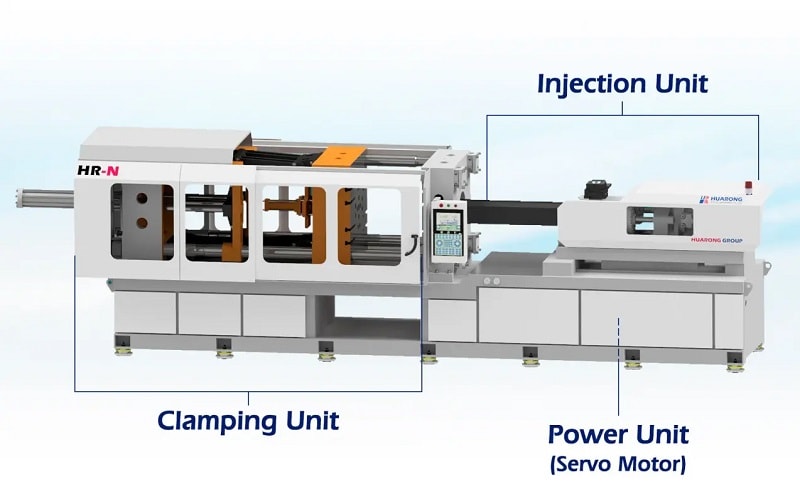

Key Components of an Injection Molding Machine

An injection molding machine includes essential parts like the base, hopper, barrel, and clamping unit. The injection unit melts thermoplastic material and injects it into the mold.

Clamping systems can be categorized into hydraulic and toggle types, each employing different mechanisms for mold operation. The mold tool defines the shape, surface texture, and size of the product in the injection molding process.

Clamping Unit

The clamping unit:

- Secures mold halves and maintains cavity integrity.

- Ensures the mold is closed so the part shape is accurately formed during injection.

- Prevents plastic leakage.

- Ensures dimensional stability and accuracy.

A sufficient clamp force is essential to withstand high injection pressure. It also helps prevent mold flash. The clamping unit also performs several critical functions, including ejecting molded parts and ensuring precision alignment of mold plates.

Injection Unit

The injection unit melts, mixes, and injects thermoplastic resin pellets into the injection mold. External heaters and friction from a reciprocating screw ensure uniform melting and thorough mixing.

The typical screw speed during thermoplastic injection molding is generally set between 100 to 200 RPM, significantly affecting the quality of the plastic melt and ensuring a uniform temperature and mixing of molten material.

Mold Tool

Mold tools are pivotal in defining the final characteristics of the molded part, including its desired shape and texture. The design of the mold influences the efficiency of the production process, supporting varying designs for productivity.

Choosing the Right Thermoplastic Materials

Selecting the right thermoplastic material is critical and often depends on the product type, especially for processes like blow molding.

Thermoplastics can be reheated and reshaped multiple times due to their chemical bond structure, making them highly adaptable. Professionals can assist in selecting the best materials for specific product requirements, including those suited for blow molding.

Thermoplastics are widely used in industries such as medical, automotive, and electronics, often formed through blow molding to leverage their chemical bond properties. Their appropriateness over thermoset plastics depends on product requirements and intended use.

These materials are valued for their ability to be molded into complex shapes, enhancing design flexibility through processes like blow molding and strong chemical bond characteristics.

Common Thermoplastic Polymers

Common thermoplastic polymers used in injection molding include polyethylene, polycarbonate, and acrylonitrile butadiene styrene (ABS).

Polyethylene is characterized by its strength and chemical resistance, with common forms including high-density and low-density polyethylene (HDPE and LDPE). Polycarbonate is known for its transparency, amorphous nature, and impact resistance. ABS, known for its impact resistance, is often used in electronics, auto parts, and toys.

Polyethylene is widely used for various types of packaging, including bags and containers. ABS is also used in applications beyond molded plastics, like drain pipe systems and golf club heads.

Material Properties and Selection Criteria

The choice of material impacts functionality, aesthetics, and longevity in thermoplastic injection molding. Understanding material properties and mechanical properties is crucial for selecting the ideal material based on final product requirements.

Polyethylene exhibits high ductility, tensile strength, impact resistance, moisture resistance, and recyclability, making it a versatile choice. Higher density polyethylene is stronger, more rigid, and more heat-resistant, enhancing its usability in various applications.

Polymethyl Methacrylate (PMMA) is known for its good optical clarity but may be brittle, affecting its application in certain products.

Applications of Thermoplastic Injection Molding

Thermoplastic injection molding is favored for producing high quality plastic parts rapidly and in large quantities. This process serves both small prototypes and large-scale production runs, catering to industries like automotive, medical, and consumer goods.

The versatility of thermoplastics showcases their wide range of applications.

Automotive Components

Polypropylene is used in automotive components due to its lightweight and durable nature. Polycarbonate is utilized in automotive parts for its strength and impact resistance.

The use of thermoplastic injection molding enhances productivity and allows for the creation of visually appealing automotive products.

Medical Devices

Injection moulding is crucial in the medical industry for producing large quantities of precise parts using medical-grade plastics. Parts made through injection molding can comply with FDA regulations, ensuring they meet safety and sterility standards.

Common applications of injection molded components in medicine include surgical instruments, diagnostic devices, and personal protective equipment. Materials like polypropylene and polyetheretherketone (PEEK) are selected for their high durability and heat resistance.

Injection molding allows for the production of complex shapes and intricate designs, essential for the functionality of many medical devices.

Packaging Materials

Polyethylene terephthalate is commonly used in packaging applications like beverage bottles and food containers. Polyethylene is used in products like plastic bags, films, and containers. These common thermoplastics are versatile, making them ideal for different packaging solutions.

BiONext, a type of bio-engineering plastic made from biodegradable materials, is applied in:

- Food packaging

- Agricultural film

- Injection molding

- Creating utensils

The versatility and cost-effectiveness of thermoplastic materials enable their widespread use in packaging applications.

Advantages and Disadvantages of Thermoplastic Injection Molding

Thermoplastic injection molding enables mass production without compromising on quality or cost efficiency. The process is particularly beneficial for medical products, ensuring they adhere to strict safety and efficacy standards.

However, there are both advantages and disadvantages to consider.

Advantages

Thermoplastic injection molding allows for the creation of detailed designs with high precision, making it suitable for various applications. The process ensures stable physical properties and a smooth glossy exterior. Additionally, thermoplastics provide a high-quality finish compared to thermosets.

Efficient cooling system design shortens cycle times and increases output, improving production economics. This sustainable method can utilize recyclable materials and generates less waste.

Thermoplastic molding has several key characteristics:

- It is reversible and can be re-melted and molded multiple times.

- It offers resistance to chemical attacks.

- It provides versatility in creating complex shapes compared to metals.

Disadvantages

Despite its many advantages, thermoplastic injection molding has some drawbacks. Initial setup costs for molds and tooling can be significantly high. The process also requires specialized knowledge to ensure accurate mold production and effective operation.

Cost Considerations in Thermoplastic Injection Molding

Factors influencing the cost-effectiveness of thermoplastic injection molding include design complexity, material type, and production volume. The primary cost factor is the mold, which can vary significantly based on its complexity and production volume.

The size and complexity of the molded part directly affect mold costs, with larger and more intricate designs requiring more expensive molds. Material costs for thermoplastics typically range from $1 to $5 per kilogram, influencing overall production expenses.

Thermoplastic injection molding is favored for its capacity for mass production, leading to lower overall manufacturing costs. High-volume production reduces the per-part cost as fixed costs are distributed over a larger number of parts. Automation in injection molding helps lower labor costs, as machines can operate with minimal human intervention once set up.

Troubleshooting Common Issues

Troubleshooting is crucial for maintaining quality and efficiency in thermoplastic injection molding. Common issues include:

- Short shots

- Flash defects

- Sink marks

- Splay marks

- Warpage

- Voids

- Bubbles.

Short shots can occur due to insufficient flow, low temperatures, or inadequate injection pressure. Flash defects often result from low clamping force or gaps in the mold parting surface. Sink marks arise from inadequate holding pressure or short cooling time.

Common molding defects and their causes include:

- Splay marks: caused by moisture in the material or high injection speeds creating gas.

- Warpage: primarily due to uneven cooling rates during molding.

- Voids: form when part thickness is excessive or if the mold temperature is too high.

- Bubbles: appear if moisture or gas is trapped in the melt during injection.

Thermoplastic vs. Thermoset Injection Molding

Thermoset materials and thermoplastics differ in several ways:

- Thermoset materials are injected into a mold at high temperatures, curing them permanently.

- Thermoplastics are melted and can be reshaped after cooling.

- Thermoplastics are more resistant to chemical attacks than thermosets.

- Thermoplastics are more prevalent in consumer products.

- Thermosets are preferred for applications requiring high heat resistance.

Thermosets are typically used in high-performance applications like medical devices and high-voltage electrical components. Injection molding for thermoplastics is generally faster and can be more cost-effective compared to the slower thermosetting plastic process.

Thermoplastics can be recycled by remelting, but thermosets cannot be reshaped or reused once cured.

Summary

Thermoplastic injection molding is a transformative manufacturing process that offers flexibility, efficiency and precision.

Its applications span a wide range of industries, including automotive, medical and packaging, demonstrating its versatility.

As you venture into the world of thermoplastic injection molding, keep in mind the importance of choosing the right materials and understanding the intricacies of the process to get the best results.

Frequently Asked Questions

What is thermoplastic injection molding?

Thermoplastic injection molding is a manufacturing technique where thermoplastic polymers are melted and injected into a mold, subsequently cooling to create solid shapes. This process enables the efficient production of precise and complex designs.

Why are thermoplastics used in injection molding?

Thermoplastics are preferred in injection molding due to their ability to become pliable upon heating, allowing for intricate shapes and ease of reshaping, which also supports recycling efforts. This versatility enhances their suitability for a wide range of applications.

What are the common issues in thermoplastic injection molding?

Common issues in thermoplastic injection molding include short shots, flash defects, sink marks, splay marks, warpage, voids, and bubbles. Addressing these issues is essential for ensuring quality and consistency in the final product.

How do thermoplastics differ from thermosets in injection molding?

Thermoplastics differ from thermosets in that they can be melted and remolded multiple times, while thermosets are permanently cured and cannot be reshaped. Consequently, thermoplastics offer greater versatility in manufacturing and applications.

What factors influence the cost of thermoplastic injection molding?

The cost of thermoplastic injection molding is primarily influenced by the complexity of the mold, the type of material used, production volume, and the size and intricacy of the molded part. Increasing production volume and utilizing automation can help lower manufacturing costs effectively.