Choosing between ABS vs HDPE depends on understanding their key differences. This guide compares their properties, applications, and benefits to help you pick the right material for your project.

HDPE: Overview and Key Properties

High-density polyethylene, commonly known as HDPE, is a rigid plastic resin made from petroleum byproducts. It consists of tightly packed long chains of ethylene molecules, which give it its characteristic high density and robust structure.

This material is known for its impressive impact resistance, chemical resistance, and UV resistance, making it incredibly durable and suitable for various environmental conditions, with favorable electrical properties for insulation applications.

HDPE plastic is extensively used in hdpe applications such as plastic bottles, pipes, and outdoor use furniture due to its durability and resistance to UV rays. Its ability to withstand different environmental factors without degrading makes it an ideal choice for products that need to last, such as outdoor playground equipment and agricultural films, as well as hdpe alternatives made from color controlled recycled material.

ABS: Overview and Key Properties

Acrylonitrile Butadiene Styrene, commonly known as ABS, is a type of thermoplastic polymer made up of three monomers: acrylonitrile, which increases fatigue resistance and maximum service temperature; butadiene, which provides toughness; and styrene, which offers a glossy finish and ease of processing. This combination makes ABS a highly valued sorted plastic in recycling streams.

This combination gives ABS plastic its excellent mechanical properties, characterized by toughness, strength, and resilience, making it suitable for handling heavy shocks and impacts, with notable scratch resistance enhancing its durability.

ABS is commonly used for automotive parts, electronic housings, and household appliances. Its moldability and ability to be altered for various uses by adjusting the ratios of its three components make it a versatile plastic material for many industries.

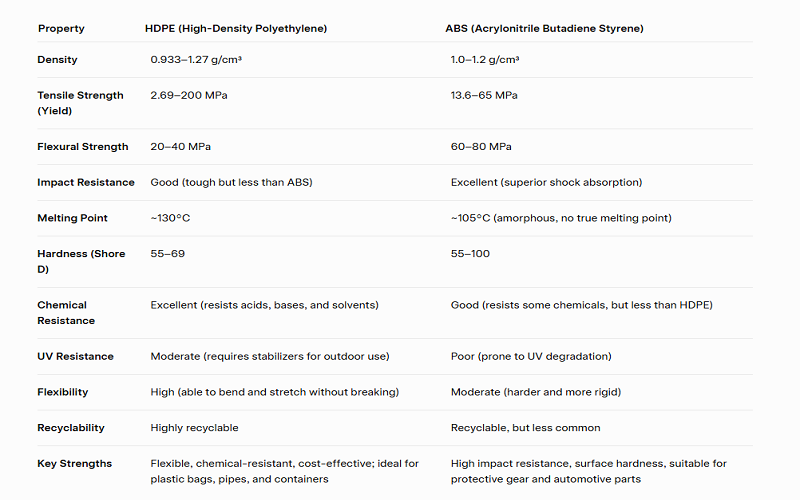

Comparing Physical Properties of HDPE and ABS

Density is a primary aspect when comparing HDPE and ABS. ABS generally ranges from 1.0 to 1.2 g/cm³, making it denser than HDPE, which varies between 0.933 and 1.27 g/cm³. This difference in density influences their weight and specific applications.

Additionally, the tensile strength yield of HDPE ranges from 2.69 to 200 MPa, while ABS exhibits a tensile strength yield of 13.6 to 65 MPa, making ABS generally stronger.

ABS and HDPE differ in the following ways:

- ABS scores between 55 and 100 on the Shore D scale, indicating it is harder and more rigid, contributing to its surface hardness.

- HDPE measures between 55 and 69 on the Shore D scale, making it more flexible and able to bend and stretch without breaking.

- ABS outperforms HDPE in impact resistance.

- Due to its properties, ABS is more suitable for high durability and shock absorption applications.

These physical properties help determine the ideal applications for each material. HDPE’s flexibility suits it for products requiring bending and stretching, such as plastic bags, while ABS’s hardness and impact resistance are ideal for protective gear and automotive parts.

Mechanical Properties Comparison

HDPE and ABS’s mechanical properties further highlight their suitability for different applications. HDPE has a yield tensile strength of 21.2 MPa, which, while adequate for many uses, is lower than that of ABS, making ABS more suitable for high tensile strength applications. ABS’s higher impact strength of 8.5 kJ/m² allows it to endure greater impacts and stresses compared to HDPE, showcasing its good tensile strength.

Dimensional stability is another critical factor. ABS maintains its shape better under stress and temperature variations, making it less prone to warping than HDPE. This stability is crucial for applications requiring precise dimensions and forms, such as car parts and electronic housings.

ABS’s superior mechanical properties, such as higher impact strength and dimensional stability, make it ideal for projects demanding robustness and precision. In contrast, HDPE’s flexibility and resistance suit applications requiring bending and chemical exposure.

Thermal Properties and Heat Resistance

Thermal properties are crucial for selecting materials for high-temperature applications. With a melting point of around 131.8°C, HDPE performs well at moderately elevated temperatures. However, it can only withstand temperatures up to 83°C, limiting its use in extremely high-temperature environments.

ABS has the following thermal properties:

- Higher melting point between 200°C and 224°C, making it suitable for applications needing greater thermal resistance.

- Can tolerate temperatures from 78 °C to 82 °C, maintaining stability and mechanical properties even under heating conditions.

- May release small amounts of VOCs at high temperatures, which is a consideration for specific applications.

Additionally, HDPE’s thermal conductivity of about 0.51 ± 0.02 W/m·K makes it more efficient for heat transfer compared to ABS, which has a lower thermal conductivity between 0.14 and 0.22 W/m·K.

This difference affects their suitability for heat-sensitive applications, with HDPE being better for heat-dissipating components and ABS for high-temperature structural parts.

Chemical Resistance and Stability

Chemical resistance is another crucial factor in material selection. HDPE is ideal for chemical containers due to its high chemical resistance to many solvents, strong acids, and gentle oxidants, making it safe for storing hazardous materials under high pressure.

Its stability in organic solvents, corrosion resistance, and chemical stability in acids or alkalis, combined with its UV resistant properties, make it preferable for products exposed to aggressive chemicals.

ABS, composed of acrylonitrile butadiene and styrene, while offering good chemical resistance against alkalis and concentrated acids, struggles against strong solvents like ether and acetone. This limitation can restrict its use in environments exposed to certain chemicals, making HDPE a better option for chemical exposure applications.

HDPE’s superior chemical resistance and stability make it ideal for products needing to withstand harsh chemical environments, while ABS’s decent chemical resistance suffices for many, but not all, applications due to its acrylonitrile butadiene and styrene composition.

Environmental Impact and Recyclability

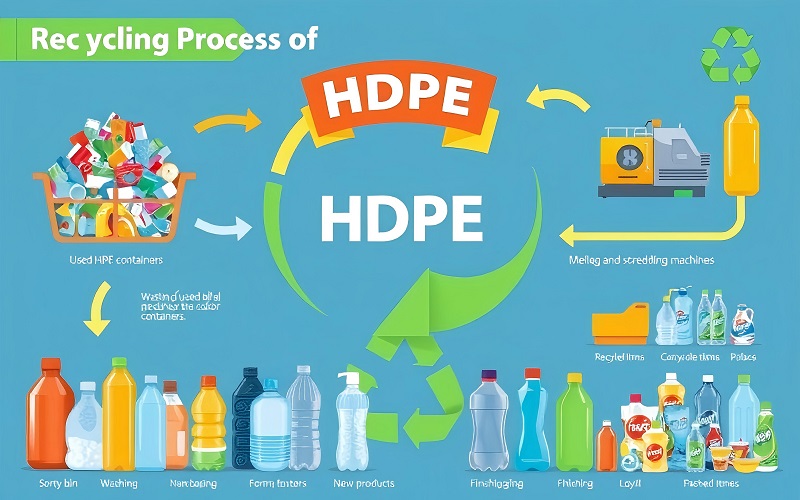

HDPE is known for its environmental benefits:

- It is fully recyclable and capable of enduring through many cycles or more.

- Recycling HDPE conserves resources and reduces energy needed for creating new materials, contributing to a lower carbon footprint.

- Its durability leads to longer product lifetimes, which helps reduce overall environmental impact hdpe.

- HDPE’s end-of-life options promote a circular economy, minimizing waste and facilitating resource reuse.

In contrast, ABS is less eco-friendly due to the chemicals used in its production and longer degradation time. One of the negative effects of ABS on the environment is that it releases harmful substances, posing environmental concerns. Despite this, many recycled ABS components are still in use, highlighting its potential for reuse in certain contexts.

HDPE’s highly recyclable nature and lower environmental footprint make it more sustainable compared to ABS, which, though recyclable, presents greater environmental challenges. In the discussion of hdpe vs other materials, its advantages become clear.

Cost Comparison

ABS tends to be pricier, whereas HDPE is usually less expensive. This higher cost can be attributed to the more complex processing requirements of ABS compared to HDPE, which is easier and cheaper to manufacture. For mass production, cost considerations may favor HDPE due to its affordability.

Material costs are as follows:

- Virgin HDPE: $0.80 to $1.20 per kilogram

- Virgin ABS: around $0.80 to $1.20 per kilogram

- Virgin material recycled HDPE: typically around $0.20 per kilogram, making it a more economical choice.

The cost of ABS granules, especially with specific additives or colors, can exceed $4.00 per kg, further emphasizing the cost advantages of HDPE.

Common Applications of HDPE and ABS

HDPE is widely employed in various industries due to its versatility and durability, often processed from pellet feedstock. Common applications include food and beverage containers, piping systems, toys, fuel tanks, and reusable thin-walled beverage cups. Its resistance to UV rays and low temperatures makes it suitable for outdoor products, such as playground equipment and agricultural films.

ABS plastic is ideal for products requiring a smooth and glossy finish, enhancing their visual appeal, such as refrigerator liners. Common applications include automotive bumpers, product enclosures, interior finishing, and electronics casings. ABS’s high impact resistance and rigidity make it perfect for protective gear and lightweight items, showcasing the strengths of these two materials.

ABS is also used for producing pipes, sheets, plates, and profiles through extrusion molding, showcasing its adaptability for various industries. Both two materials find extensive use in consumer goods and industrial applications, highlighting their importance in modern manufacturing.

Manufacturing Methods for HDPE and ABS

HDPE can be manufactured through several processes like extrusion, blow molding, and injection molding. In blow molding, heated HDPE is formed into a tube and expanded against a mold using air, resulting in high-strength, chemically resistant, and lightweight products. In injection molding, melted HDPE pellets are injected into a mold under pressure, allowing precise and durable product formation.

ABS plastic is processed using methods such as:

- Injection molding

- Extrusion

- 3D printing (fused deposition modeling)

- Thermoforming

Injection molding is particularly favored for ABS due to its ability to produce high-precision and efficient results. ABS’s suitability for intricate designs and complex shapes makes it ideal for projects requiring detailed and precise components.

Advanced manufacturing techniques enhance the properties and applications of both HDPE and ABS, ensuring they meet the diverse needs of various industries.

Alternative Materials to HDPE and ABS

Low-Density Polyethylene (LDPE) is a common alternative to HDPE, known for its flexibility and excellent resistance to moisture and chemicals. It is widely used for plastic bags, packaging films, and containers.

Polypropylene (PP) is another alternative, offering a high melting point and strength, making it suitable for packaging, automotive parts, and textiles.

Different types of plastics and their uses include:

- Polyvinyl Chloride (PVC): Known for its rigidity and used in construction materials, pipes, and medical devices.

- Polyethylene Terephthalate (PET): Primarily used for beverage bottles and food containers due to its strength and resistance to impact.

- Polycarbonate (PC): Known for its high impact resistance and optical clarity, making it suitable for eyewear lenses and safety helmets.

Biodegradable options like Polylactic Acid (PLA) are gaining popularity due to their eco-friendly nature. Derived from renewable resources, PLA is used in packaging, disposable tableware, and medical applications.

Nylon, known for its strength and flexibility, is widely used in textiles, automotive parts, and mechanical components. These alternative materials offer unique properties that can be tailored to specific project requirements.

Choosing the Right Material for Your Project

Choosing the right material for your project involves considering several factors, including durability, appearance, and cost.

HDPE is often preferred for its cost-effectiveness and sustainability, given its high recyclability and lower environmental footprint. On the other hand, ABS is chosen for its excellent mechanical properties and aesthetic appeal, making it ideal for high-stress applications and products requiring a glossy finish.

Consulting with experts can provide valuable insights tailored to your specific project needs. Professionals from companies like Unionfab can help determine whether HDPE or ABS is the best fit based on the unique requirements and constraints of your project.

Summary

In summary, both HDPE and ABS offer distinct advantages and are suitable for a wide range of applications. HDPE is valued for its high impact resistance, chemical resistance, and UV resistance, making it ideal for outdoor and industrial uses.

Its cost-effectiveness and recyclability further enhance its appeal. ABS, with its superior mechanical properties, toughness, and aesthetic finish, is perfect for automotive parts, electronics, and high-stress applications.

Ultimately, the choice between HDPE and ABS depends on the specific requirements of your project. By understanding the properties, applications, and environmental impacts of these materials, you can make an informed decision that ensures the success and durability of your products. Choose wisely, and your project will stand the test of time.