Acrylic injection molding is pivotal in manufacturing high-quality, precise parts quickly and efficiently.

This versatile thermoplastic process involves injecting hot materials—specifically melted acrylic resin—into a mold, which then cools and solidifies into complex shapes with excellent optical clarity and dimensional stability.

In this article, we’ll explore every aspect of acrylic injection molding—from the detailed injection molding process and key parameters like injection pressure, draft angle, and wall thickness to its advantages.

We will also discuss common challenges such as gas lines and surface defects, additional finishing processes, and future trends enhancing sustainability and industrial equipment applications.

What Is Acrylic Plastic?

Acrylic, chemically known as polymethyl methacrylate (PMMA), is a transparent synthetic plastic sheet derived from acrylic acid derivatives and classified as an amorphous polymer.

Commonly referred to as acrylic or Plexiglass, this versatile transparent thermoplastic is prized for its lightweight nature, excellent optical clarity, and impact resistance.

Due to its high melt viscosity and excellent UV resistance, acrylic plastic is widely used in various industries for optical applications, outdoor applications, and other plastics replacement.

Its ease of processing and ability to form complex shapes make it a popular choice in manufacturing diverse acrylic products, including refrigerator drawers and other durable components made from methyl methacrylate.

Key Properties Of Acrylic Materials

Acrylic boasts impressive mechanical and thermal properties that contribute to its widespread use in injection molding applications.

Mechanical Properties

It has a tensile strength of 75 MPa, allowing it to withstand significant stress, a flexural strength of 90 MPa that enables it to bend without permanent deformation, and a high flexural modulus of 3.2 G Pa, which enhances its resistance to bending and ensures structural integrity under load.

These mechanical properties make acrylic suitable for various structural and optical applications.

Thermal Properties

Thermally, acrylic performs well under heat exposure, with a heat deflection temperature ranging from 65 to 100 degrees centigrade at 264 psi, enabling it to maintain performance in warmer environments.

Its melting temperature typically lies between 130 and 140 degrees centigrade, while its decomposition temperature is around 270 degrees centigrade, which is critical to prevent material degradation during processing.

Acrylic also exhibits a low thermal conductivity of 3.9 (BTU – in/square foot), ensuring it does not conduct heat as rapidly as metals, making it safer and more stable in certain applications.

The coefficient of linear thermal expansion is another important thermal property, demonstrating acrylic’s tendency to expand when heated—a critical factor in mold design to accommodate dimensional changes.

Optical Clarity

Optically, acrylic’s very low haze value and high light transmittance of approximately 92% make it clearer than many other polymers, providing excellent optical clarity.

This clarity, combined with its scratch resistance, makes acrylic ideal for lenses, screens, windows, signs, and other optical applications.

Acrylic Injection Molding Process Parameter Settings

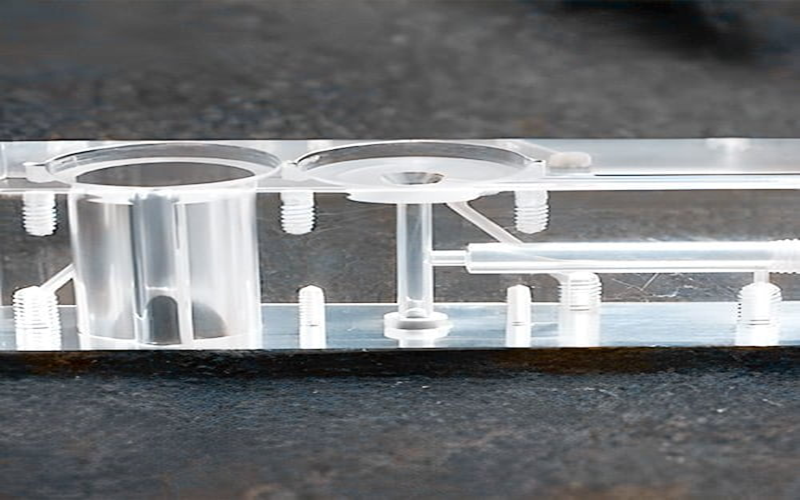

The acrylic injection molding process is a meticulous sequence that transforms raw acrylic materials into precise, high-quality parts with excellent optical clarity and dimensional stability.

It begins with the preparation and thorough cleaning of all materials to ensure they are free from contaminants.

Acrylic sheets are cut into smaller pieces to fit into the barrel of the injection molding machines and must be properly dried at an appropriate drying temperature to maintain an optimal humidity level below 0.1%, ideally around 0.04%, preventing moisture absorption that can cause surface defects such as gas lines and bubbles.

The dried acrylic is then heated to a melting temperature range between 210°C and 270°C, achieving the right melt viscosity for molding.

During the injection molding process, the acrylic is injected into the mold under carefully controlled injection pressure and injection speed.

The mold temperature is precisely managed to avoid issues like shrinkage, warpage, brittleness, and poor molding fluidity, ensuring the acrylic parts maintain their intended shape and quality.

Cooling agents, such as water, expedite the cooling process once the acrylic is injected, solidifying the material while maintaining structural integrity and dimensional accuracy.

Proper mold design elements—including runner diameter, draft angle, and avoidance of sharp corners—facilitate smooth flow, minimize stress concentrations, and enable easy ejection without cracking.

Multi-stage injection techniques, such as slow-fast-slow injection, help minimize internal stresses and visible marks on the final product.

Adequate venting and a well-maintained temperature control system prevent burn marks and other surface defects.

This precise control over temperature, material handling, and mold design is essential for producing consistent, high-quality injection molded acrylic parts with excellent impact resistance and optical properties.

Advantages Of Acrylic Injection Molding

Acrylic injection molding offers numerous advantages that make it a preferred method in various industries.

One of the primary benefits is high precision, which allows for the production of complex and detailed parts with excellent accuracy.

Such precision is crucial in applications requiring exact specifications, including injection mold PMMA injection molding.

Another significant advantage is the aesthetic appeal of acrylic products. Acrylic materials offer excellent clarity and surface finish, making them ideal for products that require a visually appealing appearance.

The process is low cost, especially for high-volume production runs, making it an economical choice for manufacturers.

The versatility of acrylic also allows for compatibility with various designs and finishes, enhancing its application scope.

Common Challenges And Solutions In Acrylic Molding

Challenges

Acrylic injection molding presents several challenges that can affect the quality and consistency of molded parts.

Common issues include air entrapment, uneven cooling, and material shrinkage, which often lead to defects such as bubbles, warping, sink marks, and dimensional inaccuracies.

Additionally, achieving a high-gloss surface finish can be difficult due to mold imperfections, moisture absorption, or improper processing parameters.

Complex part geometries may also cause problems with mold filling and release, increasing the risk of visible marks, internal stresses, and cracking.

The high melt viscosity and poor molding fluidity of acrylic materials further complicate the injection molding process, requiring precise control over injection speed, pressure, and mold temperature to minimize defects and ensure optimal performance.

Solutions

To effectively address these challenges, it is essential to optimize mold design by incorporating proper venting and efficient cooling channels, which help minimize air entrapment and ensure uniform cooling throughout the mold.

Precise control over injection temperature, injection pressure, and cycle time is critical to reducing material shrinkage, preventing warpage, and enhancing surface finish quality.

Utilizing high-quality, polished molds combined with advanced release agents facilitates smooth demolding and reduces the risk of visible marks or damage to injection molded acrylic parts.

Overall, these comprehensive process optimizations contribute to minimizing defects and producing high-quality, durable, and visually appealing acrylic injection molded parts.

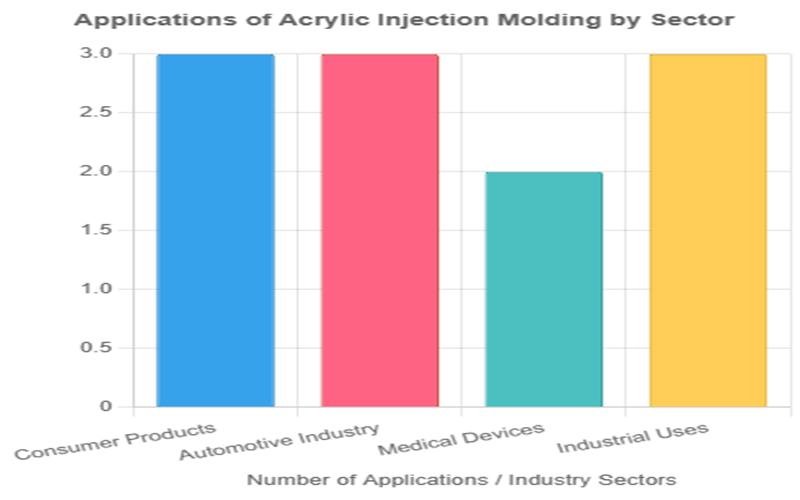

Applications Of Injection Molded Acrylic Parts

Acrylic injection molding is widely utilized across various industries due to its clarity, durability, and versatility.

Consumer Products

Acrylic’s exceptional optical clarity and aesthetic appeal make it an ideal material for producing high-quality lenses, display screens, and lighting covers.

These components benefit greatly from acrylic’s ability to achieve a durable, high-gloss finish and excellent resistance to yellowing and UV degradation, ensuring long-lasting clarity and performance.

Common consumer products utilizing acrylic injection molded parts include magnifying lenses, LED light diffusers, smartphone screens, and decorative lighting fixtures.

Additionally, the lightweight nature and impact resistance of acrylic plastic enhance the durability and user experience of these everyday items, making acrylic molding a preferred choice in the consumer goods industry.

Automotive Industry

Acrylic is extensively used for headlight lenses, interior trim, and dashboards due to its excellent light transmission, impact resistance, and UV resistance.

These properties ensure durability and enhanced visibility for headlight lenses, while its moldability allows for sleek, customized designs in interior components.

Additionally, the high dimensional stability and scratch resistance of injection molded acrylic parts make them ideal for automotive applications that demand both aesthetic appeal and long-term performance.

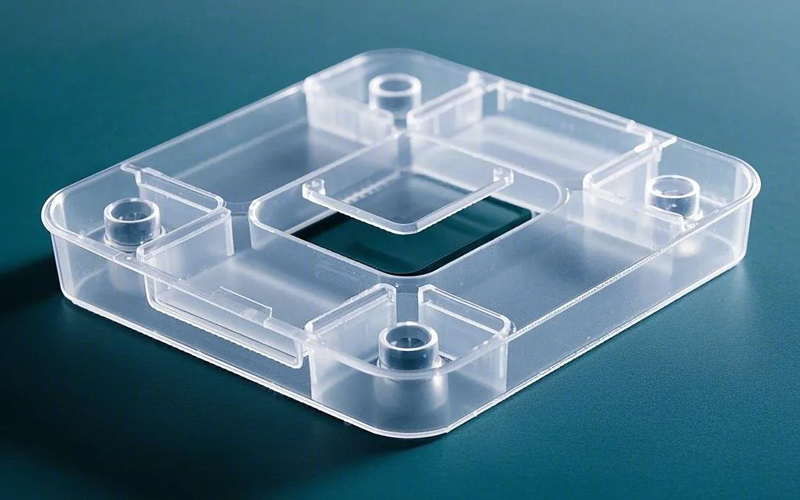

Medical Devices

Acrylic’s biocompatibility, excellent chemical resistance, and sterilizability make it an ideal choice for manufacturing medical devices and sterile components.

Its superior optical clarity facilitates precise imaging and visualization in diagnostic equipment such as endoscopes and surgical instruments.

Additionally, acrylic injection molding allows for the production of complex, high-precision parts that meet stringent medical standards, ensuring reliability and safety in sterile environments.

Industrial Uses

Acrylic’s exceptional strength, excellent weather resistance, and outstanding impact resistance make it highly valuable in various industrial applications.

Injection-molded acrylic parts are widely used in signage due to their vibrant colors, durability, and ability to withstand harsh outdoor conditions.

Protective shields crafted from acrylic offer reliable safety and clarity, making them ideal for industrial equipment and machinery guards.

Additionally, acrylic’s versatility in molding complex shapes allows for the production of custom components tailored to specific industrial needs, combining durability with precision.

These qualities ensure that injection molded acrylic parts perform reliably in demanding environments, enhancing safety and functionality across multiple sectors.

Future Trends Of Acrylic Injection Molding

The future of acrylic injection molding is promising, with several trends pointing towards continued innovation and sustainability.

One significant trend is the development of eco-friendly acrylic formulations that reduce environmental impact. These formulations aim to provide the same high-quality properties with increased sustainability.

Advancements in molding technology, such as automation and precision, are also shaping the future of the industry.

These innovations improve efficiency and product quality, making the acrylic injection molding process more reliable and cost-effective.

The growing demand for sustainable and recyclable acrylic products drives further research and development.

Emerging applications in 3D printing and hybrid manufacturing are expanding the possibilities for acrylic injection molding.

These technologies allow for more complex and customized designs, opening new avenues for innovation across various industries.

Conclusion

Acrylic injection molding offers a multitude of benefits and diverse applications, making it an indispensable process in modern manufacturing industries.

Understanding the detailed intricacies of the acrylic injection molding process—including material properties such as polymethyl methacrylate (PMMA), moisture absorption, and high melt viscosity—is essential for producing high-quality, defect-free parts.

Equally important are critical parameters like mold temperature, injection pressure, injection speed, and wall thickness, which must be carefully controlled throughout the process.

Adopting best practices such as proper drying temperature control, low temperature plasticization, multi-stage injection techniques, and effective cooling processes helps minimize common defects like gas lines, warping, and surface blemishes.

Staying informed about emerging trends, including the use of recycled materials and advancements in eco-friendly acrylic formulations, empowers manufacturers to enhance sustainability while maintaining superior optical clarity, impact resistance, and dimensional stability.

Whether you’re producing automotive parts, consumer goods, medical devices, or industrial equipment, mastering acrylic injection molding will undoubtedly enhance your production capabilities, reduce costs, and elevate product quality to meet evolving market demands.