Not sure whether to use ASA vs ABS for your 3D printing project?

This article breaks down their key differences in UV resistance, chemical resistance, and temperature tolerance to help you make an informed decision.

Key Differences Between ASA and ABS

ASA and ABS are two of the most commonly used plastic materials in 3D printing.

While they share some similarities, such as being thermoplastics, the core differences lie in their resistance to environmental factors like UV resistant properties, chemicals, temperature, and styrene.

Both ABS variants offer distinct advantages, making them suitable for consumer goods.

Knowing these differences helps in selecting the appropriate material for your specific needs.

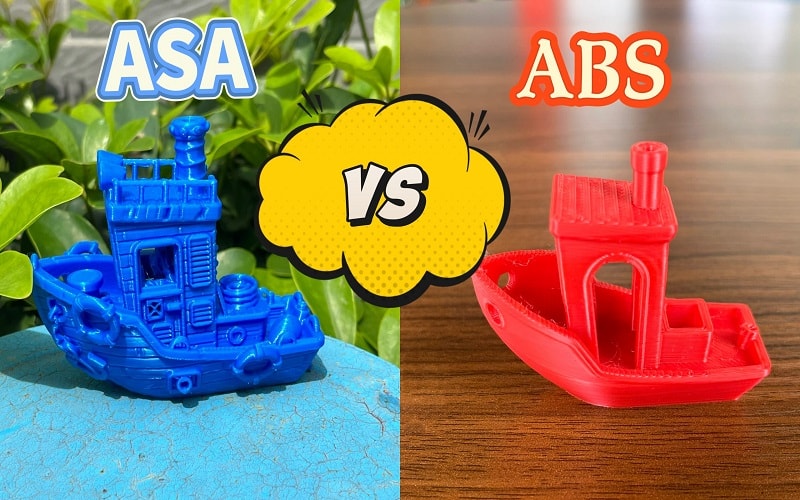

UV Resistance

ASA excels in UV resistance. ASA maintains its color and structural integrity even after prolonged exposure to UV light, unlike ABS, which can become brittle and discolored over time.

Consequently, ASA is perfect for outdoor applications with inevitable UV exposure, such as:

- Outdoor signs

- Garden tools

- Automotive parts These items need to withstand the harsh rays of the sun without losing their durability or aesthetic appeal.

In contrast, ABS tends to fade and degrade when exposed to UV light, making it less suitable for outdoor use. If you’ve ever noticed an ABS print turning yellow or becoming brittle, it’s due to its poor UV resistance.

For projects requiring longevity and sunlight exposure, ASA emerges as the clear winner.

Chemical Resistance

ASA also excels in chemical resistance. It withstands a broader range of chemicals, including:

- acids

- bases

- oils This makes it suitable for more demanding environments. If your project involves exposure to harsh chemicals or solvents, ASA is more likely to maintain its integrity and performance.

ABS, on the other hand, has a more limited range of chemical resistance. While it performs well in many basic environments, it may not hold up as well when exposed to more aggressive substances.

This makes ASA a better choice for applications where chemical resistance is a priority, especially when considering abs and asa. Additionally, ASA is more resistant to harsh chemicals than ABS.

Temperature Resistance

In terms of temperature resistance, ASA is again more robust. With a heat deflection temperature of approximately 86°C, ASA maintains its structural integrity better under high temperatures compared to ABS, which can only withstand up to 81°C.

Thus, ASA is suitable for applications that need thermal stability. Both ASA and ABS have specific bed temperature requirements for optimal printing, with ASA typically requiring a higher bed temperature to ensure good adhesion and minimize warping.

Paying attention to temperature settings, including the wait time and log of adjustments, is key to achieving high-quality prints with both materials that stick well.

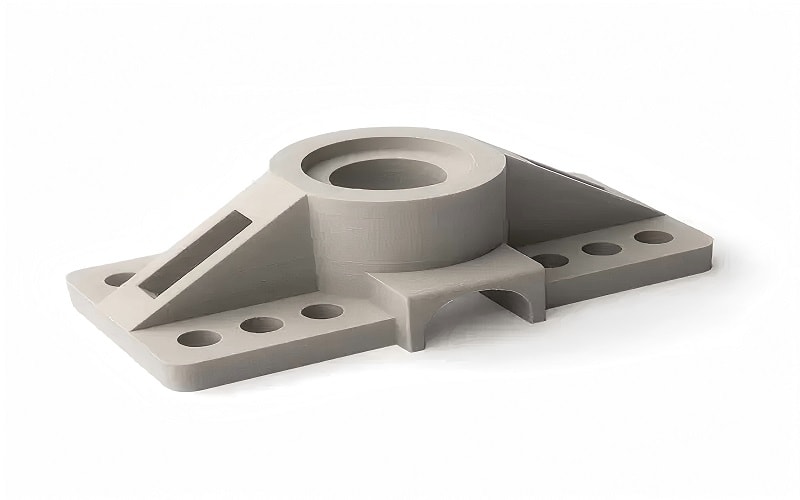

ASA vs ABS: Mechanical Properties and Durability

Mechanical properties and durability are key considerations when selecting a 3D printing material.

ASA generally offers superior mechanical properties, such as higher tensile strength and better overall robustness, making it a preferred choice for manufacturing durable tools and fixtures.

Knowing these properties aids in making an informed decision for your application.

Strength and Toughness

Strength and toughness play a critical role in many 3D printing applications. ASA is often favored for applications requiring high impact resistance, such as automotive parts, without the need to bother with frequent replacements.

Its superior strength makes it ideal for demanding environments where durability is paramount, especially for parts that need traction under stress, like those processed in a roll of production.

ABS, while still strong, is more commonly chosen for indoor prototypes due to its excellent impact resistance and lower material cost. Thus, ABS is suitable for functional prototypes needing strength and resilience but not exposed to extreme conditions.

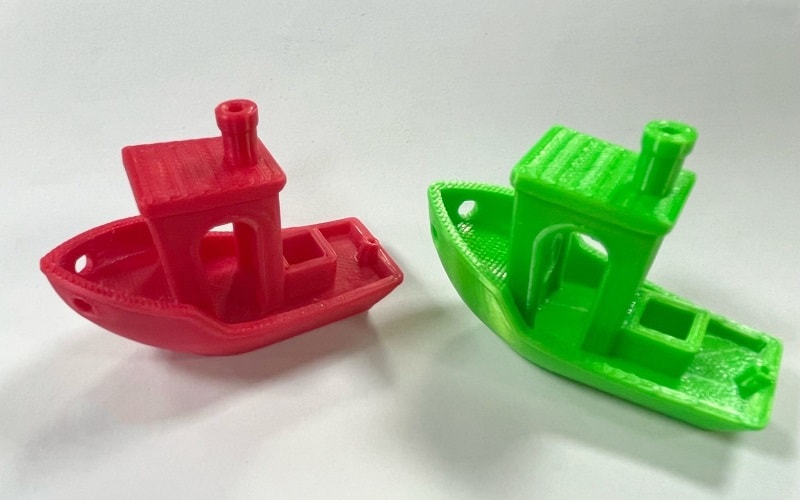

Warping and Print Quality

Warping is a common issue in 3D printing, and it can significantly impact print quality.

ASA tends to have a lower tendency to warp compared to ABS, resulting in improved print quality and higher accuracy as it stands firm during the process.

As a result, ASA is preferable for projects requiring precision and dimensional stability.

Using an enclosed printer can help mitigate warping issues for both ASA and ABS. An enclosure maintains a consistent temperature around the print, reducing the likelihood of warping and ensuring better adhesion, especially when printing stuff on a table.

This is particularly important for achieving high-quality prints with these materials.

Durability in Different Environments

ASA is known for its exceptional durability in outdoor settings. Its resistance to UV rays and harsh weather conditions makes it a versatile choice for various outdoor applications, such as automotive housings, protective covers, and outdoor furniture. This makes ASA a go-to material for projects that require long-term exposure to the elements.

While ASA excels in outdoor durability, ABS offers slightly superior impact strength, making it more suitable for some indoor applications that require toughness. Choosing the right material depends on the specific environment in which the prints will be used.

Cost and Availability

Cost is a significant factor when deciding between ASA and ABS for your 3D printing projects. Typically, ASA filaments tend to be slightly more expensive than ABS filaments, which can influence your budget considerations.

However, the additional cost can be justified by ASA’s superior properties in certain applications, especially when assuming the asa vs alternatives.

Price Comparison

The cost of ASA filament can vary significantly, typically ranging from $26.87 to over $158, depending on the brand and specific formulation.

In contrast, ABS filament generally costs between $20 and $30 per kilogram, making it a more budget-friendly option for 3D printing. This price difference is a crucial consideration for projects with tight budget constraints.

ABS is often chosen for indoor prototyping because of its cost-effectiveness and good mechanical characteristics. This makes it an ideal choice for projects where budget is a significant concern vs abs.

Filament Brand Options

When it comes to filament brand options, there are several reputable brands offering both ASA and ABS filaments. Popular brands include:

- MatterHackers

- 3DXTech

- ColorFabb

- Fillamentum These brands provide high-quality options to meet various user needs and preferences. They are recognized for their reliability, making them suitable for various 3D printing projects.

Choosing high-quality filament brands is crucial for achieving successful 3D printing results with ASA and ABS. Brands like Ultimaker and Prusa also offer excellent filament options, ensuring that you have access to reliable materials for your projects.

ASA vs ABS: Specific Use Cases

Understanding the specific use cases for ASA and ABS can help you choose the right material for your project.

ASA’s superior mechanical properties make it suitable for producing durable tools and fixtures, while ABS is often favored for its impact resistance and ease of machining.

Let’s explore these use cases in more detail.

Outdoor Applications

ASA is particularly well-suited for outdoor applications due to its excellent UV resistance and weatherability.

Projects such as outdoor signage, garden furniture, and automotive components benefit from ASA’s ability to withstand harsh weather conditions and prolonged UV exposure. Hence, ASA is the go-to material for outdoor projects needing long-term durability.

In contrast, ABS prints tend to degrade over time when exposed to outdoor conditions, becoming brittle and losing their mechanical properties. Consequently, ASA is generally the preferred choice for outdoor applications.

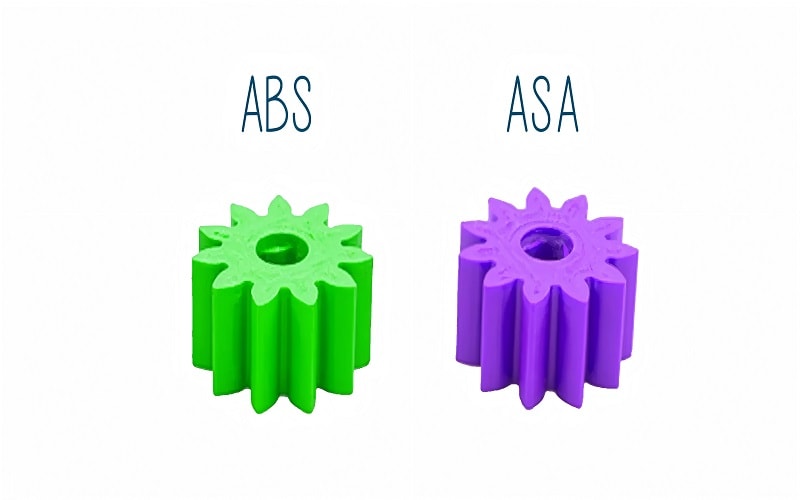

Indoor Prototyping and Manufacturing

ABS is favored for indoor prototyping and manufacturing due to its cost-effectiveness and good mechanical strength. Common applications for ABS include:

- Indoor functional parts like gears

- Electronics enclosures

- Automotive components Its ability to withstand high impact forces makes it suitable for creating durable and resilient prototypes.

Additionally, ABS’s ease of machining and post-processing capabilities make it a versatile material for various indoor projects. Hence, ABS is an excellent choice for creating functional prototypes and parts with specific mechanical needs.

Specialized Requirements

Certain niche applications benefit from the unique properties of ASA and ABS.

For example, ASA’s impact resistance and superior surface finish make it ideal for producing custom automotive interior components that need to withstand both mechanical stress and aesthetic demands.

Therefore, ASA is valuable for specialized applications needing both durability and visual appeal.

ABS, on the other hand, is often chosen for applications where its ease of machining and post-processing capabilities provide significant advantages.

This involves projects needing precise detailing and finishing, ensuring ABS meets specific requirements for specialized applications.

Printing Tips for ASA and ABS

Achieving optimal results with ASA and ABS requires careful attention to:

- Printing conditions and techniques

- Proper bed adhesion

- Temperature settings

- Post-processing methods

These are essential for producing high-quality prints with both materials.Consider these tips for the best forward page results.

Bed Temperature Settings

The recommended bed temperature for printing ASA is between 90-110°C. Maintaining this temperature range helps to ensure good adhesion and minimizes warping, resulting in higher-quality prints. For ABS, a similar bed temperature range of 95-110°C is often recommended to prevent warping and ensure stable prints.

Keeping the bed at the optimal temperature is crucial for achieving the best results with both ASA and ABS. Attention to detail significantly enhances print quality and accuracy.

Enclosure and Ventilation

An enclosed printing environment is recommended for ABS to minimize warping risks and maintain a stable temperature around the print. This helps to ensure better adhesion and reduces the likelihood of warping, resulting in higher-quality prints.

For ASA, proper ventilation is important to mitigate unpleasant fumes and ensure safety during the printing process. A well-ventilated environment improves the printing experience and maintains a safe workspace.

Post-Processing Techniques

Post-processing is essential for improving the surface quality and durability of both ASA and ABS prints.

Sanding followed by acetone smoothing are effective techniques for post-processing ASA prints, enhancing their aesthetic and functional properties.

This helps to achieve a smoother finish and better overall appearance.

Employing post-processing techniques can significantly enhance the aesthetic and functional properties of 3D printed parts. Proper post-processing with either ASA or ABS significantly impacts the final product.

Summary

Choosing between ASA and ABS for your 3D printing project depends on your specific needs and the environment in which the prints will be used.

ASA offers superior UV, chemical, and temperature resistance, making it ideal for outdoor applications and demanding environments. On the other hand, ABS is cost-effective and provides excellent impact resistance, making it suitable for indoor prototyping and manufacturing.

Understanding the unique properties and applications of ASA and ABS can help you make an informed decision and achieve the best results for your 3D printing projects.

Whether you’re looking for durability, cost-effectiveness, or specific mechanical properties, both materials have their strengths and can meet your project’s requirements.