ASA and Nylon are two widely used thermoplastics, each offering distinct properties that cater to diverse applications, from automotive components to outdoor fixtures and textiles.

While both materials are valued for their durability and versatility, their differences in composition, performance, and environmental suitability set them apart.

This article examines the key differences in the ASA vs Nylon comparison, analyzing their properties, applications, and more to guide you in choosing the best material for your specific needs.

What Is Acrylonitrile Styrene Acrylate (ASA)?

Acrylonitrile Styrene Acrylate, commonly known as ASA, is a thermoplastic polymer renowned for its excellent weather resistance, making it a popular choice for outdoor applications.

ASA is frequently used in automotive parts, outdoor furniture, and 3D printing, where its resistance to warping and moisture contributes to consistent shape retention and reliable inter layer adhesion during the printing process.

Additionally, ASA prints well on a heated build plate and benefits from an enclosure and filament dryer to maintain optimal moisture levels, making it a suitable choice for producing durable, weather-resistant objects and components.

What Is Nylon Materials?

Nylon materials, also known as polyamides (PA), are a group of versatile thermoplastic polymers widely used in 3D printing and manufacturing due to their excellent mechanical properties, including high tensile strength, wear resistance, and impact resistance.

Nylon also requires higher printing temperatures and a heated build plate to reduce warping and ensure good inter layer adhesion.

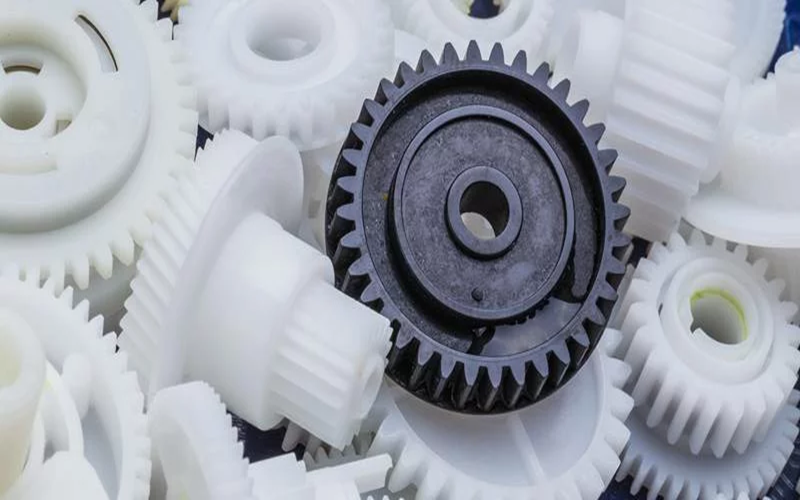

Thanks to its chemical resistance and ability to perform well under high temperatures, nylon materials are often preferred for functional parts, gears, and components exposed to mechanical wear, making them a valuable alternative to other materials like ASA and polycarbonate (PC).

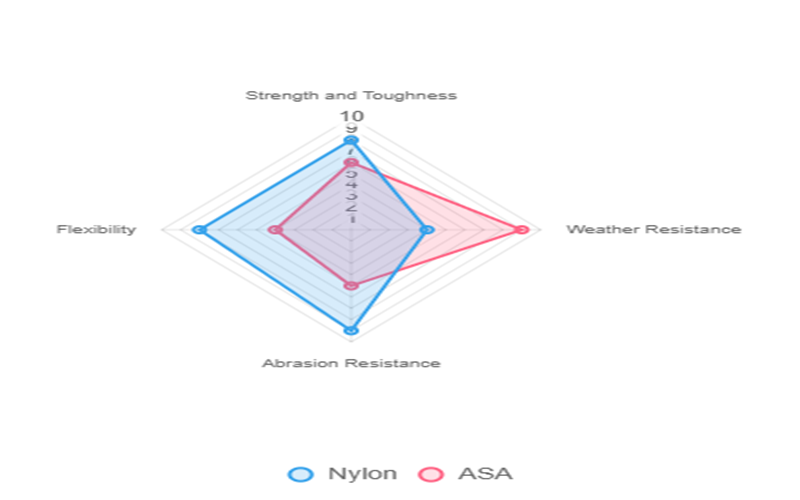

Key Properties Comparison Between ASA And Nylon

When choosing between ASA and Nylon for your project, understanding their key properties is essential. Each material offers unique strengths and weaknesses that make them suitable for different applications.

Weather Resistance

ASA excels in outdoor environments due to its excellent UV, heat, and moisture resistance, maintaining color and structural integrity over time. It is highly suitable for applications exposed to harsh weather conditions, ensuring long-lasting performance and minimal fading.

Nylon, however, is prone to moisture absorption from the air, which can weaken its mechanical properties and cause dimensional changes. Proper drying and storage with a filament dryer or in an enclosure are necessary to maintain its quality and performance during 3D printing and production.

Abrasion Resistance

Nylon’s exceptional abrasion resistance and toughness make it a top choice for textiles, gears, and industrial components subjected to frequent wear and mechanical stress.

ASA, while durable and weather-resistant, is less resistant to surface wear and abrasion, limiting its suitability for high-friction or heavy-duty applications.

Flexibility

Nylon offers greater flexibility and elongation before breaking, making it ideal for applications that require bendability and resilience under repeated stress.

This flexibility allows nylon parts to absorb impacts and flex without cracking, which is particularly useful for producing durable and tough components such as gears, hinges, and wearable items.

On the other hand, ASA is relatively rigid and provides excellent dimensional stability and stiffness, making it a good choice for applications where shape retention and structural integrity are critical.

Chemical Resistance

Nylon materials offer excellent chemical resistance, particularly against oils, greases, fuels, and many solvents, making them highly suitable for industrial and mechanical parts exposed to harsh chemical environments.

ASA, while providing moderate chemical resistance, stands out for its superior resistance to weathering, UV radiation, and moisture, which preserves its color and mechanical properties in outdoor applications.

Applications Of Nylon And ASA

When it comes to application, nylon and ASA serve distinct purposes due to their differing properties.

Nylon, known for its flexibility, toughness, and excellent wear resistance, is commonly used for functional parts such as gears, bearings, and mechanical components that require durability and the ability to withstand repeated stress.

It is especially suitable for producing thinner parts that need to flex without breaking. Additionally, nylon’s good chemical resistance and high temperature tolerance make it a preferred choice for industrial applications involving metals like steel and aluminum.

Nylon can also be combined with carbon fiber to create reinforced materials with enhanced stiffness and durability, suitable for demanding 3D printing projects involving large parts and complex geometries.

Nylon, with its soft yet tough nature, is better suited for mechanical parts that need to endure wear and flexing, such as flexible hinges or durable gears.

ASA, on the other hand, shines in outdoor and aesthetic applications thanks to its superior weather resistance, UV stability, and rigidity.

It is often chosen for automotive parts, outdoor furniture, and housings that demand good mechanical properties, excellent resistance to environmental factors, and long-term exposure to harsh conditions.

This combination of strength and durability makes ASA a reliable choice for products that require consistent shape retention and color stability under sunlight and varying weather.

Additionally, ASA prints well at lower temperatures compared to some other engineering plastics, making it compatible with a wider range of 3D printers and technologies.

All in all, ASA is a great choice for light outdoor fixtures and garden furniture, where its resistance to weather and UV rays supports long-lasting performance.

Benefits And Drawbacks Of ASA And Nylon

This section highlights the key strengths and limitations of ASA and Nylon, providing a clear comparison to guide material selection for specific applications.

Advantages Of ASA

ASA offers excellent weatherability, resisting UV rays, heat, and moisture, making it ideal for outdoor applications like automotive exteriors, signage, and garden furniture.

It maintains color and structural integrity over time, ensuring long-lasting durability. Additionally, ASA provides good mechanical properties and prints well on a heated build plate with lower temperatures compared to some other engineering plastics.

There are many good things about ASA, including its moderate cost-effectiveness and compatibility with a wide range of 3D printers.

Disadvantages Of ASA

ASA has lower tensile strength and flexibility compared to Nylon, which limits its suitability for high-stress or dynamic applications that require parts to flex or absorb impact.

Additionally, ASA’s abrasion resistance is inferior, making it less ideal for components exposed to frequent wear or mechanical friction.

ASA can also be prone to warping during 3D printing if proper conditions such as a heated build plate, enclosure, and filament dryer are not maintained.

Advantages Of Nylon

Nylon excels in high tensile strength, elasticity, and abrasion resistance, making it perfect for demanding applications like textiles, gears, and industrial components.

Additionally, nylon offers excellent chemical resistance and durability under high temperatures, enhancing its suitability for harsh environments.

In 3D printing, nylon materials demonstrate good inter layer adhesion and flexibility, allowing for the creation of durable, flexible parts that withstand repeated stress and wear.

Furthermore, nylon can be combined with carbon fiber or glass fiber reinforcements to increase stiffness and strength, making it an adaptable and reliable choice for various specific products and applications.

Disadvantages Of Nylon

Nylon’s susceptibility to moisture absorption can significantly degrade its mechanical properties and cause dimensional instability, which necessitates careful drying and storage using a filament dryer or oven to maintain optimal print quality.

This hygroscopic nature also means that prints can absorb moisture over time, potentially affecting long-term durability and requiring post-print drying or conditioning.

Additionally, nylon typically demands higher printing temperatures and a heated build plate, which may complicate the printing process for some users.

It is generally more expensive than ASA, which may affect budget-sensitive projects, but its superior mechanical properties often justify the higher cost.

How To Choose ASA And Nylon For Your Project?

Selecting between ASA and Nylon depends on your project’s specific requirements, balancing environmental, mechanical, and cost considerations.

Application Environment

Choose ASA for projects requiring outdoor durability, as its superior UV and weather resistance ensures long-term performance in harsh conditions like sunlight, rain, and varying temperatures.

ASA’s ability to maintain color and structural integrity makes it ideal for outdoor furniture, automotive parts, and signage exposed to the elements.

On the other hand, opt for Nylon in indoor or controlled environments where its superior mechanical properties and abrasion resistance can be fully utilized without the risk of moisture absorption compromising strength.

Mechanical Requirements

Select Nylon for applications demanding high tensile strength, flexibility, and durability, such as gears, ropes, and mechanical parts that require repeated bending and impact resistance.

Its excellent wear resistance and toughness make it suitable for components subjected to heavy stress and dynamic loads.

ASA, on the other hand, is better suited for moderate stress applications like signage, automotive trims, and outdoor fixtures, where good impact resistance and dimensional stability under environmental exposure are sufficient.

Wear And Abrasion Needs

For components subjected to high wear and friction, such as textiles, conveyor belts, or mechanical gears, Nylon is the preferred choice due to its superior abrasion resistance and toughness.

Its ability to withstand repeated mechanical stress without significant degradation makes it ideal for demanding industrial and functional applications.

Conversely, ASA, with its comparatively lower abrasion resistance but excellent weather and UV resistance, is better suited for static or low-friction applications like outdoor fixtures, signage, and automotive trims.

Cost Considerations

ASA is generally more cost-effective for weather-resistant applications, making it an excellent choice for budget-conscious outdoor projects where UV stability and color retention are priorities.

Nylon, although typically pricier, justifies its higher cost through superior mechanical properties, making it the preferred material for high-performance applications that demand toughness and long-term reliability.

Frequently Asked Questions

What Are The Main Differences Between ASA And Nylon In 3D Printing?

ASA offers excellent weather resistance and rigidity for outdoor use, while Nylon provides superior strength, flexibility, and abrasion resistance for durable, flexible parts. These differences make each material suitable for different materials applications depending on the project’s needs.

Which Material Is Better For Outdoor Use, ASA Or Nylon?

ASA is better for outdoor use due to superior resistance to UV rays, moisture, and weathering, maintaining color and structure over time. Nylon absorbs moisture, which can reduce its outdoor performance, so it is less suitable for prolonged outdoor exposure.

How Do ASA And Nylon Adhere To The Build Plate During 3D Printing?

ASA adheres well to build plates with proper surface preparation like PEI sheets, while Nylon often requires a heated bed, adhesives like glue stick, and strict moisture control using a filament dryer or enclosure to prevent warping and ensure good inter layer adhesion.

Can ASA Be Used For Flexible Parts?

ASA is rigid and dimensionally stable, making it unsuitable for flexible or repeatedly bent parts. Nylon’s greater flexibility and toughness make it better for such stuff, allowing parts to flex without cracking.

What Are The Printing Requirements For ASA And Nylon?

ASA prints well at lower temperatures with a heated bed and benefits from an enclosure and filament dryer. Nylon needs higher temperatures, a heated bed, and strict moisture control for best results.